Machining (MIT 2.008x Lecture Slides)

-

Upload

a-john-hart -

Category

Engineering

-

view

3.111 -

download

9

Transcript of Machining (MIT 2.008x Lecture Slides)

2.008x

MachiningMIT 2.008x

Prof. John Hart

2.008x

2.008x

Machine shop in the DC printing office (1909)National Photo Company Collection via wikimedia. This work is in the public domain.

A present-day CNC machine shop“KIM_6446.” Kim Becker (CC BY 2.0) via Flickr

CNC Tools“Drill bit set” via Pixabay.

This work is in the public domain.

2.008x

What is the highest volume CNC machined

part in history?

2.008xManufacturing the Macbook ‘unibody’

(+ iPhone etc)

Excerpt from: http://www.youtube.com/watch?v=sxbiIpXZfG8about Jony Ive (Apple VP of Design): http://www.newyorker.com/magazine/2015/02/23/shape-things-come

2.008x12” Macbook (released 2015)

Terraced CNC housing to hold 30% more battery volume;; single PCB2.03 pounds, 0.51” thick (max), 9hrs using wifi at 75% brightness

http://www.apple.com/macbook/design/

2.008xWhat is machining?

§ … “a general term describing a group of processes that consist of the removal of material and modification of the surfacesof a workpiece after it has been produced by various methods.” (Kalpakjian and Schmid)

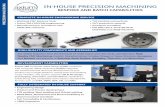

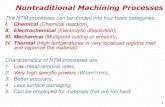

§ Traditional machining: a rotating cuttercontaining several 'teeth' that removes material from a local region of the part.

§ Other machining processes that use different removal mechanisms and/or energy sources include electron discharge machining (EDM), laser machining, and water jet cutting.

Kalpalkian and Schmid, Manufacturing Engineering and Technology

2.008xMachined parts: from small to large

Brass fittingsImage from Pixabay. This work is in the public domain.

iPhone 5 and 6 housings

Boeing 777 panel outboard

Watch mechanismhttps://pixabay.com/en/watch-time-gears-clock-time-clock-932693/

2.008x

Diagram from Kalpalkian and Schmid, Manufacturing Engineering and Technology.

Machining is good at flat and curved surfaces, threads;; tolerances ~0.001”

0.5 mm

Brass fittingsImage from Pixabay. This work is in the public domain.

2.008x

2 mm

2.008xAgenda:Machining

§ Tool-material interaction§ Cutting mechanics§ Geometry and motion§ Forces§ Energy and power

§ Demonstration experiments!§ Cutting forces§ Tools, finish, and wear

§ Milling (+iPhone housing)§ Design for machining§ Conclusion

2.008x

Machining:

2. Basics of tool-material interaction

2.008xA lathe

Kalpakjian and Schmid, Manufacturing Engineering and Technology

2.008x

2.008xCNC turning a chess rook (2X speed)

Turning

Video excerpt from: https://www.youtube.com/watch?v=lcGHtI9Lql4Diagrams adopted from Kalpakjian and Schmid, Manufacturing Engineering and Technology

Contour turning Facing

Boring (internal turning)

Cutoff (with saw)

2.008xBasic cutting (turning) nomenclature

§ Feed: axial distance tool moves per spindle revolution

§ Depth of cut: amount of material removed perpendicular to workpiece

§ Spindle speed: rotation speed of workpiece [RPM]

à The cutting tool is set to a certain depth of cut and travels to the left with a certain velocity as the workpiece rotates (spindle speed)

Kalpakjian and Schmid, Manufacturing Engineering and Technology

2.008xExample: cutting speed and MRR

A 304 stainless steel rod is being turned on a lathe. § The rod is initially 2.0 cm diameter, and becomes 1.9 cm in a single cut.§ The spindle rotates at N=300 rpm, and the tool is traveling at an axial speed of 20 cm/min.

§ The specific cutting energy is 4.0 W-s/mm3.

à What is the initial cutting speed? (tangential velocity)

à What is the initial material removal rate (MRR)?

2.008xExample: cutting speed and MRR

à What is the initial cutting speed? (tangential velocity)

m/min 18.8m/s 31.0 === NDV oc π

2.008xExample: cutting speed and MRR

à What is the initial material removal rate (MRR)?

fdVNfdDMRR c== 1π

cm/rev 0.067==NVf a

cm 0.052

=−

= fo DDd

2.008xExample: cutting speed and MRR

à What is the initial material removal rate (MRR)?

fdVNfdDMRR c== 1π

cm/rev 0.067==NVf a

cm 0.052

=−

= fo DDd

/mincm .301 3== fdVMRR c ----correct:6.3 cm3/min

2.008xMaterial removal = controlled failure

Excerpt from: https://www.youtube.com/watch?v=mRuSYQ5Npek

Material is removed (and a chip is produced) at the head of the tool by plastically deforming and continuously shearing the material

2.008xWhat do the tool and material experience during cutting?

§ Force§ Motion (sliding, vibration)§ Heating

à These lead to deformation of the workpiece and wear of the tool

à All of these are coupled and influence part quality!

2.008xHow we’ll understand cutting mechanics

Step II:Forces

Step I:Motion &Deformation

Step III:Energy &Power

2.008x

Machining:

3. Tool motion and material deformation

2.008xWe assume a 2D (orthogonal) cutting path

Orthogonal (2D)Provides insight for understanding

Oblique (3D)Realistic, yet difficult to analyze

x

y

z x

y

z

2.008x2D model: angles and assumptions

Three important angles:§ Rake angle α§ Shear angle φ§ Relief angle ε

Shear plane

Tool

Workpiece

+-

α

φ ε

Chip

Assumptions:§ The tool is perfectly sharp§ The tool moves at a constant V and t0

§ A continuous chip is produced

2.008x

Excerpt from: https://www.youtube.com/watch?v=mRuSYQ5Npek

What type of deformation do you see?α

φ ε

2.008xShear model of orthogonal cutting

In reality the ‘pages’ are very thin and related to the microstructure of the material being cut: ~0.001-0.01 mm (10-3-10-4 in)

Tool

Workpiece

Chip

tc

tc

t0

2.008xAnalysis of shear strain

φ

( ) ( )αφφγ

γ

−+=

+=

Δ=

tancotaccdbc

Ax

2.008x

What do we learn?§ φ ↓ = γ ↑ or α ↓ = γ ↑§ γ ∼2-4 (very large!)

à Think of the material ‘turning the corner’

( ) ( )αφφγ −+= tancot

Shear planeTool

Workpiece

+-

α

φ ε

Chip

Analysis of shear strain

2.008x(Tesla video)

Here, digital image correlation (DIC) is used to map the strain fieldNIST high speed videos of tool/chip/material interaction: http://www.nist.gov/el/isd/sbm/hsds-machining-videos.cfm

Mapping shear strains during cutting

2.008x

Machining:

4. Cutting forces

2.008xWhy do we study cutting forces?

§ Forces are related to the material and cut geometry

§ Forces cause the tool and workpiece to deform

§ Forces (and speed) determine the power required for cutting

à The coupling of motion and force at the cutting interface influences quality, tool life, and productivity!

2.008xCutting force (FC)

Workpiece

+-

α

φ

Chip

FC

2.008xDemo #1: Measuring cutting force

2.008xMeasuring cutting force

2.008x

Cut Feedrate [in/rev]

Spindle [RPM]

Rake angle [deg]

Depth of cut [in]

Diameter [in]

Force [lb]

1 0.0042 140 60 0.03 2 0.43 2 0.0147 140 60 0.03 2 0.90

3 0.0147 140 0 0.03 2 1.83 4 0.0147 330 0 0.03 2 2.03 5 0.0147 330 0 0.06 2 3.87

6 0.0147 330 0 0.06 1 3.38 !

Cutting force data from video

Tool

Workpiece

+-

α

φ ε

Chip

2.008xCutting force data for aluminum (AA2014)

http://www.sv-

à Here too, cutting force depends strongly on feed (f) but not on speed (Vc)

Gokkaya, “The Effects of Machining Parameters on Cutting Forces,Surface Roughness, Built-Up Edge (BUE) and Built-Up Layer(BUL) During Machining AA2014 (T4) Alloy”, Journal of Mechanical Engineering 56(2010)9, 584-593

2.008xMerchant’s relationship: relating the angles

(reference slides to be posted)

is derived assuming that the shear angle (φ) self-adjusts to minimize the required cutting energy

Tool

Workpiece

+- α

φ ε

Chip

à if rake angle ↓ or friction angle ↑: shear angle ↓

à consequences of smaller shear angle:§ chip thickness ↑§ energy dissipation via shear ↑§ heat generation ↑§ temperature ↑

224αβπ

φ +−= [radians]β = friction angle (µ = tan β)

2.008xValidating Merchant’s equation

Chart adapted from: Metal Cutting Theory and Practice, Stephenson and Agapiou

224αβπ

φ +−=

Key assumptions:§ Slow, orthogonal cutting§ Constant material properties with temperature

§ Simple sliding friction§ No strain hardening

α

φ ε

2.008x

Machining:

5. Field trip to IMTS

2.008x

2.008xRegular CNC machines

Haas DT1 drill-tap centerhttps://www.haascnc.com/mt_spec1.asp?id=DT-1&webID=DRILL_TAP_VMC#gsc.tab=0

2.008xGiant machines (25 ton table capacity)

2.008xLots of tools

2.008xLots of tools

2.008x

2.008xAnd tool mascots!

2.008xAnd chip management systems

2.008xAnd chip management systems

2.008x

Machining:

6. Tools, finish, and wear

2.008xCutting toolsMonolithic tool (e.g., HSS or Carbide)

Tooling with inserts

Diagrams from Kalpalkian and Schmid, Manufacturing Engineering and Technology

2.008x

Demo #2: Tools, finish, and wear

2.008x

ToolMaterial

Speed[RPM]

Depth of cut[in]

Feed [in/rev]

MRR[in3/min]

HSS

90 0.05 0.007 0.40

140 0.05 0.007 0.62

330 0.05 0.007 1.45

Carbide

330 0.05 0.014 2.90

385 0.05 0.014 3.29

585 0.05 0.014 5.15

Demo #2: Data

2.008xTool hardness, temperature rise

Tmean ∝Va f b

max

Kalpalkian and Schmid, Manufacturing Engineering and Technology

speed V and feed f;; a and b are constants that depend on the tool and part

2.008xTool wear

Depth of cut

Flank wearCraterwear

Flankwear

Crater wear

Crater Wear on the Rake

Face

Wear on the Flank

Face

Deposition causing a “Built Up

Edge”

Thermal Cracking

Crater Wear on the Rake

Face

Wear on the Flank

Face

Deposition causing a “Built Up

Edge”

Thermal Cracking

Images from Figure 23.2 Fundamentals of Modern Manufacturing (4th Edition) by Groover. (c) Wiley (2010).Wear schematics from: http://www.sandvik.coromant.com/en-us/knowledge/milling/troubleshooting/tool_wear

2.008xChips from demo: carbide tool, 385 RPM

Craterwear

Flankwear

à Examine both sides

2.008xChip types (selected)Continuous chip (narrow primary shear zone)§ Ductile materials @ high speed§ Entanglement bad (use chip breakers)

Continuous chip with built up edge (BUE)§ Bad for surface finish and tool wear

Discontinuous chip (good)§ Brittle materials;; very low or very high cutting speeds

Continuous chip

Continuous with BUEDiscontinuous

Kalpalkian and Schmid, Manufacturing Engineering and Technology.

2.008xWhat determines surface roughness of machined parts?

2.008xSurface roughness

Figure 7.44 from "Product Design for Manufacture and Assembly (2nd Edition)" by Marinescu, Boothroyd. © Marcel Dekker Publishing (2002)

2.008x

Taken using Zygo profilometer

2.008x

Kalpakjian and Schmid, Manufacturing Engineering and Technology.Figure 21-8 from DeGarmo's Materials & Processes in Manufacturing (10th Edition) by Black and Kohser, © Wiley (2008).

Improved tool materials à higher cutting speed

Layers: 2-20 μm thickTiN: low frictionTiCN: wear resistanceAl2O3: high thermal stability

Carbide: hardness and fracture toughness

Rate = 200x faster in 100 years

à ~5% increase per year, (1.05)100

à Machine requirements?

2.008x

Machining:

7. Cutting energy and power

2.008x

Step II:Forces

Step I:Motion &Deformation

Step III:Energy &Power

2.008xA simple estimate of cutting force

FC ~b t0 Sb = depth of cut (d in turning)t0 = feed (f in turning)S = strength

Material UTS* (MPa)Wax 0.86

Aluminum 110Aluminum 6061-T6 310

Steel (high strength alloy) ASTM A-514

760

Titanium alloys 900

*UTS = Ultimate Tensile StrengthShear strength ~0.5*UTS

Workpiece

+-

α

φ

Chip

FC

2.008xWhat other forces are present?

§ Thrust: Ft

§ Cutting: Fc

§ Friction: Ff (µ = Ff/N)

§ Tool normal: N

§ Shear: Fs

§ Chip Normal: FnR

Fc

FtFn

Fs N

Ff

2.008xEstimating the cutting powerPower input = Power out + Power dissipated

Power input:§ Machine: Pc = Fc * V

Power dissipation:§ Shear: Ps = Fs * Vs§ Friction: Pf = Ff * Vc

Vs V

Vc

Fs

Not deformed

Plastically Deformed

Fc

Fc

α

φ

Chip

- +

NOTEVc = velocity of chipV = cutting velocity

(denoted VC earlier)

2.008x

Contributions to cutting energyà specific energy = power/MRR

*Kalpakjianneglects Units =

Power/(volume/time)[W*s/mm3]

Shear + Friction + Others = TOTAL

Vs V

Vc

Fs

Not deformed

Plastically Deformed

Fc

Fc

α

φ

Chip

- +

2.008xLet’s estimate the cutting power and force§ A SS rod is initially 2.0 cm diameter, and becomes 1.9 cm in a single cut (full rotation).

§ The spindle rotates at N=400 rpm, and the tool is traveling at an axial speed of 20 cm/min.

§ The specific cutting energy is 4.0 W-s/mm3.

à How much power is required?

MRR =Vfd = πD1Nfd

àpower and force limits in demo #2?Carbide@385 = 2.45 kWKalpakjian and Schmid, Manufacturing Engineering and Technology

2.008xLet’s estimate the cutting power and force§ A SS rod is initially 2.0 cm diameter, and becomes 1.9 cm in a single cut (full rotation).

§ The spindle rotates at N=400 rpm, and the tool is traveling at an axial speed of 20 cm/min.

§ The specific cutting energy is 4.0 W-s/mm3.

à How much power is required?

drive

t

drive

spindleinput

tspindle

MRRuPP

MRRuP

ηη==

= MRR =Vfd = πD1Nfd

àpower and force limits in demo #2?Carbide@385 = 2.45 kW

P = 0.6 kWwith efficiency = 0.7

Kalpakjian and Schmid, Manufacturing Engineering and Technology

2.008xLet’s estimate the cutting power and force§ A SS rod is initially 2.0 cm diameter, and becomes 1.9 cm in a single cut (full rotation).

§ The spindle rotates at N=400 rpm, and the tool is traveling at an axial speed of 20 cm/min.

§ The specific cutting energy is 4.0 W-s/mm3.

à What is the approximate cutting force?MRR =Vfd = πD1Nfd

fduVVfdu

VMRRuF

MRRuVFP

ttt

c

tcspindle

===

==

àpower and force limits in demo #2?Carbide@385 = 2.45 kW

F = 1 kN

Kalpakjian and Schmid, Manufacturing Engineering and Technology

2.008x

Kalpakjian and Schmid, Manufacturing Engineering and Technology

Material-dependent cutting energies

à Also see ‘machinability rating’

2.008xWhat did we learn so far? (summary)

§ Cutting removes material from a workpiece by (severe) plastic deformation.

§ Using a 2D approximation (applied to turning) we can relate the geometry and motion of the tool to the cutting force and power required.

§ Tool-material interaction is dominated by shear and friction, causing deformation and heating.

§ Commercial machine tools easily exert many kN of force at many kW of power.

§ Recommended cutting parameters are stated based on material and tool limits.

à Now let’s talk about milling.

2.008x

Machining:

8. Milling

2.008xHow are milling and turning different?

Excerpt from Ingersoll https://www.youtube.com/watch?v=IUBQN1JfY80

Feed per tooth (f)v = velocity of tool or workpieceN = rotational speedn = number of teeth (‘flutes’)

Diagrams from Kalpalkian and Schmid, Manufacturing Engineering and Technology

2.008x3-axis milling machine

2.008x

Climb milling versus Conventional milling

6061-T6 Aluminum with ¼” endmillSpindle Speed: 4000rpmFeed: 20.0ipmDepth of cut: .400”Width of cut: .070”

Diagrams from Kalpalkian and Schmid, Manufacturing Engineering and Technology

2.008xCommon milling operations

Diagram from Kalpalkian and Schmid, Manufacturing Engineering and Technology.

2.008x

End$mill

Face$millFly$cutter$(single$point$for$making$smooth$surfaces)

2.008x

Front-facing camera

Faceplate

Screen (flipped)

Camera Battery

Logic board

Housing

iPhone 6 chassis assembly

Modified from: https://d3nevzfk7ii3be.cloudfront.net/igi/DSCkX6EfcARJYOHa.hug

iPhone 6 teardown

Type of joint Number

Bolted 44

Adhesive 5

Clip 8

Threaded inserts 46Counted from teardown sequence

2.008xiPhone 6 housing: What do we notice?

‘Straight’ tool path

‘Curved’ tool path

Plastic insert

Press-fit threaded insert

T-slot endmill

2.008x

2.008xFeature sizes

0.5 mm

0.5 mm

6 mm

2 mm

2.008xTool paths

Contour-parallel tool path

https://en.wikipedia.or g/wiki /CNC_pocket_milling

Zig-zag tool path

2.008x

How the toolpath for each area is designed

Add finishing passes where needed

Generate the pocket cutting pathsContour-parallel tool path Direction-parallel tool path

Begin with offset elements of the contour to generate cutting paths

Step inwards or outwards for subsequent passes

Select reference line and mill along parallel lines

Zig milling: Feed along spindle direction

Zig-zag: Both directions (includes significantly fewer tool retractions)

Finishing pass around features

Contour parallel path

Diagrams from M. Held, On the Computational Geometry of Pocket Machining;; Lecture Notes in Computer Science;; Springer Berlin Heidelberg: Berlin, Heidelberg, 1991;; Vol. 500.

Evaluate the shape of material to be removed

Boundary contours pf the pocket

Contours of drilled holes and features such as bosses

2.008xOptimization for cost or time?

Kalpakjian and Schmid, Manufacturing Engineering and Technology

Cost of machining =§ Machine use ($/time)§ Tool cost

§ Tool change cost ($/time)§ Nonproductive cost ($ for load/unload operations etc)

Time (1/rate) of machining = § Machining time§ Tool change time§ Nonproductive time (load/unload etc)

Taylor’s equationV*(Tool_life)n = Constant

2.008xiPhone housing: 4 à 5 à 6§ Materials?§ Advantages / disadvantages of each design?§ Other notable differences?

2.008x4/5/6 back

2.008x

5-axis machining

3-axis 5-axis

Photo from https://www.youtube.com/watch?v=CqePrbeAQoMDiagrams fromhttp://www.awea.com/awea_en/milling/5-axes/fmv/overview.htm

2.008x

Video excerpt from https://www.youtube.com/watch?v=mudofisRCjA

5-axis machining

2.008x

Machining:

9. Design guidelines for Machining

2.008x

Design for Manufacturing (DFM):

The process of designing parts/products to enable easier* and more robust** manufacturing.

*fewer steps, lower cost

**more reliable, better quality

2.008x

From Otto and Wood, Product Design: Techniques in Reverse Engineering and New Product Development

Design for Machining

Use standard dimensions

D = 0.627” D = 0.625”Don’t Do

DoDon’t

Provide access for tools

Avoid long, narrow holes

Avoid long, thin sections that cause vibration

Do

Don’t Difficult to fixture

Easier to hold

Design parts that are easy to fixture

Impossible

DoDon’t

Radius smaller than ¼”

Use ¼ - ½” radius

Design for reasonable internal pockets radii

Impossible

2.008x

DFM: what’s wrong with this part?

§ Sharp internal corners are impossible!

§ Avoid thin sections à(deformation, poor surface finish).

also§ Minimize the number of tool changes, while considering overall machining time (e.g., rough removal versus fine finishing).

§ Know the limits of tooling available (e.g. minimum size, maximum depth)!§ Consider fixturing (how you will hold the part, and reference it if re-fixtured)

2.008x

Machining:

10. Conclusion

2.008x

How is machining advancing now?

§ Higher speed machining, largely driven by tool materials/coatings à lower cost and higher throughput!

§ Growing demand for machining of advanced materials, e.g., titanium, composites, etc.

§ Networked machines enabling remote process monitoring and optimization à toolpath, cutting speed, tool life, surface quality, etc.

2.008x

Excerpt from: https://www.youtube.com/watch?v=8Lh600hVyt8 Figure adopted from 20.31, Degarmo, Materials and Processes in Manufacturing

High-speed machining: chip carries the heat away

Total heat generated

% to workpiece

% to tool

% to chip

Cutting speedLow High0

50%

100%

Heat generated

2.008x

Conclusion: performance of machining

Machining

Rate Low-Medium

Quality Good!

Cost Wide range, depends on design, material, production volume

Flexibility High (within machine constraints)

2.008x

References1 Introduction

Photo of CNC Mill by Roland Josch on Pixabay. This work is in the public domain.

Photo of Machine Shop in DC Printing Office by National Photo Company from U.S. Library of Congress. This work is in the public domain.

Photo of CNC Machine Shop by Kim Becker via Flickr (CC BY) 2.0

Photo of Drill Bit Set by Michael Schwarzenberger on Pixabay. This work is in the public domain.

Video of MacBook Pro Manufacturing © Apple Inc.

Image of MacBook Pro Exploded View © 2016 Apple Inc.

Machining Processes: Figure 1.5e "Manufacturing Engineering & Technology (6th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2010).

Photo of Mechanical Watch Mechanism by User: tookapic on Pixabay. This work is in the public domain.

Photo of Brass Fittings by Ingbert Merz on Pixabay. This work is in the public domain.

Machined Part: Figure IV.3 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014).

2.008x

References2 Basics of Tool-Material-Interaction

Lathe Picture: Figure 23.2 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014).

Video of Rook Machining © 2016 GlacernMachine Tools

Lathe Cutting Operations: Figure 23.1 from "Manufacturing Engineering & Technology (6th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2009).

Turning Schematic: Figure 21.2 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014).

Videos of Iscar Chip Formation © Rick Steinard.

3 Tool Motion and Material Interaction

Video of Iscar Chip Formation © Rick Steinard.

Video of Titanium machining example, by NIST of the U.S. Dept. of Commerce 2009.

Photo of CNC Mill by Roland Josch on Pixabay. This work is in the public domain.

2.008x

References4 Cutting Forces

Graphs by Gokkaya, “The Effects of Machining Parameters on Cutting Forces, Surface Roughness, Built-Up Edge (BUE) and Built-Up Layer (BUL) During Machining AA2014 (T4) Alloy”, Journal of Mechanical Engineering 56(2010)9, 584-593

Shear Angle Chart adapted from: Metal Cutting Theory and Practice, Stephenson and Agapiou

6 Tools and Wear

Lathe Cutting Tool: Figure 21.10 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014).

Tooling with Insert: Figure 22.3 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014).

Temperature Distribution: Figure 21.12 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014).

Hardness Chart: Figure 22.1 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014).

2.008x

ReferencesCrater Wear: Figure 23.2 from "Fundamentals of Modern Manufacturing (4th Edition)" by Groover. © John Wiley & Sons Inc. (2010)

Wear schematics images © 2000 Sandvik AB

Chip Types: Figures 21.5 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014).

Machining Time: Figure 22.6 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014).

Coating Cross-Section: Figure 22.8 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014).

Insert: Figure 21-8 from "DeGarmo's Materials & Processes in Manufacturing (10th Edition)" by Black and Kohser, © John Wiley & Sons, Inc. (2008).

7 Cutting Energy and Power

Turning Schematic: Figure 21.2 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014).

Cutting Energies: Table 21.2 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014).

2.008x

References8 Milling

Video of Face Milling Slow-Motion © Ingersoll Cutting Tool Company

Parts Produced by Milling: Figure 24.1 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014).

Milling Operation Parameters: Figure 24.3 b) from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014).

Conventional vs. Climbing: Figure 24.3 a) from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014).

Milling Operations: Figure 24.2 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014).

Image of iPhone 6 © 2000-2016 GSMArena.com

Image of iPhone 6 Exploded View © 2016 iFixit

Image of T-Slot End Mill Cutter © 2003 Bewise Inc. All Rights Reserved

Image of Tool Paths by Kangkan iitd on Wikimedia. (CC BY-SA) 3.0

Pocket Machining: Figure 1.3 from "On the Conceptual Geometry of Pocket Machining" by Held © Springer-Verlag (1991).

2.008x

ReferencesToolpaths: Figure 1.4 from "On the Conceptual Geometry of Pocket Machining" by Held © Springer-Verlag(1991).

Cost Optimization: Figure 25.17 from "Manufacturing Engineering & Technology (7th Edition)" by Kalpakjian, Schmid. © Upper Saddle River;; Pearson Publishing (2014).

Diagrams of Advantages of 5-Axis Milling Machines © AWEA Mechatronic Co. LTD. 2016. All Rights Reserved.

Image of 5-Axis Vertical Machining Center © Okuma America Corporation.

Video of Mazak Variaxis i700 © John Hart Pty Ltd.

9 Design for Manufacturing

DFM Practice Diagram: Figure 14.10 from "Product Design: Techniques in Reverse Engineering and New Product Development" by Otto and Wood, © Upper Saddle River;; Pearson Publishing (2001)

10 Conclusion

Image of Datron M8Cube © 2016 DATRON Dynamics, Inc.

Heat vs. Speed Diagram: Figure 20-31 from "DeGarmo's Materials & Processes in Manufacturing (10th Edition)" by Black and Kohser, © John Wiley & Sons, Inc. (2008).