MAGNE-BLAST CIRCUIT BREAKERMagne-blast Circuit Breaker GEI-88761 ed " and the driving pawl is raised...

Transcript of MAGNE-BLAST CIRCUIT BREAKERMagne-blast Circuit Breaker GEI-88761 ed " and the driving pawl is raised...

-

=531

INSTRUCTIONS ANDRECOMMENDED PARTSFOR MAINTENANCE

GEI-887611Supersedes GEI-88761H

:

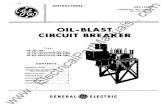

MAGNE-BLAST CIRCUIT BREAKER© TYPES

AM-4.16-250-6AM-4.16-250-7AM-4.16-250-8

© ;:: :i!

CONTENTSIntroduction . . . . . . . 3• • •Receiving, Handlingand Storage . . . . . . . 3• • •Installation . . . . . . . 4• • •Description ofOperation . . . .

^Adjustments . . ..General Maintenance . . . .1 4. • 4• • • • •

;. . . 10• •

Renewal Parts 28

SWITCHGEAR PRODUCTS DEPARTMENT

© E L E C T R I CG E N E R A LP H I L A D E L P H I A , P A .

• i

•

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

m

MAGNE-BLAST CIRCUIT BREAKERAWI-4.16-250-7 MAM-4.16-250-6

AM-4.16-250-8 (^)Letter Designation B, C, H, K, and N, used immediately following the model numberindicates basic design features..A

INTRODUCTIONage, current, and interrupting ratings are neverexceeded 0

The magne-blast breaker is the removable andinterchangeable interrupting element used in metal-

4f%clad switchgear to provide reliable control and pro-tection of electrical apparatus and power systems.

The AM-4.16-250 Magne-blast Breaker is avail-able with continuous current ratings of 1200 amperesand 2000 amperes in accordance with applicableindustry standards.plate for complete rating information of any par-ticular breaker. The nameplate also describes thecontrol power requirements for that breaker. Theapplication of a breaker must be such that its volt-

Since this book is written to include ,all ratings of the breaker as well as several design !variations, the instructions will be of a general )character and all illustrations will be typical unlessotherwise specified.

PROPER INSTALLATION AND MAINTENANCEARE NECESSARY TO INSURE CONTINUED SAT-ISFACTORY OPERATION OF THE BREAKER. Thefollowing instructions will provide complete infor-mation for placing magne-blast breakers in serviceand for maintaining satisfactory operation.

Refer to the breaker name-

RECEIVING, HANDLING AND STORAGE

Receiving and Handling against condensation, preferably by storingit in a warm dry room, since water absorp-tion has an adverse effect on the‘insulationparts. Circuit breakers for outdoor metal-clad switchgear should be stored in theequipment only when power is availableand the heaters are in operation to pre-vent condensation.

Each breaker is carefully inspected and packedIplgor shipment. Immediately upon receipt of the%J

-

GEI-88761 Magne-blast Circuit Breaker

INSTALLATION1. Remove the box barrier and mechanism

cover and make a visual inspection to as-certain that the breaker and mechanism isin satisfactory condition. Check all bearingsurfaces of the mechanism for lubrication.Refer to section on lubrication page 16 andFigure 17.Charge the breaker closing springs man-ually using a 5/8” ratchet wrench to turnthe driving eccentric (6) Figure 1. Turningthe eccentric counter clockwise will advancethe ratchet wheel and compress the springs.When the springs have reached the fullycharged position the indicator (1) will read’’CHARGED”, and the driving pawl will beraised from the ratchet wheel teeth,ditional turning of the eccentric will notadvance the ratchet wheel.

OR MECHANISM UNLESS THE CLOSINGSPRINGS ARE BLOCKED AND THE OPEN-ING SPRINGS HAVE BEEN TRIPPEDOPENOR MECHANICALLY BLOCKED.PRECAUTION IS REQUIRED TO PREVENTACCIDENTAL CLOSING OR TRIPPING.

THIS

The closing springs should now be un-blocked. Rotate the driving eccentric untilthe indicator reads ,lCHARGED” and theratchet wheel does not advance. The springblocking device can now be removed.

3. Connect the test coupler to the circuit ^y|jbreaker and operate it electrically severaltimes. Check the control voltage as de-scribed under ’’CONTROL POWER CHECK”(Page 14 ).4. Disconnect the test coupler and replace box

barrier.5. If the breaker has been stored for a long

period of time, it is recommended thatthe insulation be checked with a standard60 hertz high potential test. Refer toInsulation Test (Page 16).

2.

?!

Ad- iInsert the spring blocking device (10) andmanually discharge the springs against thepins by pushing the manual release button(4 ). The springs are now blocked and slowclosing of the breaker contacts can beaccomplished by again turning the drivingeccentric with a 5/8” ratchet wrench.During the slow closing operation check toinsure that the mechanism does not stickor bind during the entire stroke, that itlatches securely in the closed position, andthat it trips freely when the manual triplever is operated. At this time, also checkthe following adjustments:

a. Arcing contact wipe (Refer to page 10)b. Primary contact wipe (Refer to page 11)c. Primary contact gap (Refer to page 11)

If the breaker secondary wiringNOTE:is to be given a hi-potential test at 1500volts, remove both the motor leads fromthe terminal connection. Failure to dis-connect the motor from the circuit maycause damage to the winding insulation.6. Lubricate the silver portion of the ballcontact at the top of the breaker bushingby applying a thin film of contact lubricantD50H47.Refer to metal-clad instruction book GEH-1802 for instructions on inserting the break-er into the metal-clad unit.

7.DO NOT WORK ON EITHER THE BREAKER

DESCRIPTION OF OPERATION

The Magne-blast Breaker has two principal com-ponents; the breaker element and the operatingmechanism:

stored energy type designed to give high speedclosing and opening. The mechanism will operateon a-c or d-c voltage as indicated on the breakernameplate. Closing and opening operations arecontrolled either electrically from the metal-cladunit and remote location, or mechanically by themanual close and trip levers on the breaker. Allsecondary connections from the breaker to the metalclad unit are made through the coupler (1) Fig. 2.A spring release interlock, Fig 3, is providedto discharge both the closing and opening springswhen the breaker is withdrawn from or insertedinto the Metal Clad unit.

The breaker element is three similar pole units,each of which includes the current carrying parts,main and arcing contacts, interrupter, and anenclosing barrier system that provides insulationbetween poles, or phases and to ground. The pri-

' mary connections to the associated metal-cladswitchgear are made through the ball contacts atthe top of the breaker bushings.The operating mechanism type ML-13 is of the

4

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

Figure 1. (8034475) Spring Blocking Device1. Charge-Discharge Indicator2. Support Bolts3. Driving Pawl4. Manual Close Lever5. Motor6. Eccentric7. Closing Spring8. Manual Charging Wrench9. Fuse

10. Spring Blocking Device

Figure 2. (8034473) Left Side View ML-13Operating Mechanism

1. Secondary Coupler2. Interlock Switches3o Auxiliary Switch4. Latch Checking Switch5. Switch Cam6. Charge-Discharge Indicator7. Closing Latch Roller8. Power Switches9. Closing Latch

10. Closing Springs11; Motor12. Fuses

Figure 3. (8038805) Spring Discharge Linkage1. Link2. Adjusting Bolt3. Trip Latch Crank4. Discharge Crank5. Adjusting Clevis6. Spring Release Crank

5

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

"

GEI-88761 Magne-blast Circuit BreakerWhen the breaker is used interchangeably withtype MS-13 solenoid operated breakers in M-26metal-clad units, fuses (12) Figure 2, are mountedon the breaker for protection of the motor andposing circuit. These breakers are identified bya "C" or "K" suffix in the breaker nomenclature.In cases where breakers with type ML-13mechanisms must match and line up with breakers

having type ML-11 mechanisms the spring chargingcircuit for both mechanisms should be fused withBuss Company Fusetrons as follows:

A positive interlock (3) Figure 4 and interlockswitch (2) Figure 2, are provided between thebreaker and metal-clad unit to prevent raisingor lowering of the breaker in the unit while in aclosed position and to prevent a closing operationwhen the breaker is not in either the fully raisedor lowered position. To insure that this interlockwill function during manual, as well as duringelectrical operation of the equipment, both mechan-ical and electrical blocking is provided. If forany reason the closing springs should be dis-charged against the positive interlock the mechan-ism will be jammed and be inoperable. Themechanism can be released and returned to thereset position by pushing in on the trip lever (8)Figure 5. It may require more than normalforce to release the interlock.

A plunger interlock, Figure 14 can be providedwhen required to operate a stationary auxiliaryswitch and/or a rod interlock mounted in the metal-clad unit.

Cont. Volt. Fuse Size Cat. No.a48v d-cHOv d-c

125v d-c115v a-c220v d-c250v d-c230v a-c

10A FRN 10FRN 4FRN 4FRN 4FRN 2.5FRN 2.5FRN 2.5

4A4A4A

2.5A2.5A2.5A

Spring Charging

The mechanism has a high speed gear motor(10) Figure 5, that compresses a set of closingsprings through the action of an eccentric, ratchet,and pawl assembly. The rotary action of the motoris converted to a straight stroke through the eccen-trie (11) Figure 4, and a lever that carries a spring ^p)loaded driving pawl (3) Figure 1.

miWPFigure 4. (8034463) Right Side View ML-13

Operating MechanismFigure 5. (8034471) Front View ML-13

Operating Mechanism1. Upper Spring PinLatching PawlsPositive Interlock RollerOpening SpringCam ShaftRatchet WheelBearing BlockDriving PawlLower Spring PinDriving Pawl LeverEccentricClosing Spring

2.3. 1. Auxiliary Switch

Open - Close IndicatorTrip CoilProp SpringOperation CounterTrip LatchCharge-Discharge IndicatorManual Trip LeverManual Close LeverMotor

4. 2 .5. 3.6. 4.7. 5.8. 6.9. 7.

10. 8.11. 9.12. 10.

6

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

Magne-blast Circuit Breaker GEI-88761ed" and the driving pawl is raised from theratchet wheel. The use of the ratchet wrenchprovides for maximum safety in the event thatcontrol power is suddenly restored without warning.In this event, the motor drive will override theratchet wrench and continues to charge the springs.Closing Operation

The breaker can be closed electrically byenergizing the spring release solenoid (15) Figure6, or manually by pushing the close button (9)Figure 5. In either method the closing latch isrotated from under the closing roller to releasethe closing springs (10) Figure 2. The energyin the springs is used to rotate a cam (16) Figure7 and close the breaker through the operatingmechanism linkage. During the closing operationthe mechanism is trip-free at all times. The break-er is held closed by the closing prop (14) movinginto position under the prop pin (13). During theclosing operation the opening springs (4) Figure 4,are compressed and held ready for an openingoperation with the trip latch (8) Figure 7 bearingagainst the trip latch roller (9).

When the closing operation of the breaker iscompleted and the closing latch is fully reset,

The pawl advances the ratchet wheel (6) Figure 4a few degrees each stroke where it is held in pos-ition by the latching pawls (2). When the ratchet

f*%vhpel has been rotated approximately 180 degrees^the closing springs (12) will be fully compressed.As the ratchet wheel continues to rotate, the springload will shift over center and attempt to discharge.After a few degrees of rotation, the closing roller(7) Figure 2, will engage the closing latch (9) andthe compressed springs will be held by the latchuntil a closing operation is required. During thelast few degrees of the ratchet wheel rotation thepower switches (8) are opened and the drivingpawlis raised from the ratchet wheel surface. Thisallows the motor and driving mechanism to coastto a natural stop expending all residual energy.

During the time the springs are being com-pressed a relay (17) Figure 6, is energized to holdthe closing circuit open. The relay remainsenergized until the springs are fully charged andthe control switch contacts are re-set.

The closing springs may be charged manuallyif control voltage is lost. A 5/8" ratchet wrenchcan be used to rotate the eccentric in a counterclockwise direction until the indicator reads"Charg-

1011121314151617

Figure 6. (8034467) Control Mechanism1. Latch Checking Switch2. Switch Cam3. Switch Striker4. Switch Support Bolts5. Switch Support6. Closing Latch Roller

7. Power Switches8. Closing Latch9. Closing Latch Shaft

10. Latch Adjusting Screw11. Release Coil Bolts12. Closing Latch Spring

13. Latch Monitoring Switch14 o Switch Mounting Bracket15. Spring Release Solenoid16. Release Coil Support17. Control Relay

7

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

I

GEI-88761 Magne-blast Circuit Breakerthe contacts of the latch monitoring switch closesto permit the spring charging motor to be energiz-ed and recharge the closing springs.Opening Operation

The breaker can be opened either electricallyby energizing the trip coil (3) Figure 5, or man-ually by pushing the trip lever (8). In each methodthe trip latch is rotated off the trip latch roller,permitting the operating mechanism linkage tocollapse. The energy stored in the opening springsis released to provide the required opening speedfor successful interruption of the circuit.

As the breaker opens to interrupt a current,the arc first starts at the arcing contacts (6 & 27;Figure 8, transfers to the arc runner (4 & 10)^and energizes the blow-out coils (3 & 11). This||j|action introduces a magnetic field between the^^pole pieces (5 & 9) of the interrupter that forcesthe arc deeper into the arc chute (8). At the timethe arcing contacts part a discharge of air isexpelled through the booster tube (28) acrossthe arc. This air flow assists the arc transferand interruption by blowing the arc away from thecontacts and into the arc. chute. The magneticfield forces the arc deeper into the interrupteralong the diverging arc runners.

i

24 JJ t-v/ v• - 'la 'V iI I! r~ :.* /\l !n :!

0_ V" f\LA. ‘V .o' x."X _t3.c13

XK

14

15 //25

JT

!

Fig. 7 (0114C5320) Sectional Side View of MechanismI1. Handle

Trip Coil SupportTrip CoilTrip ArmatureProp Reset SpringCam Follower RollerTrip ShaftTrip LatchTrip Latch Roller

10. Trip Latch Roller Support11. Crankshaft12. Cranks13. Prop Pin14. Prop15. Drive Shaft16. Cam.17. Check Nut

18. Stop Plate19. Spring Rod20. Spring21. Spring22. Spring Guide23. Stop Pin24. Main Shaft Bearing25. Cam Shaft Bearing

2.! 3.4.5.6.7.8.9.

8

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

jR*sl

Magne-blast Circuit Breaker GEI-88761

CD

141516

17r\

2 185 19

2042152262324

- 8 252627

9 2829

10I t \ 30\\2 i

I fU$-t3 CO

Fig. 8 (0258C0689) Cross Section of Breaker Pole Unit21. Operating Rod22. Stationary Primary Contacts23. Movable Primary Contacts24. Cup Bearing25. Yoke26. Movable Contact Arm Assembly27. Movable Arcing Contact28. Booster Tube and Piston29. Connection Bar30. Booster Cylinder

11. Lower Blow-out Coil12. Lower Blow-out Core13. Lower Barrier14o Front Bushing15. Rear Bushing16. Frame17. Main Operating Crank18«, Upper Horizontal Barrier19. Spring Retainer20. Lower Horizontal Barrier

1. Box Barrier HandleUpper Blow-out CoreUpper Blow-out CoilUpper Arc RunnerUpper Pole PieceStationary Arcing ContactBox BarrierArc Chute SideLower Pole PieceLower Arc Runner

2.3.4.5.6.7.8.9.

10.9

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

I !

GEI-88761 Magne-blast Circuit BreakerThe arc chute has a series of interleaving cer-

amic fins, Figure 19. As the arc is forced into theinterrupter it is lengthened in the gradually deep-ening serpentine path between the fins so that theelectrical resistance of the arc is rapidly increasedand its heat is absorbed by the ceramic material.The increased resistance reduces the magnitudeand phase angle of the current and at an earlycurrent zero the arc cannot re-establish itselfand interruption occurs.

Trip Free Operation

If the trip coil circuit is energized while thebreaker is closing, the trip armature will forcethe trip latch (8) Figure 7 away from the triproner (9) causing the mechanism linkage to colla;and the breaker to re-open. The closing camwill complete its closing stroke and the springswill re-charge as in a normal closing operation.

pse(16)

i

ii'

i ADJUSTMENTSMECHANISM UNLESS THE CLOSINGSPRINGS AREBLOCKED AND THE OPENING SPRINGS HAVEBEENBLOCKED.PREVENT ACCIDENTAL CLOSING OR TRIPPING.

All adjustments should be checked during per-iodic inspections and whenever it becomes nec-essary to repair or replace parts that have becomeworn or defective while in service. The followingadjustments are listed in the order in which theyare to be checked after removing the box barriersand front cover from the breaker.

TRIPPED OPEN OR MECHANICALLYTHIS MEASURE IS REQUIRED TO

Arcing Contact Wipe

Refer to Figure 9. Close the breaker untilDO NOT WORK ON EITHER THE BREAKER OR::

7l

« y\J i

'r . _* +° MIN

J 2 2)3 3i4 U\ •57

Primary Contact Wipe Arcing Contact Wipei?;

Figure 9B. "-8” Contact Structure (0132C2709)Figure 9 Contact Adjustments

1. Stationary Primary Contacts 5.2. Movable Primary Contacts3. Buffer Block4. Stationary Arcing Contacts

Movable Arcing Contacts6. Contact Arm7. Throat Bafflej

Is

10

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

Magne-blast Circuit Breaker GEI-88761This can bethe arcing contacts just touch,

determined with the use of a circuit continuitytester such as a light indicator or bell set. In

H this position, the gap between the stationaryprimary*contacts (1) and the movable primary contact (2)should be 5/16" or greater. This setting has beenmade in the factory and no adjustment is provided.A wipe of less than 5/16" is an indication that thearcing contacts need to be replaced. When makingthis check, see that the movable arcing contact (5)passes between the probes on the upper arc runnerwithout touching. On the "-8" design, also checkfor clearance between the arcing contact (5) andthe slot in the throat baffle (7) during entire strokeof the moving contact assembly.

Primary Contact Gap

Refer to Figure 10. With the breaker closed,press the manual trip button allowing the breakerto trip open normally. Do not force the contactsopen wider by hand. The gap between the stationaryprimary contacts (5) and the movable primary con-tact (8) measured between the closest points, shouldbe 3 5/8" to 3 15/16". To change this gap, loosenthe check nut (17) Figure 7, and turn the adjustingnut (18) on stud (19). Screwing the adjusting nutdown willdecrease the primary contact gap. Tightenthe check nut and re-measure the contact gap(close and trip the breaker before checking themeasurement). Whenever the primary contact gapis changed, the primary contact wipe should berechecked and, if necessary, readjusted.

WHEN WORKING ON THE MECHANISM IN THECLOSED POSITION, KEEP FINGERS CLEAR OFTHE LINKAGE, AS ACCIDENTAL TRIPPING CANCAUSE SEVERE INJURY.Trip Latch Wipe

Refer to Figure 7. The wipe of the trip latch(8) on the trip roller (9) should be from 3/16"to l/4". This can be measured by putting a filmof grease on the latch (8), closing the breakerpart way, and tripping. The mechanism has theproper trip latch wipe when the latch rests againstthe stop pin (23). No adjustment is provided anda visual inspection is usually all that is required.If this setting is not correct, look for insufficienttravel of the trip shaft (7).Trip Armature Travel

Refer to Figure 7. The trip armature (4)should have 7/32" to 9/32" travel before the triplatch (8) starts to move. This can be adjusted bymoving the trip coil support (2) and/or by adjustingthe trip armature screw (12) Figure 11. Alocking screw located behind the trip armature^crew must first be loosened. Retighten lockingscrew after making adjustment.Release Latch Wipe

} Primary Contact Wipe

Refer to Figure 9, when the breaker is closedthe stationary primary contacts (1) should risefrom 1/4" to 5/16". Before checking this dimen-sion be sure the mechanism is re-set so thatthe prop pin (13) Figure 7 is resting on the prop..To obtain the proper contact adjustment, openthe breaker and, referring to Figure 10, loosen thecheck nut (4) and turn the adjusting nut (3). Screw-ing up on the adjusting nut will decrease the primarycontact wipe, down will increase it. Tighten thecheck nut, close the breaker and recheck the wipe.With the primary contact wipe correctly adjusted,the clearance between the contact arm (6) Fig-ure 9 and the buffer block (3) should be 1/16" orgreater when the breaker is fully closed.

Refer to Figure 6. The wipe between the releaselatch (8) and roller (6) should be 3/16" to 1/4".If re-setting is required, loosen, set, and re-tighten adjustment nut and screw (10).Release Latch Monitoring Switch

Refer to Figure 6. The release latch must befully re-set and the latch monitoring switch (13)operated before the motor will start. When thelatch is fully reset the clearance between the switchstriker arm and the switch mounting bracket (14)is 1/32" or less, this can be adjusted by bendingthe striker arm.

Figure 10. (8039618) Adjustable Coupling ForMaking Primary ContactWipe Adjustments

1. Operating Rod2. Operating Rod Pin3. Adjusting Nut4. Check Nut5. Stationary Primary Contacts6. Yoke7. Contact Arm8. Movable Primary Contacts

Motor and Relay Switches

Refer to Figure 6. With the closing springsblocked rotate the switch cam (2) until the switch

11

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

GEI-88761 Magne-blast Circuit Breaker

s

Figure 11. (8039585) Auxiliary Switch andTrip Coil

1. Open - Close Indicator2. Auxiliary Switch3. Prop Spring4. Trip Latch Spring5. Spring Discharge Crank6. Cotter Pin7. Trip Coil Support8. Trip Coil9. Mounting Bolts

10. Latch Set Screw11. Trip Latch12. Trip Arm Screw13. Manual Trip Lever

Figure 12. (8034474) Positive Interlock Switch1. Positive Interlock Shaft2. Switch Arm3. Switch Support4. Interlock Switch5. Auxiliary Switch6. Switch Support7. Latch Checking Switch8. Switch Arm9. Trip Shaft

s

1

striker (3) has traveled the maximum amount(about 180 degrees rotation of cam). At this pointthe clearance between the striker and the switchsupport (5) should be 1/32" or less. This can beadjusted by loosening the switch support mountingbolts (4) and rotating the support.Interlock Switch Wipe

Refer to Figure 12. With the positive interlockin the reset, or normal position the clearancebetween the interlock switch arm (2) and the switchmounting plate (3) should be 1/32" or less. Thiscan be adjusted by bending the switch arm.Driving Pawl Adjustment

to its maximum travel. Now check the clearancebetween the ratchet tooth and the latching pawl. Theclearance should be approximately equal for boththe driving and latching pawls and not less than.015" in either case.

If adjustment is required for either pawl thesprings must first be fully charged and blocked.Loosen seven motor support bolts (2) Figure 1and move entire motor assembly to the rear ifthe clearance is under the minimum at the latchingpawls, and to the front if the clearance is underthe minimum at the driving pawl. Move the motorassembly approximately twice the dimensional in-crease required at the pawl. Be certain themotor assembly is moved straight forward orrearward and tighten the one bolt on the right sideof the mounting frame first to assure properalignment. After tightening the remaining boltsthe springs should be released and the clearanceagain checked as described above.

The driving pawl (8) mustRefer to Figure 4.advance the ratchet wheel (6) sufficiently on eachstroke to allow the latching pawls (2) to fallinto the ratchet teeth. This should be checked withthe closing spring load against the driving members.With the mechanism unblocked, hand charge theclosing springs with the manual charging wrenchuntil they are slightly more than half charged.Slowly rotate the charging wrench until the drivingpawl has traveled through its return stroke andcheck the maximum clearance between the pawland the ratchet tooth. Rotate the charging wrenchuntil the driving pawl has advanced the ratchet tooth

AUXILIARY DEVICES

Latch Checking SwitchaRefer to Figure 13. Charge the closing springs

sufficiently to reset the mechanism linkage. Rotatethe trip latch (4) by pressing the manual trip lever

mm

12

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

Magne-blast Circuit Breaker GEI-88761

i

k2

3

mFigure 14. (8034464) Plunger Interlock

1. Plunger BoltWasherBreaker Lifting Rail

Figure 13. (0114C5320) Latch Checking SwitchSwitch Support

2. Latch Checking Switch3. Switch Arm

Trip Latch5. Reset Pin Stop6. Latch Roller7. Latch Roller Link8. Latch Roller Pin

1.

4.II

to open the latch checking switch (2). Allow thetrip latch to reset slowly and determine the pointat which the contacts are made by using a circuitcontinuity tester (light indicator, bell set, etc).The contacts of the latch checking switch shouldjust make when the g(4) and the stop pin (5)link (7) is 1/16".1/64" between the switch arm (3) and the switchsupport (1). To obtain adjustment of the latch check-

switch, bend the latch checking switch arm

Figure 15. (8034471) Driving Elements1. Mounting Bolts

Manual Close ButtonEccentricRetaining Ring

5. Hex Charging Stud6. Driving Link

Motor SupportRetaining Ring

9. Motor10. Fuse

2.ap between the trip latchlocated on the latch roller

There should be a minimum of

3.4.7.8.mg

(3).Plunger Interlock

§,,,Refer to Figure 14. With the breaker in the

closed position, the vertical distance ”A” from thetop of the plunger bolt (1) to the bottom of thebreaker lifting rail (3) should be 16-19/32” to16-23/32”. To change this adjustment, add orremove washers (2).

Inspection and Test

1. For ease in reviewing the adjustments, thefollowing are recapitulated:

Primary contact wipe: 1/4” to 5/16”.Arcing contact wipe: 5/16” or greatergap at primary contacts.Primary contact gap: 3-5/8” to 3-15/167Trip latch wipe: 3/16” to 1/4” with triplatch resting against stop pin.Trip armature travel 7/32” to 9/32”.Release latch wipe: 3/16” to 1/4”.Release latch monitoring switch: Max-imum clearance 1/32”.

a.b.

Auxiliary Fusesc.

Refer to Figure 15. On breakers with a ”C” or”K” suffix, a set of protectingfuses (10) are mounted

igj^ on the front of the breaker. These fuses are theprimary protective devices for the closing controlcircuit on those breakers that are used in metal-clad units designed for solenoidoperatedbreakers*

d.e.I f.g.

13

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

GEI-88761 Magne-blast Circuit Breakertangent to the lower surface of the probes on theupper runner. Proper servicing and lubricationof the breaker and its operating mechanism shouldmaintain these speeds and no adjustment is provided.Control Power Check

Motor and relay switch:clearance 1/32".Interlock switch: maximum clearancel/32".Driving and Latching Pawl: minimumclearance to ratchet teeth .015".Latch checking switch contacts makewhen the gap between the trip latchand the stop pin is 1/16".Plunger interlock: 16-19/32" to 16-23/32".

Check all nuts, washers, bolts, cotter pins,and terminal connections for tightness.Inspect all wiring to make sure that nodamage has resulted during installation,and test for possible grounds or shortcircuits.

maximumh.i.j*

k.After the breaker has been operated several

times with the manual charging wrench and themechanism adjustments are checked as described,the operating voltages should be checked at therelease coil, trip coil, and motor terminals.Control Power for electrical operation of thebreaker may be from either an alternating ordirect current source. The operating ranges forthe closing and tripping voltages as given on thebreaker nameplate, are as follows:

1.

2.I

3.

NominalVoltage

ClosingRange

TrippingRange! 4. See that all bearing surfaces of the mech-anism have been lubricated. Refer to the

section on LUBRICATION. (Page 16 andFigure 17).

5. Operate the breaker slowly with the manualcharging wrench and note that there is noexcessive binding or friction and that thebreaker can be moved to thefully opened andfully closed positions.

6. See that any place where the surface of thepaint has been damaged is repainted immed-iately.

7. Check the trip coil plunger and the releasecoil plunger to see that they move freely.

Opening and Closing Speeds

I

24v d-c48v d-c

llOv d-c125v d-c220v d-c250v d-c115v a-c230v a-c

14 30v d-c60v d-c

125v d-c140v d-c250v d-c280v d-c125v a-c250v a-c

: 34 2850v d-c115v d-c130v d-c230v d-c260v d-c125v a-c250v a-c

80 607090

160 120180 140

95 95190 190

If the closed circuit voltage at the terminalsof the coil or motor does not fall in the specifiedrange, check the voltage at the source of power andline drop between the power source and breaker.

When two or more breakers operating from thesame control power source are required to closesimultaneously, the closed circuit voltage at theclosing coil or motor of each breaker must fallwithin the specified limits.

W

The closing speed of the arcing contact of thebreaker should be a minimum of 11feet per second.This represents the average speed of the movablearcing contact from a point 3" before the tip istangent to the lower surface of the probes on theupper arc runner to the tangent position. Electrical closing or opening is accomplished by

energizing the closing or trip coil circuit. Controlswitches are provided for this purpose on themetal-clad unit. It is also possible to trip or closethe breaker manually by pressing the manual triplever (8) Figure 5 or the manual close button (9).

The opening speed of the arcing contact shouldbe a minimum of 12 feet per second. This repre-sents the average speed over 3" from the pointwhen the tip on the movable arcing contact is

GENERAL MAINTENANCEGeneral

every 2000 operations, or once per year, whichevercomes first. If the breaker is also required tointerrupt fault currents during this period of timeadditional maintenance and replacement of partsmay be necessary.

Safe and dependable service from electrical ap-paratus and power systems is contingent upon re-liable performance of power circuit breakers. Toobtain maximum reliability the breaker should beinspected and maintained on a regular schedule.The breakers are designed in accordance with ap-plicable standards which require that they becapable of performing up to 5000 operations for1200 ampere breakers and 3000 operationsfor 2000ampere breakers switching rated continuous cur-rent before any replacement of parts should benecessary.breakers being serviced, or maintained, at least

BEFORE ANY MAINTENANCE WORK IS PER-FORMED, MAKE CERTAIN THAT ALL CONTROLCIRCUITS ARE DE-ENERGIZED AND THAT THEBREAKER IS REMOVED FROM THE METAL-CLADUNIT.MECHANISM WHILE IN THE CLOSED POSITIONUNLESS THE PROP AND TRIP LATCH HAVEBEEN SECURELY WIRED OR BLOCKED TO PRE-

DO NOT WORK ON THE BREAKER OR

This requirement is based on the

14

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

e-jMagne-blast Circuit Breaker GEI-8876

pieces (3 & 6) Figure 1-8 and the uppe:mounting support (10) should be inspecte<for breaks in the insulation. If there areholes or breaks in the insulation they shoulcbe repaired or the part replaced.

VENT ACCIDENTAL TRIPPING. DO NOT WORKON THE BREAKER OR MECHANISM WHILE THE

^SPRINGS ARE CHARGED UNLESS THEY ARESECURED IN THAT POSITION BY THE MAIN-TENANCE SPRING BLOCKING DEVICE.tmPeriodic Inspection

The frequency of the inspection and maintenanceoperations required should be determined by eachoperating company and will depend on the applica-tion of the breakers and the operating conditions.Factors which should be considered are: Import-ance to overall plant or system operation; numberof operations and magnitude of currents switched bybreaker; frequency of fault interruptions; and theatmospheric conditions in which the breaker nor-mally operates. Extreme conditions of dust,moisture, corrosive gases etc., can indicate thatinspection and maintenance will be required morefrequently than every 2000 operations. Very cleandry operating conditions with low current switchingduty can justify a longer period of time betweeninspections. Any time a breaker is known tohave interrupted a fault at or near its rating itis recommended that the breaker be inspected andnecessary maintenance be performed as soon afterthe interruption as is practical. The followinginstructions give the items that should be includedin an inspection and general recommendations onthe maintenance of breakers.

.•’•twMRr/aanifUHam

Interrupters

Since there are no movingparts, the interrupters^ of a magne-blast breaker will normally require

little or no inspection unless there is evidenceof damage to the arc chutes sides or contaminationin the throat area. If either of these conditionsare present the interrupters should be removedfrom the breaker and the following points noted:

1. The throat area of the interrupter shouldbe cleaned with sandpaper (Do Not useemery cloth or other metallic abrasives).All flat areas on either side of the movablearcing contact travel should be sanded.Do not sand or otherwise attempt to cleanthe ceramic fins of the arc chute sides.Heavily contaminated parts should be re-placed.

2. Cracks which have formed in the fins of thearc chute are to be expected in ceramicmaterials of this type when subjected tothe severe heat of an arc. These cracksdo not interfere with the operation of thedevice in any way and should be disregarded.

30 If the arc chute has suffered any mechanicalinjury due to droppingor accidentalstriking,resulting in the actual breaking off of fins,replacement will be necessary. Smallbroken corners on the exhaust end of thearc chute sides will not interfere with itsperformance and can be disregarded.

4. The plastisol flexible covering for the pole

m

Fig. 16 (8039584) Interrupter Removed ShowingAccessibility of Arcing Contacts

1. Rear Bushing2. Upper Horizontal Barriers3. Supporting Bolt4. Upper Interrupter Support5. Stationary Arcing Contacts6. Movable Arcing Contact7. Mounting Bolts8. Arc Chute Brace9. Support Bracket

10. Lower Supporting Bolt11. Lower Interrupter Support12. Interrupter

15

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

GEI-88761 Magne-blast Circuit Breaker,

Interrupter Removal and Replacement All other insulation parts on the breaker shouldbe kept clean and dry. Smoke or dust collectedbetween inspection periods should be wiped off,and if dampness is apparent, heaters should be||J|installed in the metal clad switchgear to insuredryness.

Refer to Figure 16. To remove the interrupterloosen the two upper supporting bolts (3) and the onelower' support bolt (10) using a standard 3/4"wrench. Raise the assembly approximately 3/8"and slide it toward the rear of the breaker.

To reassemble the interrupter to the breaker,rest the lower interrupter support (11) on thesupport bracket (9). Slide the arc chute forward,lifting it slightly to engage the supporting bolts (3)in the slots of the upper interrupter support (4).On the "-6" design check the spring baffle (11)Figure 22, to assure that it closes the gap be-tween the upper insulation (7) Figure 19, andthe back surface of the contact support (4) Figure22. On the "-8" design check to assure that

!Insulation Test

SWhen insulation has been repaired or replaced,

or when breaker has been operating in adversemoisture conditions, it is recommended that theinsulation be checked before the breaker is placedback in service. A standard 60 hertz high poten-tial test at 14,000 volts RMS for one minute willnormally indicate whether the breaker is satis-factory for service. With the breaker contacts inthe fully opened position, apply the test potentialto each terminal of the breaker individually with allother terminals and the breaker frame grounded.After high potential tests are made on organic in-sulating materials, these materials should beinspected for visible leakage current paths, andnecessary action must be taken to repair or replaceinsulation that may have been affected by moistureabsorption.

If the breaker secondary wiring is to be givena high-potential test at 1500 volts, remove both ofthe motor leads from the terminal board. Failureto disconnect the motor from the circuit may causedamage to the winding insulation.Lubrication

!;

gjjtu

W .h

the upper insulation is properly positioned withinthe barrier suspended from the stationary contactsupport (9) Figure 23.Tighten the supporting bolts (3 and 10) Figure

16. These bolts serve as both the electrical andmechanical connections between the bushings andthe arc runners within the interrupter. Checkthat the movable arcing contact (6)tween the probes on the upper arc runner (5)Figure 19 without touching.Breaker Contacts

:

passes be-

By removing the box barrier the movable andstationary primary contacts and the movable arcingcontacts can be inspected. The stationary arcingcontacts can be inspected only after removing theinterrupter. If the contacts are burned or pitted,they can be made smooth with a fine file.

After completing inspection of the contacts,check the contact adjustments as specified underADJUSTMENTS.

In order to maintain reliable operation, it isimportant that all circuit breakers be properlylubricated at all times. Most of the bearings androlling surfaces utilize a new type of dry lubricationthat will require no maintenance and will last thelife of the equipment. Only few bearings and sur-faces listed in the chart, Figure 17, requirelubrication. These have been properly lubricatedduring assembly at the factory, using the finestgrades of lubricants available. However, even thefinest oils and greases have a tendency to oxidizewith age, as evidence by hardening and darkeningin color. Elimination of the hardened lubricantis essential for the proper operation of circuitbreakers. Also frequent operation of the breakercauses the lubricant to be forced out from betweenthe bearing surfaces. A simple lubrication willoften clear up minor disturbances which mightbe mistaken for more serious trouble.

Mechanism

A careful inspection should be made to checkfor loose nuts or bolts and broken retaining rings.All cam, roller, and latch surfaces should beinspected for any evidence of damage or excessivewear. Lubricate the mechanism as outlined below,then, using the manual charging wrench, open andclose the breaker several times to make certainthat the mechanism operates freely throughout itsentire stroke. Check the mechanism adjustmentsas specified under ADJUSTMENTS,control wiring for tightness of connections anddamaged insulation.Bushings and Insulation

§lb

Check theA definite lubrication schedule should be set up

taking into consideration the frequency of operationof the breaker and local conditions.

It is recommended that lubrication of the breakerand its operating mechanism be a part of the per-iodic inspection and maintenance program, with notmore than a two year period between lubrications.It is also recommended that all circuit breakers beoperated at regular intervals, at least once a year,to insure the lubrication is in good condition andthe breaker is operable.

The surface of the bushings should be kept cleanand unmarred to prevent moisture absorption.If the insulation surface should become damaged,it should be sanded and cleaned, and should berefinished with either clear varnish or clearresin. Allow to dry smooth and hard.

16

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

PF~

Magne-blast Circuit Breaker GEI-88761formed on the breaker at the factory, and should beused when a general overhaul of the breaker isnecessary.

General Electric Lubricants D50H15andD50H47are available in l/41b collapsible tubes. It is sopackaged to insure cleanliness and to preventoxidation.

The lubrication chart, Figure 17, is divided intotwo methods of lubrication. The first method out-lines the maintenance lubrication which should beperformed at the time of periodic maintenance, andrequires no disassembly. The second method out-lines a lubrication procedure similar to that per-

LUBRICATION ATMAINTENANCE

PERIODALTERNATE LUBRICATION(REQUIRES DISASSEMBLY)

PART

Sleeve Bearings - links, tripshaft, etc. (Teflon coatedbearings)

No lubricationrequired

No lubrication required

Sleeve Bearings - main crankshaft, driving pawl lever.(Bronze or cast iron)

Light applica-tion of machineoil SAE 20 orSAE 30.

Remove bearings or links,clean per instructionsand apply D50H15 lubri-cant liberally.

Contact Arm Hinge AssemblyCup bearingLoose rings between bushingand contact arm.

No lubricationrequired. Wipe clean and applyD50H47.

Roller and Needle Bearings Light applica-tion of machineoil SAE 20 orSAE 30.

Clean per instructionsand repack with D50H15lubricant.

Ground surfaces such as cams,ratchet teeth, etc.(Surfaces coated with M0S2)

No lubricationrequired. No lubrication required.

Ground surfaces such aslatches, rollers, prop, etc. Wipe clean and applyD50H15 lubricant.Wipe clean andapply D50H15

lubricant.Silver plated contacts andprimary disconnect studs. Wipe clean andapply D50H47. Wipe clean and applyD50H47.Booster Cylinder Do not lubricate Do not lubricateArcing Contacts Do not lubricate Do not lubricate

g

Figure 17. Lubrication Chart

17

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

'1,1 :

GEI-88761 Magne-blast Circuit Breakerthe alcohol in a well ventilated room; excessiveexposure to the fumes is sometimes unpleasantto personnel,. Washing the bearings in the lightoil, draining and repacking with lubricant D50H15should follow immediately.

Bearings that arepressed into theframeor other ,members such as the motor support (7) Figure 15,should not be removed. After removing the shaftand inner race the bearing can be cleaned satis-factorily with petroleum solvent or a similarcleaner and a stiff brush. Follow the procedureoutlined above using a light machine oil and G-Elubricant D50H15 before reassembling the innerrace and shaft.

METHOD OF CLEANINGBEARINGS

Whenever cleaning of bearings is required, asindicated in the lubrication chart, the followingprocedures are recommended.Sleeve Bearings

The sleeve bearings used throughout the linkageutilize Teflon surfaces and do not require lu-brication. After a number of operations, the sur-face will acquire a thin black film. Do not remov'ethis film unless there is evidence of outside con-taminates, such as dry or hardened grease. Ifcontaminants are present they should be removedby immersing the link and bearing in clean petro-leum solvent, or similar cleaner, and using astiff brush. Do not remove the bearings from thelinks. DO NOT USE CARBON TETRACHLORIDE.

The hinge of the primary contact arm (24)Figure 8, should be disassembled, cleaned, andlubricated with G-E D50H47 lubricant at generaloverhaul periods.

The main shaft bearings (24) Figure 7 and thebearings in driving pawl lever (10) Figure 4,should be removed, cleaned, and lubricated withG-E D50H15 lubricant at general overhaul periods.Roller and Needle Bearings

Rolling Surfaces

A number of rolling and rubbing surfaces in themechanism have been lubricated with a baked-ondry, molybdenum disulfide coating. This lubri-cation, which can be recognized by its dark, almostblack color (e.g. Face of switch cam (5) Figure 2)requires no maintenance and should last the lifeof the breaker.

Other rolling or rubbing surfaces that are notlubricated with molybdenum disulfide should havethe dried, dirty grease removed and a thin filmof fresh lubricant D50H15 applied.

MAINTENANCEMagne-blast breakers used for switching arc

furnaces or capacitors will require more frequentand more detailed inspection and maintenancebecause of the repetitive nature of the applications.The following schedule is recommended for suchbreakers:

A. Every 500 Operations, or Every Six Months-Whichever Comes First:

Refer to Figure 7. The. cam follower bearings6), latch roller bearing (9), and cam shaft bearings25) should be removed from the mechanism and

the inner race disassembled. They should then beplaced in a container of clean petroleum solventor similar cleaner.TETRACHLORIDE .has become badly oxidized, it may be necessary touse alcohol (type used for thinning shellac) toremove it. Ordinarily, by agitating the bearings inthe cleaning solution, and using a stiff brush toremove the solid particles, the bearings can besatisfactorily cleaned. Do not handle the bearingswith bare hands as deposits from the skin onto thebearings are inductive to corrosion. If the bear-ings are touched, the contamination can be removedby washing in alcohol.. After the bearings have beenthoroughly cleaned, spin them in clean new lightmachine oil until the cleaner or solvent is entirelyremoved. Allow this oil to drain off and then repackthem immediately with G-E lubricantD50H15beingsure all metal parts are greased. The inner racesshould then be assembled.

Etaif

DO NOT USE CARBONIf the grease in the bearings

Il

Remove the box barriers.1.'i

Wipe all insulating parts clean of smokedeposit and dust with a clean dry cloth,including the bushings, and the insideof the box barriers.

2.I

3. All flat parts in the throat area of theinterrupters should be thoroughly clean-ed by using sandpaper. This cleaningshould be performed any time the inter-rupter is removed. The fins on the arcchute sides should not be cleaned.Whenever the interrupter is removed,loose dust and dirt should be blownout before replacing arc chutes. Throatinsulation which is heavily contaminatedshould be replaced.

B. Every 2000 Operations, or EverySix MonthsWhichever Comes First:

1 If it becomes necessary to clean thebearings in alcohol (shellac thinner), be surethe alcohol is perfectly clean, and do not allow thebearings to remain in the alcohol more than a few7hours. If it is desirable to leave the bearings inthe alcohol for a longer time, an inhibited alcoholsuch as is used for anti-freeze should be used.Even then the bearings should be removedfrom thealcohol within twenty-four hours,against the toxic effects of the alcohol must beexercised by wearing rubber gloves and by using

NOTE:

I

In addition to the servicing done each500 operations, the following inspectionshould be made and work done whenrequired.

1 .Precautions

18:

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

Magne-blast Circuit Breaker GEI-88761positions. Its electrical operationshould then be checked using either thetest cabinet or the test couplers.

C. After Every 10,000 Operations:1. In addition to the servicing done each

2000 operations, the interrupters shouldbe removed from the breaker and dis-assembled to permit a detailed inspec-tion of insulation, blow-out coils, arcrunners and assemblies which canbecome contaminated by arc products.

2. The blow-out coils should be carefullyexamined and if the insulation has beencracked, shrunk or eroded from arcaction and heat so that the turns of thecoils are not fully insulated from eachother, the coils should be replaced. Allconnections should be checked fortightness.

3. The arc runners should be inspectedand replaced when any part of theirarea has been reduced to 25% of theoriginal metal thickness as a resultof arc erosion.

2. Primary Contacts (3 and 10 Figure 23).Inspect the condition of the stationarycontact fingers and movable contactblocks. Badly pittedor burned contactsshould be replaced. (Note: Burnedprimary contacts indicate the probableneed for arcing contact replacement*)If the contact surfaces are only rough-ened or galled, they should be smoothedwith crocus cloth or draw filed. Aftercontact dressing the primary contactsshould be greased lightly with D50H47.

3. Arcing Contacts (6 and 27 Figure 8).When the arcing contact wipe is lessthan the minimum specified under AD-JUSTMENTS, the contacts should bereplaced.inspected for uneven wear and/or dam-age using a mirror to inspect thestationary contacts. Normally it willnot be necessary to remove the inter-rupters for this 2000 operation ser-vicing unless inadequate wipe or con-tact condition indicate a need for re-placement. If the interrupters are re-moved, the contact braids, and otherparts subject to arcing shouldbe check-ed for possible cleaningor replacement.Do not grease the arcing contacts underany circumstances.

The contacts should be

4. Check the stationary arc contacts toassure that the arcing contacts are ingood condition and that their connectionsare tight.Insulating material that is carbonizedand cannot be satisfactorily cleanedshould be replaced.Any parts damaged or severely burnedand/or eroded from arc action shouldbe replaced.NOTE: Fine cracks may develop in thefins of the arc chute sides. This is tobe expected with ceramic materialswhen subjected to the high heat of anarc and may be disregarded unlessthey are long and present a possibilityof fin sections breaking completely off.Small broken corners on the exhaustend of the arc chute will not interferewith its performance and can alsobe disregarded.

4. Check the breaker and mechanism ad-justments as summarized under IN-SPECTION AND TEST. The necessaryreadjustments should be made as de-scribed under ADJUSTMENTS.

5.

6.5. The breaker and operating mechanismshould be carefully inspected for loosenuts, bolts, retaining rings, etc., allcam, latch and roller surfaces shouldbe inspected for damage or excessivewear. The buffer blocks and theirretainers on the bottom of the stationarycontact support should be inspectedforpossible need of replacement.

6. The contacts of the control relay (17)Figure 6, should be inspected for wearand cleaned if necessary.

7. Lubricate the breaker operating mech-anism in accordance with instructionsunder LUBRICATION, page 16 and thelubrication chart Figure 17.

8. Inspect all wiring for tightness of con-nections and possible damage of in-sulation.

7. The cup bearing and the contact ringat the hinge point of the contact bladeshould be disassembled, inspected,cleaned, and relubricated with G-Econtact lubricant D50H47. The contactring should be inspected for wear andreplaced when reduced in thickness toless than 1/32". When reassemblingthe cup bearing, be sure the cotterpin is properly assembled in the castlenut on the hinge pin (7) Figure 23.This assures proper contact pressureat the hinge.

9. After the breaker has been serviced,it should be operated manually to besure there is no binding or frictionand that the breaker contacts can moveto the fully opened and fully closed

191

-~?W;

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

J

GEI-88761 Magne-blast Circuit BreakerD. Every 20,000 operations or Approximately

Every Five Years - Whichever comesfirst:1. The breaker should be given a general

inspection and overhaul as required.All excessively worn parts in both themechanism and breaker should be re-placed. Such wear will usually beindicated when the breaker cannot beadjusted to indicated tolerances. Thisoverhaul and inspection is more detail-ed and will require disassembly of mech-anism and breaker operating parts.

2. All roller and needle bearings in theoperating mechanism should be dis-assembled, cleaned, and repacked withG. E. lubricant D50H15 as describedunder LUBRICATION.

2. Remove the side brace (5), and pole pieces(3 & 6).

3. To remove the upper interrupter support(10) remove the assembly bolt (1), andthe bolted connection (2) Figure 20 be-tween the upper interrupter support andthe blowout coil.

4. Remove the assembly bolt (16) Figure 18to remove the lower brace (8).

5. Remove the lower .interrupter support (14)by removing the assembly bolts (15) and theconnection nut (8) Figure 20.

6. At this point, the side shields (5) Figure20, and the arc runner assemblies (4 & 6)can be removed.

i

3. The stationary primary contactfingers(3) Figure 23, should be disassembledand the silver-plated pivot area of thecontact and contact support cleaned

lubricated with G-E lubricant7. Further disassembly of both the upper and

lower arc runner assemblies can be doneby removing the various screws and assem-bly bolts (not illustrated) as shown inFigure 19.The arc chute sides (6) Figure 19, canalso be separated for inspection afterremoving assembly bolts (2 & 4) Figure

andD50H47.

8.4. The breaker and operating mechanismshould be serviced as described forevery 2,000 operations and properlyadjusted before being put back intoservice. 18.

Reassemble the interrupter in the reverse order.The following items should be noted during re-assembly:REPAIR AND REPLACEMENT1 US'

l This section covers the proper method ofremoving and replacing those parts of the breakersubject to damage and wear that may require repairor replacement at the installation. IMPORTANT:UPON COMPLETION OF ANY REPAIR WORK, ALLBREAKER AND MECHANISM ADJUSTMENTS MUSTBE CHECKED.STALLATION, paying particular attention to AD-JUSTMENTS and FINAL INSPECTION.

The fins of the arc chute sides should beequally spaced and aligned before boltingtogether. The front edge (along the runner)of the two arc chute sides should be paralleland in line.

1.

2. The gap between the fins at the rear of thearc chute sides measured at least1" infromthe back end of the arc chute (See Figure21) should be 1/64" to 3/32".

3. Check to insure that electrical connectionsto the blowout coils are tight.

4. When reassembling the arc runner as-semblies, check that the spacers are cor-rectly installed.

5. Before bolting the upper supports in place,make certain that the upper arc runnerassembly is tight against the arc chuteside so that the gap between the throatinsulation (7) Figure 19, and the arcchute sides (6) is a minimum.

6. Make certain that the electrical connections(2 & 8) Figure 20 are tight.

Reassemble the arc chute on the breaker asdescribed under INTERRUPTER REMOVAL ANDREPLACEMENT, page 16.

Refer to the section on IN-

ARC CHUTE (To inspect or replace blow-out coilsand arc runners):

With the breaker open and the closing springsin the blocked position, remove the box barrier(7) Figure 8. The interrupter can now be re-moved as described under INTERRUPTER RE-MOVAL AND REPLACEMENT page 16.

To disassemble the interrupter after it has beenremoved from the breaker, proceed as follows:

NOTE: When disassembling the arc chute andits components some small washers, spacers,etc., will be found that cannot be identified inthese instructions. Care should be taken tocollect and identify these items so they can bereassembled correctly.

1. Remove the caps and assembly bolts (7,9, 11, & 13) Figure 18.

s

1

I m1S .!!i

201

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

HP""

Magne-blast Circuit Breaker GEI-88761

-910

11

12Iii ?./>m Sw MOA: Ml-W-12 ..13

& ;.'im a 13 iV §p|! '35 mk 1414 >y»“ \:: : : •?15 © HJ j ,- ' ' [16 •a® m ®ft: srr. 15

5

IFigure 19. (8039603) Interrupter Assembly

with Side RemovedFigure 18. (8039601) Interrupter Assembly

1. Assembly Bolts and Bushing2. Assembly Bolts3. Upper Pole Piece4. Assembly Bolt5. Side Brace6. Lower Pole Piece7. Assembly Bolt8. Lower Brace9. Assembly Bolt

10. Upper Interrupter Support11. Insulating Cap12. Side Shield13. Assembly Bolt14. Lower Interrupter Support15. Assembly Bolts16. Assembly Bolts

31. Upper Arc Runner Spacer2. Upper Arc Runner Assembly3. Blowout Core4. Blowout Coil5. Upper Arc Runner6. Arc Chute Side7. Throat Insulation8. Lower Shield9. Lower Arc Runner

10. Blowout Coil11. Blowout Core12. Lower Insulation13. Lower Arc Runner Assembly14. Lower Coil Connection15. Lower Arc Runner Spacers

sI

*i

*

21

- • T- - Vrv...

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

'1

GEI-88761 Magne-blast Circuit BreakerCONTACTS

Open the breaker and remove the box barrierand interrupters as previously described. Toremove the contacts, proceed as follows:

A. Stationary Arcing Contacts (10) Figure 22.1. Disconnect the contact braids (7) from

the contact fingers by removing twobolts and locking plates (8).

2. Grasp the lower end of the contactfingers with pliers and pull contactassembly downward to remove fromstud assembly.

3. To disassemble braids from stud plateremove one bolt (5).

4. To disassemble stud platefrom contactsupport, remove two bolts (6).

5. Reassemble in the reverse order, makesure locking plates are properly re-assembled with bolts (8).

B. Movable Arcing Contact (14) Figure 23.1. Remove the assembly bolts (12) making

note of quantity and location of shimsand spacers used between contacts andcontact arms.

2. Reassemble in reverse order, re-usingthe shims and spacers.

3. Close the breaker slowly to checkthat the movable arcing contact isapproximately centered on the station-ary arcing contact and that it doesnot rub on either side of the throatbarrier (9).NOTE: Whenever it is found necessaryto replace arcing contacts on any poleof a breaker it is recommended thatboth the stationary and movable con-tacts on that pole be replaced at thesame time.

WJW

h

Figure 20. (8039604) Interrupter Assembly1. Upper Mounting Support2. Connection Bolt

Insulation Plate4. Upper Arc Runner Assembly5. Side Shield6. Lower Arc Runner Assembly7. Lower Coil Connection

Connection Nut9. Lower Mounting Support

i 3.i

8.

j

C. Stationary Primary Contacts (9) Figure 24.1. Compress the contact spring (6) by

use of the spring compressor.2. Remove spring and spring guide (1).3. Raise the contact finger to clear the

primary contact stop plate (8) and liftthe finger out of contact support (7).Remove one contact finger at a time.

To replace theStationary Primary Contacts:

IS

a1. Apply a thin coating of D50H47 grease

the hinged edge of the finger (9) thenplace it on the contact support (7) so

i onFigure 21. (8G29373) Arc Chute Fin Spacing

22;

r.-.tr?I'rsvrv-?"

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

W "

Magne -blast Circuit Breaker GEI-88761

2

3

4

5-689

1011

12is

Fig. 226 (8039586) "-8" DesignFig. 22A (8025170) "-6" & "-7" DesignsFigure 22. Rear Bushing Assembly

8. Connection Bolt9. Stud for Mounting Arcing Fingers

10. Stationary Arcing Contact Assembly11. Spring Baffle12. Insulating Plate13. Throat Baffle

I 1. Rear Bushing2. Guide and Support for Interrupter3. Bolts for Contact Support4. Contact Support5. Bolt for Flexible Braid6. Mounting Bolt7. Flexible Braid

sI

!s;

I

that it is retained by stop plate (8).Open spring compressor (3) and as-semble spring guide, spring and springcompressor (Figure 24A).Turn nut (2) in clockwise direction tocompress contact spring (Figure 24B).Hold spring firmly in yoke on spring-compressor to prevent spring fromslipping out of the compressor.Place washer (not shown) on guide ontop of spring, place top of guide intohole in spring retainer (4) andround end of spring guide in cutout inprimary finger (Figure 24C).Hold spring assembly firmly in placeand remove spring compressor.

1 D. Movable Primary Contacts (10) Figure 23,To replace the movable primary con-tacts on a 1200 ampere breaker proceed as

follows:

i2.

3. 1. Disassemble nuts from assembly bolts(11) and remove the movable primarycontacts (10).Reassemble in reverse order.2.

4. To replace the movable primary con-tacts on a 2000 ampere breaker it is firstnecessary to disassemble the movable arc-ing contacts, then proceed as follows:1. Disassemble operating rod pin (4),first

noting quantity and location of washersin the assemble.

the

5.S

23

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

GEI-88761 Magne-blast Circuit BreakerE. Contact Arm Assembly (8, 10, 12, 14,

Figure 23).1. Remove connection bar (15).

; ;5i

2. Disassemble hinge pin (7), cup bearing(4 ) noting(6), and operating rod pm

quantity and location of any washersand spacers used in assemblies.The contact arm assembly including thepiston assembly (13) can now be re-moved.

3.

4. When reassembling, first insert pistontube assembly (13.) into the boostercylinder and reassemble the cup bear-ing, making sure the silvered contactwashers between the bushing and con-tact arms (both sides) are in place.

5. Reassemble operating rod pin (4) andconnection bar (15).

F. After disassembly and reassembly of anycontacts, check all contact adjustments asdescribed under ADJUSTMENTS.

Sil;!»

BUSHINGS! DO NOT REMOVE ALL SIX

The bushings have beenIMPORTANT:

BUSHINGS AT ONCE,carefully aligned with the breaker frame, duringassembly at the factory, and it is important thatthis alignment be maintained to insure interchange-ability of the breakers in the metal-clad units. Itis, therefore, recommended that the bushings beremoved and reassembled one at a time. Also,before removing any one bushing, measure the dis-tance from that particular bushing to adjacentbushings in both directions, so that it may bereinstalled in the same location.

Figure 23. (8039588) Contact Assembly1. Front Bushing2. Contact Springs3. Stationary Primary Contacts4. Operating Rod Pin5. Buffer6. Cup Bearing7. Hinge Pin8. Contact Arm9. Throat Barrier

10. Movable Primary Contacts11. Assembly Bolts12. Assembly Bolts13. Piston Assembly14. Movable Arcing Contact15. Connection Bar

1 i

S3 However, it is possible to remove and re-assemble three bushings at one time. If this ispreferred, alignment of the bushings may beaccomplished by placing the breaker in a de-energized spare metal-clad unit before tighteningthe bushing mounting bolts0 This must be donebefore the interrupters are reinstalled.To replace the bushing, proceed as follows:Rear Bushing

Isj

1

I

II

i iI

Pry contact arms (8) apart enough todisengage pivot pins of piston assembly(13) allowing piston to drop down intoits booster cylinder.Rotate the two parts of the contact armassembly away from each other so as-sembly bolts (11) are accessible andmovable primary contacts (10) can beremoved.

1. Open the breaker and remove the boxbarrier and interrupters as already de-scribed.

2.l iS i

Remove the upper and lower horizontalbarriers (18 and 20) Figure 8.Remove the four bolts at the mountingflange of the rear bushing being removedand lower the bushing assembly.NOTE: Shims may be found between thebreaker mounting plate and the bushing

2.13o

l 3.I

4. Reassemble in reverse order.

24

BSS3S358

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

Magne-blast Circuit Breaker GEI-88761

r

/:

i5|

I!;;

Figure 24A (8034466) Figure 24B (8034465)

i;

#:

ii1

Figure 24C (8034469) Figure 24D (8034468)Figure 24. Method of Installing Primary Contact

Springs Using a Spring Compressor

6. Spring7. Contact Support8. Stop Plate9. Stationary Primary

Finger

1. Spring Guide2. Compressor Nut3. Spring Compressor4. Spring Retainer5. Assembly Bolts

25

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

m ‘^=^i

GEI-88761 Magne-blast Circuit Breakermoynting flange on some, or all bolts.These shims are for squaring up the bushingand may be required when new bushings areassembled.Referring to Figure 24, disassemble theprimary contact springs (6) as previouslydescribed.Disassemble the spring retainer (4) byremoving mounting bolts (5).Referring to Figure 22, disassemble thecontact support (4) and interrupter mountingbracket (2) removing two bolts (3).Reassemble in the reverse order. Theinterrupter mounting bracket (2) is notsymmetrical and must be assembled cor-rectly to orient the interrupter properlyon the breaker. The longest projection ofthe bracket should be toward the lower endof the bushing.

MOTOR, RELAY AND LIGHT SWITCHES

Two or three switches (7) Figure 6, are mountedin tandem as required by the application.

Remove the opening spring per instructionsbelow.Remove (2) mounting bolts (4) from switchbracket (5).Remove the (2 ) mounting screws of the lowerswitch.Remove the (2) mounting screws of the centerswitch.Remove the (2) mounting screws of the upperswitch.

4. 1.2.

5.3.

6.403

7. 5.Disconnect the lead wires of switch to bereplaced.6.

7. Reassemble in the reverse order and checkswitch adjustment as explained under AD-JUSTMENTS.Front Bushing

Open the breaker and remove the boxbarrier and interrupters as already de-scribed.Remove the upper and lower horizontalbarriers (18 and 20) Figure 8.Remove the connection bar (15) Figure23, cup bearing (6) and hinge pin (7).Remove the four bolts at the mountingflange of the front bushing being removed,and lower the bushing. (See note underrear bushings concerning use of shims.)When reassembling, first mount the bushingand assemble the cup bearing(6),contact arm(8), and replace pin (7) being sure thesilvered contact washers between the bush-ing and contact arms are in place. Thecontact surfaces at the hinge point of thecontact blade and bushing should have a thincoating of D50H47 grease.Check all contact adjustments as outlinedunder ADJUSTMENTS.

1. TRIP SHAFT AND LATCH (See Figure 11)Remove spring discharge crank (5), manual

(13) and if furnished, the latch1.2. trip leverchecking switch operating arm (8) Figure12 from the trip shaft.

3.1 2. Disengage trip latch spring (4) Figure 11.

3. Remove three (3) cotter pinsfrom trip shaft.4„ Remove trip arm screw (12) and trip latch

set screw (10).5. Place a block between the trip latch (11)

and the left side of the mechanism frame.Drive the trip shaft to the left until thelatch is free of the key, then remove the key.

6. Check for and remove any burrs raisedaround the keyway on the shaft to avoiddamaging the trip shaft bearings.

7. Shaft, latch, etc., may now be removed bydriving it to the left. Note quantity andlocation of washers used as spacers in theassembly.

8. Reassemble parts in reverse order. Be suretrip latch is aligned in center of trip latchroller and that the latch spring is properlyinstalled. Check latch adjustment as de-scribed under ADJUSTMENTS.

TRIP LATCH ROLLER BEARING

4.

5.i

6.

INTERLOCK SWITCH

To remove the interlock switch (4) Figure 12,remove the two mounting screws and disconnectthe lead wires. Reassemble in the reverse orderand check the switch adjustments as explainedunder ADJUSTMENTS.LATCH CHECKING SWITCH

1. Remove (2) cotter pins at ends of trip latchroller shaft (8) Figure 13.

2. Partially remove shaft out right side offrame until latch roller (6) is free.

To remove the latch checking switch (7) Figure12, (when furnished), remove the two mountingscrews and disconnect the lead wires. Reassemblein the reverse order and check the switch adjust-ments as explained under ADJUSTMENTS.

a1 1

26

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

Magne-blast Circuit Breaker GEI-887613. Reassemble in reverse order with proper

spacing of washers. Be sure latch rollerrotates freely.CLOSING LATCH

as far as it will go. Slide the shaft to theleft until key is fully exposed. Remove keyand check shaft for burrs.

5. Remove shaft out left side of frame.1. Remove cotter pins at both ends of closing

latch shaft (9) Figure 6.Remove spring and paddle (12).Remove set screws from latch (8).Move shaft (9) to left (away from frame) bytapping lightly on the inside end of shaft.Rotate shpft and continue tapping until shaftis free. Shaft will push outside needle bear-ing from housing.Reassemble in reverse order putting bearinginto frame last. Use a small piece of tubingor pipe when inserting bearing to assureproper alignment.Check closing latch adjustments as de-scribed under ADJUSTMENTS.

6. Reassemble in reverse order using thecorrect number of washers and spacers toproperly locate the parts.

7. Rotate the mechanism through a closingoperation using the manual charging wrench.Check the location of the cam follower (6)Figure 7, on the cam (16). If necessary,move the cam to correct the alignment.Complete the closing operation and check thelocation of the prop pin (13) on the prop (14).It should be approximately centered.

2.3.4.

5. TRIP COILTo replace the potential trip coil (8) Figure 11,proceed as follows :1. With the breaker in the open position, removethe two mounting bolts (9).

Remove trip coil support (7) and spacers.

6.MOTOR SUPPORT 2.

1. To remove motor support (7) Figure 15.first remove the closing latch spring (12)Figure 6.Remove the retaining ring (4) Figure 15,and driving link (6).Remove motor leads from the terminalboard.Remove six 3/8" bolts (1) Figure 15, onbottom and one 3/8" bolt on the right side(not shown).Remove four mounting bolts from motor(not shown).Remove the retaining ring (8) from theeccentric (3).Reassemble all parts of the motor supportin the reverse order and re-align it properlyas described under DRIVING PAWL AD-JUSTMENTS.

3. Cut wires at the butt connectors and removecoil.4. When replacing the coil be sure to assemblethe correct fiber spacers at the ends beforebolting support (7).

Adjust coil location to allow approximately1/4" of armature travel before latch startsto move.Butt connect wires and check operation ofsolenoid electrically and mechanically.

SPRING RELEASE COIL

2.I

3. 5.4.

6.,

5.To remove the spring release coil (15) Figure6, proceed as follows:

Block the closing springs as described inINSTALLATION.

6.:

1.7.2. Remove the left hand closing spring asdescribed in CLOSING SPRINGS below.

CAM 3. Remove two mounting bolts (11), coil support(16), and spacers.Cut wires at the butt connectors and removecoil.Replace the coil and the correct number offiber spacers before bolting support.Butt connect wires and check that the arm-ature is not binding. Check coil forelectrical operation.

1. Remove 2 set screws from ratchet wheel(6) Fishaft

Remove 2 set screws from switch cam (5)Figure 2 and remove cam from the mainshaft.Remove prop reset spring (4) Fig. 5.Remove 2 set screws from cam (16) Figure7, and move cam to the right on the shaft

re 4 and remove wheel from main.gui(5). 4.2,

5.6.3.

4.

27

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

. _ v. •.. yerrtr. ». y.

-

Magne-blast Circuit Breaker GEI-88761RECOMMENDED RENEWAL PARTS FOR

TYPE ML-13 STORED ENERGY MECHANISMUSED FOR AM-4.16-250-6 (*), -7 (*), & -8 (*), 1200 & 2000 AMPERE

( * SUFFIX LETTERS - H, C, K, N, R )

i

Fig. Ref. No. Catalog No.DescriptionNo. No. Req'd.5 10 1 Spring Charging Motor - **

48 V-DC110 & 125 V-DC & 115 V-AC, 60 Hz220 & 250 V-DC & 230 V-AC, 60 Hz0105C9393P0010105C9393P0020105C9393P003

Relay - **,48 V-DC110 & 125 V-DC220 & 250 V-DC115 V-AC, 60 Hz230 V-AC, 60 Hz

176 1

0137A7575P0040137A7575P0010108B1978G0010137A7575P0050137A7575P002

3 Potential Trip Coil - **110 & 125 V-DC220 V-DC250 V-DC115 V-AC, 60 Hz230 V-AC, 60 Hz24 V-DC48 V-DC

15006174582G001006174582G015006174582G002006174582G013006174582G032006275070G001006275070G002

Spring Release Coil - **110 & 125 V-DC220 V-DC250 V-DC115 V-AC, 60 Hz230 V-AC, 60 Hz48 V-DC

16 15

006174582G001006174582G015006174582G002006174582G010006174582G014006275070G002

0456A0866P0050456A0866P006

Switch, Normally OpenSwitch, Normally ClosedAuxiliary SwitchClosing Latch SpringProp SpringDriving Pawl SpringLatching Pawl Spring - 9

6 7 56 7 1

ZL5 1 10161A4231P0010137A9252P0010161A4241P0010161A5909P001

6 12 14 15

4 1824 2

** Refer to breaker nameplate or summary for proper voltage rating.# Quantity Two (2 ) relays required on special control circuits. Check

breaker and connection diagram.9 Furnish 0161A4241P001 for breakers without closing spring discharge

mechanism.-9- Relays on Early "-6" design0137A7575P043 - 48V-DC0137A7575P042 - 110V-DC & 125 V-DC0137A7575P041 - 220V-DC & 250 V-DC0137A7575P045 - 230V-DC, 60 Hz.0137A7575P047 - 115V-AC, 60 Hz.

Zs Refer to breaker auxiliary switch for proper model.Type SBM - 0137A9192G003Type SB-12- 0137A9192G01129

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

GEI-88761 Magne-blast Circuit Breaker

RECOMMENDED RENEWAL PARTS FOR MAGNE-BLAST BREAKERS

TYPE AM-4.16-250-6(& ), -7(A ), and -8(* ), 1200 & 2000 AMPERES( A SUFFDC LETTERS H, C. N, K, B, & R)

i:!

i

.!1 Catalog Number for Type AM-4.16-250- No.Fig. Ref. Ampere

RatingDescriptionType Req’d.No. -6 -7 -8No.

30281B0708G002 0281B0708G0020281B0708G008

0281B0708G0020281B0708G008All ** Operating Rod

Assembly218 3All B

I 3 Flexible Connector (Right)Flexible Connector (Left )Insulating PlateThroat Barrier AssemblyArcing Contact Assembly

0236C0791G0010236C0791G0040414A0116P004

0236C0791G0010236C0791G0040236

C0791G0010236C0791G0040414A0116P004

22 7 All All 322 7 All All 322 12 All All 30195A7388G0020236C0790G00922 13 AllAll 30236C0790G00922 0236C0790G009All All10

120121A5964P001006509787P001

1200 All 242000 All1 Primary Contact Finger Spring23 2 180121A5964P0010121A 5964P001

0121A5964P0010121A5964P001All ** 24All B1

!?:0236C0791P0080236C0791P008

121200 All 242000All

All Primary Contact Finger23 3 180114C 5382P0020114C5382P002

0114C5332P0020114C5382P002**I 24All B

30137A9164P0030137A9164P0040137A9164P0030137A9164P004

1200 All 31200 All!

6All2000 623 2000 All Movable Primary Contact10 0114C5382P0040137A9164P0030137A9164P004

0114C5382P0040137A9164P0030137A9164P004

6All ** 6All B 6All B1

0802B0742G001 3All 0802B0742G001 : 0227A5306G0040802B0742G002 0227A5306G005

Movable Arcing Contact23 14 3All B

pi!

0213X0343G0430213X0343G044

0213X0343G0430213X0343G044

31200 All 0213X0343G0910213X0343G0900213X0343G091

32000 All Tube & Piston Assembly23 13 31200 **II 31200 B1 6All 0414A0117P001 Throat InsulationThroat Insulation (Right )

Throat Insulation (Left )All 0195A7377G001

0195A7377G0020108B1965G0010108B1965G002

37 All All19s 3All AllIf0383A0932P001 0161A5906P0010258C0616P006 0114C5381P0010414A0116P002 0114C5381P004000421711P001 000421711P001000407193P001 000407193P0010258C0616P009 I 0836C0197P014

0161A5906P0010114C5381P0100414A0116P002000421711P001000407193P0010836C0197P014

6 Lower Runner ShieldLower Insulation BarrierInsulating PlateInsulating CapThreaded Washer (For Insul. Cap)Upper Runner Insulation

8 All19 All12 All 619 All

1 3 320 All AllAll 618 11 All18 All All 611 6All All*

* Not Illustrated** All except Breakers with "B" in suffix.

i :t1:rS i

1:l

i .HiII!i:!!

;

30' i

www.nationalswitchgear.comCourtesy of NationalSwitchgear.com

-

Magne-blast Circuit Breaker GEI-88761

TYPICAL ELEMENTARY WIRING FOR MAGNE-BLAST BREAKERS

+OR 1IX ii il

PD.CS*r Hi AA A/N4, 52* IS4^

52IS

JCAPJ 5 2 Y SPARE CONTACTS5 2-u 5 g_„7f - SM/ LS

L 52r 5 2 Y —r— 5 2 Y AUX . SW 52SM/ LS I J U.T AUX. SW

ON AUX . SWM. 52rr CL/MSLC

ii

I

-

in

•*:-v • •;

GENERAL ELECTRIC INSTALLATION AND SERVICE ENGINEERING OFFICESFOR YOUR LASTING SATISFACTION . . . with the performance and availability of your Gen-eral Electric equipment, GE provides this nationwide network of field service offices, servingutility, industrial, transportation and marine users. Qualified field engineers provide instal-lation, start-up, employee training, engineering maintenance and other services, throughoutthe productive life of the equipment. For full information, call your nearest Installation A Ser-vice Engineering office.

FIELD SERVICE OFFICE CODE KEY* Mechanical & Nuclear Servicet Electrical & Electronic Servicet Marine ServiceX Transportation;

ALABAMA LOUISIANA OKLAHOMAt Birmingham 35205 . . . . 2151 Highland Ave.

Mobile 36609Baton Rouge 7080SNew Orleans 70125 . . . . 4747 Earhart Blvd.Shreveport 71104 . . . 2620 Centenary Blvd.Monroe 71201

8312 Florida Blvd.t • t 2000 Classen Blvd.Oklahoma City 73106.Tulsa 74105 . . P. O. Box 7646, Southside Sta.* t t 1111 S. Beltline Highway * t 1 f

• t1 ALASKA t 1028 North 6th St. OREGONt Eugene 97401.

• T t Portland 97210t Anchorage 99501 115 Whitney Rd. . . . 1170 Pearl St.

2929 NW 29th Ave.MARYLAND* t t Baltimore 21201ARIZONA 1 N. Charles St.&* t Phoenix 85012

Tucson 85716 .3550 N.Central Ave.. 151 S. Tucson Blvd. PENNSYLVANIAt MASSACHUSETTS

* t t Wellesley 02181 Allentown 18102Philadelphia 19102 . . . 3 Penn Center PlazaPittsburgh 15222 . . . . 300 6th Avenue Bldg.

1444 Hamilton St.I Washington St. • + IARKANSASI • tt North Little Rock 72119 120 Main St. MICHIGAN* + J Detroit 48202

T Jackson 49201t Saginaw 48607

. 700 Antoinette St.210 W. Franklin St.CALIFORNIA