Machining Guidelines for Vesconite

Transcript of Machining Guidelines for Vesconite

Home Products Design &

Technical Successes &

References Contact us About us

Search

Industries Marine Pumps Rail Mining Suspensions

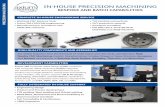

Machining guidelines for Vesconite.Vesconite is easily machined to fine tolerances on standard metal working equipment.

Turning Tool cutting anglesCutting speeds

Machining guidelines for Vesconite. http://www.vesconite.com/design/techinfo/mach_guides.htm

Cutting speedsMachining standard bearings with diameters < 200 mmBearing groove designMachining bearings with diameters > 200 mm

Drilling solid rodMillingSawing

Please refer to the Material Safety Data Sheet for Vesconite for material safety precautions.

Turning

Machining guidelines for VesconiteVesconite and Vesconite Hilube are easily machined to fine tolerances on standard metal workingequipment.

Vesconite should not be clamped like a metal, but should be clamped gently and with care toavoid distortion.

Cooling water should be used where possible to cool the cutting surface.

Take cuts no more than 2 mm (0.1") deep at a time.

Allow the bush to cool before taking the final cut.

Cutting Speeds and Feeds

Cutting speeds - Maximum of 300 m/min (1000 fpm)

Diameter mm 200 300 400 500 600 700

Diameter inches 8" 12" 16" 20" 24" 28"Diameter inches 8" 12" 16" 20" 24" 28"

RPM 350 300 200 150 100 70

Cutting Feeds

Rough turning: 0,5 - 0,7 mm per revolution

(0.020" - 0.030" per revolution)

Finish turning: 0,3 - 0,4 mm per revolution

(0.012" - 0.016" per revolution)

1 of 7 5/12/2012 12:59 PM

Tool Cutting Angles

Machining straight and flanged bushes for small quantities

Machining guidelines for Vesconite. http://www.vesconite.com/design/techinfo/mach_guides.htm

Machining straight and flanged bushes for small quantities(Machining standard bearings. Diameters < 200 mm (8"))

Allow extra length for chucking, parting and facing, usually 25 mm (1").

Cut bushing stock to required length using a cut-off saw.

Set the bush in the chuck as squarely as possible.

Use an internal support disc machined to size. The disc can be made of any available material,approximately 10 to 25 mm thick (½" to 1").

Tighten the chuck lightly, but only enough to support the bush. Vesconite should not be clampedlike a metal.

Machine bush inside diameter using a boring bar.Ensure that there is not an excessive build-up ofshavings inside the bush.

Grooves may be added at this stage if required.

Machine bush outside diameter using an external turningtool.

If required, machine flange outside diameter.If required, machine flange outside diameter.

Face the end of the bush to length.

2 of 7 5/12/2012 12:59 PM

Part bush to length using parting tool.

Ensure that bush does not fall when parted.

Machining in NC lathesBushes can also be machined on numerically controlled lathes.Take care to ensure that the clamping pressure does not distort the Vesconite.

Machining guidelines for Vesconite. http://www.vesconite.com/design/techinfo/mach_guides.htm

Face the end furthest from the chuck

Machine the inside diameter

Machine the outside diameter

Cut to length at the chuck end

Machining standard bushes for production runsWhen machining many Vesconite bushes on center lathes, the following procedure saves timeand minimises waste.

Step 1 - Cut to lengthCut bush to final length using a cut-off circular saw. Take care to ensure that the cut is square.

If a fine length tolerance is required, allow extra material for facing both ends of the bush later.

Step 2 - Machine outside diameterMachine two mandrels with outside diameters the size of theinside diameter of the Vesconite bushing.

Machine one for the chuck and another for the tail stock.

Mandrels can be made of Vesconite, steel or other readilyavailable rigid material.

Support the bush between these two mandrels by applying alight pressure, and machine outside diameter using externalturning tool.turning tool.

Step 3 - Machining the inside diameterMachine a "pot" with suitable available material (eg Vesconite, steel, etc). The inside diametershould be size to size to the outside diameter of the bush already machined.

Make the length of the pot about 10-25 mm (½" to 1") shorter than the length of the bush. Thewall thickness of the pot must be sufficient to support the bush.

Drill a hole in the end of the pot so that the bush may be removed after machining by pushing arod through this hole.

3 of 7 5/12/2012 12:59 PM

Machine a disc to be placed loosely inside the pot forremoval of the part after machining.

Push the bush lightly into the pot.

Machine the bush inside diameter using a boring bar.Ensure that there is not a large buildup of shavings insidethe bush being machined.

Grooves or other internal details may be added at thisstage.

Machining guidelines for Vesconite. http://www.vesconite.com/design/techinfo/mach_guides.htm

Machining bearings with groovesGroove design

Machining spiral and round groovesThis is done on the NC or manual lathe by normal operating procedures.

If the groove continues right through the bearing, it will usually be required to face the bearingafter cutting the grooves.

Machining straight grooves

Secure the bearing in the chuck or pot and lock the chuck.

Attach a broaching tool to the tool post.

Set up the tool and machine a groove taking no more than 2 mm with a cut.

Index the chuck to the next point and repeat the process.

Machining large bearings. Diameters >200 mm (8")

Due to the size of these bearings, extra care needs to be taken to ensure that there are nounnecessary stresses placed on the material. These bearing are referred to as XL bearings.

Vesconite XL bearings are easily machined on standard lathes if proper support is provided toprevent deformation and cracking.

Remember that Vesconite should not be clamped like a metal, but should be clamped gently andwith care to avoid distortion.

Allow 50 mm (2") extra length for holding and parting the bearing.

Step 1

Set the bearing in the chuck. First face one end of thebearing square. This helps with alignment.

To prevent deformation and cracking, it is important to usean internal support disc machined to size. This disc may be

4 of 7 5/12/2012 12:59 PM

machined from steel, wood, particle board or plywood about30mm (1¼") thick.

The jaw clamping pressure should not be excessive butonly enough to secure the bearing.

Step 2

Machining guidelines for Vesconite. http://www.vesconite.com/design/techinfo/mach_guides.htm

Switch bearing around, align and face the other end. Onceagain the internal support is required.

Step 3

Machine the outside diameter of the bearing. Maximum cutdepth is 5 mm. Allow bearing to cool before taking final cut.Final cut to be no more than 2 mm deep.

Step 4

Machine the inside diameter without removing the bearingfrom the chuck, and with the support disc in place. Ensurethat there is not a large buildup of shavings on the tool.Maximum cut depth is 5 mm. Allow bearing to cool beforetaking final cut. Final cut to be no more than 2 mm deep.

Step 5

Face the bearing to the required length taking care that theFace the bearing to the required length taking care that thebearing does not fall.

Please refer to the Material Safety Data Sheet for Vesconite for material safety precautions.

Drilling solid rod

5 of 7 5/12/2012 12:59 PM

Drilling a large diameter Vesconite rod

Use high speed twist drills

Drill a pilot hole of ±15mm initially

Cooling is very important. Use cutting fluid or water. This is one of the biggest reasons forfailures.

It is very important to remove the shavings when drilling. It is best to regularly withdraw thedrill and remove shavings, and then only continue with drilling.

Once the 15mm hole is achieved, machine to the required inside diameter using a boring bar

Machining guidelines for Vesconite. http://www.vesconite.com/design/techinfo/mach_guides.htm

Once the 15mm hole is achieved, machine to the required inside diameter using a boring baron a lathe. Do NOT use a larger drill, this could lead to cracking.

SawingUse band saws and circular saws for Vesconite. If possible use saws with offset teeth to minimizeheat build up and blocking of the saw.

Band saw:Tooth pitch 3-5 mmSaw speed 200-500 m/min

Circular sawTooth pitch 8-12 mmSaw speed 500-1500 m/min.

MillingMillingUse single point tungsten carbide tipped fly cutters or alternatively staggered tooth cutters.

Cutting Speed 500 m/min

Tool relief angle 5° to 10°Tool rake angle 0° to 5°

Updated Nov 29 2002

For information and quotes, e-mail [email protected] Africa (011) 616 11 11 Rest of world +27 11 616 44 44

Home | Contact us | Site map | Search | Enquiry form | Copyright | Privacy | Webstore

Toll free/Linea gratuitaAustralia 1800 833 448Brasil 0800 891 87 16Canada 1 866 682 3484

FaxAustralia +61 386 485 671

Canada (416) 352 15 27Canada 1 866 682 3484Chile (2) 570 3855Germany 0443 1892 3899Hong Kong 800 930 211Ireland 1800 552 711Netherlands 08000 223 805New Zealand 0800 450 878Portugal 800 827 007UAE 800 027 01 03UK 0800 731 9745 / 020 3239 9044USA (7-3EST) 1 866 635 75 96 / (713) 574-7255

Canada (416) 352 15 27

UK 0207 681 3444USA (212) 937 3184

6 of 7 5/12/2012 12:59 PM

©2012 Vesco Plastics Sales, Pty Ltd. All rights reserved. Content of this site may not be copied or redistributed without

the express written consent of Vesco Plastics Sales, Pty Ltd. Warranty disclaimer

Machining guidelines for Vesconite. http://www.vesconite.com/design/techinfo/mach_guides.htm

7 of 7 5/12/2012 12:59 PM