MA 4701 AY 15 S1 Aircraft Design - Course Activities and Planning

description

Transcript of MA 4701 AY 15 S1 Aircraft Design - Course Activities and Planning

-

MA 4701 Aircraft Design Page 1

MA 4701 Aircraft Design

Course Activities and Planning

Aircraft Design Project AY 2015 16 S1

Division of Aerospace Engineering

School of MAE

August 2015

-

MA 4701 Aircraft Design Page 2

Contents

1. Welcome to Aircraft Design Course 3

2. Teaching Plan Weeks 1 to 13 4

3. Reference Books and Material 5

4. Aircraft Design Project Request for Proposal (RFP) 6

5. Schedule for Aircraft Design Project Activities Weeks 2 to 13 14

6. Aircraft Design Project Activities - Weeks 2 & 3 20

7. Template and Guidelines for Phase 1 Presentation 23

8. Template and Guidelines for Phase 2 Presentation 24

9. Template and Guidelines for Final Report and Final Presentation 25

-

MA 4701 Aircraft Design Page 3

1. Welcome to Exciting Experience of Learning Aircraft Design

Dear Students,

In this course on Aircraft Design you will have an opportunity to apply and synthesise your

knowledge in many disciplines like Aerodynamics, Flight Mechanics, Controls,

Propulsion, Structures, Aircraft Systems and Costing. We will have some lectures to

supplement your background in some of these areas and prepare you to take up a Group Project

on Aircraft Design.

In pursuing the design project, you need to gather design information on successful aircrafts

belonging to similar category, take a close look at the customer requirements and applicable

airworthiness requirements of relevant class of aircraft, estimate takeoff mass, do preliminary

aircraft sizing and engine selection, carry out layout studies to arrive at 3 view drawing, relook

at the takeoff mass considering component and system mass break down, carry out aircraft mass

and CG balance calculations, obtain aircraft drag, lift & pitching moment characteristics, predict

aircraft performance, stability & control characteristics, prepare design compliance matrix and

finally do some cost analysis to help project USPs of the aircraft .

Apart from over all configuration design studies, each Group has also been assigned some

special topic and/or further design calculations, around the main design project, such as studies

on aircraft variants, aircraft system/s etc.

The whole range of activities outlined above has to be carried out iteratively and

accomplished within a time frame of 10 - 11 weeks, also making a few intermediate

presentations. This truly calls for well organised Group effort. The key to success will be to work

in a team with equitable task partitioning from the very beginning, also giving due attention to

periodic project documentation and sharing the same within the group. Hopefully this will give

you a feel for the Conceptual and Preliminary Design phases of Aircraft Design, and working in

a Group in a time bound manner.

We welcome you to this exciting experience of learning Aircraft Design through hands on

calculations in various disciplines.

Greetings and best wishes

Tonse G Pai

Aug 01, 2015 Sunil Joshi

-

MA 4701 Aircraft Design Page 4

2. Teaching Plan

Weeks 1 to 13*

1. Introduction, Aircraft Design Project RFP and Project Activity Schedule

2. Aircraft Mission Analysis and Take Off Weight Estimation

3. FAR Part 25 Performance Related Sections, Constraint Analysis and Aircraft Sizing

4. Aircraft Layout Location of Wing, Tail, Fin, Engine & Landing Gears

5. Some Successful Aircraft Designs Military Aircrafts and Special Aircrafts

6. Some Design Features of Transport Aircraft and UAV

7. Review of Drag Analysis and Balance Field Length

8. A Relook at various Mission Segments and Analysis

9. Component Mass Estimation, A/C Mass and CG Balance for range of Pay Load and Fuel

10. Trade Off between Range and Pay load

11. Aircraft Material Selection

12. Aircraft Cost Analysis

* Weeks 12 and 13 will be devoted to Final Report Submission and Presentations

-

MA 4701 Aircraft Design Page 5

3. Reference Books and Material

Reference Books Daniel Raymer, Aircraft Design: A Conceptual Approach, 5

th Edition (TL 671.2 R267, 2012)

Lloyd Jenkinson, Civil Jet Aircraft Design (TL 671.2 J52 c, 1999)

LM Nicolai and GT Carichner, Fundamentals of Aircraft and Airship Design (TL 671.2 N636,

2010)

Lloyd R Jenkinson, Aircraft Design Projects (TL 671.2 J 52, 2003)

Jan Roskam, Airplane Design, Part I Preliminary Design Sizing of Airplanes (TL 671.2 R821,

1985)

Denis Howe, Aircraft Conceptual Design Synthesis (TL 671.2 H855, 2000)

Steven A Brandt, Introduction to Aeronautics A Design Perspective (TL 671.2 I61i, 2004)

E Torenbeek, Advanced Aircraft Design: Conceptual Design, Technology and Optimization of Subsonic Civil Airplanes, 2013 (eBook accessible from NTU Library)

Documents and Web Pages 1. http://www.aoe.vt.edu/~mason/Mason_f/ModernAircraftDesignWHM.pdf

Modern Aircraft Design Techniques, WH Mason (2003), Virginia Tech University,.

Gives very good coverage on overall design process including Take Off Weight estimation and

Constraint analysis. Also gives several useful tables on Transport Aircraft Data including

Aircraft Geometry, Aerodynamics, Performance, Engines etc

2. http://www.aoe.vt.edu/~mason/Mason_f/SD1.html http://adg.stanford.edu/aa241/AircraftDesign.html

Aircraft Design Course Web pages, Virginia Tech and Stanford Universities

Excellent Source of Aircraft Design material for project. Also excellent class room lecture

material on Aircraft Design. Emphasis and coverage at VT by Mason is different and unique

3. http://www.dept.aoe.vt.edu/~mason/Mason_f/M96SC.html Landing Gear Integration in Aircraft Conceptual Design, ST Chai and WH Mason

Somewhat specialized report covering many design and analysis aspects of landing gear

including run way related issues

In every Group there will be some people interested in doing literature search, writing reports,

preparing presentation material, in addition to help carrying out design calculations, drawing lay

outs and 3 views etc. Please make use of above and other material available just a click away

from you, for your Aircraft Design Project and share the knowledge with your group and others.

-

MA 4701 Aircraft Design Page 6

4. Aircraft Design Project Request for Proposal (RFP)

4.1 Project Objective

The objective of this project is to design and present a configuration of a Transport Aircraft

capable of providing operators with efficiency of operations 15 - 20% better than current aircraft

in their respective category. Technologies available in 2020s should be considered.

4.2 Design Requirements and Constraints

4.2.1 Design Mission:

The design mission for this aircraft must be accomplished with full pay load as relevant eg.: Passengers, Baggage and Cargo. Annexure 1 gives Pay Load and Range for 10 different aircraft variants.

4.2.2 Aircraft Mission Profile:

Warm up and taxi to take off position typically with10 min idle power and take off with applicable full power

Climb/accelerate to intermediate/cruise altitude & Mach number in suitable segments. Take distance credit for climb/acceleration segments.

Cruise at relevant subsonic/transonic Mach number at constant altitude. Total climb plus cruise distance must equal to design range set by the customer. See Annexure - 1 for

Speed, Altitude and Range for different aircrafts. Include additional cruise segment of 1

hour for domestic flight or 10% cruise duration for international flight (whichever is

higher) for estimation of mission fuel.

Descend negligible or nominal fuel penalty and no distance credit

Land- negligible or nominal fuel penalty

Taxi with10 min idle power

4.2.3 Other Requirements

The cabin of Transport aircraft shall include a flight deck (cockpit) for two pilots, a passenger compartment (cabin) with stand-up headroom not less than 1.83 m (72 inches)

along the aisle and over head baggage compartments on both sides of the aisle/s.

-

MA 4701 Aircraft Design Page 7

The Transport Aircraft cockpit must have two flight crew stations in a side by side arrangement. For aircraft with mission time exceeding 8 9 hours, it is necessary to accommodate spare team of flight crew in the passenger cabin

Full passenger capacity with single class/mixed class seating as specified for Transport Aircraft (Annexure - 1)

At maximum landing mass, the aircraft approach speed must be 150 Knots. The maximum landing mass must be not greater than 80% of the maximum design takeoff

mass (from the considerations of loads on landing gear)

Cabin Pressure for Transport Aircraft shall provide an equivalent altitude of 8000 ft., including in the baggage compartment for mission time of 9 hours or less and 5500 ft for

longer mission duration..

Baggage compartment below the passenger cabin must be big enough to accommodate passenger/crew baggage (23 Kg or 0.25 m

3 for economy class Pax and higher baggage

allowance as applicable for higher class of Pax) and 30% in excess of this for

accommodating nominal freight (perishable/courier packages) and Pax excess baggage.

In case of Combi (Passenger + Cargo) configuration additional volume may have to be

provided for cargo at cabin level. For passenger baggage and cargo, the containers and

pallets of standard sizes shall be used. Assume cargo density applicable for cargo mix of

perishable (~ 30%) and heavy machinery (70%).

Maximum operating altitude is as specified for different aircrafts in Annexure - 1

Maneuvering load factors for Transport Aircraft : +2.5 g and -1.0 g

Aircraft shall be designed to meet FAR Part 25 requirements or equivalent

The aircraft shall have a maximum cruise Mach number (< Drag Divergence Mach number) as specified in Annexure - 1

4.2.4 Safety Constraints:

For refused landing and diversion to alternate airport provide fuel reserves for 200 Nm cruise plus 30 minutes loiter at 15000 ft. Assume that the aircraft in its descent path gets

the diversion signal from Air Traffic Controller, at 3000 ft altitude and climbs to 15000 ft

before cruising 200 Nm to alternate airport..

The aircraft must have an FAA balanced field length as specified at 4000 ft ISA.

For multi-engine aircraft the second segment climb gradient (CGR) capability with one engine inoperative (OEI) shall be greater than 2.8%. Conditions for second segment

climb are landing gear retracted and wing flaps in takeoff position with Speed not less

than 1.2Vstall and Altitude of 400 ft above take off field altitude.

Other conditions are as specified in FAR 25.

4.2.5 Economic Constraints:

Production Cost estimates may be based on a production run of 500 aircraft.

Total flyaway cost, DOC and life cycle cost (LCC) are to be estimated.

-

MA 4701 Aircraft Design Page 8

DOC is a primary factor in selection. Efficiency of the design is to be optimized and specific design features applied to this end are to be described in the proposal.

Emphasis shall also be placed on minimizing airport turn-around times. Any special design features that address turn-around time shall be highlighted in the proposal.

4.2.6 Manufacturability:

The proposal may include some considerations or features that simplify manufacturability and assembly.

4. 2.7 Sustainability:

The proposal may include brief description of features of the aircraft design that maximize reliability, simplify maintenance, and minimize special ground support

equipment and airport turnaround time.

4. 2.8 Environmental:

The proposal must describe design features that minimize environmental impact as far as pollution and noise are concerned

4. 2.9 Recommended Weights for Pay Load Estimation:

Passenger/Crew 91 Kg per pax

Baggage Cabin Economy/Crew:10 Kg per pax

Business/First: 2 x 10 Kg per pax

Check in Economy/Crew: 23 Kg per pax

Business/First: 2 x 32 Kg per pax

4. 2.10 Recommended Seat Pitch:

Economy 30 to 32

Business 36 to 38

First Class 60 to 62

-

MA 4701 Aircraft Design Page 9

4.3 Aircraft Subsystems:

Broad specifications for conventional systems are given below. Alternative/advanced subsystems

are permitted with appropriate substantiation and assurances that they would be available within

the specified technology timeframe.

4.3.1 Landing Gear

Retractable gear shall be incorporated into the design

Gear must withstand with no damage, a 3 m/sec vertical velocity (approach glide of 3) at maximum permissible landing mass (80% of maximum TO mass).

Brakes must be capable of stopping the aircraft at maximum takeoff mass within specified balance field length (BFL).

Nose Landing gear must be positioned so that the aircraft possesses radius of turning circle not greater than 30 m

4.3.2 Hydraulic System

The system must be designed for operating pressures of at least 3000psi. Emergency pressurization of the hydraulic system shall be provided in case of primary system failure.

Burst testing of components shall exceed 2 times the operating pressure.

Emergency hydraulic power shall be sufficient to lower and lock the landing gear in down position as well as providing sufficient braking force for landing and ground taxi.

The hydraulic system shall provide sufficient power for 30 minutes of flight maneuvers to include one landing approach sequence.

4.3.3 Fuel System

The fuel system shall be capable of fuel jettison in an emergency situation to reach design landing weight within 3 minutes (optional)

The fuel system shall be both pressure and gravity refuelable. The former shall withstand pressures up to 50 psi.

The fuel system shall incorporate suitable gauges and display fuel quantities to the crew during refueling and in flight.

Shut off valves shall be incorporated to cut off supply of fuel to engine/s in the event of an engine fire.

The system shall allow crew to manage fuel distribution in the aircraft.

The fuel system shall have in-flight CG management system to limit the CG traverse and maintain static margin (SM) of 5 - 7%

-

MA 4701 Aircraft Design Page 10

5. Special Studies:

Different groups have been assigned some special topics for design studies which include

aircraft systems like hydraulic system, fuel system, landing gear, cockpit & avionics system etc

structural joints and lay out for integration of strut (brace) with fuselage & wing, engine pylon with wing, cargo loading doors with the fuselage etc.

aircraft variants to meet extended range and/or enhanced pay load, fully freighter version for the combi aircraft etc.

aircraft CG management for combi aircraft using partial PAX and cargo loads

These topics have been identified in Annexure 2A for different groups along with aircraft

pay load, range, speed and configuration lay out such as wing location (low wing or high

wing) engine location (wing or fuselage mounted) and special features like strut support

for wing (braced wing).

-

MA 4701 Aircraft Design Page 11

Annexure - 1

4.4 Aircraft Design Project - RFP

Performance Requirements

Aircraft Pay Load Speed/ Range/ Take Off/ Engine

Altitude Endurance Landing Type/

Distance Location

Medium Haul 130 150 Pax 0.75 - 0.85 M 3250 Km < 1600 m Turbofan/ Transport Two Class 10 to 12 Km Wing or

(MHT-1/MHT-2 Fuselage

MHT-3

Long Haul 325 420 Pax 0.86 - 0.89 M 12500 Km < 2600 m Turbofan/ Transport Mixed Class 11 to 13 Km Wing or

(LHT-1/LHT-2 Fuselage

LHT-3

Long Haul 220 320 Pax 0.86 - 0.89 M 12500 Km < 2600 m Turbofan/ Combi Mixed Class 11 to 13 Km Wing or

(LHC-1/LHC-2 Cargo 15 - 20 T Fuselage

LHC-3

Ultra Long Haul 650 820 Pax 0.89 - 0.92 M 15500 Km < 3000m Turbofan/ Transport Mixed Class 11 to 13 Km Wing

(UHT-1)

Ultra Long Haul 250 350 Pax 0.89 - 0.92 M 16000 Km < 3000m Turbofan/ Transport Mixed Class 11 to 13 Km Wing

(UHT-2)

Note:

A total of 11 configuration variants have been suggested for above four Aircraft requirements to

enable formation of 11 Student Projects (6 students each) with specific system related or design

studies added to each of the Student group.

-

MA 4701 Aircraft Design Page 12

Annexure 2A

4.5.1 Aircraft Design Project RFP

Aircraft Design Projects in 4 Categories of Transport Aircraft

Config. Configuration Engine/ Location Special Studies/Systems

Code

MHT1 Conventional Turbofan/Wing Hydraulic System MHT2 Conventional Turbofan/Fuselage Cockpit & Avionics System MHT3 Braced Wing Turbofan/Wing Blended Wing Body Variant

LHT-1 Conventional Turbofan/Wing Main and Nose Landing Gears

LHT2 Braced Wing Turbofan/Fuselage Brace joints with Fuselage and Wing LHT-3 Conventional Turbofan/Fuselage Engine Pylon and Wing joint

LHC1 Conventional Turbofan/Wing CG Mgmt with partial PAX & Cargo Loads LHC2 Conventional Turbofan/Fuselage Cargo Loading Doors Structural & System LHC-3 Braced Wing Turbofan/Fuselage Blended Wing-Body Freighter Variant

UHT-1 Conventional Turbofan/Wing Fuel System with CG Management

UHT-2 Conventional Turbofan/Wing Enhanced Pay Load Variant

-

MA 4701 Aircraft Design Page 13

Annexure 2B

4.5.2 Aircraft Design Project Allocations

Tutorial Group MA1

Project Config. Configuration Engine Location

No. Code

1. MHT1 Conventional Wing

2. MHT2 Conventional Fuselage

3. LHT1 Conventional Wing

4. LHT2 Braced Wing Fuselage

5. LHC1 Conventional Wing

6. LHC2 Conventional Fuselage

Tutorial Group MA2

7. MHT3 Braced Wing Wing

8. LHT-3 Conventional Fuselage

9. LHC-3 Braced Wing Fuselage

10. UHT- 2 Conventional Wing

11. UHT- 1 Conventional Wing

-

MA 4701 Aircraft Design Page 14

5 Schedule for Aircraft Design Project Activities Weeks 2 - 13

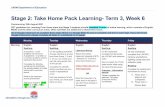

5.1 Phase 1 - Weeks 2 to 6 (Aug 17 to Sep 18, 2015)*

1. Study of RFP, Aircraft Mission Profile and relevant sections of regulation document (FAR Part 25). Collection of Statistical Data of similar Aircraft. Short list 2 - 3 aircrafts falling under the category of transport aircraft (pay load & range) in your RFP. As you

proceed with the design, choose one of these as Reference Aircraft for further design

comparison studies.

2. Study typical aircraft cabin layout of successful designs or your reference aircraft for providing for doors including emergency exits, galleys, toilets, stairs to upper deck etc.

where applicable. Finalise cabin dimensions (floor width and cabin length) and layout for

accommodating number of passengers (economy/executive/first class) with twin/single

aisle(s) in single/double deck(s) allowing for necessary galley space (front/central/rear),

doors (entry/exit/emergency) and toilets, using applicable seat pitch and width for

different classes. Cabin layout studies to be carried out for both single class and mixed

class seating and longer cabin length of the two is to be adopted. For Combi aircraft

please see Para 5 below for additional considerations in finalising the cabin length

3. Finalise fuselage cross section considering cabin width, overhead cabin baggage compartment, head room above aisle(s) for single/double deck(s), cross section of cargo

bay or baggage compartment below the passenger cabin floor/lower deck accommodating

baggage/cargo container(s) of standard dimensions, side by side as the case may be. In

arriving at outer contour of the fuselage add 0.1 to 0.125 m. for fuselage bulk head and

skin and similar thickness for floor structure.

4. Finalise overall fuselage length and geometry by adding suitable segments for Flight Deck/Cockpit in front and empennage (HT and Fin) in aft end, maintaining smooth cross

sectional area distribution from fuselage nose to after body. The fuselage should have

nearly closed aft end with very small base area. For Combi aircraft please next Para 5

applicable for determining cabin length.

5. In case of Combi aircraft choose appropriate container(s) (cross section, length, and volume and load capacity) and estimate the number of containers required to

accommodate passenger baggage and Cargo, assuming appropriate cargo density for

mixed kind of cargo. By adopting side by side lay out for the containers in the baggage

hold or cargo bay, estimate the length of cargo bay required to accommodate these

---------------------------------------------------------------------------------------------------------------------

*for further elaboration of Week 2 & 3 activities see Sec 6 on pp 20 - 22

-

MA 4701 Aircraft Design Page 15

containers. If cargo bay length works out to be longer than the cabin length estimated in

Para 2 above for passenger seats and other amenities, take the average of passenger cabin

length and cargo bay length as revised cargo bay length, if necessary by marginally

increasing the same to accommodate an integer number of containers. The remaining

containers not accommodated in the cargo bay have to be accommodated in the extended

passenger cabin, by using appropriate container/s which fit/s in passenger cabin cross

section, with minor increase in length.

6. Estimate aircraft pay load or useful load considering passenger capacity (RFP),

flight/cabin crew, cabin/check-in baggage allowances, cabin amenities for

passengers/crew (food, beverages, reading material, life jacket, entertainment etc),

additional passenger baggage, cargo (in case of Combi) etc as applicable.

7. Considering technologies of 2020s, in the areas of Aerodynamics (low drag airfoil and

large AR), Flight Controls, Structures, Materials, Manufacturing, Engine etc to get 15

20% performance improvements, assume suitable (L/D)max (from present day value of 17

to possible maximum value of 23 for blended wing- body configuration) and Structural

Technology factor KS (0.75 for aircraft with 50% composites to 0.85 for aircraft with

nominal composites), and thrust specific fuel consumption (TSFC) for the engine (10 to

15% lower than the contemporary value).

8. Estimation of mission fuel mass fraction considering major mission segments like

cruise/loiter including extra cruise time/distance, diversion to alternate airfield, hold up in

flight prior to landing etc., as applicable for aircraft mission (higher of the cruise

allowance: 10% range for international or 1 hour cruise for domestic operations). Make

suitable assumptions on weight fractions for takeoff, climb and descent segments, and

trapped fuel (1 to 2 %).

9. Estimation of aircraft gross take off mass based on aircraft pay load (Para 6), mission

fuel mass fraction (Para 8) and statistical correlation between aircraft empty mass and

take off mass (for all metal aircraft), considering Structural Technology factor KS

applicable for aircrafts of 2020s (0.75 to 0.85). Excepting for Ultra Long Haul Transport

(UHT) aircraft, Nicolai/Raymers correlation between empty mass and take off mass of

transport aircraft gives reasonable estimation of take off mass and empty mass for Long

Haul and Medium Haul aircraft (LHT, LHC and MHT). UHT group working on ultra -

long haul transport aircraft need to consider reference aircraft mass data - takeoff mass,

empty mass and fuel mass, towards finalising TO mass.

-

MA 4701 Aircraft Design Page 16

10. Draw Constraint Diagram for identifying feasible design space in W/S - T/W domain,

meeting the range of performance and safety requirements as design constraints for multi-

engine aircraft from civil aviation (FAR) or other requirements. Make suitable

assumptions on rolling friction coefficient for ground run, CLmax (for TO and landing),

number of engines etc. Select optimum values for W/S and T/W within the feasible

design space, with some built-in margin allowing for aircraft growth potential, catering

for marginally higher pay load and/or range for possible design variants of your aircraft

(larger wing or lower W/S and larger engine or larger T/W).

11. Aircraft Sizing: Using max gross takeoff weight (Para 9) and optimum values chosen for

wing loading W/S and thrust to weight ratio T/W (Para 10), estimate wing area S and

engine thrust T (total thrust of all the engines)

12. Wing Design: Choose wing planform parameters - sweep (for higher Mcrit), taper ratio

(for efficient aerodynamic loading and structure), aspect ratio AR (braced wing, stiffer

structure vis-a-vis low CDi), high lift devices (CLmax for low landing speed and distance)

and winglets (drag reduction). These values (, AR, ) may be chosen in the range of

values corresponding to successful transport aircraft or your reference aircraft. The wing

sweep normally refers to quarter chord sweep.

Select wing airfoil thickness ratio (t/c: 12 to 15% for fuel volume and efficient structure)

and type of airfoil (laminar supercritical airfoil with sufficiently large Mcr and low Cd0)

towards realising the targeted value of cruise Mach number (below the Mcrit of the wing

considering sweep ) and with min profile drag (Cd0) or efficient (L/D) (see Para 7).

Calculate wing span b using the wing area S obtained in aircraft sizing (Para 11) and AR

chosen. Using S, b, , calculate wing tip and root chords, Ct and Cr. With this, wing

planform may be drawn and wing can be initially located with its root apex about 40%

behind the fuselage length. Choose the wing mounting location on the fuselage to be low

or mid or high. For braced wing only high wing configuration is possible maintaining

upper wing surface clean. Calculate the mean aerodynamic chord (MAC) of the wing.

13. Estimate available fuel volume in the wing assuming fuel tanks to be extended from front

spar (20% chord line) to rear spar (65 - 70% chord line) and from wing root to station

70% of semi span outboard, and configuring available fuel volume into 2 or 3 (inboard,

midboard and outboard) wing tanks on each side. The net volume available for fuel is

about 65 to 70% of geometric volume within the wing, allowing for volume occupied by

the structural components like spar, ribs, stringers etc. Estimate fuel mass & CG for wing

tanks full and check for adequacy of wing fuel volume vis--vis mission fuel with

allowances (10 15%) made for aircraft growth potential (longer range) and for possible

Pay Load Vs Range trade off options. If wing fuel tank is not adequate for

-

MA 4701 Aircraft Design Page 17

accommodating mission fuel, include a fuel tank in rear fuselage. (Fuselage fuel tank is

normally avoided for transport aircraft.)

14. HT and Fin Sizing: Select ratio of HT area with Wing area ( 0.25 to 0.3), ratio of Fin area

with Wing area ( 0.2 to 0.25), airfoil sections (symmetric), t/c ratio (10 12%) and

planform parameters , AR, of HT and Fin from statistical data of similar aircraft.

Finalise horizontal and vertical location of HT and Fin with respect to the wing. HT is

always located above the wing plane, mounted between the Fin root and the Fin tip. HT

located at Fin tip is known as T tail. Draw a preliminary 3 View drawing of Aircraft,

reflecting relative locations of Wing, HT and Fin with each other. Calculate the tail

volume coefficient and fin volume coefficient and compare the same with reference

aircraft value.

15. Engine Selection: Based on engine thrust T estimated above (Para 11) for the multi-

engine layout (twin or four) chosen, select an engine from off the shelf successful engines

meeting the thrust requirements (within 10 to 15%) and TSFC targeted in Para 7,

considering the technologies of 2020s. Get the engine geometry (dia and length), mass

and sea level performance data (T and TSFC) for the chosen engine. Also collect the

engine data (if available) on variation of the thrust with altitude and TSFC with altitude.

16. Complete the 3 view drawing of the aircraft by locating the engines either on the wings or

on the rear fuselage (as per the location suggested for your project) and accordingly the

main and nose landing gears. In case of fuselage mounted engines make sure to locate the

engine such that wing wake is not ingested in the engine. In case of braced wing

configuration with fuselage mounted engine, also ensure that the wake of the brace as

well as the wing is not ingested in the engine.

17. Studies on Special Topics (to be initiated in Phase 1 and continued in Phase 2): Collect

the data on the system(s) (eg.: Hydraulic System, Fuel System, Landing Gears, Flight

Control Systems, Cockpit & Avionics System, Engine Mounting Scheme etc) identified

under special studies for your group, from your reference aircraft or any other sources.

Also collect reference material for pursuing special studies (eg.: Blended Wing - Body

configuration, typical Structural Joints etc) identified for your group. For the identified

system, study the system architecture, functionalities and block diagram, major building

blocks like subsystems or components and possible system input/output and interface

with other aircraft systems. In these studies only description of one of the existing

systems adoptable to your aircraft need be addressed. Sizing studies or design

calculations are optional. In case of Blended Wing Body variant identified for a few

groups, cabin lay out studies may be initiated based on passenger seating with amenities

in a triangular planform of leading edge sweep back of 30 to 45 considering passenger

entry/emergency evacuation, and also the layout of cargo compartment below the

DeuniqueHighlight

DeuniqueHighlight

DeuniqueHighlight

DeuniqueHighlight

-

MA 4701 Aircraft Design Page 18

passenger cabin considering landing gear location, cargo loading/unloading, engine

mounting at wing trailing edge (top or bottom) etc. Depending on the available time, any

quantitative design studies like preliminary sizing of the airframe, takeoff weight

estimation, simple aerodynamic calculations (L/D = 22 to 23), T/W etc may be

attempted. For studies on CG management with partial PAX and Cargo for Combi

aircraft see Para 23.

18. Group Presentations on Ph 1 activities - Week 6 : Sep 14 and 16, 2015 (20 min) PPT File to be submitted a day prior to presentations.

5.2 Phase 2 - Weeks 7 to 10 (Sep 21 to Oct 23, 2015)

19. Aircraft Data for Performance and Mission Analysis: Estimation of Aircraft Drag using

component drag approach (CD0, k), compilation of data on Engine thrust T & thrust

specific fuel consumption TSFC variation with altitude based on the engine data at sea

level and take off mass

20. Relook at the mission fuel considering updated (L/D) and TSFC data and realistic flight

segments for takeoff, acceleration, constant speed climb, cruise, deceleration and descent.

Revisit of constraint diagram for fine tuning/confirming optimum W/S and T/W values

(in Para 10).

21. Estimation of aircraft systems and structural component mass landing gear, propulsion

system, Wing, HT, Fin, Fuselage, etc. using statistical data from all metallic aircraft and

applying appropriate Technology Factor (0.75 to 0.85). Use of component mass data for

checking/updating/reconciling aircraft empty mass from Para 9. Please note that there is

NO change in Pay load already estimated earlier..

22. Relook at Aircraft Take off Mass based on realistic mission fuel (Para 20) and empty

mass (Para 21) and finalization of Take off Mass, revision in empty mass and aircraft CG

for revised empty mass case.

23. Aircraft Mass and CG balance for a range of pay load and fuel conditions based on

component mass, system mass and revised mission fuel mass (Para 22). Wings may have

to be relocated (aft or forward position) to limit CG travel requirement/Static Margin

(Para 27). In case of Combi aircraft composite CG management considers several

operationally feasible flight combinations with partial payload, partial cargo and partial

fuel to limit the CG traverse and maintain SM within 5 7%

-

MA 4701 Aircraft Design Page 19

24. Aircraft Performance: Flight envelope, Cruise, Range, Endurance, Climb, Take off/

Landing, Balance Field Length (at SL and 4000 ft) and Climb gradient for one engine

inoperative (OEI) case for multi-engine aircraft as per FAR.

25. Overall design compliance matrix - Aircraft performance and safety (FAR).

26. Trade off between Range and Pay Load leading to options of aircraft variants

27. Aircraft Stability & Control Analysis: Longitudinal and Directional analysis. Static

Margin (SM) for range of CG operations. HT setting for CL > 0 flights. Longitudinal

Controllability for forward most CG and CLmax, Elevator deflection (preferably zero) for

cruise. Directional controls for Engine failure case and cross wind landing or take off

28. Aircraft Costing: Initial look at formulation of costing of DOC, fly away cost and Life

Cycle Cost.

29. Group Presentations on Ph. 2 activities Week 10: Oct 19 & 21, 2015 (20 min) PPT File to be submitted a day prior to the presentation.

5.3 Phase 3- Weeks 11 to 13 (Oct 26 Nov 13, 2015)

30. Special Studies and System: Depending on activities pursued in Phase 2 and time

available, these activities may be continued as discussed in Para 18

31. Aircraft Cost Analysis Fly away cost, Direct and Indirect operating cost, Life cycle cost

32. Final Project Report Submission (Week 12) : Nov 04, 2015, Wednesday, 5 pm

One Hard Copy (both sides printed, coloured) to be submitted

Soft copy is to be uploaded in NTULearn.

Main Report size is to be limited to approx 80 pages (A4) including figures.

Use Times Roman, Font size 12, 1 line spacing, 20 mm border all round

Appendices may include some details from Phase 1 & 2.

All material and figures reproduced in the report should be properly referenced

33. Final Project Presentations 45 min (Week 13): Nov 9, 11 and 13, 2015

PPT File to be submitted/uploaded in NTULearn a day prior to the presentation

-

MA 4701 Aircraft Design Page 20

6 Aircraft Design Project Activities in Weeks 2 and 3

(Aug 17 to 28, 2015)

The first two weeks activities are further elaborated here within overall scope of Phase 1

1. Statistical Data for 2 3 Transport Aircrafts:

Collect as much data as available for 23 aircrafts broadly falling in the category of your project including

Range/ payload, cruise speed/ altitude, take off and landing distance/speed etc.,

Gross takeoff weight, payload, fuel, empty weight, equipment weight etc.,

Geometrical details like aircraft length, span, aspect ratio, wing/tail/fin areas,

Control surface areas (ailerons, elevators, rudder) and range of control deflections

High lift devices, Winglets, etc.

Engines, sea level thrust, TSFC, size (dia & length), weight, location etc.

A detailed list is given in Annexure 1 to this. Please note Braced Wing configuration is

futuristic one and for design project with braced wing configuration, collect statistical

data for aircraft with similar pay load, range, cruise speed and altitude.

2. FAR Part 25 Airworthiness Standards (for Transport Aircraft): Study of FAR pertaining

to Transport Category Airplanes: relevant to second segment climb gradient, balance

field length, engine failure case, climb following diversion to alternate airport etc which

are converted as design constraints in the constraint analysis to follow

3. Aircraft Mission Profile and Estimation of Mission Fuel: From the RFP prepare a specific

mission profile applicable to your aircraft and carry out mission fuel weight fraction

estimation making suitable assumptions on weight fraction for takeoff, climb, descent

and landing segments and also on aircraft L/D and engine TSFC for cruise/loiter

segments including for diversion.

4. Study of Cabin Lay out, Baggage Compartment and Cross Section of Fuselage

considering seat width, seat pitch, head room, cabin baggage compartment, storage space,

galleys, doors, emergency exits, toilets, crew seating, standard baggage container and

pallet dimensions, baggage loading and access doors etc

5. Fuselage cross section considering the interior dimension of the cabin, baggage/cargo

compartment below the floor and fuselage structure bulkhead / skin and floor structure

-

MA 4701 Aircraft Design Page 21

6. Estimation of Aircraft Pay Load or Useful Load: Passengers & Crew; Cabin/Check-in

baggage; Cabin amenities for Passengers and Crew; Additional Passenger baggage;

Cargo (in case of Combi)

7. Overall Plan of action for the project for Phase 1 and Phase 2

8. Finalise a Project Title or Aircraft Name for your Aircraft Design Project (Optional)

-

MA 4701 Aircraft Design Page 22

Annexure 1

6.1 Detailed List of Aircraft Parameters

Range, Pay Load, Take off/Landing Distance, Cruise Altitude and Speed, Max speed, Service

Ceiling, Climb Rate etc.

Take off Mass, Pay Load, Empty Mass, Fuel Mass, Structural Mass, Break up of System Mass

Wing Location (high/mid/low), Location from fuselage nose, Span, Area, Root and Tip Chords,

Mean Aerodynamic Chord, Aspect Ratio, Taper Ratio, Sweep, Airfoil, Airfoil Thickness Ratio at

the Root and Tip, Type of Wing Structure (wing with or without fuel tank), Fuel Capacity in

Wing, Engine Mounts on Wing, Wing Fuselage Faring, Leading Edge Devices like Slat, Type of Slat, Slat Geometry Span/Chord/Area/Deflection, Type of Trailing Edge Flap, Flap Geometry Span/Chord/Area/Deflections, BL Flow Control Devices, Winglet Geometry etc

Horizontal Tail: Location with respect to FRL/Wing/whether Fuselage or Fin mounted or T Tail.

Span, Area, Root and Tip Chord, Mean Aerodynamic Chord, Aspect Ratio, Taper Ratio, Sweep,

Airfoil, Airfoil Thickness Ratio at the root and tip; Elevator chord, span, area, deflection range.

Vertical Fin: Longitudinal location of Fin apex with respect to wing apex, Twin Fin or single

Fin, Span, Area, Root and Tip Chord, Mean Aerodynamic Chord, Aspect Ratio, Taper Ratio,

Sweep, Airfoil, Airfoil Thickness Ratio at the root and tip; rudder chord, span, area, deflection

range.

Fuselage: length, cross section elliptic/double bubble/circular, width/height/diameter, Seating capacity/seat pitch/ seat width/cabin lay out with number of seats abreast (for different class) ,

number of aisle/s and decks, passenger boarding doors, emergency doors, seats for cabin crew,

cabin baggage compartment, number of galleys/toilets and their location, volume of baggage

compartment, container size/standard designations, baggage doors and loading provision. Type

of Fuselage Structure,

Engine: number of engines, location, engine mounting details, pylon and nacelle, mass, SL thrust

and TSFC and variation of the same with altitude, length, diameter, company/designation,

engine T/W ratio.

Engine mounted hydraulic motors and electrical generators, Auxiliary Power Unit,

Fuel tanks, Location, capacity, Fuel system, Fuel gauging, Refuel point

Under carriage: Type, location of nose and main under carriage, type of retraction: forward or

rearward or sideward, under carriage bay. Wheel track and wheel base, radius of turning circle,

Tire diameter and type of brakes

Cockpit size and lay out.

Broad details of other aircraft systems: Avionics, Flight control system (FBW), Hydraulic

system, cabin cooling etc.

DeuniqueHighlight

-

MA 4701 Aircraft Design Page 23

7. Template and Guidelines for Phase 1 Presentations

(Sep 14 & 16, 2015)

7.1 Suggested Coverage of Group Presentation No of

Slides

1. Title Slide: Aircraft Project number/Project Name/Team Members 1

2. Outline of Presentation and Topics covered by each presenter for this phase 1

3. Aircraft Data (geometry & other) including 3 views/pictures of successful designs 2

4. Tabulated Aircraft Data with Analysis 1

5. Aircraft Specifications, Mission Profile and applicable Regulations: 2

6. Cabin Layout/ Baggage Compartment / Fuselage interior and external Geometry 2

7. Aircraft Pay Load and Mission Fuel Weight fraction (L/D, TSFC etc) 1

8. Take Off Weight Estimation 1

9. Constraint Analysis and Optimum (W/S), (T/W) 2

10. Aircraft Sizing : Wing Area S and Engine Thrust T 1

11. Wing Design: Planform S, b, AR, , , Airfoil, HLD, Ailerons and Winglet 1

12. Fuel Volume in Wing vis-a-vis Mission Fuel + allowances for growth 1

13. Horizontal Tail and Fin Geometry (S, b, AR, , , Airfoil, Elevator, Rudder) 1

14. Engine selection; Number of Engines, location, Thrust and SFC at SL 1

15. 3 View Drawing showing location of Engines and Landing Gears 1

16. Preliminary work on Special Topic 2

17. Plan of action for Weeks 7 to 10 activities/Task Partitioning in the Group 1

18. Summary/Conclusions: 1

7.2 General Guidelines for Phasewise Presentation

Total Time: 30 min

Presentation Time: 20 3 min

Q&A time: 7+ min

Entire Design Team is responsible for the Project and will participate in the presentation

Number of People to Present: 3 4 in each Phase (opportunity for every team member)

Each team member will participate equitably in coverage (time and/or number of slides)

Topics and number of slides are only indicative. Groups may follow their own formats

Busy slides with details may be just flashed and if necessary revisited during Q&A

Entire Project Group will participate in Q&A sessions of both the Phases

PPT soft copy should be sent in advance, a day prior to the presentation.

2 sets of hard copy with any update to be submitted prior to the presentation

-

MA 4701 Aircraft Design Page 24

8. Template and Guidelines for Phase 2 Presentations

(October 19 & 21, 2015)

8.1 Suggested Coverage of Group Presentation (As many topics as completed as of Week 9)

No of

Slides

1. Title Slide: Aircraft Project number/Project Name/Team Members: 1

2. Outline of Presentation and Topics covered by each presenter for this phase 1

3. Summary of Phase 1 presentations including actions identified for Phase 2 1

4. Aircraft Drag Estimation (component drag break up and summary) 2

5. Mission Analysis based on revised inputs on Drag and TSFC , Refined weight 3

fractions for mission segments like take off, climb (acceleration + constant speed

climb), cruise, loiter etc

6. Aircraft component mass estimation and relook at maximum take off mass 2

7. Aircraft mass Table for empty mass, operational empty mass, zero fuel mass etc 1

including Reference Aircraft data

8. Aircraft Mass & CG balance for a range of pay load (Pax & Cargo) & fuel cases 2

9. Performance estimation: Flight envelope, Take off/Landing distance, BFL, Climb 2

10. Stability & Control: Estimation of NP; SM for CG range. Long/ control CLmax trim 2

for forward most CG, Tail setting and elevator for cruise (if any)

11. Dir control adequacy - Cross wind TO / landing and Engine failure case 1

12. Aircraft variants and Pay Load Vs Range Trade off studies 1

13. Compliance matrix: FAR and RFP (Pay Load, Range, Performance etc) 2

14. Special Topic & Costing 2

15. Proposed coverage or Content Page(s) of Final Report 1

8.2 General Guidelines for Phasewise Presentation

Total Time: 30 min

Presentation: 20 3 min

Q&A time: 7+ min

Entire Design Team is responsible for the Project and will participate in the presentation

Number of People to Present: 3 4 in each Phase (opportunity for every team member)

Each team member will participate equitably in coverage (time and/or number of slides)

Topics and number of slides are only indicative. Groups may follow their own formats

Busy slides with details may be just flashed and if necessary revisited in Q&A session

Entire Project Group will participate in Q&A sessions of both the Phases

PPT soft copy should be sent in advance, a day prior to the presentation.

2 sets of hard copy with any update to be submitted prior to the presentation

-

MA 4701 Aircraft Design Page 25

9. Template and Guidelines for

Aircraft Design Project Final Report and Final Presentation

9.1 Final Report Coverage

Executive Summary

Introduction

Analysis of RFP vis--vis reference aircraft

3 View Drawing of Aircraft

Design features of Aircraft Configuration

Constraint Analysis for optimum W/S and T/W

Gross Takeoff Weight, Pay Load, Fuel Weight, Structural Weight, Systems Weight and Engine

Weight break down (compare weight fraction with Reference Aircraft data)

Geometric parameters of Wing, Horizontal Tail, Vertical Tail, Fuselage and Engine

Lift and Drag Aerodynamic analysis of Aircraft, CD0, k, CL, CLmax with and without HLD

Engine features. Thrust and TSFC parameters at SL and altitudes

Aircraft Mass and CG balance for a range of Pay Load (Pax / Cargo) and Fuel conditions. Most

forward and aft CG vis--vis NP location

Aircraft Performance: Take off with full Pay Load, Balance Field Length at SL and 4000 ft,

Landing, Flight Envelope, Climb rates, Climb gradients for one engine failure case (FAR), Turn

rates, Mission Performance. Trade off between Range and Pay Load. AircraftVariants. Design

Compliance matrix Aircraft Performance parameters vis-a-vis RFP and FAR

Stability and Control Analysis: Neutral Point, Static Margin, Directional Stability, Control

Effectiveness and adequacy Elevator and Rudder for range of flight situations, Trimmability at CLmax with forward CG, Elevator deflection for cruise (preferably zero) and tail setting.

Directional control for cross wind takeoff/landing, Engine failure case.

Special Studies/Systems as Assigned and Applicable : Aircraft System Requirements/

Architecture/ Functionality/ Block Diagrams/Building Blocks or Components etc for Hydraulic,

Fuel, Flight Controls, Avionics Systems, Main and Nose Landing Gears, Cockpit Layout;

Structural Layout of joints Wing Brace Fuselage, Engine Pylon Wing or Fuselage, Cabin and Cargo Bay Layout for Wing- Body Configuration.

Aircraft Cost Analysis; Fly away cost; Direct Operating Cost (DOC) and Indirect Operating Cost

Summary / Conclusions / USPs of your Aircraft

References

Appendices

-

MA 4701 Aircraft Design Page 26

9.2 General Guidelines for Final Report

Follow the Template suggested above for Final Report coverage

Limit the Main Report size to approx 80 pages (A4) including figures.

Use Times Roman, Font size 12, 1 line spacing, 20 mm border all round

Include essential details from Phase 1 and 2 not covered in Main Report in Appendices

Material/figures reproduced from elsewhere should be properly acknowledged/ referenced

Submit 1 Hard Copy coloured (both sides printed)

Upload Soft Copy in NTULearn

9.3 Coverage of Final Presentation of Aircraft Design Project

First 2 - 3 slides:

Outline of the presentation

Task Partitioning and Scope of presentation of each Design Team Member

Summary of Phase 1, 2 & 3 results (follow final report coverage)

Use Tables, Figures, 3 Views, Pi charts, Bar charts, Plots etc. in giving final results.

Give comparison of your data with Reference Aircraft data - highlighting USPs of your design

Avoid reading busy slides.

Last 3 4 slides:

Design Compliance RFP & FAR

Summary, Conclusions, USPs of your Aircraft

General Guidelines

Entire Team should share the presentation equitably following suitable sequencing.

Total Time: 45 min

Presentation: 25 5min. (avoid videos)

Q & A: 15 5 min.

PPT soft copy should be sent/uploaded in NTULearn in advance, a day prior to the

presentation. 2 sets of hard copy with any update to be submitted prior to the presentation

Note: Pier Review also should be completed through NTULearn before the final

presentations

//End of Document//