Managing Well Integrity During Transfer of Field Ownership Well... · What is Well Integrity? The...

-

Upload

truongnguyet -

Category

Documents

-

view

239 -

download

2

Transcript of Managing Well Integrity During Transfer of Field Ownership Well... · What is Well Integrity? The...

Managing Well Integrity During

Transfer of Field Ownership

–A Case Study

Rob Kuyper Mike Richardson

TAQA Bratani Senergy

What is Well Integrity?The ability of the well to contain fluids from the well construction phase through production and intervention to suspension and abandonment

•Drilling integrity

•Production Integrity

•Suspension Integrity

•Abandonment Integrity

Introduction

TAQA acquired mature North Sea assets

• Acquisition from Shell/Esso completed 1st December 2008

• 4 Platforms (Cormorant Alpha, North Cormorant, Tern, Eider)

• 3 Subsea well clusters (Pelican, Kestrel, UMC)

• 100% equity in fields, >100 wells

In 2008, TAQA was not ready to become Well

Operator

• Intermediate Well Operatorship by Senergy

• Transfer of Well Integrity responsibility

• 2008: Shell => Senergy

• 2009: Senergy => TAQA

The Case

To develop TAQA into a fully functional Well Operator as quickly as

possible while maintaining safety, integrity and production.

The Objective

… and their oil production history at acquisition

Cormorant Alpha

Eider

North Cormorant

Tern

-

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

1979

1981

1983

1985

1987

1989

1991

1993

1995

1997

1999

2001

2003

2005

2007

Oil p

rod

ucti

on

(b

/d) South Cormorant

Pelican

-

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

1979

1981

1983

1985

1987

1989

1991

1993

1995

1997

1999

2001

2003

2005

2007

Oil p

rod

ucti

on

(b

/d)

North Cormorant field

-

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,00019

79

1981

1983

1985

1987

1989

1991

1993

1995

1997

1999

2001

2003

2005

2007

Oil p

rod

ucti

on

(b

/d)

Tern

Kestrel

-

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

1979

1981

1983

1985

1987

1989

1991

1993

1995

1997

1999

2001

2003

2005

2007

Oil p

rod

ucti

on

(b

/d)

Eider

Otter

WELL TRANSFER ROAD MAP

• Establish Wells Team

• Transfer data

• Create policies & procedures for well management

• Well integrity management system working

• Assessment of readiness

• Transfer of asset ownership / well operator / duty

holder

• Monitor & enhance

PREPARATION FOR HANDOVER

• Wells Team in place early

•Resourced through Senergy

• Data Transfer

•Sale not complete

•Confidentiality –transfer to Senergy

•Early start to check completeness

•Meetings with technical teams

• Policies & procedures

•Purchase established system

•Minimise change, evaluate, amend later

•Installation specific retained from previous owner

•Additional material generated as required

PREPARATION FOR HANDOVER

• Contracting Strategy

•Outsource through transition phase

•Services ranked according to criticality for well integrity

•Accelerate by use of existing service contracts

•Migrate to direct contracts afterwards

WELL OPERATOR TIMELINE

Evaluation of

assets for sale

Agreement

to purchase

Preparation of

wells organisation

Transfer of

Well Operator

to Senergy

Transfer of Well

Operator & Duty

Holder to TAQA

Today:

Mature TAQA

well integrity

team in place

2007 2008 2009 2010 2011

Shell Senergy TAQA

WELL OPERATOR TIMELINE

Evaluation of

assets for sale

Agreement

to purchase

Preparation of

wells organisation

Transfer of

Well Operator

to Senergy

Transfer of Well

Operator & Duty

Holder to TAQA

Today:

Mature TAQA

well integrity

team in place

2007 2008 2009 2010 2011

Shell Senergy TAQA

ASSESSMENT OF READINESS

• Shell retained responsibility until 1st Dec 2008

• Shell ensured they were handing the assets over

to a competent organisation

• TAQA, Wood Group & Senergy also needed this

assurance

ASSESSMENT OF READINESS

• Audits

Wood Group audit Senergy as Well Operator

Senergy audit Wood Group as Duty Holder

• Management Review

Shell, TAQA, Wood Group, Senergy

3 day Shell assessment of readiness

• Roles & responsibilities

•3rd party facilitation of organisation iterfaces

•Topsides / wells / pipelines

•Clearly defined limits & responsibilities

ASSET HANDOVERS

Date From To Comments

License Holder

Dec 08 Shell TAQA Smooth transition

Well Operator

Dec 08 Shell Senergy Smooth transition

Duty Holder Dec 08 Shell Wood Group Smooth transition

Well Operator

Sept 09 Senergy TAQA Smooth transition

Duty Holder Sept 09 Wood Group TAQA Smooth transition

TOOLS & SYSTEMS USED

•WIST - Well Integrity Status Tool•Bespoke database –live Q1 2009

•Temporary spreadsheets used while WIST tested

•Well Examination•Direct contract established

•Increased emphasis on existing wells versus “new

wells”

•Interface with platform ICP verification process

•Testing routines•Base routines maintained from Shell

•Transferred from SAP to Maximo

•Direct (annulus) pressure monitoring to WIST via PI

TOOLS & SYSTEMS USED

• Well integrity visibility & management•Clear Roles & Responsibilities (Cairntoul)

•Meetings & reports•Daily monitoring and reports

•Weekly well integrity meetings

•Monthly management well integrity meetings

•WIST available to onshore & offshore personnel

•Valve failure register published on intranet

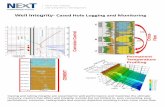

•SUCIT•Ultrasonic casing integrity tool developed

•Well services stock control system•To minimise time between failure and fix

•Well Management Procedures•Senergy, Shell & new

MODIFICATIONS

•Fine tuning of procedures

•New wellbore surveying manual

•Well services stock control system

•Repair grace period review

•Recalculated all casing pressure triggers &

limits

•Platform specific intervention procedures

•Well integrity management KPIs

•Improved pressure information for well

planning

KEY LEARNING

• Prioritise purchase of critical well spares

to avoid long lead time

• Education campaign to promote

policies & procedures to the new team

• Early access to data and good file structures

from start

• Cooperation & trust between buyer and seller

are important. Trust but verify.

• Use of management company allows project

acceleration