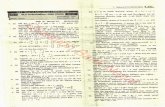

Manufacturing-Technology-II Question bank

-

Upload

ravi-sankar -

Category

Engineering

-

view

78 -

download

1

Transcript of Manufacturing-Technology-II Question bank

SRI ESHWAR COLLEGE OF ENGINEERING, COIMBATORE

DEPARTMENT OF MECHANICAL ENGINEERING

QUESTION BANK

MANUFACTURING TECHNOLOGY-II

SEM:IV YEAR:II

S No Question Blooms taxonomy

Remarks Appearance of

Question

UNIT 1 THEORY OF METAL CUTTING

PART-A

1 Briefly explain the effect of rake angle during

cutting U Nov 2010

2 What is rake angle? What is the effect of noise radius in tools?

U June 2009

3 State any two situations where positive rake angle is recommended during turning.

R Dec 2011

4 When will the negative rake angles be used? R May 2013

5 Name the factors that contribute to poor surface finish in cutting.

R Dec 2005

6 What is orthogonal cutting? R Dec 2006 &

May 2014 7 Sketch the orthogonal cutting U Nov 2003

8 Give two examples for orthogonal cutting R Dec 2007

9 Compare orthogonal and oblique cutting R

May 2011 ,

2015,2016& Nov 2013

10 What is meant by built up edge? R May & Dec

2012

11 What are the favourable factors for continuous chip with built up edge

R June 2009

12 What is the function of chip breakers? R Dec 2005 13 Define machinability of metal U Nov 2003

14 How do you classify tool wear? U

(May 2010,

May 2013 &

Nov 2013

15 Name any two reasons for flank wear in cutting tools.

U Dec 2011

16 What is electro chemical wear in tools? R June 2009

17 Define tool life. R May 2011 & 2010, Dec

2012

18 Write Taylor’s tool life equation. R

19 What are the four important characteristics of materials used for cutting tools?

U

Dec

2007,2015,May 2016

20 Name the various cutting tool materials. U Dec 2008

21 What are the advantages of diamond tools? U May 2012

22 What are objectives and functions of cutting fluids?

R Dec 2006 & Nov 2010

23 What are the factors responsible for built up edge in cutting tools?

R Dec 2009

24 List the essential characteristics of cutting fluid. U Dec 2008

25 Why is lubrication not required while machining cast iron?

U May 2014

26

Calculate the power required for cutting a steel

rod of 50mm in diameter at 200rpm. Assume cutting force of 160kg,

E Dec 2006

27 What is tool signature. U 28 What is side rake angle? And mention its effects? U

29 What is clearance angle? And mention its types? U 30 Explain the nose radius. R

31 What is shear plane? U

32 What is cutting force? R 33 What is chip and mention its different types? R

34 Define machinability of metal. R 35 Write Taylor’s tool life equation. R

36 How does metal removed in metal cutting. E May 2010

37

In an experimental on orthogonal cutting, a chip

length of 85mm was obtained from an uncut chip length of 202mm while cutting with a tool of 20degree rake angle using a depth of cut of 0.5mm.Determine the shear plane angle.

An Nov 2009

38 Define chip thickness ratio. U Nov 2015 39 Write a short note on Heat zones in cutting U May 2015

40 Write a short note on any two modern tool materials.

R May 2015

41 What are the main requirements of cutting tool material?

R May 2015

1 How is metal removed in metal cutting? Explain the process with simple sketch.

U May 2014

2 Describe the mechanism of metal cutting. U May 2011

&2012

3 What is orthogonal rake system? Show the ORS of tool analysis with the help of a sketch.

R Dec 2008

4 Explain “Merchant force circle” along with

assumptions. R May 2010

5 Using merchant‘s circle diagram, derive the expression for estimating the cutting force during

machining. Mention the assumption made

An Dec 2006

6 Describe an expression for the determination of

shear angle in orthogonal metal cutting. R Dec 2005

7 Discuss the various produced during metal machining.

R Dec

2005,2006, Nov 2009,

Nov 2010, May 2010

,2011, 2015

8

Explain the conditions that promote the formation of the following types of chip

1) Continuous chips 2) Continuous chips with Build-up edge 3) Discontinuous chips

R Dec2007

9

What is the use of a chip breaker? Discuss the

various types of chips produced during metal machining process

R Dec 2008

10 What is meant by orthogonal cutting and oblique cutting?

R May 2010

11 Define the various tool parts of a single point cutting tool with a neat sketch

R Dec 2007

12 Explain the geometry of a single point tool with suitable sketches.

R June 2009

13 What are the standard angles of cutting tool? Illustrate with an example.

R Dec 2007

14 Enumerate the essential requirements of a tool

material. U

May

2009,2013

15

List the various tool materials used in industry.

State the optimum temperature of each of the tool materials.

R May 2011 &

Nov 2013

16

Discuss the advantages and limitations of the following cutting tool materials.

a. Cemented carbides b. Cubic boron nitride

Also state the desirable characteristics of a cutting tool material.

R Dec 2011

17 Write a short note on different tool wear mechanism in metal cutting.

R Nov 2013, May 2015

18 Describe the forms of wears on the cutting tool with neat sketches.

R Dec 2006

19 What is tool life? R Dec 2006

20 State the parameters that influence the life of tool and discuss

R May 2010

21 Mention the functions of cutting fluids. R Nov 2009, Nov 2010

22 What is the main function of cutting fluids? And its

types. R

Dec 2009,

May 2013 &2014

23 Write a short note on cutting fluids in metal cutting.

R Nov 2013 & May 2014

24 What is the measure of metal removing process

machinability? What are the factors that affect it? R Dec 2005

25 Write briefly about different cutting tool materials

used in metal cutting. R Nov 2013

26 Write short notes on surface finish.

27 In an orthogonal cutting operation on a work piece An Nov 2010

of width 2.5 mm, the uncut chip thickness was 0.25mm and the tool rake angle was zero degree. It was observed that the chip thickness was 1.25mm. The cutting force was measured to be 900N and the thrust force was found to be 810N.

1) Find the shear angle. 2) If the coefficient of friction between the chip and the tool was 0.5, what is the machining constant Cm?

28 a) Describe the different types of chips with neat sketches. b) Mention the function of cutting fluids.

R Nov 2010

29

With the help of sketches, explain the following

types of chips produced during metal machining. a) Continuous chips b) Continuous chips with

built up edge.

U Nov 2011

30

a) With the help of a sketch show crater wear and

flank wear on a cutting tool. b)Explain the types and applications of different

types of cutting tools. c)Enumerate the factors that effect the cutting

temperature during machining.

R Nov 2011

31 Draw three views of a single point cutting tool and indicate various angles.

Nov 2012

32

During an orthogonal turning operation of C20 steel, the following data were recorded:

Rake angle =10degree; Chip thickness = 0.48mm; Width of the cut =2.0mm; Feed = 0.25mm/rev;

Tangential cutting force= 1200N; Feed thrust force= 300N; Cutting speed = 2.5m/s;

Find the value of shear force at the shear plane; find also the kinetic coefficient of friction at the

chip tool interface.

An Nov 2012

33

During straight turning of a 24mm diameter steel

bar at 300rpm with an HSS a tool life a 9min was obtained. When the same bar was turned at 250

rpm , the tool life increased to 48.5min. What will be the tool life at a speed of 280rpm?

An Nov 2012

34 Discuss briefly about the following tool materials with respect to composition and properties: High

speed steel and cemented carbides.

An Nov 2012

35

The end of a pipe was orthogonally cut with a tool of 20 degree rake angle. The cut chip length was 85mm corresponding to uncut chip length of 202mm.If the depth of cut was 0.5mm, find the

chip thickness and shear plane angle.

Nov 2012

36

In an orthogonal cutting test with a tool of rake angle 10degree, the following observations were made: Chip thickness ratio=0.3

An May 2012

Horizontal component of cutting force=1290N Vertical component of cutting force=1650N From merchants theory calculate the various components of the cutting forces and the coefficient of friction at the chip tool interface.

37 Describe the mechanism of chip formation in orthogonal cutting.

R May 2012

38 Explain the following mechanism of tool wear: Attrition, Diffusion

R May 2012

39

A cutting tool when used for machining work piece at a cutting speed of 50m/min. lasted for 100min.

Taking n=0.26 in the Taylor’s tool life equation determine the life of the tool for an increase in

cutting speed by 25% and the cutting speed to obtain a tool life of 180min.

An May 2012

40

A specimen of 100mm length along the stroke of shaper is machined with a tool with 15degree rake angle. The uncut chip thickness is 1.5mm. If a chip length of 40mm is obtained during the one stroke of machining. Find the shear plane angle and the thickness of cut chip.

An May 2012

41 What are the various forms of wear found in

cutting tools? Show with a neat sketch. U May 2010

42 How do the cutting process parameters affect the cutting tool wear in single point tools?

U May 2010

43 Derive the expression for shear angle in orthogonal cutting in terms of rake angle and chip thickness ratio,

E May 2010

44 How do you define tool life? Explain the parameters that control the tool life of a single

point cutting tool.

U May 2010

45

The Taylor ’ s tool life equation for machining C-40

steel with a HSS cutting tool at a feed of 0.2mm/min and a depth of cut of 2mm is given by

VT^n = C, where n and C are constants. The following V and T observations have been noted:

V, m/min 25 35 T, m/min 90 20

Calculate n and C, Hence recommend the cutting speed for desired tool life of 60min.

An May 2013,

May 2011

46 Sketch a single point cutting tool under ASA system. Define various tool angles for machining

mild steel and justify.

R Nov 2009

47 List various types of tool wear and discuss the factors affecting them.

U Nov 2009

48

The following equation for tool life is given for turning operations:

VT0.13 f 0.77 d0.37 =C A 60 min tool life was obtained while cutting at V =

30m/min, f= 0.3mm/rev and d=2.5mm

An Nov 2009

Determine the change in tool life if the cutting speed, feed and depth of cut are increased by 20% individually and also taken together.

49 Derive the expression for chip reduction coefficient.

R Nov 2015

50 Discuss purpose of cutting fluids. R Nov 2015 51 Describe the factors affecting tool life. R Nov 2015

52 Draw the merchant force diagram and explain the force acting on it.

R Nov 2015

53 With reference to orthogonal cutting. Explain the following terms: shear stress in shear plane, shear

strain, cutting ratio, shear angle.

U May 2015

54

Prove that in orthogonal cutting, the kinetic

coefficient of friction is given by µ= (Fe sin α + Ft cos α)/ (Fe cos α– Ft sin α)

E May 2015

55

Tool life tests in turning yield the following data:1) V =110m/min, T= 20min; 2) V =85m/min, T= 40min. A) Determine the n and C values in the

Taylor tool life equation. Based on the equation compute B) the tool life for a speed of 95m/min

and C) the speed corresponding to a tool life of 30 min.

An May 2015

56 Describe the merchant’s model for orthogonal cutting.

R May 2015

57 The useful tool life of a HSS machining mild steel 20m/min is 3 hrs. Calculate the tool life when tool operation at 26m/min. (n=0.125)

An May 2015

58

In an orthogonal cutting process, the following observations were made uncut chip thickness = 0.25mm; cutting force= 1100N; feed force= 120N; chip thickness ratio=0.46 ; rake angle =22degree; width of cut= 4.5mm and cutting velocity = 35m/min. Determine the friction angle, shear

plane angle, resultant cutting force and power consumption.

An May 2015

59

The following equation for tool life is given for HSS tool: VT0.13 f 0.6 d0.3 =C A 60 min tool life was obtained while cutting at V = 40m/min, f= 0.25mm/rev and d=2mm Calculate the effect of tool life if the cutting speed, feed and depth of cut are increased by 25% individually and also tif they are increased by 25%.

E

60 Describe any four important cutting tool materials. U May 2016

61 Determine the shear angle, friction angle, shear stress along the shear plane and the power for the

cutting operation.

An

62 In an orthogonal cutting operation, the following data have been observed. Uncut chip thickness = 0.127mm

An May 2016

Width of cut = 6.35mm Cutting speed = 2m/s Rake angle = 20 degree Cutting force = 567 N Thrust force = 227N Chip thickness = 0.228mm Determine the shear angle, friction angle, shear stress along the shear plane and the power for the cutting operations.

PART-C

1 Discuss tool wear and its causes and also explain

how to reduce tool wear rate. R

2 Assume, you have given with 60 HRC materials,

which tool material you will select. Justify E

UNIT 2 TURNING MACHINES

PART – A

1 What is swing diameter? R Nov 2003

2 Write the specification of a typical lathe. R Apr 2004,

2015& Nov 2013

3 Explain following parts of a lathe. R Dec 2010

4 Write down the names of any four lathe accessories.

R Nov 2003

&2004

5 State the various parts mounted on the carriage. R May 2013

6 What are the functions of feed rod and lead screw?

R Dec 2005

7

Why is it essential that the cutting point of the tool

should be level with the spindle centre while machining taper on a work piece?

U Dec 2007

8

Calculate the time taken for one complete cut on a work piece of 500mm long and 50mm diameter.

The cutting speed is 30m/min and the feed rate is 0.5mm/rev.

E Dec2006

9 What is an apron? R Dec2010 10 What are the various thread cutting methods? R May2011

11 What is a centre gauge that is used in threading? R May 2014

12 Mention two limitations of a centre lathe. R Dec 2011 &

May 2012

13 What is the difference between a ram type turret lathe and saddle type turret lathe?

R

14 What are programmed automatic lathes? R May 2014

15 What is the need of automatic lathes? R Nov 2013

16 What is the purpose of tumbler gear mechanism of a lathe?

R May 2012

17 Mention four different types of chucks used in a machine shop.

R June 2009

18 Why was power chucks developed? R Dec 2005

19 What is the application of air operated chuck? R Apr 2004

20 What are the advantages of using a collect chuck? Dec 2008

21 What is the purpose of a mandrel? How many types of mandrels is there in common use?

R Dec 2008

22 List the different taper turning methods. R May 2011, Dec

2011 & May 2012

23

Determine the angle at which the compound rest will be swivelled when cutting a taper on a piece of

work having the following dimensions. Outside diameter-60mmLength of the tapered portion

80mm and smallest diameter-20mm

E Nov 2004

24 Draw a neat sketch of ‘Geneva mechanism’ used in

turret lathes for automatic indexing. R May2011

25 Define automatic machine. R

26 What are advantages of automatic lathes? R Dec 2006

27 What are the types of single spindle automatic

lathes? R May 2013

28 What is Swiss type automat? R

29 What is the application of air operated chuck? R 30 Define the term ‘Concity”. U

31 Write down the formula for calculating taper turning angle by compound rest method.

E

32 Distinguish between capstan lathe from turret

lathe. R May 2010

33 State the different methods of taper turning U May 2010

34 What is the function of apron of a lathe? R Nov 2012

35 State the purpose of providing lead cam in single

spindle automatic screw cutting machine? U May 2012

36 How is thread chased in a lathe? U May 2010

37 List the three most commonly employed types of single spindle automatics.

R May 2010

38 Why is hollow spindle used in lathe? E Nov 2009 39 How is the size of turret lathe specified? E Nov 2009

40 Name the cutting tool nomenclature of single point tool.

R Nov 2015

41 Mention the work holding and supporting devices used in lathe.

R Nov 2015

42 What is meant by ‘swing of the lathe’? R May 2015

43 What do you meant by copy turning? R May 2015

44 How are automatic lathe classified? E May 2015

45 With simple sketches show the single point tool nomenclature.

R May 2016

46 What are the advantages of automats. U May 2016 PART-B

1 Explain the constructions and working principle of a lathe with sketch

R Dec2006

2 What is lathe carriage? Explain the various parts of a lathe carriage with a neat diagram.

R Dec2005

3 Mention the specification of lathe with a neat sketch.

R Dec2010

4 Describe the work holding devices in a lathe. R Dec 2006,

2010 , May 2013 &2014

5 Name the various lathe accessories. How does a

four jaw chuck differ from a three jaw chuck? R Dec2010

6

Sketch the following work holding devices used in

a lathe and state when they are used: 1) Self cantering three jaw chuck

2) Collet chuck and 3) Angle plate with face plate

R May2012

7 Draw neat sketches of steady and follower rests and brief their applications.

R May2011

8 Explain the thread cutting operation in a lathe with a neat sketch. Also make a note on knurling, grooving, and forming operations in a lathe.

R June2006

9

Explain with neat sketches the working principle of

taper turning operation using a form tool and by swivelling the compound rest.

R

Nov

2013,May 2016

10

Explain the following with a neat sketch:

Taper turning by swivelling the compound rest Taper turning attachment method Taper turning with tailstock set over method

R

Nov 2003,2004,20

12, Dec 2010, May2011, May 2014

11 Enumerate the purpose of various attachments used on a centre lathe.

R Dec 2005, 2006, May

2011& 2013 12 Discuss the main parts of a turret lathe. U May2010

13 Describe the special features of a turret, with a line sketch. Also mention any two advantages of it.

R June 2006 &

Dec 2011

14 Explain the working principle of turret lathe. R May 2013)

15 Write down the difference between a capstan and

a turret lathe. U

Dec 2006 &

Nov2013, May 2016

16 Explain the following with suitable sketches. turret indexing mechanism or Geneva mechanismBar

feed mechanism

R May 2011

,2015& Dec

2011 17 What is meant by “Tool layout” of a turret lathe. R May2010

18 Explain the tooling layout for the production of a

hexagonal bolt in a capstan lathe. R

Nov 2003 &

2004

19 Classify transfer machines. R Nov 2003, Apr 2004 & May

2010 20 What are the advantages of automatic machines. R Nov2004

21

What is a Swiss type automatic screw machine?

How does it function and what are its main applications?

R

2003, Apr

2004, Dec 2005,2006,

May 2010,2011,20

16 Dec 2011, Nov 2013

22 Describe with a neat sketch a turret automatic R Dec2006

screw machine.

23 Explain parallel action and progressive action multi spindle automatics.

R June 2006, Dec 2006 &

May 2014

24

(i) Differentiate between parallel action and

progressive action multi-spindle automatics (ii) Make a comparison of operational and other

features of single spindle and multi spindle automatic lathes.

R Apr 2004 &

May 2012

25

Explain the working of Swiss type auto lathe with a

neat sketch (May 2010), Describe a single spindle automatic lathe.

R

Apr 2004, May 2013 &

2012,2015, Nov 2009

26 Name the various lathe accessories. How does a four jaw chuck differ from a three jaw chuck?

R

27 Sketch and describe the thread cutting operation in an engine lathe using compound slide.

R May 2011

28 How will you specify the capacity of a lathe? Indicate the specifications on a line diagram.

U May2012

29

Sketch a line diagram of a capstan lathe and

indicate its principle parts. State also the function of these parts.

R May2012

30 Explain with the neat sketch, the turret indexing mechanism of a turret lathe.

May2015

31

A blank 180mm long and 70mm diameter is to be machined in a lathe to 175mm long and 60mm diameter. The work piece rotates at 450rpm, the feed is 0.3mm/rev and the maximum depth of cut

is 2mm. For turning operation, the approach plus over travel distance is 6mm.Assuming that the

facing operation is done after the turning calculate the machining time.

An May 2012

32

What are the various methods available for taper

turning in a lathe? Explain their specific advantages and limitations.

U May 2010

33

Calculate the change gears to cut a single start thread M16 to 2mm pitch on a center lathe, having a lead screw of 6mm pitch. Calculate the depth of cut and number of passes preferred. (A typical set contains the following change gears with number of teeth: 20,25,30,35,40,45, 50,55,60,65,70)

An May2011

34 Explain the bar feeding mechanism used in turret lathe while machining bar stock.

R May 2011

35 Explain with the neat sketch how movement of carriage of lathe is reversed.

R Nov2009

36 Explain with the neat sketch how a face plate is

used for machining asymmetrical components. R Nov2009

37 Explain the types of possible machining operation

on a turret lathe. R Nov 2009

38 Explain different machining operation performed on lathe with sketches.

U Nov 2015

39 Name the taper turning methods and explain any

two with sketch. U Nov 2015

40 How does a turret lathe differ from a capstan

lathe? Explain E Nov 2015

41 Discuss the features of single spindle and multi spindle automatic lathe.

U Nov 2015

42 Enumerate the purpose of various attachments used on a center lathe

U May 2015

43 Define Engine lathe. R

44 Explain the salient features of automatic screw machine.

U May 2015

45 Explain various types of chucks used in lathe. U May 2015

46 Describe bar feed mechanism of capstan lathe. R May 2015

PART-C

1 Could you select CNC machine for rough turning operations. Explain.

R

2 In which case you will select conventional machines, semi automatic and fully automatic

A

UNIT 3

SHAPER ,MILLING AND GEAR CUTTING MACHINES PART A

1 Write any four shaper specifications. R May2013

2 Compare hydraulic shaper with mechanical shaper.

R Dec2006

3 How are shaping machines specified? R May2012

4 Write down any four operations performed by a shaper.

R Nov2004

5 Give the functions of flutes on taps. U May2004

6 What is deep hole drilling? State its applications. R Dec2011 7 How do you specify radial drilling machine? U Nov2004

8 Write down any four operations that can be performed in a drilling machine.

R Nov2003

9 What is meant by “Sensitive hand feed”? R Apr2004

10 Define cutting speed, feed and machining time for drilling.

R Dec2010

11 Calculate the tap drill size to cut an internal thread for bolt of outside diameter 10mm, pitch 1.5mm

and depth of the thread 0.61 pitch.

An Apr2004

12 State the nomenclature of a standard drill. R

13 What are the differences between drilling and reaming?

R May2011

14 What do you know about straight fluted drill and fluted drill?

R June2009

15 Write the differences between drilling and tapping.

R Dec2008

16 What are the common work holding devices used on milling machines?

R Dec2007

17 How do you classify milling cutters? E May2010

18 What is a shell mill? R Nov 2005 & June 2006

19 What is meant by up milling and down milling? R Dec 2006 & June 2009

20 What is climb milling? Mention its advantages. R Dec2011

21 What are the differences between up milling and down milling?

R

Nov 2003, 2004, 2013 &

May2011, 2016

22 What is thread milling? R June2006

23 Write down the rule for gear ratio in differential indexing.

U (Nov 2003

24 List the gear generating process. R May2013 25 What is gear hobbing? R May2011

26 Mention any two advantages of gear hobbing. U Dec2011

27 What is roller burnishing process? R June2009

28 Compare gear forming with gear generation

method. R May2010

29 Define feed and depth of cut. U

30 What is the function of clapper block in a planner? U

31 What are the differences between up milling and

down milling . U

32 Define “Face milling “. R

33 Write down the rule for gear ratio in differential indexing.

R May 2015

34 How do you specify radial drilling machine. E

35 Distinguish between polishing and buffing

processes. U May2015

36 What is a difference between a plain milling machine and an universal milling machine?

U May2012

37 How are work pieces held in a shaper? R May2010

38 What are the various types of end mills in milling? U May2010

39 What are all the parameters that would affect the MRR in abrasive jet machining?

R May 2011

40 What are the differences between face and end milling.

U Nov 2009

41 List the types of driving mechanisms used in a slotter for driving the ram.

R Nov 2009

42 What is an arbor? U

43 How does a vertical shaper differ from a slotter. E Nov 2015

44 What do you meant by differential indexing? R May 2015

45 Why is milling a versatile machining process? E

46 What is a reamer? R May 2015

47 What is straddle milling? R May 2015

48 What is the need of milling operations? R May 2013 49 State the uses of planer U May 2013

PART-B 1 Describe the principle of operation of a shaper R Dec2010

with a neat sketch

2 Explain the hydraulic drive mechanism of a horizontal shaper with a neat sketch.

R May2014

3 Describe the working of a crank and slotted link mechanism.

R Nov 2003 &

Dec 2010

4 Describe with neat sketch whit worth quick return

mechanism used in a shaper R

June 2006,Dec

2015

Enumerate any two advantages of a hydraulic drive.

R Dec

2008,2011 & May 2011

6 Sketch and explain the working principle of upright drilling machine.

R Dec2006

7 With a line diagram, describe the construction of radial drilling machine.

R Dec

2010,2011

8 Write a short note on BTA deep hole drilling. R Nov 2013 & May 2014

9

Sketch the following operations performed in

drilling machine. Drilling, Reaming, Boring, Counter boring, Counter sinking, Spot facing, Tapping,

Trepanning Add one or two lines of explanation for each.

R May 2010, 2012, Dec

2015

10 Write short note on reaming operation. R Dec 2008 & May 2014

11 Discuss the various hole making processes. R May2011

12 Explain the counter boring and counter ringing

operation. R Nov2004

13 Explain the twist drill nomenclature and define various elements of twist drill.

R Apr 2004,

Dec 2008 &

June2009

14 Write short notes on expanding hand reamers and adjustable machine reamers.

R Dec 2006

15 With neat sketches, explain the working of a vertical boring machine.

R Apr 2004 & May 2013

16 Write short notes on boring operations. R Dec2008

17 With neat sketches, describe the working principles of a jig boring machine. State its applications.

R Dec2011

18 Describe the horizontal knee type milling machine with a suitable sketch.

R June 2006,

Dec 2010 &

May 2013

19

State the difference between horizontal and

vertical spindle column and knee type milling Machines.

R Nov2013

20 State the methods of holding milling cutters. R Dec 2007

21 With a neat sketch, indicate the various parts of an arbor assembly.

R Nov 2003

22 Sketch and describe the basic types of milling cutters.

R Nov 2005

23 Describe the constructions of the following milling R June2009, Apr

cutters. a. Plain milling cutters. b. End mills.

2004 & Dec 2011

24 List out the various milling operations. R Nov 2005 & May 2013

25

How will you cut the following types of surfaces on milling machines?

c. Flat surfaces d. Slots and Splines.

R May2011

26 Explain the indexing mechanism of a dividing head on milling machine.

R May 2014

27 Describe the working mechanism of a universal dividing head, with neat diagrams.

R Apr 2004& June 2006

28 Explain simple indexing, compound indexing and differential indexing with suitable

examples.

R Dec2007

29 Explain the gear cutting by a formed tool. R Nov 2004 &

Dec 2010

30 Describe gear cutting by shaping and list the advantages and disadvantages of gear shaping

Process.

R May 2010 &

Dec 2010

31 Explain the principle of operation of gear hobbing operation. What are the advantages of Gear

hobbing?

R

Nov 2003,

2006, 2007, June 2006,

May 2010 & Dec 2011

32 Explain the gear shaving process. R June2009

33 List out various methods used for gear finishing and explain any four methods.

R June 2006,

May 2015

34 Give the advantages and limitations of gear hobbing.

R Apr 2004 & Nov 2005

35 Why is gear finishing required? Discuss the various types of gear finishing operations.

U May 2014

36 Differentiate between gear forming and generating.

R Apr 2004

37

Explain with neat sketches with its process

parameters: honing and lapping. Explain with neat sketches with its process parameters: honing and lapping.

R Nov 2008

&June 2009, Nov 2013

38

With a simple sketch, explain the working of the crank and slotted link quick return motion

mechanism used in shaper and explain the

arrangements used for adjusting the position of stroke

R May 2016

39 State the differences between shaper and planer. R Nov2013

40 With a neat sketch, indicate the various parts of an

arbor assembly.

41 With a simple sketch, explain the principal parts

and angles of a plain milling cutter .Explain them . R

42 What are the operations performed on a milling machine?

U May 2010

43 Explain different types of drilling machine with

their specific features? R May 2010

44 Discuss the common work holding devices used on

shapers, slotters and planers. R May 2010

45 Sketch the drive mechanism of a shaping machine having crank and slotted lever type of quick return. Explain briefly how the ram is made to reciprocate.

R May2012

46 Explain how the stroke length of the ram is altered. R May2012

47 Explain how the ends of stroke of the ram are

positioned relative to the work piece. R May2012

48

Sketch a twist drill and indicate on it the helix

angle, the point angle, chisel edge angle and other names and parameters.

R May 2012

49 With a neat sketch, describe the major parts of a radial drilling machine.

U May 2012

50

With a help of neat diagram, describe the parts of

a planning machine. Also explain a working of this machine.

U May 2012

51

Sketch and briefly explain the following operation performed in milling machine.

1. Plain milling 2. Face milling 3. End milling

Dovetail milling

U May 2012

52 Compare a shaper and planar in terms of operation and type of work piece.

E May2010

53 Write a small note on slotting machine. U May 2010

54

What are the differences between compound

indexing and differential indexing? Explain the relative merits.

U May2010

55 Sketch and explain the hydraulic drive of a horizontal shaper.

R May 2011

56 Sketch the quill mechanism. Write its main parts and their functions.

R May 2011

57 With the help of neat sketch, discuss the working of surface broaching machine.

R May 2011

58 Explain the various operations performed by a broaching machine.

R May 2013

59 Sketch and explain the mechanical feed drive of a

horizontal shaper. R Nov 2009

60 Distinguish between climb and conventional

milling. Explain their characteristics. U Nov 2009

61 Name and describe the four work holding devices or methods used in drilling machines.

R Nov 2009

62 Classify the various boring tools and explain how

they are used for boring operations. E Nov 2009

63 What is a boring bar? Explain its utility R Nov2015

64 Differentiate between reciprocating saw and band E Nov 2015

saw

65

Explain with neat sketches the procedure for carrying out the following operations on a shaper:

Horizontal cutting, Vertical cutting, Concave surface, Keyway cutting.

R May 2015

66 Enumerate with a neat sketch Gear shaping. R May 2015 67 Compare plain and Universal milling machine. E May 2015

68 What is tap? How are taps classified? U May 2015

69

Discuss the operation that can be effectively

performed by planer and also indicate the tools for the operations.

R May 2015

70 Illustrate the hydraulic quick return mechanism in shaper and also its function?

R May 2015

71 How mass production of small parts is done in broaching? Explain with sketches.

R May 2015

72 Describe the various sawing machines. R May 2016

73 Describe the Universal milling machine R May2015

PART-C

1 Why milling machine is most widely used in the

production shop? Justify. U

2 Explain procedure of gear milling process. Explain its advantages and disadvantages

R

UNIT 4 ABRASIVE PROCESS AND BROACHING

PART-A

1 What are the types of surfaces that could be produced using plain cylindrical grinders?

R Nov2006

2 What are the types of surface grinders? R Dec2011

3 What is a tool post grinder? R May2014

4 State the abrasives used in manufacture of grinding wheels.

R

5 What is meant by “grade” and “structure” of a grinding wheel?

R May2011

6 What are the specifications of grinding wheel? R Dec 2010 & May 2013

7 What are grinding points? Sketch the various

grinding points? R May 2014

8 What do you mean by loading of grinding wheels? R Nov 2005

9 What is meant by dressing and truing? R Dec 2008 & Nov 2013,

2009

10 Mention four important factors that influence the

selection of grinding wheel. R June 2009

11

Under what conditions planning operations would

be proffered over other machining processes like milling, broaching, shaping, etc?

U Dec 2007

12 What is broaching? U Dec 2007

13 What are the advantages and limitations of broaching (2 points from each )?

R May 2012

14 List four applications of broaching machines. R May 2011

15 List some of the materials of broaching tools. R May 2014

16 What is the process of self sharpening of the

grinding wheel U

17 What are the four moments in a cylindrical centre type grinding.

U

18 What is meant by centerlessgrinding. U

19 Define the terms abrasive grains. U 20 what is open and dense structure U

21 state the application of honing and lapping finishing methods

R

22 Define hardness of the grinding wheel. U Nov 2010

23 Define lapping U Nov 2010,

May 2016

24 Name two artificial abrasive materials R May 2012 25 Write any four applications abrasive jet machining. R May 2012

26 How is grinding different from other machining operations?

U May 2010

27 What is the difference between forming and generation of gears with respect to principle?

U May 2010

28 How is the grinding wheel designated. U 29 How is broaching machine specified. U Nov 2009

30` State the difference between push and pull broaching

U Nov 2015

31 Name the indexing methods. E Nov 2015

32 How does loading differ from glazing in grinding process?

U May 2015

33 What are the principal types of broaching machines?

U May 2015

34 How does wheel dressing differ from wheel

truing? U

May 2015

35 What are natural and artificial abrasives? U May 2015

36 List the various grinding process. U

37 What is the need of broaching operations? U May 2016 PART-B

1 Explain self -sharpening characteristics of grinding wheel.

R Nov 2007

2 Briefly discuss about the different types of abrasives used in a grinding wheel.

R June 2009

3 Discuss the various bonding materials used for making grinding wheels.

R Nov 2004, 2009, May 2011, 2014

4 Give the specifications of grinding wheel. R Nov 2005 & May 2010

5 Explain the factors to be considered to select a

grinding wheel and recommended parameters. R May 2012

6 Classify the grinding machines. R May 2013

7 Explain the abrasive belt grinding with diagram. R Nov 2006 & May 2014

8 With the help of sketches, describe any two methods of cylindrical grinding.

R Dec 2011

9

How do you classify cylindrical grinders? What is

the difference between “plain and universal” cylindrical grinder?

U Nov 2005

10 Explain the working mechanism of cylindrical and

surface grinding. R

Nov 2004, June 2006 &

Dec2010

11 Explain the working principle of centre less grinding process.

R May 2013

12 Sketch and explain the three methods of external cylindrical centre less grinding.

R Nov 2004, May 2010,

2012

13 Explain the salient features of a centreless grinding machine and discuss the different operations that

can be carried out in it. Mention some advantages.

R June 2009

14 Write briefly about tool and cutter grinder. R Nov 2013

15 Explain wheel truing and dressing. R Nov 2007 &

May 2010 16 Describe the use of cutting fluids in grinding. R Nov 2007

17 Discuss the various types of broaches. R May 2010

18 Write briefly about broaching machines and its

operation with neat sketches. R

May 2013 &

Nov2013

19 Discuss push and pull type broaching machines

with neat sketches. R May 2011

20 Explain the construction and working principles of continuous broaching machine.

R Dec 2006,

2008, & May 2011

21 Sketch a typical broach and indicate important elements.

R June 2006

22 State the advantages and limitations of broaching. R Dec 2007

23 Name the process parameters involved in the

lapping process. R Nov 2013

24 Explain the vitrified and resinoid bonding process. R

25 Explain the gear cutting by a formed tool. R

26 Differentiate between gear forming and

generating E

27 Give advantages and limitations of gear hobbing. R

28 List the advantages and limitations of gear

shaping. RR May 2010

29 Explain the working principle and various methods of centreless grinding with a neat sketch.

R Nov 2010

30 1) Write short notes on gear forming. 2) Write short notes on gear shaping.

R Nov 2010

31

With a neat diagram describe the working

principle of abrasive jet machining. State its product applications.

R May 2011

32 Explain the working principle and product application of the following processes.

a)Honing

R May 2011

b)Lapping

33

Sketch a block diagram of a plain cylindrical grinding machine and briefly explain its working.

Distinguish clearly between “traverse grinding and plunge grinding” done in this type of cylindrical

grinding machine.

R May 2012

34

Sketch the set up of grinding wheel and workpiece

for the following and add few lines of brief explanation:

a) Chucking type internal grinding b) Centreless internal grinding

R May 2012

35 Explain the ’lapping’ and ‘buffing’ processes indicating clearly the tool involved.

R May 2012

36

Explain the working principle and product application of the following processes. a)Honing b)Lapping c) polishing d) buffing e) super finishing

R May 2012

37

Sketch the following: a) The setup of wheels and work piece for a through feed centre less grinding:

b) The setup of wheels for in-feed and end feed centre less grinding add few lines of brief

explanation for the above sketches.

R May 2012

38

Describe a grinding wheel structure with the help of neat sketch and different bonding and abrasive materials used in it? What would u like as an abrasive for grinding steel?

R May 2010

39 Compare gear shaping and gear hobbing giving the processes and product requirement.

E May 2010

40 Sketch and explain the three methods of external

cylindrical centre less grinding. R

Nov 2009,

May 2011

41 List the advantages and disadvantages of gear

shaping process. R May 2011

42 Explain how a spur gear is machined in a gear shaping machine.

R Nov 2009

43 Discuss two types of lapping operations. R May 2013

44 Explain the principle of operation of gear hobbing process.

R May 2013, May 2011

45 Sketch a broaching tool and explain the different nomenclature.

R Nov 2009

46 Discuss the factors influencing the selection of

grinding wheel. R Nov 2015

47 Explain the centreless grinding wheel with neat

sketch R Nov 2015

48 Explain buffing and polishing R Nov 2015

49 Explain the Indian standard marketing system for grinding wheel.

R Nov 2015

50 List the advantages and disadvantages of centre less grinding.

R May 2015

51 Explain the following in grinding: Dressing and R May 2015

Truing.

52 The performance of a grinding wheel depends upon types of abrasive grain size, grade, structure,

and bonding material. Discuss the effect of each.

R May 2015

53 Discuss with neat sketch vertical broaching

machine. R May 2015

54 How do you select a grinding wheel for a given application?

U May 2015

55 Explain the honing process with suitable sketches. R May 2015

56 Give a block diagram of a tool and cutter grinder and also indicate its principal parts.

May 2015

57 Describe the gear hobbing process with neat sketch.

U May 2015

58 How a grinding wheel is specified? And describe the various factors involved in selection of a grinding wheel.

U May 2016

59 Describe with a neat sketch, centerless grinding. R May 2016

60 With neat sketch, explain any one gear shaping process.

R May 2016

61 With a neat sketch, Explain the various elements

of broach tool? R May 2016

PART-C

1 Which grinding process is used for grinding long shaft? Explain

R

2 Which process is used for mass production of internal keyways? Explain.

R

UNIT 5 CNC MACHINING

PART-A

1 What is meant by numeric control? State their

advantages. U

June 2009 &

Nov 2013

2 What is meant by ‘tool magazine’ in a CNC machine?

U June 2012

3 Compare a closed loop NC system with open loop system.

R May 2012, Nov 2009

4 What are the classifications of NC machines? U Dec

2008,2010

5 What is point to point system? U Dec 2006

6 Distinguish between point to point and continuous

path systems. U Dec 2011

7 What is a preparatory function? How is it important in CNC programming?

U May 2012, Nov 2009

8 What are G-codes and M-codes? Give examples. U Dec 2006

9 What is the role of computer for NC machine tool? U Dec 2007

10 Name the various elements of CNC machines. R

Dec 2008,

June 2009 & May 2014

11 State the limitations of CNC machine tools. R May 2010

12 List the differences between NC and CNC. R May 2011, Nov 2015

13 State the difference between CNC and DNC. R Nov 2013

14 What do you meant by machining centre with respect to NC machines?

U Dec 2011

15 Mention the advantages of stepping motor. R May 2013 16 What are linear bearings? U May 2011

17 Mention the types of ball screws. R May 2011 18 What are feed drives? U May 2011

19 What is the difference between incremental and absolute system?

U Dec 2007

20 Define subroutine. R May 2013

21 What is the function of a subroutine in part

programming? U June 2012

22 What is a canned cycle? U May 2010,

2014

23 What is meant by APT program? U Dec 2010

24 Write down the types of statements in APT

languages. R Dec 2005

25 What is ‘Adaptive control’? U May 2014,

2015 26 Draw the simple configuration of CNC machine R

27 What is the function of servo valve. U 28 Define absolute and incremental programming. R

29 What are the important steps to be followed while preparing part programming.

U

30 What is meant by MACRO U 31 What is meant by APT programme U

32 What are the types of motion control system used in NC machine. (Nov 2010)

U

33 With reference to CNC manual part programming state what is linear interpolation.

R May 2012

34

A stepping motor of 200 steps per revolution is mounted on a lead screw of a NC machine table.

The pitch of a screw is 2.5mm/rev. If the stepping motor receives pulses at a frequency of 2000Hz.

What is the linear speed of table?

An May 2012

35 Show the axes of the CNC horizontal boring machine.

R May 2010

36 What are the basic assumptions made while programming in APT language?

U May 2010

37 Compare a closed loop NC system with open loop NC system.

E May 2011

38 What is a preparatory function? How is it important in CNC programming.

U May 2011

39 List the feed drives used in CNC machine. R Nov 2015

40 Define CNC and DNC R May 2015

41 List the advantages of CNC machine. R May 2015,

2016

42 Name any four motion statements used in APT? R May 2015 43 Write the general format of a block in CNC part R May 2016

programming.

PART-B

1

Under what conditions of production the

numerically controlled machine tools are employed?

R May 2010

2 Explain the working of a NC machine tool with the help of a diagram. Also state any two advantages and limitations of NC machines.

R Dec 2005,

2011 & May 2014

3 Discuss about the closed loop system open loop system and adoptive system with a neat sketch and with suitable example.

R Dec 2006,May

2010 & Nov 2013

4 Discuss about the straight cut system and continuous system with a neat sketch and with

suitable example.

R May 2010 &

Dec 2010

5

With a help of an example explain the differences

between point to point and continuous path type of numerically controlled machine tools.

R

Dec 2007, Dec

2011& May 2010

6 How is manual programming of a NC machine

done? R

Dec 2005,May

2015

7 Write briefly about machining centres. R May 2013 &

Nov 2013

8 Describe in brief the basic components of a tape operated NC machine tool.

R Dec2007 & May 2012

9

Explain the following terms with reference to CNC machines.

I. Tool length compensation II. Cutter radius compensation

R Dec 2011

10 State a few typical applications where the use of

numerical control would be justified. R Dec 2007

11 Discuss the major elements of CNC machine tools. R Dec 2005

12 Describe the spindle drives used in CNC machine tools.

R May 2011

13

What are the special requirements of feed drives

of CNC machines? Name also the method of speed control for each type.

R May 2012

14 Discuss about slide ways used in CNC machine

tools. R

May

2011,2015 15 What are the requirements of sideways? R May 2013

16

Sketch and explain the following features of CNC machines.

I. Hydrostatic slide ways

II. Linear bearing with balls

R May 2012

17 With a neat sketch, explain the working of ATC? R May 2012

18 Narrate the design consideration of CNC machines. R June 2009 &

May 2011

19 Compare NC machines with CNC machines. U Dec 2005

20 List the difference between manual and computer

assisted part programming. R May 2011

21 List the advantages of CNC systems over conventional systems.

R Dec 2007 &

May2014

22 Explain the various steps to be followed while developing CNC part programs

R Dec2006, May 2013 & 2014

23 List and explain G and M code for turning and

milling operations. R May 2013

24 List any five motions and control statements of

computer assisted NC programming and explain. R May 2010

25

Explain the following in CNC machining. I. Linear interpolation

II. Circular interpolation. III. Cubic interpolation.

R Dec 2010 & May 2013

26 Write short notes on APT language. R Dec 2005

27 Explain APT geometry and motion statements. R Dec 2006 28 Explain various types of CMM R

29 Explain NC axis conventions. R

30 Explain the various elements of NC machine with

closed loop control system. R May 2010

31 Describe the spindle and feed drives. State the requirement of the drives of CNC machine tools.

R Nov 2010

32

Write a part program for that part shown in fig

C Nov 2010

33

Write a part program for drilling holes in the part shown in fig. 2 The plate thickness is 20mm.

C Nov 2010

34

Discuss the functions of following with reference to NC machine.

a) Linear bearings b) Ball screws

R 2011

35 State the specific advantages of recirculation ball screws in CNC machines. Also explain briefly the

R May 2011

purpose and method of pre loading of ball screws.

36

What are the special requirements of motors for spindle drives of CNC machines? What types of

motors are used for spindle drives? Name also the method of speed control for each type.

U May 2012

37

The bracket shown in fig is 15mm thick. Its profile is slightly oversized by about 1mm. Write a APT

program to do finish milling of the profile of the bracket. The following data may be assumed:

a) A 20mm end mill cutter is to be used.

b) The X,Y,Z axes are as shown. c) The start point is at (0,30,25)

d) For milling, the spindle speed is 1740rpm and feed rate is

500mm/min. The post processor statement is MACHIN/UNI.

C May 2012

38

Write a manual part program to turn the

component shown on a CNC lathe from 75mm bar stock. The following data can be assumed:

1. There will be two rough turnings and one finish turnings. The first cut is with a depth of

3 mm for a length of 58 mm:the second with a depth of 3 mm for a length of 59 mm:and

the third with a depth of 1.5 mm for the length of 60 mm.

2. The shoulder of the workpiece is also

machined during each cut 3. The spindle speed is 400 rpm and the fee

rate is 0.5 mm/rev. Make a free hand sketch showing relevant points

of tool positions for each of the three turning operation and then write the manual part

programs.State also what each line of the program

C May 2012

does. Note: If the exact G codes and M codes are not known, the student can use his/her own code numbers, but the function of such codes must be clearly stated. (May 2012)

39 Describe the main features of CNC machines which distinguishes them conventional machine tool.

R May 2010

40 How does cutter compensation given in the case of machining centre? Explain with an example.

R May 2010

41 Describe the functions of post processor? R

42 List the main components of an NC machine tool and explain their functions.

R ( Nov 2009, May 2011,

May 2015

43 With a neat sketch, explain any one type of axis feed drive of a CNC machine and list its advantage.

R May 2011

44 With a neat sketch, explain the working of ATC. U May 2011

45

A 110 mm long cylindrical rod of 75mm diameter is to be turned into a component as shown. Write a

CNC program for manufacturing this component.

C May 2011

46 List down the various features of CNC machine R Nov 2009

47 Explain point to point and contour path

programming with simple program statement. R Nov 2009

48

Write a program ( manual part program) to drill

five holes in the location shown in the fig. and pause at each location where a hole should be

drilled.

C Nov 2009

49 Describe the numerical control elements present in NC system.

R Nov 2015

50 Describe the actuation system employed in CNC machine tools.

R Nov 2015

51

Explain the following: 1). Canned cycles

2) preparatory functions 3) Motion commands in computer aided part programming.

U Nov 2015

52 List and explain the advantages of CNC systems over conventional NC systems.

U May 2015

53 Explain the main difference between point to point and continuous path type numerically

controlled machine tools.

U May 2015

54 Describe the constructional details of CNC

machine tools. U May 2015

55 With the aid of block diagram explain the steps involved in computer assisted part programming.

U May 2015

56

Write a part program for the part shown in fig.

C May 2015

57 What are the components of NC system? Describe them.

U May 2016

58 Explain with the neat sketch, the slide ways and

ball screws used in CNC machine. R May 2016

PART-C

1 When do you select CNC turning centre and CNC machining centre? Justify

R

2 What is G code and M code? Explain with suitable diagram as example.

R