Manual EAP1.5-2kg 040

-

Upload

mykeenzo5658 -

Category

Documents

-

view

82 -

download

18

Transcript of Manual EAP1.5-2kg 040

Service Manual

for

Electric Antenna Positioner EAP 1.5-2kg

Index

General Instructions and Precautions Page 3

A) Technical Data of Electric Antenna Stand Page 4

B) Assembly and Installation Page 5

C) Maintenance Page 6

D) Trouble Shooting Page 7

Appendix: - Warranty Statement Page 10- Declaration of Conformity Page 11- Circuit Diagram Page 12- Drawing Page 13- Integrated Components Page 14

2

General Instructions and Precautions

Before this device is applied with power:Ground it properly through the protective conductor of the power cable to a power source provided with protective earth contact. Any interruption of the protective (grounding) conductor, inside or outside the device, or disconnection of the protective earth terminal could result in personal injury.

The electrical installation of this product should be accomplished by an individual who is authorized to so do by the appropriate local authority. The installation should be in compliance with local electrical safety codes.

Location of the mast inside the chamber:Do not position the antenna mast underneath halogen headlights or any other heat source – the plastic design could get damaged.

Only qualified personnel should operate or service this equipment.

Before making service, contact maturo GmbH Service or modifications of the device by yourself may void your warranty. If you attempt to service the unit by yourself, disconnect all electrical power before starting. There are voltages at many points in the components which could, if contacted, cause personal injury. Only trained service personnel should perform adjustments and/or service procedures upon this device. Capacitors inside this instrument may still be charged even when instrument is disconnected from its power source.

Stay clear of moving components during the operation of the device.Do not operate the device while somebody is close to moving parts.

The protection of the area of risk at site is part of the operator.

Read this manual completely before starting installation. This equipment should be installed and operated only by qualified personnel.

Regularly inspect all equipment and conduct scheduled maintenance in accordance with the factory recommendations provided. Only use replacement parts and fasteners ordered directly from the factory.

The discharge current for the drive unit is approx. 25mA. However, it is higher when powering on the Positioner. Therefore a fault current protection switch of 50mA is required if only one Positioner is connected. If a whole chamber is connected a fault current protection switch of 100mA is required.

The antenna mast must be clean and dust-free. Dirty or dusty environment can cause electrostatics.

Information presented enclosed is subject to change as product enhancements are made regularly. Pictures included are for illustration purposes only and do not represent all possible configurations.

3

A) Technical Data Electrical Antenna Positioner EAP 1.5-2kg

Antenna height fixed 1.5 mLoad capability max. 2 kg Depending on the distance of the antenna centre of gravity

Positioning accuracy +/- 1°Rotating angle 360°Rotating speed adjustable between 0.5 to 6.0 rpm

Material Plastic + reinforced fibreglassMast cross-section 0.1 m x 0.1 mBase L x W 0.9 m x 0.6 mMoveable with 4 casters Antenna support drive Toothed belt Material of toothed belt Kevlar reinforced (non-metallic)

Motor Brushless DC motor Drive unit shielded and radio interference

suppressed under EN 55022 class B

Control cable Fibre optic lines Remote control via IEEE interface

Current consumption max. 2A Voltage 208-230 VAC, 50/60 Hz, single phase

25mA per drive unit(higher in the moment when powering on)

Temperature range -10 °C...+35 °C Total weight approx. 30 kg

Accessories Interface to SCU/MCU Controller1.5 m power supply cable Service manual

Brief description

The Electric Antenna Stand EAP 1.5-2kg is specifically designed for measurements in electromagnetic absorption chambers at a fixed measuring. The height of the antenna is manually adjustableThe antenna stand, with the exception of the drive unit, is fabricated from plastic (PVC and reinforced fibreglass). Metal parts are located only in the base plate and the drive mechanism (max. 0.3 m above ground level).

Antenna Adapters for all commercially available antennas are available upon request. All antennas during polarisation rotate around their axis to eliminate any elevation errors.

The IEEE 488.2 (GPIB) bus provides an additional control option for all functions, when operated with the SCU/MCU Controller.

4

B) Assembly and Installation

1) Insert the antenna pipe into the hollow shaft at stand slide and fasten the fixing screws carefully at both sides

2) Install the counter weight at the antenna pipe and fix it with the plastic screw

3) Install the pipe bend at the stand tube and fix it with the plastic screw

4) Connect the power cable and switch on the powerAttention: Power Consumption: 208-230V, 50/60 Hz, 16AOnly use the provided power supply cable!Note: The power supply cable must be shielded and have good earthing!

5) Connect the fibre optic control cables from the antenna stand to the controller

6) Start referencing at the controller according to the manual for the controller

CAUTION!Do not position the antenna mast underneath halogen headlights or any other heat source – the plastic design could get damaged.

5

C) Care and Maintenance

Caution:Before performing any maintenance, disconnect the unit and turn off power:

Routine Check:

- Prior to beginning normal operation of the positioner, check the stand for any signs of damage or excessive wear

- Verify that the antenna is secure mounted

- Check the routing of all cables to make sure they do not interfere with the operation of the positioner

Six-month Check:

- Pay attention that no dirt or foreign objects are on the toothed belt and clean when necessary.Note: The toothed belt must be operated without lubrication!

The positioner must be clean and dust-free. Dirty or dusty environment can cause electrostatics.

Routine Maintenance

To ensure a high level of reliability of operation, a long working life of the products, and substantially to avoid major repair costs, we offer the option of a maintenance contract with our service department.

This maintenance contract is carried out by our service engineers who accurately check and examine all the important components and functions at regular intervals of time, to be agreed from case to case.

The contract covers the mechanical and electrical or electronic parts of our products as well as the cooling units, safety devices, alternative and optional equipment, where these have been fitted to the products.

The details of the services to be provided by our maintenance service are agreed from case to case. We shall be happy to provide a suitable quotation on request.

6

D) Trouble Shooting for Positioner EAP

If there are problems with the device, please always carry out the following first:

1. Check power supply and fuses

2. Check fibre optic cables and connections (if possible change cables from a differentdevice and check)

3. Check user limits and remove the limits, if not in use (see manual of controller)

4. Use a short cable for connection directly to the antenna stand in the chamber

5. Disconnect the power supply of the antenna stand and the controller for approx. 1 minute; reconnect the power supply and carry out referencing

Fault Probable Cause Suggested RemedyController shows “referencing” but the positioner does not move

- Software problem - Disconnect power supply of turn device and controller and reconnect after approx. 1 minute again

- Delete all user limits

- Hardware problem - Check all cables and connectors; also at the drive unit

- Check DCC board at the drive unit- Check, if light is coming out of the

fibre optic connectors after switching off and on again

Positioner does not reference

- Problem with positioning switch

- Check positioning switch

Device not found - Connection problem - Check all connections, power supply and hardware components

Positioner does not work properly after some time in use

- DCC board malfunction - Check DCC board

Positioner moves to a different position as shown at the controller

- Software problem - Check positioning switch

7

Check DCC board:

- Disconnect antenna stand from power- Open drive unit box- Check fuse on DCC; 3.15A- Connect antenna stand to power- At 7-segment display the symbol “_” is shown- Try to move the antenna stand manually with the controller- If the antenna stand does not move and a number is shown at the 7-segment-display,

the DCC board is damaged

DCC Board:7-segment-displayFuse

8

Drive Unit Electrical Antenna Positioner EAP:

DC MotorGearbox

DCC Board FiltersFOCD

9

Warranty Statement

Maturo GmbH, hereinafter referred as maturo, warrants that our standard products are free from defect in materials and workmanship for a period of one year from date of shipment. Standard maturo products include the following:

- Antenna Mast and Stands

- Turntables and Turn Devices

- Cable guide rails

- Controllers

- Dynamometers for the automotive industry

If the Buyer notifies the Seller of a defect within the warranty period, the Seller will, at the Seller’s option, either repair and/or replace those products that prove to be defective.

There will be no charge for warranty services performed at the location maturo designates. The customer must, however, prepay inbound shipping costs and any duties or taxes. Maturo will pay outbound shipping cost for a carrier of maturo’s choice, exclusive of any duties or taxes. If maturo determines that warranty service can only be performed at the customer’s location, the customer will not be charged for maturo’s travel related costs.

This warranty does not apply for:

- Improper storage of our products outside our area of influence,

- Errors during installation, commissioning or operation,

- Wear and tear during normal operations,

- Unqualified maintenance works,

- The application of unsuitable equipment and materials,

- The results of repair works or other activities undertaken on our products, which have

not been expressly approved by us.

- Consumable items such as fuses, batteries, etc.

- Products which have been operated outside the specifications

Note: Please always contact maturo before shipping equipment to us.

10

EG Konformitätserklärung gemäß EMV-Richtlinie 2004/108/EGDeclaration of Conformity in accordance with EMC guideline 2004/108/EC

Hiermit wird erklärt, dass das Produkt:We hereby declare that the product:

Produktbezeichnung:

Product:Electrical Antenna Positioner EAP 1.5-2kg

Seriennummer:

Serial number: EAP1.5-2kg/040/8341011

Baujahr:

Year:2011

Hersteller:

Manufacturer: maturo GmbH, Bahnhofstr. 26, 92536 Pfreimd

mit den Vorschriften folgender Europäischer Richtlinien übereinstimmt:has been manufactured according to the regulations of the following European directives:

- 2004/108/EG Elektromagnetische Verträglichkeit – EMV-Richtlinie- 2004/108/EC Electromagnetic compatibility – EMC directive

- 2006/95/EG Niederspannungsrichtlinie - 2006/95/EC The Low Voltage Directive

Grundlagen dafür sind folgende harmonisierte Normen:Basis for that are the following harmonized standards:

- EN 55011:2010-05 Class B- EN 55022:2006 + A1:2007 Class B- EN 61000-4-2:2009 Level 2/3- EN 61000-4-3:2006 + A1:2008 Level 2- EN 61000-4-4:2004 Level 2- EN 61010-1:2002

Pfreimd, den 19.01.2011

FirmenstempelCompany stamp

Ort und Datum der Ausstellung

Place and date of issue

rechtsverbindliche Unterschrift

Name and signature of authorised person

11

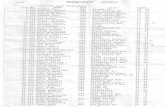

N L1

bl sw

Com

test

SR

L

M

Sch

neid

er T

yp B

DM

7548

S01

3432

5VD

C, 1

.0A

200W

wh

Ref

eren

cing

sw

itch

(S2)

8341

0112

32

1

12

32

3

ST2 ST7

ST1

61

45

65

43

21

76

54

32

18

76

54

65

43

21

15

43

12

34

56

7ST

3ST

4

ST9

ST8

ST10

ST5

ST6

JP3JP2

JP1

bkor

rdblwhbkor

Hal

l 1H

all 2

Hal

l 3H

all G

ND

Hal

l +5V

UVW

rd

bn

gn

CAN

-Bus

10pi

nfla

t-ca

ble

123

OU

T

IN

JP1

123

JP2

14

14

filte

r jac

kD

-Sub

9-pi

n

9-pi

nD

-Sub

plug

11

bk bl

3x1,

5²bl bkgn/y

e

EA

P, S

chne

ider

200

W, 2

x D

uFi,

DC

C

abou

t CA

N to

SC

U,

1 re

fere

ncin

g sw

itch

FOC

D, C

AN0

Fibe

r opt

ic to

SC

U

T1.6

A25

0V

RE

V.:

Dat

e:

Title

:

She

et:

1/1

EA

P-S

200-

DuF

i-e

28.1

0.20

11 1

1:50

:56

mat

uro

Gm

bHB

ahnh

ofst

rass

e 26

,

9

2536

Pfre

imd,

Ger

man

y

e-m

ail:

info

@m

atur

o-gm

bh.d

e

the

time

is ri

pe

phon

e: +

49(0

)960

6-92

3913

-0

DuF

i EPC

OS

250V

AC, 2

5A, 5

0/60

Hz

DuF

i EPC

OS

250V

AC, 2

5A, 5

0/60

Hz

12

contained herein without the written consent of the company maturo-gmbh. All copyrights, trademarks, patents and

HINWEIS: Sämtliche Informationen, die in diesem Dokument enthalten sind, sind STRENG VERTRAULICH. Jeder Empfängerdieses Dokuments darf die darin enthaltenen Informationen, direkt oder indirekt, nur mit ausschliesslicher, schriftlicherZustimmung der Firma maturo-gmbh an Dritte weitergeben oder offenlegen. Die Firma maturo-gmbh behält sich alle Rechte in Bezugauf Urheberrechtsgesetz, Patent- und Gebrauchsmusterschutz vor. Lizenzrechte werden hierdurch nicht erteilt.

NOTE: The information or material contained in this document is STRICTLY CONFIDENTIAL and any recipientof this document shall not disclose or divulge, directly or indirectly, this document or the information or material

other rights in connection herewith are expressly reserved to the company maturo-gmbh and no license is created hereby.

1500

Pola

risa

tion

0° -

360°

K:\S

olidW

ORKS

_Pro

jekte\

Proje

kte 20

11\#8

3410

11\E

AP1.5

-2kg

\

EAP1

.5-2k

gtol

eran

ce

DIN

ISO

2768

T2 -

KEA

P1.5-

2kg

file na

meap

pr. b

yDI

N IS

O 27

68 T

1 - m

Germ

any

Zeus

name

draw

erda

te

Solid

Wor

ks; D

IN A

3

title

#834

1011

30.68

kgpr

oject

no.

weigh

ttre

atmen

tma

terial

part

no.

sh.

shee

t

scale 11

1:10

Bahn

hofst

raße

26

925

36 P

freim

d

17.10

.2011

13

Brushless DC drivesDC motorsProduct Description

The motors of the Berger Lahr RECM series are brushless DC motors that are desi-gned as electronically commutated 3-phase synchronous motors. Because of the me-chanical design of the brushless DC motor they have a low rotor inertia and very good dynamic characteristics. The use of high-energy magnetic materials means high out-put power with small sizes. The motors are available with a distinct or low detent torque when not under power.

In specific cases an additional holding brake is unnecessary in the version with high detent torque. The motor version with low detent torque is noted for increased running smoothness.

The motors can be fitted with various types of gearboxgearboxes such as spur wheel or planetary gear depending on the torque and service life requirements. The brush-less DC motors are fitted with Hall sensors as standard. High-resolution encoder sys-tems are optionally available for higher positioning resolutions.

• High detent torque that makes a holding brake unnecessary• Low holding torque for smooth running• High torque in relationship to size• Constant torque over complete speed range

In industrial applications the brushless DC motors are noted for their high power den-sity with small dimensions and high efficiency. Examples of applications are conveyor drives, pump drives, applications in the textile industry and format changes.

The RECM34• motors with the flange dimension of 42 mm are particularly useful in device technology for new functions, such as in coffee machines and centrifuges.

Product Description

Special features

Application possibilities

1414

Brushless DC drivesBLV Brushless DC driveFunctions

Status display via LED

The two LEDs display the current operating status.

Flash code of LED1 and LED2

(A) No power supply.

(B) Power amplifier is activated.

(C) Holding brake set.

(D) Power amplifier is deactivated.

(E) System error.

(F) Power amplifier overtemperature.

(G) Overvoltage, including with feedback.

(H) Undervoltage.

(J) Commutation error.

(K) Short circuit between two motor phases.

Status display via LED

1 4321 3

0 1 2

34

56789A

BC

D

E F

LED1 LED2

2s

G

H

F

D

E

C

A

B

LED1 LED2

K

2s

J

1515

Brushless DC DrivesBLV Brushless DC drivesTechnical Data

(1) The levels correspond to EN 61131-2 Type 1

(2) For power supply of ACTIVE_OUT and N_OUT outputs. Must not be bridged with VDC power supply, otherwise danger of feedback.

Technical DataMechanical dataDimensions (H x W x D) mm 23.5 x 117 x 74.5

Weight kg 0.25

Type of cooling Free convection

Electrical DataPower data

Nominal voltage VDC 24 … 48

Input voltage VDC -15% / +20% 1)

Residual ripple < 5%

Current consumption A 6.5

Nominal power (power output) W 150 / 300 2)

Power loss W ≤ 7

Capacity value µF 1100

Signal interfaces BLV14H•• BLV14L••

Analogue inputs

Measuring range VDC 0 … 10 0 … 5

Max. input voltage VDC 30 10

Input resistance kΩ ≥ 10 ≥ 10

Resolution Bit 10 10

Digital inputsActive VDC 15 … 30 0 VDC / < 0.8

Inactive VDC ≤ 5 open / > 4 … 6

Input current mA ≤ 7 -

Debounce time ms 1 … 2 1 … 2

Output for potentiometer

Voltage VDC 10 5

Max. allowable current mA ≤ 20 ≤ 10

Potentiometer resistance kΩ 1 1

Digital outputs

Max. switching voltage VDC ≤ 30 ≤ 30

Max. switching current mA ≤ 50 ≤ 50

Voltage drop at 50 mA load VDC ≤ 0.5 ≤ 0.5

Short-circuit-resistant and overload-proof yes yes

Nominal voltage 24V VDC 24 2) 0 VDC / < 0.8

N_OUT output (speed signal)

Number of pole pairs Pulses / revolutions

2 12

3 18

4 24

6 36

Ambient conditionsAmbient temperature 1) °C 0 ... +50

Transport and storage temperature °C -25 ... +70

Pollution degree Step 2

Rel. humidity as per IEC 60721-3-3, Class 3K3, 5 ... 85%, non-condensing

Installation height above mean sea level for 100% power m < 1000

Installation height m < 2000; with max. ambient temperature 40 °C, without protective film and a radial distance >50 mm

Oscillation and vibration as per IEC/EN 60068-2-63 ... 13 Hz: 1.5 mmpeak 13 ... 150 Hz: 1g

Shock loading as per IEC/EN 60068-2-2715 g for 11 ms

Degree of protection IP20

IP40 restricted: from above only, without distance to protective cover

1) No icing

1616

r

Brushless DC drivesDC motorsRECM 37•RECM 374/4

Dimensional drawing RECM 374/4

RECM 374/4Dimensional drawing

52 ± 0.2 6 ± 0.2

25 ± 0.5 100 ± 1 400 ± 15

66

2+0.5

4 x Ø 4.3 ± 0.2

Ø 4

0 h8

Ø 8

j 6

300 ± 15

15 ± 1

14.5 ± 1

Technical DataDC bus voltage UDC V 24 48 325Number of pole pairs p 4 4 4

Nominal power PN W 160 200 200

Nominal torque MN Nm 0.37 0.44 0.44

Nominal speed nN 1/min 4250 4350 4400

Nominal current IN A 9.2 5.54 0.8

Nominal current îN A 11.3 6.78 1.0

No-load speed n0 1/min 5800 5800 5850

No-load current I0 A 0.63 0.46 0.07

Continuous holding torque Md0 Nm 0.58 0.58 0.58

Continuous holding current Id0 A 11.9 7.29 1.2

Max. continuous holding current îd0 A 14.5 8.92 1.4

Max. torque Mmax Nm 1.40 1.40 1.40

Max. current Imax A 36.5 18.3 2.7

Detent torque MS Nm 0.030 0.030 0.030

Torque constant (Md0/îd0) kM Nm/A 0.040 0.065 0.406

Generator voltage constant kEtt mV/(1/min) 2.924 5.848 38.990

Terminal resistance Rtt Ω 0.11 0.28 9.85

Terminal inductivity Ltt mH 0.318 1.272 56.514

Rotor inertia JR g cm2 340 340 340

Heat resistance (winding/surface) Rth1 K/W 0.63 0.63 0.63

Ambient temperature °C -25 ... 40 -25 ... 40 -25 ... 40

Max. permissible radial shaft load Fq N 80 80 80

Max. permissible axial shaft load Fa N 30 30 30

Mass m kg 1.4 1.4 1.4

Vibration strain as per DIN EN 60068-2-6 m/s² 20

Degree of protection as per DIN EN 60592 IP 41 IP 41 IP 41

Heat class as per DIN EN 60034-1 155 (F) 155 (F) 155 (F)

1717

Brushless DC drives DC motorsRECM 37•RECM 374/4

Torque characteristic RECM 374/4

(A) S1: continuous operation

(B) S2 ... S9: Short-term operation

Terminal assignment

The pull-up resistance is not integrated. The maximum current at the Hall sensors is 30 mA.

Characteristic curves

Motor connection

Pin Motor cable Colour

1 U orange (OR)

2 V black (BK)

3 W white (WS)

4 PE yellow/green (GN/YE)

Pin Motor cable Colour

5 Power supply 5 V … 18 V red (RD)

6 Power supply GND blue (BU)

7 Hall U orange (OR)

8 Hall V black (BK)

9 Hall W white (WH)

1000

2000

3000

4000

5000

6000

7000

0 0.15 0.750.3

0

1

2

3

M [Nm]

n

B

n [1/min]

0MN

I IN

__

I

IN

__

0.45 0.5

A

1234

56789

M 12 x 1.5 (EN60423)

1818

Instruction manual standard planetary gearbox 4 Description

' (�����)���

'3� ��$���� ����

������������ �����������

������������

�������������

�������� ����

4�5�# #�1��#�������1���������#1���� ���

D���E/� D6��E/� D��E/� D6��E/� D6��E/�

?�������)�1���������� %&�2�� %&�2�� %&�2�� %&��,� %&��,�

���'�� ;��-�( �'��+��-�)�����'��

;��-�( �'��+��-�)�����'��

;��-�( �'��+��-�)�����'��

���'��� ��������

���'��� ��������

�

�������������'����-����'��������)������� �����������1����===��� ��������

'3" ���7�����%

�%./��+���#��������)������ �����%����������.51�������/-�# ��������-��� ��������'�1��������#1�����������������1���� �������-������ �5��"-���+���#���������������������-��� �1 ���-�)������������������-������ �5��������&0��;&�����&0��;&��

;��-�1���� ���������#1���� ����� �������������)������������=��������-�������+��-�)�����'�����-������ �5��"-���%./��+���#�� ��� ���-����� '���������1���� �������-������ �5� +�������������-����' #���"-����������������' #�������-������ +��-��#�# ������)��-���%./��+���#9�=-��-������ ��� 1��

"-��1���� �����#1���������)���'���������-��-����������1��������'������#������������������'���

����#������)��#��������)�������-���.7*8�"�����'�� �����������'+�����.7*8�"�B����/-�1�����C��

'3& ����������

8''��.7*8�"����� �5���-����'�)����#��' ���������B����/-�1����3�C��

�������

#�0����+�

1919

Instruction manual standard planetary gearbox 8 Service/Maintenance

�

/ ���0���������������

��%��1�����-�����'���)��-������ �5�)���'��$������+�����-��������+�-�')�+�����

/3� ����������

�

�

7�����

(�%�+��+������$��+$0��$�����+3

"-������ �5������#������)���������� ))������'+�' ���������

��/�'� '�����-��1�������)� ���)����-��' ��������

��;�����-��' ���������1'������)���������+��

/3�3� 7� �� ����+�$�)����!���!�$� ��������

��4��� ����-����#1���� ������������ ������/-�1��������

��8�����E/�����-����#1���� ���+� �#��� �����

��7����-�����' ����������#�����-��1�������)� ����)��-��' �������)��#��������

time of lubrication usage [h]

1000

10000

100000

50 60 70 80 90 100 110 120 130

temperature [°C]

tim

e o

f lu

bri

cati

on

usag

e [

h]

�

�����>�&�������)� ����)��-��' �������

���J-K� &�������)� ����)��-��' �������

"�JE/K� @1����������#1���� ���� ����������� � ���1��������

� &0.��&0.�&0�.�� &0���&0��&0��;&�&0��;&�&0:�

� &0���&0��&0���

�

�

��8�$��.7*8�"������1'�����-��' ��������

2020

maturo GmbHBahnhofstrasse 26 o 92536 Pfreimd o GermanyWeb: www.maturo-gmbh.de

Notes

maturo GmbH

2121