m4 Sd Manual

-

Upload

griffin-armament-suppressors -

Category

Documents

-

view

216 -

download

0

Transcript of m4 Sd Manual

-

8/3/2019 m4 Sd Manual

1/2

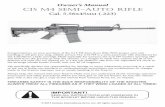

TM- M4-SDSound Suppressor

WARNING: FAILURE TO READ AND UNDERSTAND THIS MANUALPRIOR TO USE MAY RESULT IN INJURY OR DAMAGE TO

PROPERTY

Griffin Armament / Hearing Protection LLC.

Fire Schedule Guidelines: The M4-SD is constructed of highstrength materials, however, care needs to be taken to keep rate of fireconservative as temperature builds quickly in use. The recommendedmaximum rate of fire is no more than the mil-spec rate of fire for theM4 carbine which is 14 rounds per minute sustained. Do notquench/cool your heated silencer with water, ice, or snow.

Maintenance: Clean your suppressors mounting system and muzzledevice after every use to ensure surfaces are free of copper andcarbon fouling. Failure to clean the mounting system can result inyour M4-SD becoming stuck to the muzzle device on your weapon.No other maintenance is required with this silencer. If the silencer forwhatever reason becomes filled with water, shake out excess water inthe direction of the rear mount and store unit muzzle down to dry, orbake at 300F for 2 hours to dry at the earliest convenience. An OateyNo. 31328, 3/4 In. Heavy-Duty Inside Diameter Fitting Brush Model# 31328, can be used to cleam the mount surfaces inside thesuppressor. This brush is available for $2.20 currently at HomeDepot in the plumbing department, and can be purchased online fromother retailers. The brush has carbon steel bristles so residue left onthe 17-4PH Stainless mount by the brush may give the appearance ofvery light rust- Application of Hoppes number 9 or some othercleaner/protectant to the mounting bore between uses will preventthat, as well as help to loosen copper fouling. Dental pics can be usedto remove any copper deposits on the forward flash hider support.

FINISH: Operation at temperatures exceeding 1100F after firingseveral magazines rapidly, may damage your silencer, or its finish. Ifrefinishing is desired, rub the old loosened, heat affected paint off

with rubbing alcohol and a clean rag and apply the finish of yourchoice. We recommend 1200F grill paint. Use a light coat with thelocking gate down and silencer standing on the rear cap. Painting themount bore, locking gate, or locking gate pocket may result intolerance interference, rendering the unit inoperable till interferingcoating thickness is removed.

CAUTION: The M4-SD Silencer confronts the Impulse noise at themuzzle of your weapon and cannot account for the actions associatedoperating noise which will vary by weapon type and barrel length.For the highest level of hearing protection, wear hearing protection at

all times while using your silencer.WWW.GRIFFINARMAMENT.COM

Page 4 Page 1

-

8/3/2019 m4 Sd Manual

2/2

provide the best alignment and most insurance against baffle strikes.Do not use on muzzle devices mounted with split lock washers orcrush washers. Before the first use on each new weapon it isimperative the operator check suppressor alignment on that weapon.

Confirm Alignment: clear weapon in accordance with procedureslaid out in its user manual, remove the bolt. While allowing thesuppressor to hang unsupported from the muzzle device, look downthe suppressor bore with the front sight post in normal firingconfiguration (vertical above bore axis). Look parallel to the walls ofthe barrel on all sides to confirm that the suppressor bore is alignedwith the weapon bore and no element of the suppressor occludes anyside of the bore. Once a muzzle device is checked for compatibilityand properly mounted, it is then safe to use the suppressor on thatweapon in the future. In some cases alignment may be obviously outof true, due to production barrel thread inadequacies. In these cases asingle very thin [~.001 thick] shim from the peel washer can be cutin half using a scissors and used to force better alignment conditions tobe met. The procedure for that is as follows- loosen the compensator - turn, insert the half moon shim into the middle of the shimstack on the side of the suppressor exhibiting the most clearance andcarefully tighten the compensator confirming the shim remains in theproper location- re-torque the compensator to proper orientation andrecheck suppressor alignment. If alignment is now good, you havesuccessfully installed your compensator and now have a suppressorready weapon.

Suppressor Threading: Not all barrels are properly threaded. If anelement of the suppressor occludes a part of the bore after mountingwith a peel washer, or if you desire the most minimal POI shift andmaximum safety from baffle strikes or other issues, send your barrelto ADCO firearms in Ohio for barrel threading. ADCO firearms isHPLLCs recommended threading service provider. ADCO can befound on the web atwww.adcofirearms.com

To remove your M4-SD silencer, lift the spring plate .07, raise thegate and remove the silencer. Do not deflect the spring when thespring is too hot to touch. When your silencer is not in use, store thelocking gate in the full down position. Do not over-deflect thespring. Doing so may cause it to take a set. If this occurs, contactHearing Protection LLC to purchase a replacement.

Thankyou for purchasing an M4-SD silencer. Please read theseinstructions carefully prior to use. The M4-SD 5.56 soundsuppressor is rated for 5.56 NATO ammunition in barrel lengthsdown to 10.5 length. Barrels 14.5 or longer will provide maximumsuppressor wear life. 1/7 twist rifling is recommended.

Flash Suppressor compatibility: There is a broad spectrum ofNATO groove dimensions tolerated by the specifications of theA1/A2 muzzle device. In order for your flash suppressor to be ideallycompatible the rear groove will need to be 0.125-0.130 wide. Thatdimension will be accurate of most flash hiders. To testcompatibility, measure the groove with a caliper or ensure the lockinggate rises and falls into the groove with no resistance. If the groove isoutside that range you will need to purchase another $6-8 flash hiderand replace it. Do not force the locking gate into engagement. Ifresistance to disengagement is felt, use penetrating oil such as PBblaster to assist in dismounting. Do not force- pry, or beat on thelocking gate- The part is very hard and will break before it bends.

To mount your M4-SD silencer, deflect the spring plateapproximately 0.070 by pressing on the raised tab of the spring.This will unlock the latch plate which is then free to move. Lift thelatch plate to its full upright position. Insert the A1/A2 muzzleaccessory into the rear mount of the M4-SD to the stop. Align thelocking gate with one of the flats on the muzzle accessory and dropthe locking gate. The 45 degree angled surface on the gate will liftthe spring plate. Observe and confirm the spring plate has locked thegate in the full down position- the spring will audibly click as itengages. Attempt to rotate- do not use excessive force- this is just atest- if the locking gate spring is not locked, the suppressor will rotatefull circle. If the silencer does not rotate beyond a narrow zone, thesilencer is now properly mounted on the A1/A2 muzzle device. Firingthe suppressor with the locking gate unlocked will result in thesuppressor flying downrange this will be accompanied by aggressiverecoil which can injure the shooter if an object mounted to theweapon collides with the shooters face.

Compatible Muzzle devices: The M4SD was designed to bemounted to a standard issue A1 Birdcage flash suppressor or A2compensator. The Griffin Armament M4-SD Tactical Compensatoris also compatible. We recommend re-mounting muzzle devices witha peel washer and 30 foot pounds of torque. Peel washers will

Page 2 Page 3

http://www.adcofirearms.com/http://www.adcofirearms.com/http://www.adcofirearms.com/http://www.adcofirearms.com/