MACHINING UNIT HEAD...CA-16 Slide CAN-16 Slide SB Column VH Multispindle head Tool holder Machining...

Transcript of MACHINING UNIT HEAD...CA-16 Slide CAN-16 Slide SB Column VH Multispindle head Tool holder Machining...

MACHINING UNIT HEAD

FEEDING SLIDES

CUSTOMIZED ASSEMBLIES

designed byERLO Group

www.erlogroup.es

Txerloie auzoa nº3

20720 AZKOITIA (SPAIN)

T: +34 943 851 858

Email : [email protected]

2

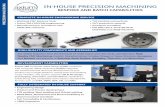

Since its establishment in 1962, ERLO has distinguished in manufacturing high quality machinery and demonstrated reliability, as proved by the thousands of drilling and tapping machines sold since then, being the users our best sellers.

In 2003 ERLO manufactured its first machining unit for the construction of an automatic machine and since then, it has been designing and manufacturing different models, always according to the customer’s needs.

The year 2012 ERLO decided to make available this range of machining units, together with the feeding slides, multispindle heads and all necessary equipment, for its customer’s installations.

This new catalogue that you are holding, aims to expand this offer and make available all the necessary elements to allow you to easily integrate our heads in the solution you have devised. We are at your disposal to design and make any adjustments you would need, please consult.

CR. 14

3

CA-16 Slide CAN-16 Slide SB Column VH Multispindle head Tool holder

CGCM.30

CG.30

CG.40

CG.50

CA-30 Slide SB Column VH Multispindle head Tool holder

CA-30 Slide SB Column Tool holder

CA-40 Slide VH Multispindle head Angular headstock*request for models

Customized desing under request

Tool holder

VH Multispindle head Angular headstock*request for models

Customized desing under request

Tool holder

CAN-30 Slide

CAN-30 Slide

Page 6

Page 8

Page 12

Page 10

Page 14

CS. 14

Page 4

Cabezal revolver

Angular headstock*request for models

Customized desing under request

Tool holderPage 16

CG.16

INDEX

M:\

Oficin

a_

Tecnic

a\E

RLO

\CA

D\c

ata

logo\U

NID

AD

ES

_C

G\0

7-2

018\C

S-1

4\C

S-1

4-G

enera

l.dft

O55

O85

20 110

150 580 69

138

160

M12

25

36

0

37

8

165

213

EJE B-16

3531

80

EJE ER-20

EJE TR-16

3575

80

1633542

Carr

era

(mm

)

Stro

ke (m

m)

Fuer

za d

e av

ance

(kN

)

Max

. Thr

ust (

kN)

Peso

(Kg

)

Wei

ght

(Kg)

Capa

cidad

tala

drad

o m

ax.

Pres

ion

min

ima

requ

erid

a (B

ar)

Requ

ired

min

imum

pre

ssur

e (B

ar)

CS-14

80 3 55 Ø14 5

COMBINABLE ELEMENTS

VH Multispindle head Tool holder4

CS

14

ø 14 mm N/A N/A

Maximum drilling capacity in steel (700 N/mm2) Ø 14 mmRevolutions range (50 Hz) 304-7250 r.p.m.Maximum turning torque 35 Nm.Spindle Cone B-16, TR16, ER-20Weight (without motor) ~55 Kg.

Available motors (50 Hz)1.000 r.p.m. /1.1 Kw.1.500 r.p.m. / 1.5 Kw3.000 r.p.m. / 2.2 Kw.

CS 14

[ THERE ARE OTHER POSSIBLE COMBINATIONS, PLEASE CONSULT ]

DIMENSIONS

Drilling unitwith pneumatic feed quill

M:\

Oficin

a_

Tecnic

a\E

RLO

\CA

D\c

ata

logo\U

NID

AD

ES

_C

G\0

7-2

018\C

S-1

4\C

R-1

4-G

en

era

l.dft

EJE ER-20

EJE TR-16

3575

80

20 110

150163

O55

O85

274

M12

160

69

138

25

36

0

37

8

165

210

238

3542

Carr

era

(mm

)

Stro

ke (m

m)

Peso

(Kg

)

Wei

ght

(Kg)

Capa

cidad

rosc

ado

max

.

CR-14

80 55 M12

EJE B-16

3531

80

COMBINABLE ELEMENTS

VH Multispindle head Tool holder 5

DIMENSIONS

* Measures can vary without previous notice. Ask for the updated drawing in every case.

CR

14

N/A M 12 N/A

Maximum drilling capacity in steel (700 N/mm2) M12Revolutions range (50 Hz) 304-7250 r.p.m.Maximum turning torque 35 Nm.Spindle Cone B-16, TR16, ER-20Weight (without motor) ~55 Kg.

Available motors (50 Hz)1.000 r.p.m. /1.1 Kw.1.500 r.p.m. / 1.5 Kw3.000 r.p.m. / 2.2 Kw.

CR 14

[ THERE ARE OTHER POSSIBLE COMBINATIONS, PLEASE CONSULT ]

Tapping unitwith pneumatic feed quill

6

CG

16

Maximum drilling capacity in steel (700 N/mm2) Ø 16 mmMaximum tapping capacity in steel (700 N/mm2) M12Revolutions range (50 Hz) 210—9000 r.p.m.Maximum turning torque 31 Nm.Spindle Cone ISO 30 DIN 2080Weight (without motor) ~40 Kg.

Available motors (50 Hz)750 r.p.m. / 0,55 Kw.1500 r.p.m. / 1,5 Kw3000 r.p.m. / 2,2 Kw.

CG.16

OPTIONAL EQUIPMENT

RG: Encoder for rigid tapping and tool positioning.

RU: Rotary joint for tool internal cooling.

RGU: Rotary joint + encoder. Protection bellows for slides guides.

** Pneumatic clamping (AN) and hydraulic clamping (AH), NOT AVAILABLE.

ø 16 mm M 12 N/A

COMBINABLE ELEMENTS

CA-16 Slide CAN-16 Slide SB Column VH Multispindle head Tool holder

Machining unit for modular assembly

[ THERE ARE OTHER POSSIBLE COMBINATIONS, PLEASE CONSULT ]

7

DIMENSIONS

RECOMMENDED ACCESSORY

The pulley box as well as the connectors box of the motor can be assembled in any of these positions.

* Measures can vary without previous notice. Ask for the updated drawing in every case.

Z:\O

ficin

a_Te

cnic

a\ER

LO\C

AD\c

atal

ogo\

UNID

ADES

_CG

\201

5_05

\CA-

16.d

ft

603190

793

200230173

98

3,7

7510H7

16,519019019016,5

75 170

2575130M10

1110

514

130

10,5

10H7

3,7

145x230

1315

Carr

era

(mm

)

Stro

ke (m

m)

Husil

lo a

bol

as (m

m)

Ball s

crew

(mm

)

Fuer

za d

e av

ance

máx

ima

(kN

)

Max

. Thr

ust (

kN)

Par m

áxim

o en

el h

usillo

(Nm

)

Ball s

crew

max

. tor

que

(Nm

)

Serv

omot

or

Velo

cidad

de

avan

ce m

áxim

a (m

/min

)

Max

. Fee

d ra

te (m

/min

)

Peso

con

mot

or (K

g)

Wei

ght w

ith m

otor

(Kg)

Peso

sin

mot

or (K

g)

Wei

ght w

ithou

t mot

or (K

g)

HG-SR1024B

CA-16

38200 Ø25x5 9 8 15 50

2525

195

Z:\O

ficin

a_Te

cnic

a\ER

LO\C

AD\c

atal

ogo\

UNI

DAD

ES_C

G\2

015_

05\C

AN-1

6.df

t

155230

60335010H7

21,5

253

105

126,

5

25145x23025

10,51315 7510H7

3,7

195

M10 75

75 170

16,519019019016,5

21,5

9813

3,5

253

25

3,7

Carr

era

(mm

)

Stro

ke (m

m)

Fuer

za d

e av

ance

máx

ima

a 6

bar (

kN)

Max

. Thr

ust t

o 6

bar (

kN)

Peso

(Kg)

Wei

ght (

Kg)CAN-16

150 6 70

953

Stroke 200 mmBall spindle Ø25x5Thrust force (kN) 5,4Weight with motor 40 Kg.Weight without servomotor 50 Kg.

CA.16

Stroke 100 mmMax. Thrust to 6 bar (kN) 4,4Weight 65 Kg.

CAN.16

\\S

rv1\d

ato

s\O

ficin

a_

Tecnic

a\E

RLO

\CA

D\c

ata

logo\U

NID

AD

ES

_C

G\0

7-2

018\C

G-1

6\C

G-1

6.d

ft

3,5 9

6 12

0

75

33

7

559055

200

ISO 30

13580280 - 320 47

542 - 582

41

2

140

12

61

03

-

RG

757,5 3075O10,5

47

3075

1358058,5

8

CG

CM

. 30

Maximum drilling capacity in steel (700 N/mm2) Ø 30 mmMaximum tapping capacity in steel (700 N/mm2) M18Revolutions range (50 Hz) 308—8961 r.p.m.Maximum turning torque 59 Nm.Spindle Cone ISO40 DIN 2080Weight (without motor) ~75 Kg.

Available motors (50 Hz)

750 r.p.m. / 1,5 Kw.1000 r.p.m. / 2,2 Kw.1500 r.p.m. / 4 Kw.3000 r.p.m. / 4 Kw.

CGCM.30

OPTIONAL EQUIPMENT

RG: Encoder for rigid tapping and tool positioning.

RU: Rotary joint for tool internal cooling.

RGU: Rotary joint + encoder. Protection bellows for slides guides.

ø 30 mm M 18 NO

COMBINABLE ELEMENTS

CA.30: Feed slide with or without servo coupling joint.

SB Column VH Multispindle head Tool holderCAN.30: Oleopneumatic feed slide.

Machining unit for modular assembly. Special design for Multispindle head.

** Pneumatic clamping (AN) and hydraulic clamping (AH), NOT AVAILABLE.

[ THERE ARE OTHER POSSIBLE COMBINATIONS, PLEASE CONSULT ]

9Z:\O

ficin

a_Te

cnic

a\ER

LO\C

AD\s

ubco

njun

tos\

Uni

dade

s\C

arro

s\C

AN-3

0\C

AN-3

0_C

arre

ra_1

50_Ø

125.

dft

125

17,514014014014014017,5735385

1120

130

130 25320

M10

136

Gas 1/2"Gas 1/2"

118

209

Carr

era

(mm

)

Stro

ke (m

m)

Fuer

za d

e av

ance

máx

ima

a 6

bar (

kN)

Max

. Thr

ust t

o 6

bar (

kN)

Peso

(Kg)

Wei

ght (

Kg)CAN-30

200 6 100

320 205

180x320 2525230

14H7

4,5

2325

125

130,

525

5,5

DIMENSIONS

RECOMMENDED ACCESSORYThe pulley box as well as the connectors box of the motor can be assembled in any of these positions.

* Measures can vary without previous notice. Ask for the updated drawing in every case.

Z:\O

ficin

a_Te

cnic

a\ER

LO\C

AD\c

atal

ogo\

UNI

DAD

ES_C

G\2

015_

05\C

A-30

.dft

253320162

14H7

4,5

10

25130

130

209

17,514014014014014017,5

68735204

939

125

10,5 23 25

130

13

143

230

253

180x320

Carr

era

(mm

)

Stro

ke (m

m)

Husil

lo a

bol

as (m

m)

Ball s

crew

(mm

)

Fuer

za d

e av

ance

máx

ima

(kN

)

Max

. Thr

ust (

kN)

Par m

áxim

o en

el h

usillo

(Nm

)

Ball s

crew

max

. tor

que

(Nm

)

Serv

omot

or

Velo

cidad

de

avan

ce m

áxim

a (m

/min

)

Max

. Fee

d ra

te (m

/min

)

Peso

con

mot

or (K

g)

Wei

ght w

ith m

otor

(Kg)

Peso

sin

mot

or (K

g)

Wei

ght w

ithou

t mot

or (K

g)

HG-SR1524B

CA-30

65250 Ø25x5 27 28 15 77

Stroke 250 mmThrust force (kN) Up to 8Ball spindle (mm) Ø25x5Weight without motor 68 Kg.Weight with motor 78 Kg.

CA.30/250

Stroke 150 mmThrust force to 6 bar (kN) 7Weight 65 Kg.

CAN.30

Stroke 350 mmThrust force (kN) Up to 8Ball spindle(mm) Ø25x5Weight without motor 80 Kg.Weight with motor 90 Kg.

CA.30/350

2020

\\S

rv1\d

ato

s\O

ficin

a_

Tecnic

a\E

RLO

\CA

D\c

ata

logo\U

NID

AD

ES

_C

G\0

7-2

018\C

GC

M-3

0\C

GC

M-3

0.d

ft

ISO 40

3

O10,5

15 130 15

160

3,5

11

03

62

47

2

30 130

35,5190100 8

459

30 130

35,5190100 8

459

RG

30

11

0

30

325-470

Ø1

77

-Ø2

61

O250

165

18

9-2

08

15

4-1

73

O8

8,8

82

10

CG

. 30

Maximum drilling capacity in steel (700 N/mm2) Ø 30 mmMaximum tapping capacity in steel (700 N/mm2) M18Revolutions range (50 Hz) 328—3834 r.p.m.Maximum turning torque 56 Nm.Spindle Cone ISO 40Weight (without motor) ~65 Kg.

Available motors (50 Hz)

750 r.p.m. / 1,5 Kw.1000 r.p.m. / 2,2 Kw.1500 r.p.m. / 4 Kw.3000 r.p.m. / 4 Kw.

CG.30

OPTIONAL EQUIPMENT

RG: Encoder for rigid tapping and tool positioning.

RU: Rotary joint for tool internal cooling.

RGU: Rotary joint + encoder. AN: Pneumatic clamping (5,5 bar.)

AH: Hydraulic clamping (20 bar.) Protection bellows for slides guides.

ø 30 mm M 18 YES

COMBINABLE ELEMENTS

SB Column Tool holder

Machining unit for modular assembly

Available in NORMS DIN 2080 / DIN 69871 / MAS 403-BT

CA.30: Feed slide with or without servo coupling joint.

CAN.30: Oleopneumatic feed slide.

[ THERE ARE OTHER POSSIBLE COMBINATIONS, PLEASE CONSULT ]

11

165

2020

\\S

rv1\d

ato

s\O

ficin

a_

Tecnic

a\E

RLO

\CA

D\c

ata

logo\U

NID

AD

ES

_C

G\0

7-2

018\C

G-3

0\C

G-3

0_M

ecanic

o\C

G-3

0.d

ft

160

11

03

62

47

2

105,519010039 8

442,5

105,5190100 8

ISO 40

105,5190100 8

RGU/AN 828

RGU/AH 779

ISO 40

RGUAN/AH

O250Max.

15130

O10,5

ISO 40

3013030

Ø1

77

-Ø2

61

325-470

11

01

89

-20

81

54

-17

3

O8

8,8

82

3013030

11

0

RU=555RG=472

3013030

11

0

RU/RG

Z:\O

ficin

a_Te

cnic

a\ER

LO\C

AD\s

ubco

njun

tos\

Uni

dade

s\C

arro

s\C

AN-3

0\C

AN-3

0_C

arre

ra_1

50_Ø

125.

dft

125

17,514014014014014017,5735385

1120

130

130 25320

M10

136

Gas 1/2"Gas 1/2"

118

209

Carr

era

(mm

)

Stro

ke (m

m)

Fuer

za d

e av

ance

máx

ima

a 6

bar (

kN)

Max

. Thr

ust t

o 6

bar (

kN)

Peso

(Kg)

Wei

ght (

Kg)CAN-30

200 6 100

320 205

180x320 2525230

14H7

4,5

2325

125

130,

525

5,5

The pulley box as well as the connectors box of the motor can be assembled in any of these positions.

Z:\O

ficin

a_Te

cnic

a\ER

LO\C

AD\c

atal

ogo\

UNI

DAD

ES_C

G\2

015_

05\C

A-30

.dft

253320162

14H7

4,5

10

25130

130

209

17,514014014014014017,5

68735204

939

125

10,5 23 25

130

13

143

230

253

180x320

Carr

era

(mm

)

Stro

ke (m

m)

Husil

lo a

bol

as (m

m)

Ball s

crew

(mm

)

Fuer

za d

e av

ance

máx

ima

(kN

)

Max

. Thr

ust (

kN)

Par m

áxim

o en

el h

usillo

(Nm

)

Ball s

crew

max

. tor

que

(Nm

)

Serv

omot

or

Velo

cidad

de

avan

ce m

áxim

a (m

/min

)

Max

. Fee

d ra

te (m

/min

)

Peso

con

mot

or (K

g)

Wei

ght w

ith m

otor

(Kg)

Peso

sin

mot

or (K

g)

Wei

ght w

ithou

t mot

or (K

g)

HG-SR1524B

CA-30

65250 Ø25x5 27 28 15 77

DIMENSIONS

RECOMMENDED ACCESSORY

* Measures can vary without previous notice. Ask for the updated drawing in every case.

Stroke 250 mmThrust force (kN) Up to 8Ball spindle (mm) Ø25x5Weight without motor 68 Kg.Weight with motor 78 Kg.

CA.30/250

Stroke 150 mmThrust force to 6 bar (kN) 7Weight 100 Kg.

CAN.30

Stroke 350 mmThrust force (kN) Up to 8Ball spindle(mm) Ø25x5Weight without motor 80 Kg.Weight with motor 90 Kg.

CA.30/350

12

CG

. 40

Maximum drilling capacity in steel (700 N/mm2) Ø 40 mmMaximum tapping capacity in steel (700 N/mm2) M24Revolutions range (50 Hz) 322—2175 r.p.m.Maximum turning torque 228 Nm.Spindle Cone ISO 40Weight (without motor) ~100 Kg.

Available motors (50 Hz) 1000 r.p.m. / 5,5 Kw.1500 r.p.m. / 7,5-11 Kw.

CG.40

OPTIONAL EQUIPMENT

RG: Encoder for rigid tapping and tool positioning.

RU: Rotary joint for tool internal cooling.

RGU: Rotary joint + encoder. AN: Pneumatic clamping (5,5 bar.)

AH: Hydraulic clamping (20 bar.)

ø 40 mm M 24 YES

COMBINABLE ELEMENTS

Machining unit for modular assembly

Available in NORMS DIN 2080 / DIN 69871 / MAS 403-BT

[ THERE ARE OTHER POSSIBLE COMBINATIONS, PLEASE CONSULT ]

CA-40 Slide Customized desing under request

VH Multispindle head Angular headstock*request for models

Tool holder

Protection bellows for slides guides.

13

DIMENSIONS

The pulley box as well as the connectors box of the motor can be assembled in any of these positions.

* Measures can vary without previous notice. Ask for the updated drawing in every case.

CG.40 with multispindle head

250

\\S

rv1\d

ato

s\O

ficin

a_

Tecnic

a\E

RLO

\CA

D\c

ata

logo\U

NID

AD

ES

_C

G\0

7-2

018\C

G-4

0\C

G-4

0.d

ft

57

0

11036

ISO 40

15

11

0

120

14552,5 52,5

24

5-2

50

19

5-2

00

O2

60

4510510545

114300

434 8

552

1023

471

O300

O8

8,8

82

M1

6

4510510545

114300

434110 16,5405

RGU/AN=1030RGU/AH=929

O11,5 4510510545

114300

8434110

RU=698RG=621

RU/RG

ISO 40ISO 40

RGUAN/AH

RG

RU

RGU/AN

RGU

\\S

rv1\d

ato

s\O

ficin

a_

Tecnic

a\E

RLO

\CA

D\c

ata

logo\U

NID

AD

ES

_C

G\0

7-2

018\C

A-4

0\C

A-4

0.d

ft

955

473295187336

305

331

Carr

era

(mm

)

Stro

ke (m

m)

Husil

lo a

bol

as (m

m)

Ball s

crew

(mm

)

Fuer

za d

e av

ance

máx

ima

(kN

)

Max

. Thr

ust (

kN)

Par m

áxim

o en

el h

usillo

(Nm

)

Ball s

crew

max

. tor

que

(Nm

)

Velo

cidad

de

avan

ce m

áxim

a (m

/min

)

Max

. Fee

d ra

te (m

/min

)

Peso

con

mot

or (K

g)

Wei

ght w

ith m

otor

(Kg)

Peso

sin

mot

or (K

g)

Wei

ght w

ithou

t mot

or (K

g)

CA-40

238350/400 Ø32x5 24 21 15 250

O11

377

39 50

13,5 116 116 116 116 116 116 116 116 13,5

18

5,5

30

45105105

12

0

M10

30

6

RECOMMENDED ACCESSORY

Stroke 350/400mmThrust force (kN) Up to 24Ball spindle(mm) Ø32x5Weight without motor 238 Kg.Weight with motor 250 Kg.

CA.40

14

CG

. 50

Maximum drilling capacity in steel (700 N/mm2) Ø 80 mmMaximum tapping capacity in steel (700 N/mm2) M42Revolutions range (50 Hz) 380—1475 r.p.m.Maximum turning torque 540 Nm.Spindle Cone ISO 50Weight (without motor) ~300 Kg.

Available motors (50 Hz) 990 r.p.m. / 22 Kw.1475 r.p.m. / 22 Kw.

CG.50

OPTIONAL EQUIPMENT

RG: Encoder for rigid tapping and tool positioning.

RU: Rotary joint for tool internal cooling.

RGU: Rotary joint + encoder. AH: Hydraulic clamping (80 bar.)

** Feed slide with or without servo coupling. CUSTOMIZED DESIGN UNDER REQUEST.

** Protection bellows for slides guides. CUSTOMIZED DESIGN UNDER REQUEST.

** Pneumatic clamping (AN), NOT AVAILABLE.

ø 80 mm M 42 YES

COMBINABLE ELEMENTS

VH Multispindle head Angular headstock*request for models

Customized column design under request

Tool holder

Machining unit for modular assembly

[ THERE ARE OTHER POSSIBLE COMBINATIONS, PLEASE CONSULT ]

Available in NORMS DIN 2080 / DIN 69871 / MAS 403-BT

15

DIMENSIONS

The pulley box as well as the connectors box of the motor can be assembled in any of these positions.

* Measures can vary without previous notice. Ask for the updated drawing in every case.

STANDARD=613 RU=722 RG=641

\\S

rv1\d

ato

s\O

ficin

a_

Tecnic

a\E

RLO

\CA

D\c

ata

logo\U

NID

AD

ES

_C

G\0

7-2

018\C

G-5

0\C

G-5

0.d

ft

265

31045 45

400

5

18

55

20

Ma

x.

82

0

30

42

95

-2

80

-33

0

Ø3

80

-Ø4

20

25125125

300 94 21150

565 12,5688615-

ISO 50

RGU/AHAH

O1

28

,57

M2

4

O1

85

25125125

300150 94

16,5565

AH=758 RGU/AH=906

21

O18

22,5

STANDARD/RU/RG

16

Rev

olve

r H

eads

Revolver heads to integrate in machining units.

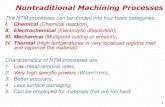

Maximum positions number 6 6 6/8 6/8/12Torque transmissible to spindle (Nm) 80 200 300 800Rpm. max. spindle 12.000 10.000 10.000 8.000Spindle positioning accuracy +/-3” +/-3” +/-3” +/-3”Motor power (Kw) 4 5 6,5 16Turning time one position (sec.) 0,9 1,0 1,1 1,5Crown diam. Hirth 160 200 250 350A 160 200 250 360B (depends on the spindle type) 70/80 100/150 100/150 120/170C 160 200 250 350D 180 230 290 400Available spindle typeWeight (kg) (*only revolver head) 35 60 140 300

ABS, HSK , ER, DIN 55058

UR160 UR200 UR250 UR360

F1: Oil circuit for locking and unlocking of the revolver headstock.F2: Cooling entry for tools.F3: Fixation holes of the revolver headstock.F4: Oil-air entry.F5: Electric connector.

UR160 UR200/6 UR250/6 UR360/6

17

DIMENSIONS AND DISPOSITIONS

SAMPLES OF DIFFERENT SPECIAL APPLICATIONS

* Measures can vary without previous notice. Ask for the updated drawing in every case.

5-3

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

applicazioni - applications

5-3

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

applicazioni - applications

18

SB C

olum

n

Z:\O

ficin

a_Te

cnic

a\ER

LO\C

AD\c

atal

ogo\

UNID

ADES

_CG

\201

5_05

\SB_

CG

-30.

dft

1516516515

360305

665

265

735

1000

14

12,5 335 12,5

360

209 45,545,5

30028

514

014

014

014

014

0

M10

Z:\O

ficin

a_Te

cnic

a\ER

LO\C

AD\c

atal

ogo\

UNID

ADES

_CG

\201

5_05

\SB_

CG

-30.

dft

1516516515

360305

665

265

735

1000

14

12,5 335 12,5

360

209 45,545,5

300

285

140

140

140

140

140

M10

DIMENSIONS

COMBINABLE ELEMENTS

Translation slide in Y axisFeed slide in Z axisMachining unit

Standard SB Column for CG.16, CG.30 and CGCH.30 models.

*The columns and supports for CG.40 and CG.50 models, designed under request.

Z:\O

ficin

a_Te

cnic

a\ER

LO\C

AD\c

atal

ogo\

UNI

DAD

ES_C

G\2

015_

05\S

B_C

G-3

0_C

arro

_Y.d

ft

(CG-16) 500(CG-30) 540

(CG-16) 445-95(CG-30) 485-135

15

20 155 155 155 155 155 20

815 322

1137

175175

168,

5(C

G-1

6) M

ax.8

50(C

G-3

0) M

ax.6

35

1375

285365

650 1515

680

(CG

-16)

Max

.200

(CG

-30)

Max

. 250

SB Column manual centering guides

Column for vertical modular assembly of the machining units.

Special slides for units assembly in Gantry type bridge structures.

Slid

esG

antr

y

Gantry slide Horizontal left CP.HI

Gantry slide Horizontal right CP.HD

Gantry slide vertical CP.V

* Measures can vary without previous notice. Ask for the updated drawing in every case. 19

20

Mul

tispi

ndle

he

adst

ocks Multispindle

headstocks to integrate in machining units.

Tapping capacity 2 x M3 3 x M3 4 x M3 2 x M5 3 x M5 4 x M5 2 x M6 3 x M6 4 x M6 Erlo units with which they combineCG.16 YES YES YES YES YES YES YES YES -CGCM.30 - - - - - - - - YESCG.40 - - - - - - - - -CG.50 - - - - - - - - -

42 43 44 62Multispindle headstock typeVH Model 63 64 82 83 84

Tapping capacity 2 x M8 3 x M8 4 x M8 2 x M12 3 x M12 4 x M12 2 x M14 3 x M14 4 x M14 2 x M20 3 x M20 4 x M20 Erlo units with which they combineCG.16 YES - - - - - - - - - - -CGCM.30 YES YES YES YES YES - - - - - - -CG.40 - - - - - YES YES YES YES YES - -CG.50 - - - - - - - - - - YES YES

102 103 104 132Multispindle headstock type VH Model 133 134 182 183 184 252 253 254

21

Multispindle headstocks to integrate in machining units.

DIMENSIONS

VH04

Article VH 042 PH VH 043 LP VH 043 P VH 044 PSpindle typeSpindle number 2 3 3 4Min. working area 12 mm 12+12 Ø18,5 Ø29,5Max. Distance between centers 72 42+42 Ø78,5 Ø89,5Drilling capacity SteelDrilling capacity FoundryTapping capacityDrive relationAllowed maximum revolutionsWeight (Kg) 0,95 1,05 1,4 1,9

ER8 máx. Ø5

VH042 VH043L VH043 VH044Multispindle headstock model

Ø4Ø5M31:1

4.000

* Measures can vary without previous notice. Ask for the updated drawing in every case.

VHM6x10

(VH043 n°3 a 120°)

85

60

97

ø 588

ø 40 g6

ø 12

VH 042

VH 043 L

VH 043

VH 044

VH 042

VH 043 L

VH 043

VH 044

VH 042 PV

2

0,95

12

72

3

1,05

12 + 12

42 + 42

3

1,4

ø 18,5

ø 78,5

4

1,9

ø 29,5

ø 89,5

VH 043 LP

ER 8 - max ø 5

M 3

1 - 1

4.000

VH 043 P VH 044 P

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

CAPACITA’ FORATURA DRILLING CAPACITY ø 5

Testa modelloHead type

ArticoloItemAttacco utensileSpindle typeArticoloItemAttacco utensileSpindle typeN. mandriniSpindles nr.Campodi lavoro min.Centredistances max.Capacità foraturaDrillingcapacityMaschiaturaTappingRapportoRatioVelocitàRPMPesoWeight Kg.

Acciaio Rm 500 N/mm2 - ø 4

Ghisa GG25 - ø 5

modello 04

6-2

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

VH042

VH043L

VH043

VH044

VHM6x10

(VH043 n°3 a 120°)

85

60

97

ø 588

ø 40 g6

ø 12

VH 042

VH 043 L

VH 043

VH 044

VH 042

VH 043 L

VH 043

VH 044

VH 042 PV

2

0,95

12

72

3

1,05

12 + 12

42 + 42

3

1,4

ø 18,5

ø 78,5

4

1,9

ø 29,5

ø 89,5

VH 043 LP

ER 8 - max ø 5

M 3

1 - 1

4.000

VH 043 P VH 044 P

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

CAPACITA’ FORATURA DRILLING CAPACITY ø 5

Testa modelloHead type

ArticoloItemAttacco utensileSpindle typeArticoloItemAttacco utensileSpindle typeN. mandriniSpindles nr.Campodi lavoro min.Centredistances max.Capacità foraturaDrillingcapacityMaschiaturaTappingRapportoRatioVelocitàRPMPesoWeight Kg.

Acciaio Rm 500 N/mm2 - ø 4

Ghisa GG25 - ø 5

modello 04

6-2

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

DIMENSIONS

22

VH 0

6

Article VH 062 P VH 063 LP VH 063 P VH 064 PSpindle typeArticle VH 062 D VH 063 LD VH 063 D VH 064 DSpindle typeSpindle number 2 3 3 4Min. working area 17 mm 17,5+17,5 Ø27 Ø41Max. Distance between centers 93 55,+55,5 Ø103 Ø117Drilling capacity SteelDrilling capacity FoundryTapping capacityDrive relationAllowed maximum revolutionsWeight (Kg) 1,65 1,95 2,3 3,1

ER11 máx. Ø7

VH062 VH063L VH063 VH064Multispindle headstock model

DIN 55058 máx. Ø8

Ø6Ø7M51:1

4.000

VH

M6x10

(VH063 n°3 a 120°)

85

71

148

ø 70

8ø 55 g6

ø 20

(ø 08 DIN 55058)

ø 15

136

VH 062

VH 063 L

VH 063

VH 064

VH 062

VH 063 L

VH 063

VH 064

VH 062 P

VH 062 D

2

1,65

17

93

3

1,95

17,5 + 17,5

55,5 + 55,5

3

2,3

ø 27

ø 103

4

3,1

ø 41

ø 117

VH 063 LP

VH 063 LD

ER 11 - max ø 7

DIN 55058 - ø 8

M 5

1 - 1

4.000

VH 063 P

VH 063 D

VH 064 P

VH 064 D

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

CAPACITA’ FORATURA DRILLING CAPACITY ø 7

Testa modelloHead type

ArticoloItemAttacco utensileSpindle typeArticoloItemAttacco utensileSpindle typeN. mandriniSpindles nr.Campodi lavoro min.Centredistances max.Capacità foraturaDrillingcapacityMaschiaturaTappingRapportoRatioVelocitàRPMPesoWeight Kg.

Acciaio Rm 500 N/mm2 - ø 6

Ghisa GG25 - ø 7

modello 06

6-4

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

VH062

VH063L

VH063

VH064

VH

M6x10

(VH063 n°3 a 120°)

85

71

148

ø 70

8ø 55 g6

ø 20

(ø 08 DIN 55058)

ø 15

136

VH 062

VH 063 L

VH 063

VH 064

VH 062

VH 063 L

VH 063

VH 064

VH 062 P

VH 062 D

2

1,65

17

93

3

1,95

17,5 + 17,5

55,5 + 55,5

3

2,3

ø 27

ø 103

4

3,1

ø 41

ø 117

VH 063 LP

VH 063 LD

ER 11 - max ø 7

DIN 55058 - ø 8

M 5

1 - 1

4.000

VH 063 P

VH 063 D

VH 064 P

VH 064 D

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

CAPACITA’ FORATURA DRILLING CAPACITY ø 7

Testa modelloHead type

ArticoloItemAttacco utensileSpindle typeArticoloItemAttacco utensileSpindle typeN. mandriniSpindles nr.Campodi lavoro min.Centredistances max.Capacità foraturaDrillingcapacityMaschiaturaTappingRapportoRatioVelocitàRPMPesoWeight Kg.

Acciaio Rm 500 N/mm2 - ø 6

Ghisa GG25 - ø 7

modello 06

6-4

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

DIN 238 CODICE

DIN 55058 CODICE

DIN 228 CODICE

B 10 B 12 B 16 B 18 B 22 B 24

16 20 28 36

CM 1 CM 2 CM 3 CM 4 CM 5

011277 011278 011279 011280 011281 011282

525405 525406 525407 525408

011115 011120 011125 011130 011135

CONO ISO CODICE

30 - 40 500202

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

MANICOTTO DI COLLEGAMENTO - CONNECTION COLLAR

Vista da AView from A

NOTA: A.B.C.D. dati macchinaNOTE: A.B.C.D. machine features

FLANGIA DI POSIZIONEPOSITIONING PLATE

ACCESSORI PERTESTE MULTIPLE

MULTISPINDLEHEADS ACCESSORIES

6-5

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

23

DIMENSIONS

VH08

Article VH 082 P VH 083 LP VH 083 P VH 084 PSpindle typeArticle VH 082 D VH 083 LD VH 083 D VH 084 DSpindle typeSpindle number 2 3 3 4Min. working area 24 24+24 Ø36 Ø53,5Max. Distance between centers 108 66+66 Ø120 Ø137,5Drilling capacity SteelDrilling capacity FoundryTapping capacityDrive relationAllowed maximum revolutionsWeight (Kg) 2,2 2,9 3,4 4,6

ER16 máx. Ø10

VH082 VH083L VH083 VH084Multispindle headstock model

DIN 55058 máx. Ø8

Ø8Ø10M61:1

4.000

* Measures can vary without previous notice. Ask for the updated drawing in every case.

VH

M6x10

(VH083 n°3 a 120°)

8ø 70

85

74

134

148

ø 10 DIN 55058

ø 20

ø 55 g6

ø 23

VH 082

VH 083 L

VH 083

VH 084

VH 082

VH 083 L

VH 083

VH 084

VH 082 P

VH 082 D

2

2,2

24

108

3

2,9

24 + 24

66 + 66

3

3,4

ø 36

ø 120

4

4,6

ø 53,5

ø 137,5

VH 083 LP

VH 083 LD

ER 16 - max ø 10

DIN 55058 - ø 10

M 6

1 - 1

4.000

VH 083 P

VH 083 D

VH 084 P

VH 084 D

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

CAPACITA’ FORATURA DRILLING CAPACITY ø 10

Testa modelloHead type

ArticoloItemAttacco utensileSpindle typeArticoloItemAttacco utensileSpindle typeN. mandriniSpindles nr.Campodi lavoro min.Centredistances max.Capacità foraturaDrillingcapacityMaschiaturaTappingRapportoRatioVelocitàRPMPesoWeight Kg.

Acciaio Rm 500 N/mm2 - ø 8

Ghisa GG25 - ø 10

modello 08

6-6

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

VH082

VH083L

VH083

VH084

VH

M6x10

(VH083 n°3 a 120°)

8ø 70

85

74

134

148

ø 10 DIN 55058

ø 20

ø 55 g6

ø 23

VH 082

VH 083 L

VH 083

VH 084

VH 082

VH 083 L

VH 083

VH 084

VH 082 P

VH 082 D

2

2,2

24

108

3

2,9

24 + 24

66 + 66

3

3,4

ø 36

ø 120

4

4,6

ø 53,5

ø 137,5

VH 083 LP

VH 083 LD

ER 16 - max ø 10

DIN 55058 - ø 10

M 6

1 - 1

4.000

VH 083 P

VH 083 D

VH 084 P

VH 084 D

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

CAPACITA’ FORATURA DRILLING CAPACITY ø 10

Testa modelloHead type

ArticoloItemAttacco utensileSpindle typeArticoloItemAttacco utensileSpindle typeN. mandriniSpindles nr.Campodi lavoro min.Centredistances max.Capacità foraturaDrillingcapacityMaschiaturaTappingRapportoRatioVelocitàRPMPesoWeight Kg.

Acciaio Rm 500 N/mm2 - ø 8

Ghisa GG25 - ø 10

modello 08

6-6

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

CONO ISO CODICE

30 - 40 500202

DIN 238 CODICE

DIN 55058 CODICE

DIN 228 CODICE

B 10 B 12 B 16 B 18 B 22 B 24

16 20 28 36

CM 1 CM 2 CM 3 CM 4 CM 5

011277 011278 011279 011280 011281 011282

525405 525406 525407 525408

011115 011120 011125 011130 011135

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

MANICOTTO DI COLLEGAMENTO - CONNECTION COLLAR

ACCESSORI PERTESTE MULTIPLE

MULTISPINDLEHEADS ACCESSORIES

FLANGIA DI POSIZIONEPOSITIONING PLATE

Vista da AView from A

NOTA: A.B.C.D. dati macchinaNOTE: A.B.C.D. machine features

6-7

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

24

DIMENSIONS

24

VH 1

0

Article VH 102 P VH 103 LP VH 103 P VH 104 PSpindle typeArticle VH 102 D VH 103 LD VH 103 D VH 104 DSpindle typeSpindle number 2 3 3 4Min. working area 28 28+28 Ø40 Ø60Max. Distance between centers 120 74+74 Ø132 Ø152Drilling capacity SteelDrilling capacity FoundryTapping capacityDrive relationAllowed maximum revolutionsWeight (Kg) 3,5 4,9 4,9 7,2

ER16 máx. Ø10

VH102 VH103L VH103 VH104Multispindle headstock model

DIN 55058 máx. Ø12

Ø10Ø12M81:1

3.500

VHø 80 g6

ø 4016

ø 94

M8x12

(VH103 n°3 a 120°)

89,5

150

1010

162

ø 12 DIN 55058

ø 23

VH 102

VH 103 L

VH 103

VH 104

VH 102

VH 103 L

VH 103

VH 104

VH 102 P

VH 102 D

2

3,5

28

120

3

4,9

28 + 28

74 + 74

3

4,9

ø 40

ø 132

4

7,2

ø 60

ø 152

VH 103 LP

VH 103 LD

ER 16 - max ø 10

DIN 55058 - ø 12

M 8

1 - 1

3.500

VH 103 P

VH 103 D

VH 104 P

VH 104 D

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

CAPACITA’ FORATURA DRILLING CAPACITY ø 12

Testa modelloHead type

ArticoloItemAttacco utensileSpindle typeArticoloItemAttacco utensileSpindle typeN. mandriniSpindles nr.Campodi lavoro min.Centredistances max.Capacità foraturaDrillingcapacityMaschiaturaTappingRapportoRatioVelocitàRPMPesoWeight Kg.

Acciaio Rm 500 N/mm2 - ø 10

Ghisa GG25 - ø 12

modello 10

6-8

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

VH102

VH103L

VH103

VH104

VHø 80 g6

ø 4016

ø 94

M8x12

(VH103 n°3 a 120°)

89,5

150

1010

162

ø 12 DIN 55058

ø 23

VH 102

VH 103 L

VH 103

VH 104

VH 102

VH 103 L

VH 103

VH 104

VH 102 P

VH 102 D

2

3,5

28

120

3

4,9

28 + 28

74 + 74

3

4,9

ø 40

ø 132

4

7,2

ø 60

ø 152

VH 103 LP

VH 103 LD

ER 16 - max ø 10

DIN 55058 - ø 12

M 8

1 - 1

3.500

VH 103 P

VH 103 D

VH 104 P

VH 104 D

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

CAPACITA’ FORATURA DRILLING CAPACITY ø 12

Testa modelloHead type

ArticoloItemAttacco utensileSpindle typeArticoloItemAttacco utensileSpindle typeN. mandriniSpindles nr.Campodi lavoro min.Centredistances max.Capacità foraturaDrillingcapacityMaschiaturaTappingRapportoRatioVelocitàRPMPesoWeight Kg.

Acciaio Rm 500 N/mm2 - ø 10

Ghisa GG25 - ø 12

modello 10

6-8

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

CONO ISO CODICE

30 - 40 50

525402525403

DIN 238 CODICE

DIN 55058 CODICE

DIN 228 CODICE

B 10 B 12 B 16 B 18 B 22 B 24

16 20 28 36

CM 1 CM 2 CM 3 CM 4 CM 5

011277 011278 011279 011280 011281 011282

525405 525406 525407 525408

011115 011120 011125 011130 011135

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

MANICOTTO DI COLLEGAMENTO - CONNECTION COLLAR

ACCESSORI PERTESTE MULTIPLE

MULTISPINDLEHEADS ACCESSORIES

FLANGIA DI POSIZIONEPOSITIONING PLATE

NOTA: A.B.C.D. dati macchinaNOTE: A.B.C.D. machine features

Vista da AView from A

6-9

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

25

DIMENSIONS

VH13

Article VH 132 P VH 133 LP VH 133 P VH 134 PSpindle typeArticle VH 132 D VH 133 LD VH 133 D VH 134 DSpindle typeSpindle number 2 3 3 4Min. working area 35 35+35 Ø51 Ø75Max. Distance between centers 151 93+93 Ø167 Ø191Drilling capacity SteelDrilling capacity FoundryTapping capacityDrive relationAllowed maximum revolutionsWeight (Kg) 5,3 7,2 7 10,8

ER20 máx. Ø13

VH132 VH133L VH133 VH134Multispindle headstock model

DIN 55058 máx. Ø16

Ø13Ø14M121:1

3.000

* Measures can vary without previous notice. Ask for the updated drawing in every case.

VHø 80 g6

ø 4016

ø 116

M8x12

(VH133 n°3 a 120°)

9010

10

177

ø 16 DIN 55058

ø 25

183

VH 132

VH 133 L

VH 133

VH 134

VH 132

VH 133 L

VH 133

VH 134

VH 132 P

VH 132 D

2

5,3

35

151

3

7,2

35 + 35

93 + 93

3

7

ø 51

ø 167

4

10,8

ø 75

ø 191

VH 133 LP

VH 133 LD

ER 20 - max ø 13

DIN 55058 - ø 16

M 12

1 - 1

3.000

VH 133 P

VH 133 D

VH 134 P

VH 134 D

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

CAPACITA’ FORATURA DRILLING CAPACITY ø 14

Testa modelloHead type

ArticoloItemAttacco utensileSpindle typeArticoloItemAttacco utensileSpindle typeN. mandriniSpindles nr.Campodi lavoro min.Centredistances max.Capacità foraturaDrillingcapacityMaschiaturaTappingRapportoRatioVelocitàRPMPesoWeight Kg.

Acciaio Rm 500 N/mm2 - ø 13

Ghisa GG25 - ø 14

modello 13

6-10

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

VH132

VH133L

VH133

VH134

VHø 80 g6

ø 4016

ø 116

M8x12

(VH133 n°3 a 120°)

9010

10

177

ø 16 DIN 55058

ø 25

183

VH 132

VH 133 L

VH 133

VH 134

VH 132

VH 133 L

VH 133

VH 134

VH 132 P

VH 132 D

2

5,3

35

151

3

7,2

35 + 35

93 + 93

3

7

ø 51

ø 167

4

10,8

ø 75

ø 191

VH 133 LP

VH 133 LD

ER 20 - max ø 13

DIN 55058 - ø 16

M 12

1 - 1

3.000

VH 133 P

VH 133 D

VH 134 P

VH 134 D

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

CAPACITA’ FORATURA DRILLING CAPACITY ø 14

Testa modelloHead type

ArticoloItemAttacco utensileSpindle typeArticoloItemAttacco utensileSpindle typeN. mandriniSpindles nr.Campodi lavoro min.Centredistances max.Capacità foraturaDrillingcapacityMaschiaturaTappingRapportoRatioVelocitàRPMPesoWeight Kg.

Acciaio Rm 500 N/mm2 - ø 13

Ghisa GG25 - ø 14

modello 13

6-10

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

CONO ISO CODICE

30 - 40 50

525402525403

DIN 238 CODICE

DIN 55058 CODICE

DIN 228 CODICE

B 16 B 18 B 22B 24

16 20 28 36

CM 2 CM 3 CM 4 CM 5

011279 011280 011281 011282

525405 525406 525407 525408

011120 011125 011130 011135

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

MANICOTTO DI COLLEGAMENTO - CONNECTION COLLAR

ACCESSORI PERTESTE MULTIPLE

MULTISPINDLEHEADS ACCESSORIES

NOTA: A.B.C.D. dati macchinaNOTE: A.B.C.D. machine features

NOTA: l’utilizzo di questo accessoriorichiede il mandrino preposto.La lunghezza degli accessori,comprensivi di manicotto attaccorapido, aumenta di mm 9,5.

NOTE: the use of this accessory requiresprearranged spindle. The length of this accessories whit quick connectionsleeve increases of mm 9,5.

Vista da AView from A

FLANGIA DI POSIZIONEPOSITIONING PLATE

6-11

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

2626

DIMENSIONS

26

VH 1

8

Article VH 182 P VH 183 LP VH 183 P VH 184 PSpindle typeArticle VH 182 D VH 183 LD VH 183 D VH 184 DSpindle typeSpindle number 2 3 3 4Min. working area 41 41+41 Ø59 Ø89Max. Distance between centers 173 107+107 Ø191 Ø218Drilling capacity SteelDrilling capacity FoundryTapping capacityDrive relationAllowed maximum revolutionsWeight (Kg) 8,3 10,75 12 15,75

ER25 máx. Ø16

VH182 VH183L VH183 VH184Multispindle headstock model

DIN 55058 máx. Ø28

Ø18Ø20M141:1

2.500

VHø 80 g6

ø 4016

ø 116

M8x12

(VH183 n°3 a 120°)

1010

89

225

ø 28 DIN 55058

ø 40

183

VH 182

VH 183 L

VH 183

VH 184

VH 182

VH 183 L

VH 183

VH 184

VH 182 P

VH 182 D

2

8,3

41

173

3

10,75

41 + 41

107 + 107

3

12

ø 59

ø 191

4

15,75

ø 86

ø 218

VH 183L P

VH 183 LD

ER 25 - max ø 16

DIN 55058 - ø 28

M 14

1 - 1

2.500

VH 183 P

VH 183 D

VH 184 P

VH 184 D

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

CAPACITA’ FORATURA DRILLING CAPACITY ø 20

Testa modelloHead type

ArticoloItemAttacco utensileSpindle typeArticoloItemAttacco utensileSpindle typeN. mandriniSpindles nr.Campodi lavoro min.Centredistances max.Capacità foraturaDrillingcapacityMaschiaturaTappingRapportoRatioVelocitàRPMPesoWeight Kg.

Acciaio Rm 500 N/mm2 - ø 18

Ghisa GG25 - ø 20

modello 18

6-12

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

VH182

VH183L

VH183

VH184

VHø 80 g6

ø 4016

ø 116

M8x12

(VH183 n°3 a 120°)

1010

89

225

ø 28 DIN 55058

ø 40

183

VH 182

VH 183 L

VH 183

VH 184

VH 182

VH 183 L

VH 183

VH 184

VH 182 P

VH 182 D

2

8,3

41

173

3

10,75

41 + 41

107 + 107

3

12

ø 59

ø 191

4

15,75

ø 86

ø 218

VH 183L P

VH 183 LD

ER 25 - max ø 16

DIN 55058 - ø 28

M 14

1 - 1

2.500

VH 183 P

VH 183 D

VH 184 P

VH 184 D

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

CAPACITA’ FORATURA DRILLING CAPACITY ø 20

Testa modelloHead type

ArticoloItemAttacco utensileSpindle typeArticoloItemAttacco utensileSpindle typeN. mandriniSpindles nr.Campodi lavoro min.Centredistances max.Capacità foraturaDrillingcapacityMaschiaturaTappingRapportoRatioVelocitàRPMPesoWeight Kg.

Acciaio Rm 500 N/mm2 - ø 18

Ghisa GG25 - ø 20

modello 18

6-12

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

CONO ISO CODICE

30 - 40 50

525402525403

DIN 238 CODICE

DIN 55058 CODICE

DIN 228 CODICE

B 16 B 18 B 22B 24

16 20 28 36

CM 3 CM 4 CM 5

011279 011280 011281 011282

525405 525406 525407 525408

011125 011130 011135

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

MANICOTTO DI COLLEGAMENTO - CONNECTION COLLAR

ACCESSORI PERTESTE MULTIPLE

MULTISPINDLEHEADS ACCESSORIES

NOTA: A.B.C.D. dati macchinaNOTE: A.B.C.D. machine features

NOTA: la lunghezza degli accessori,comprensivi di manicottoattacco rapido, aumentadi mm 10.

NOTE: the length of this accessories whit quick connection sleeveincreases of mm 10.

Vista da AView from A

FLANGIA DI POSIZIONEPOSITIONING PLATE

6-13

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

2727

DIMENSIONS

VH25

Article - - - -Spindle typeArticle VH 252 D VH 253 LD VH 253 D VH 254 DSpindle typeSpindle number 2 3 3 4Min. working area 55 55+55 Ø79 Ø116Max. Distance between centers 239 147+147 Ø263 Ø300Drilling capacity SteelDrilling capacity FoundryTapping capacityDrive relationAllowed maximum revolutionsWeight (Kg) 27 32 39,5 52

-

VH252 VH253L VH253 VH254Multispindle headstock model

DIN 55058 máx. Ø36

Ø25Ø28M201:1

2.000

* Measures can vary without previous notice. Ask for the updated drawing in every case.

VHø 160

16

M10x15

(VH253 n°6 a 60°)

VH254 n°6 a 60°

1010

125

290

ø 36 DIN 55058

ø 50

ø 110 g6

ø 58

VH 252

VH 253 L

VH 253

VH 254

VH 252

VH 253 L

VH 253

VH 254

VH 252 D

2

27

55

239

3

32

55 + 55

147 + 147

3

39,5

ø 79

ø 263

4

52

ø 116

ø 300

VH 253 LD

DIN 55058 - ø 36

M 20

1 - 1

2.000

VH 253 D VH 254 D

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

CAPACITA’ FORATURA DRILLING CAPACITY ø 28

Testa modelloHead type

ArticoloItemAttacco utensileSpindle typeArticoloItemAttacco utensileSpindle typeN. mandriniSpindles nr.Campodi lavoro min.Centredistances max.Capacità foraturaDrillingcapacityMaschiaturaTappingRapportoRatioVelocitàRPMPesoWeight Kg.

Acciaio Rm 500 N/mm2 - ø 25

Ghisa GG25 - ø 28

modello 25

6-14

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

VH252

VH253L

VH253

VH254

VHø 160

16

M10x15

(VH253 n°6 a 60°)

VH254 n°6 a 60°

1010

125

290

ø 36 DIN 55058

ø 50

ø 110 g6

ø 58

VH 252

VH 253 L

VH 253

VH 254

VH 252

VH 253 L

VH 253

VH 254

VH 252 D

2

27

55

239

3

32

55 + 55

147 + 147

3

39,5

ø 79

ø 263

4

52

ø 116

ø 300

VH 253 LD

DIN 55058 - ø 36

M 20

1 - 1

2.000

VH 253 D VH 254 D

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

CAPACITA’ FORATURA DRILLING CAPACITY ø 28

Testa modelloHead type

ArticoloItemAttacco utensileSpindle typeArticoloItemAttacco utensileSpindle typeN. mandriniSpindles nr.Campodi lavoro min.Centredistances max.Capacità foraturaDrillingcapacityMaschiaturaTappingRapportoRatioVelocitàRPMPesoWeight Kg.

Acciaio Rm 500 N/mm2 - ø 25

Ghisa GG25 - ø 28

modello 25

6-14

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

CONO ISO CODICE

50 525403

DIN 238 CODICE

DIN 55058 CODICE

DIN 228 CODICE

B 18 B 22B 24

16 20 28 36

CM 3 CM 4 CM 5

011280 011281 011282

525405 525406 525407 525408

011125 011130 011135

Teste

mul

tiple

ad

assi

varia

bili

• Var

iabl

e axi

s hea

ds

MANICOTTO DI COLLEGAMENTO - CONNECTION COLLAR

ACCESSORI PERTESTE MULTIPLE

MULTISPINDLEHEADS ACCESSORIES

NOTA: A.B.C.D. dati macchinaNOTE: A.B.C.D. machine features

NOTA: la lunghezza degli accessori,comprensivi di manicottoattacco rapido, aumentadi mm 12.

NOTE: the length of this accessorieswhit quick connection sleeveincreases of mm 12.

Vista da AView from A

FLANGIA DI POSIZIONEPOSITIONING PLATE

6-15

BA

HM

OH

TVH

TA.C

PTA

TSI/

TSX

TM

T-TC

-TC

3A

cces

sori

Acc

esso

ries

Appe

ndic

e te

cnic

aTe

chni

cal s

uppl

emen

t

28

Tool

hol

ders

Erlo code Erlo code Erlo code K D1 h6 L L1 L2 D2

79010-D69871 79010-D2080 79010-M403BT 40 16 request per Norm 17 27 3279015-D69871 79015-M403BT 40 16 request per Norm 17 27 3279020-D69871 79020-D2080 79020-M403BT 40 22 request per Norm 19 31 4079025-D69871 79025-M403BT 40 22 request per Norm 19 31 4079030-D69871 79030-D2080 79030-M403BT 50 16 request per Norm 17 27 3279035-D69871 79035-M403BT 50 16 request per Norm 17 27 3279040-D69871 79040-D2080 79040-M403BT 50 22 request per Norm 19 31 4079045-D69871 79045-M403BT 50 22 request per Norm 19 31 4079050-D69871 79050-D2080 79050-M403BT 50 27 request per Norm 21 33 4879055-D69871 79055-M403BT 50 27 request per Norm 21 33 48

COMBINED MILL HOLDER:For shell end mills with driving slot DIN 138

Erlo code Erlo code Erlo code K K1 L L1 D79100-D69871 79100-D2080 79100-M403BT 30 1 50 request per Norm 2579105-D69871 79105-D2080 79105-M403BT 30 2 request per Norm request per Norm 3279110-D69871 79110-D2080 79110-M403BT 40 3 request per Norm request per Norm 4079115-D69871 79115-D2080 79115-M403BT 40 4 request per Norm request per Norm 4879120-D69871 79120-D2080 79120-M403BT 50 4 request per Norm request per Norm 4879125-D69871 79125-D2080 79125-M403BT 50 5 request per Norm request per Norm 63

EXTENSIONS AND REDUCING ADAPTERS TO MORSE:For tangged Morse taper tools DIN-228-B or Morse taper tools with thread DIN-228-A

TOOL-HOLDERS FOR MACHINING UNITS:AVAILABLE IN NORMS DIN 2080 / MAS 403 BT / DIN 69871

29

Erlo code Erlo code Erlo code K D1 L D2

79200-D69871 79200-D2080 79200-M403BT 30 6 request per Norm 2579205-D69871 79205-D2080 79205-M403BT 30 8 request per Norm 2879210-D69871 79210-D2080 79210-M403BT 30 10 request per Norm 3579215-D69871 79215-D2080 79215-M403BT 30 12 request per Norm 4279220-D69871 79220-D2080 79220-M403BT 30 14 request per Norm 4479225-D69871 79225-D2080 79225-M403BT 40 12 request per Norm 4279230-D69871 79230-D2080 79230-M403BT 40 14 request per Norm 4479235-D69871 79235-D2080 79235-M403BT 40 16 request per Norm 4879240-D69871 79240-D2080 79240-M403BT 40 18 request per Norm 5079245-D69871 79245-D2080 79245-M403BT 40 20 request per Norm 5279250-D69871 79250-D2080 79250-M403BT 40 25 request per Norm 6579255-D69871 79255-D2080 79255-M403BT 40 32 request per Norm 7279260-D69871 79260-D2080 79260-M403BT 50 25 request per Norm 6579265-D69871 79265-D2080 79270-M403BT 50 32 request per Norm 7279270-D69871 79270-D2080 79275-M403BT 50 40 request per Norm 8079275-D69871 79275-D2080 79280-M403BT 50 50 request per Norm 98

WELDON HOLDERS:For end mills with shank DIN 1835-B and DIN 6535-HB

COLLET CHUCKS ER TYPE (DIN 6499):

Erlo code Erlo code Erlo code K Collet size D1 Máx. L D G79150-D69871 79150-D2080 79150-M403BT 30 ER25 16 request per Norm 42 request per Norm79155-D69871 79155-D2080 79155-M403BT 40 ER25 16 request per Norm 42 request per Norm79160-D69871 79160-D2080 79160-M403BT 40 ER32 20 request per Norm 50 request per Norm79165-D69871 79165-D2080 79165-M403BT 40 ER40 26 request per Norm 63 request per Norm79170-D69871 79170-D2080 79170-M403BT 50 ER40 26 request per Norm 63 request per Norm79175-D69871 79175-D2080 79175-M403BT 50 ER50 34 request per Norm 78 request per Norm

* Measures can vary without previous notice. Ask for the updated drawing in every case.

30

QUICK-CHANGE TAPPING CHUCKS:With self feed and compression system for BILZ system tap adapter

Erlo code Erlo code Erlo code K CAP. D1 L D2 F1 F2

79280-D69871 79280-D2080 79280-M403BT 30 M3-M12 19 request per Norm 36 7,5 7,579285-D69871 79285-D2080 79285-M403BT 40 M8-M20 31 request per Norm 53 12,5 12,579290-D69871 79290-D2080 79290-M403BT 50 M14-M33 48 request per Norm 78 20 20

QUICK-CHANGE DRILL CHUCKS FOR DIN 2080:Does not require machine stop

Erlo code K D L D1

79300-D69871 30 40 78 6379305-D69871 40 51,5 102 8379310-D69871 50 68,7 133 100

Adapters for all type of tools, such as collet holder ER type, Morse Taper, fitting shank DIN 238, Bilz type tap holders, integral drill chucks, tap holders with double axial compensation, etc.Please consult.

31* Measures can vary without previous notice. Ask for the updated drawing in every case.

MAS 403 BT PULL STUDS (45º):With through coolant channel

Erlo code G G1 L L1 D D1

79350-D69871 M16 M16 52 25,15 25 1779355-D69871 M24 M24 65 25,2 39,3 25

PULL STUDS DIN 69872 (15º):With through coolant channel

Erlo code D G L L1 D1 D2

79370-D69871 19 M16 54 26 17 1479375-D69871 28 M24 74 34 25 21

MAHO OTT PULL STUDS:To adapt MAS 403-BT and DIN 69871 tool-holders to DIN 2080 cone

Erlo code G G1 L L1 D D1

79350-D69871 M16 M16 52 25,15 25 1779355-D69871 M24 M24 65 25,2 39,3 25

MACHINING UNIT HEAD

FEEDING SLIDES

CUSTOMIZED ASSEMBLIES

designed byERLO Group

www.erlogroup.es

Txerloie auzoa nº3

20720 AZKOITIA (SPAIN)

T: +34 943 851 858

Email : [email protected]