M Maaggnneettoo EEnnccyyccllooppeeddiiaaEEnnccyyccllooppeeddiiaa VOLUME 1 OF 2 968 pages plus...

Transcript of M Maaggnneettoo EEnnccyyccllooppeeddiiaaEEnnccyyccllooppeeddiiaa VOLUME 1 OF 2 968 pages plus...

CCoovveerriinngg oovveerr 220000 MMooddeellss

MAG-S-317Complied by

MMMMaaaaggggnnnneeeettttooooEEEEnnnnccccyyyyccccllllooooppppeeeeddddiiiiaaaa

VOLUME 1 OF 2

968 pages plus illustrations. Includes over 10 pages of Fundamentals and Physics.

AAmmeerriiccaann BBoosscchhAAppooll lloo CCaassee DDiixxiiee

EEiisseemmaannnn FFaaiirrbbaannkkss MMoorrssee

HHeennrriicckkss IInntteerrnnaattiioonnaall HHaarrvveesstteerr

International & McCormick-Deering

John Deere Applications by:Edison, Fairbanks-Morse, & Wico

K-W Ignition Co.Webster

WicoWizard

Model Listing on Inside Cover...

Warren D. Jensen

All rights reserved. No part of this book may bereproduced in any form whatsoever without writtenpermission from the copyright owner.Jensales Inc. • 200 Main St. • Manchester, MN 56007-5000www.jensales.com • 800-443-0625 • 507-826-3666

American Bosch:AT, BA, DU, FB, FO, FY, FY-2, MJA4/2,MJA4C, MJA6C, MJB4/2, MJB4A, MJB6A,MJC1B, MJC4/2, MJC4C, MJC6/2, MJC6C,MJK, MVA1A, MVA2A, U-4, ZEV, ZR.

Apollo:2-cylinder: 4/2 FR, 4/2 FL, 4/2 VL, 4/2 VR.4-cylinder: 4 FL, 4 FR, 4 MFL, 4 MFR,

4 MVL, 4 MVR, 4 VL, 4 VR.6-cylinder: 6 FL, 6 FR, 6 VL, 6 VR.

Case:4-CAMA, 4-CMA, 4-JMA, 41, 601,Robert Bosch FU4, Robert Bosch FU-4-A,Bosch FU-4-BR.

Dixie: 235 Oscillating.

Eisemann: RC-2Q, RT-2H, RT-4, RT-6, RT-2Q.

Fairbanks Morse: 273-E, FM-B2B6, FM-B2B6D, FM-B4B, FM-B4B11, FM-B4B11A, FM-B4B11B, FM-B4B3, FM-B4B3A, FM-B4B5, FM-B4B9,FM-E, FM-J4A, FM-J4B, FM-JH2B70, FM-X1-2B7, FM-X1A2, FM-X1A39A, FM-X1A52B, FM-X1A7, FM-X1A79, FM-X1A7E, FM-X1B2B, FM-X1B7E, FM-X2A, FM-X2A39B, FM-X4A, FM-X4B,FM-X4B16B, FM-X4B7A, FM-XAB2A, FM-XC1B7, FM-XC1B7D, FM-XCE1B7P, FM-XD1B7, FM-XD1B7D, FM-XDE1B7P, FM-XE1-2B7C, FM-XE1A7F, FM-XF2B7, FM-XOR, FM-XR, FM-XV4B7, FM-XV4B70,FM-XV4C73, FM-XVE4B7G, FM-XZE4B7,FM-ZV4B7, FM-ZVE4B7, RV 4-B, V.

Henricks: Comet J6, Comet J6X, Comet L, Comet LX, Comet M, Comet MX, Comet S6, Comet S6C, Comet S6X, Eureka BC-1, BC-2, D.C., LC, LD1, LD2, S, S4.

International Harvester: E4A, F-4, F-6, H-1, H-4, J-4, AH Wico, AP Wico, EK Wico, H Wico, Dixie and Aero Splitdorf

International & McCormick-Deering:Low Tension - Rotating: A, B, L, M, R. Oscillating: O, OL, U.

John Deere Applications by: Edison CD, RM. Fairbanks-Morse RV-2-A, Fairbanks-Morse RV-2-B. Wico AP477B, C.

K-W Ignition Co.:High Tension, Low Tension, A, AL, A-M, C-M, D, DL, E, EL, F, FL, H, HT, J, M, ML, O, OC, Special, U, UL.

Webster:JY, JZ, K, L, M, MM, PY.

Wico: AP-1, AP-2, AP-3, AP-4, AP-6, AP-G, AP-R,EK, FW-1718, FW-1781, Series C, XB-2, XB-4, XB-6, XH, XH-1, XH-2, XH-2D, XHD,XHD-1, XHD-2, XHD-4, XHD-6, XHG-2,XHG-4, XHG-6, XV-2, XV-2065, XV-4, XV-6 automatic adv., XV-6 minus auto-adv.

Wizard:Oscillating.

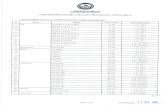

-Index-

Technical Information

II International Harvester Magnetos

III IHC Low Tension Magnetos

IV J.t. Case Magnetos Models 4-JMA, 4-CMA, 41

V J.I. Case Model 41 Magneto

VI J.t. Case Model 601 Magneto

VII J.t. Case Model FU-4-BR

VIII From here to end are Miscellaneous Magnetos

IX Apollo Magnetos

X American Bosch Magnetos

XI American Bosch MJB4A MJB6A

XII American Bosch MJC 1 B

XIII Dixie Magneto

XIV Eisemann Magnetos

XV John Deere Magnetos (Fairbanks Morse, WICa, Edison)

XVI Fairbanks Morse FM-X

XVII Fairbanks Morse FM-X1-2B7 FM-XE1-2B7C

XVIII Fairbanks Morse FM-ZV4B7 FM-ZVF4B7

XIX Fairbanks Morse FM-X4B7A

XX Fairbanks Morse FM-X4B7A FM-XZE4B7

XXI Fairbanks Morse 273-E Magneto for "Z" Engine

- Index -

XXII Fairbanks Morse Type RV Magneto

XXIII Fairbanks Morse FM-J4A, FM-J4B

XXIV Fairbanks Morse "Super Spark" Type FM Magneto

XXV Fairbanks Morse FM-X Magneto for Wisconsin

XXVI Fairbanks Morse For Wisconsin VE4, VF4, VP4D Engines

XXVII Henricks Magneto "Comet" Model

XXVIII Henricks Magneto Type S, S4, Comet M, LC, Eureka D.C.

XXIX Webster Magneto

XXX WICO Magneto for May tag

XXXI WICO Magneto XH & XHD

XXXII WICO Magneto XHG-4 for Kohler

XXXIII WICO Magneto Series AP

XXXIV WICO Magneto Series C

XXXV WICO Magneto Series XB

XXXVI WICO Magneto Series XV

XXXVII WICO Magneto Type EK

XXXVIII Wizard Magneto

11

"

(

\

. , ( \-----

. r-'~ f \ '-.--

,

INDEX

To facilitate finding the various section:J into which this Manual is divided,' black marks are printed on the margin of the first right-hand page in each sec tion. By bending. the Manual backward. these marks are exposed in line with the sections as listed on the margin 'of this page. A separate alphabetical index is listed for each section.

~[F~-~4~A~N~D __ F_-_6_I7N~T_E~R~N~A~·T~I~O~N~A~L~M~A~G~N~E~T~O~S ____ ~~ __________ AIIIIII Name . Page Name Page Name Page Name Page

Bearings .......................... 23 Removing .................... 12 'Shaft and Bearing •...... 19 Rotor •.......... : ............ 22. 23 Replacing .............. 13.14 Ground Connection .... 11. 14 Safety Gap ................ 11.16 Breaker:

Adjustment .................... 9 Cup .......................... 9.22 Point •...................... 9.21

Brushes ...................... 10.20

Coil: Identification .. : ........ : .. 13 In.talling .............. 11. 13

Testing .................. 11.12 S k PI 16 High Tension Lead.Out .... 14 par ug ................ .19

Condenser ...................... 15 Impulse Couplings: Special Feature ......... 17. 18 F·Type ................ 24 to 26 Teding: Cro .. Sectional Drawings .. 8

Distributor: Bl6ck ...................... 16. 22 Disc ...................... 10.19 Gears .......................... 17

E4A Type .......... ~6 to 30 Coil ........................ 12.13 Conden.er .................. 15

Magnet _ .................... 20.21 Primary Lead.Out

Primary Lead.Out Wire ........................ 11 Wire .•.....•.......... 11. 19 Timing to Engine ........ 23. 24

Name

~E~4~A~I~N~T~E=R~N~A~T~I~O~N~A~L~M~A~G~N~E~T~07-__ ~ ________ ~~~~ _______ 111111 Page Name Page Name Page Name . Page

. Armature: Brushes ............................. 32 . Impulse Coupling: Breaker ............•.......... ·.33· Removing .................... 33 Replacing .................••. 36

Bearings .................... 33.34 Breaker:

Adjustment .................. 32 T e.ting for Ground ...... 33

"BX" and "BH" . Coil ............................. 34.35 T . 36 38 Collector. ~ing ............ 35

. ype ....•......... to C d 35 Collector Ring ................ 35 E4A Type : .... : .... 26 to 30 on en.er ................. .

'Condenser ...•.•..........•. 35. 36. Safety Gap ............... : ...... 33 Coil .....•........••...•........ 34 Cross Sectional DrAwing: .. 31, Testing: Distributor ..........•....... 32 Distributor ....... ; .... :, .. :.~ ... 32' . Bearing : ................. 33, 34 Timing/to Engine ..•.• ; .•...... 36

!':ame

I H-4 AND H-l INTERNATIONAL MAGNETOS'_ ~~~~~~~~~~H~.~4~H;.;I~==~~~~~~~~~H;.-4~H7.~I~~~~~~~-------.7H7.~4~H7.~I------------------~ H.4·.H.1

Page Name Page Na.me • Page Name Page Bearings:

End Play ............. .48 58 Removal ............. .46 57 Impulse Coupling: Mounting Flange: .. Testing ........•...... .46 57 Markin.gs .........••• 55 57 Removal ....••.•. ~ .•. .48· 58

Removal ............. .49 58 Replacement ....... .49 58

Breaker: Adjustment ......... .42 56 Auembling ......... .43 56 Greasing ............. .43 56 Inspection ..... .41.42 56

Breaker Cam: Removal ....... .49. 50 59 Replacement ........ 50 59 Timing .......... 50.51 59

Condenser: Removal .....•.. 53, 54 57 Oil Seal .•.••..... ; .... .47 58 P . W' 47 57 Replacement .•.....• 54 57 Rotor Shaft.' • nmary Ire ...... S . 54 57 Removal ............. .45 57 pring .........•......•. Magnet ..•..•......... .48 58.' Testing ............... .46 57 Magneto: Oil Seal ...•....•.... .47 58'

Circuit ................ .40 56 .Removal· ............• .47 58' Cross Sectional Cover .•............... .45 57

Drawing ......... ,39 General .....•.......... 39 56 Testing: Magnet ...•.•......... .49 58 Coil ...••....•.........•. .46 57

Distributor:- Markings .............. 55 56 Condenser ...•..... .46 ,57 Cap ..................... .41 Reversal .............. 55 Distributor .......... 52 Rotor ............ 52. 53 End Play ....... _ .... .48 58 Spindle ................ 52 Marking.: Timing ....... ".~43. 51 59

Coil ......•............•. .47 Coil:

Assembling ... .45. 46 57 Core ................... .45 57 Markings ........... .47 57

Distributor Geara: Markings ............ 52 Oil Seals .............. 52 Removal .............. 51

Di.tributor Ti~ing: Spindle ...... 52, 55 Breaker .. ~ ............. 50 56

Impulse Coupling .. 55 58 '. Cam .................... 51 56 Magneto .............. 55..56 Distributor Gears 51

Primary Wire ....... .47 57 Timing ................ 51 Serial Numbers .... 54 . 56 Engine .....•..... .43. 44 59.

LI'~IH~·_'~A~N~D~·~'A~H~"~W~IC~O~M~A~G~N~E~T~O~S~~ ________ ~ ______ ~ ____ ...... Name Pace" Na:me Page Name Pagt: Name Page

Bearings .......................... 64 Renewal .....•.....•.......... 62 Cross Sectional Magnet ............................ 66·

Breaker: Coil .......................... 64. 65 Drawing ......•..... 60. 61 Rotor .......•...........•.... 63. 64 ~ Adjustment ............ 61.62 Condenser ~ ..................... 62 Impuls .. Coupling ..•..• 62.63 Timing to uL~" Engine .... S7

LI'~IE=K~·_'~W~I~C~O~M~A~G~N~E~T~O~· ______ ~--~--------~--~------~-Name Pa~e Name Page Name Page Name Pa~c

Breaker Points ................ 67 Coil-Teating .... .,: ..... : ... : .•. 68 Condenser. Testing' ......... :·68 Charging Magneto ....•.•... 68 ~~~~~~~~~~~~~~~~~--~~~--"AP" WICO MAGNETO :-..lame Pave Page

Bearings ......................... 74 Cam Stud ........................ 74 Coil ............................ 71.72

Breaker: Condenser ........................ 71

Name

Magneto: Page Name Page

Mounting Flange .............. 73

Circuit ....................... 69 Testing: Cover .......................... 71 Coil .............................. 71

Croll Sectional Drawing .. 69 End Plate ...................... 73 Condenser .................. i 1 Cam ............................ 73 Distributor ...................... 70 General ........................ 69 Timing: . G 3 Arm ............................ 70

Plate ............ '" ............ 72 Distributor Geara ........ 72.73 Lubrication .................. 69 . Distributor ears .......... 7 Magnet ........................ 74 End Plate .................... 73

Points ........................ 70 Impulle Coupling ........ 72. 73 Stop Button ............... 74 Engine ......................... 69

~[D~IX __ IE~A=N==D-=A~E~R~O-=S~P=L~IT~D~O~R~F~M~A~G~N~E~T~O~S~ ______ ~ __________ ~1111111 ~ame Pag~ N.ame Page (\;ame Page Name Paa:e

Breaker Point ................. 75 Coil ............................... 76 Diltributor ................ 75 Rotor ............................ 77 Brushes ...... 75 Condenler ...................... 76 MAgnet •. Rech"r~inli:' ........ 76 Safety. CAP Prote<:tor ....... 77

TABLE OF CONTENTS

rNTRODUCTro~

DESCRIPTIO~ OF ~vIODEL 41 )IAC;-rETO. Rotation of :vlagneto Rotol". Type of ~rounting. Impulse .. Rotol" .. Points and Cam. Fl"ame .. Spark Intensity ... . Weatherproof.. ....... . . ........... .

PREPARING :\WDEL 41 MAG::-JETO FOR INSTALLATION ON OTHER THAN CASE ENGINES.

Page ... 1

3 3 3 3 4

4

'" 4 4

. ............. 4

INSTALLING AND TI1I'IING MODEL 41 MAGNETO ON CASE ENGINES. 5 . Mounting Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 7 Automatic Spark Advance. ............................................... 7 Impulse Coupling Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 8 Impulse Coupling Selector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 9 Installing and Timing Model 41 Magneto on Case Tractors and Engines ....... 10

SERVICING THE MODEL 41 MAGNETO IN THE FIELD .................... 13 Checking Impulse Coupling Operation ....................................... 15 Checking Ignition Spark Intensity .......................................... 16 Checking ~Jagneto Timing with Engine ..................................... 16 Distributor Cap .......................................................... 16 Distributor Disc .......................................................... 17 Breaker Points and Cam. . . ............................................ 18 Field Service Suggestions .................................................. 19

SHOP EQUIPMENT AND SPECIAL TOOLS ................................... 21 S ynchroscope ............................................................. 23 Ivlagnet Charger .......................................................... 23 Coil Tester ............................................................... 24 Condenser Tester ......................................................... 24 Arbor Press .............................................................. 25 Degreasing Fluid. . . . . . . . . . . . . . . .. . ...................................... 25 Special Tools. . . . . . . . . . . . . .. .... . . . . . . . . ...................... 25 Repair Parts for Special Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ......... 26

REPAIRI)JG THE ?vWDEL 41 }IAGNETO IN A MAGNETO SERVICE SHOP ............................................................ 27

Suggested ~raximum Charge for Overhauling Model 41 ~Tagneto .. Preliminary Testing of ~1agneto ...... . Disassembling ~'Iagneto . . ...... . Assembling ~Jagneto ..

ALPHABETICAL INDEX. WARRA~TY .

2

. ... 29 . .......... 30

. .. 34

. .. 43 . .... 53

. ..... ;);)

I I I r <

r

I (

[

l

l l I [

\ ,

INDEX

Arbor Press.

Assembling :Vlagneto ... 43

Bearing .-\ssembly in Bearing Plate, InstalIinr- .. 45

Bearing Assembly in Frame, InstaIlinr ....... 4:3

Bearing Inner Race, Installing.

Bearing Plate Installation.

Bearing Plate Removal ..

Bearing Removal ..

Breaker Points ..

Breaker Point Adjustment ..

Breaker Point Installation

. ... 43

.46

. .38

.42

. .. 18

. .... 46

.... 46

Breaker Point Removal. .' ............... 37

Cam ....... . . ...... 37

Cam Installation .... . . .. .46

Cam Removal ..... . . .37

Carbon Brushes ..... . . ................. 17,35

Carbon Track Removal ....................... 17

Charging }Iagnets ............................ 48

Cleaning }Iagneto ............................ 30

Coil Installation ............................. 45

Coil Removal ................................ 38

Coil Tester .................................. 24

Condenser Installation .................... .4G, 47

Condenser Removal .......................... 38

Condenser Tester ............................. 24

Corroded Magneto ........................... 20

Degreasing F1uid ............................. 25

Description of ~Iagneto. .. ................... 3

Disassembling :Ylagneto. . . .................. 34

Distributor Cap. . . . . . . . . . . ............... 16

Distributor Cap Installation ................... 52

Distributor Cap Removal ..................... 35

Distributor Disc ............................. 17

Distributor Disc Installation. . . .51

Distributor Disc Removal. . . . . . . .36

Distributor Gear Drive Timing ....

Distributor Gear Installation ..

Distributor Gear Removal.

.37

. .. 51

. .... . .. .37

53

Page

Impulse Coupling .-\ssembly :.mcl Installation. ..48

Impulse Coupling, Checking Operation of. . . .15

Impulse Coupling Lubrication. . . . . . . . .. 49

Impulse Coupling Removal and Disassembly .... 39

Impulse Coupling Selector. 9

Lubrication, Distributor Disc Bearing

Lubrication, Impul.se Coupling.

Lubrication, Rotor Bearings.

:\Iagnet Charger ..... .

:\Iagnets, Charging the.

Preliminary Testing of :\Iagneto ...

51

')'., ......... _0

. ......... 48

. .:30

Removing Rust Preventive from Points ........ .47

Repairing Magneto in Service Shop. . . ... 27

Rotation, :Magneto Rotor. . . . . . . . . . . . . . . . . . . .. 3

Rotor Installation ........................... ,46

Rotor Removal. . . . . . . . . . . . .... . ... .41

Sales Slip, Customer's. . . . . . . . . . . . . . . . . . ..... 29

Sectional View of :\Iagneto . . . . . . . . . ... 34,

Service Charge, Recommended. . . . . . . . .... 29

Servicing }Iagneto in Field .................... 15

Service Suggestions, Field ..................... 19

Shop Equipment Required .................... 23

Spark Advance, Automatic. . . . . . . . . . . . . . . .. 7

Spark Intensity .............................. 16

Special Tools ................... .

Specifications, Impulse Coupling .. . 8

Specifications, Mounting. . . . . . . . . . . . . . . . . . . . .. j

Synchroscope. . . . . . . . . . . . . . . . ..... 23, 30

Table of Contents ...

Testing }Iagneto on Synchroscope.

Timing )'Iagneto on Case Engines ..

\Varranty ...

2

.30

.. 10

.. 55

INDEX

Page No.

ASSEMBLy ____________________________________________________________________________________________________ ---------------------------------------_________________________ 6-11

Bearings ____________________________________________________________________________________________________ ----------------------------------________________________ 6, 7

CoiL ________________________________________________________________________________________________________ ---------------------________________________________________ 8

Rotor Gear, Cams, Contact Points________________________________________________________________________________________________________________ 8, 9

Distributor Gear Timing___________________________________________________________________________________________________________________________________ 9

Stop Pin Plate _________________________________________________ --------------------------------------------------.--------------------------------------_________ 10

Charging the Magnets______________________________________________________________________________________________________________________________________ 10

Impulse Coupling______________________________________________________________________________________________________________________________________________ 11

DISASSEMBLy _________________________________________________________________________________________________ -__________________________________________________________ 3-5

Distributor Housing__________________________________________________________________________________________________________________________________________ 3

Distributor Block _________________________________________________ -____________________________________________________________________________________________ 4

Distributor Gear __________________________________________________ -------------------------------_______________________________________________________________ 4

Rotor Drive Gear and Cam ___________________________________________________ -------__________________________________________________________________ 5

Bearing Plate and CoiL ___ _____________________________ -___ --_ --- ______ -- ______ --- _____________ --___________ _______ _____________________ ___ ____ _____________ 5

Impulse Coupling______________________________________________________________________________________________________________________________________________ 5

Rotor Shaft and Bearings________________________________________________________________________________________________________________________________ 5

FEATURES _________________________________________________________________________________________________________________________________________________________________ _ 2

SPECIFICATIONS____________________________________________________________________________________________________________________________________ 2

WARRANTy ______________________________________________________________________________________________________________________________________________________ _ 12

1

Assembly

INSTALLING COIL

Before installing a coil that has been in service, check it on the coil tester.

Slip the coil into position in the magneto frame. Place the wedge type holders into position as shown m Figure 10, and tap them until the coil is securely locked against the laminated pole pieces.

Before assembling the distributor gear bearing plate set the secondary lead spring on coil to create a spring pressure on the carbon brush in the distributor shaft. This will assure good contact between spring and brush, and hold the shaft against the thrust bearing in the distributor block.

This should also be tested after distributor block is in place by pressing the gear towards the coil through the vent holes. Pressure of spring should force gear and shaft back against the thrust bearing in the distributor block.

TIGHT

SPRING ON COIL HOLDS DISTRIBUTOR SHAFT AGAINST THRUST IN DISTRIBUTOR BLOCK BEARING. SHOULD BE IN THIS POSITION BEFORE ASSEMBLING

BEARING

Figure 10. Installing Wedge Type Coil Holders

Finally, press the bearing plate (with bearing assembled) into position over cam end of rotor shaft and into the frame. Before installing rotor gear and cam, CHECK END PLAY OF ROTOR. END PLAY MUST BE BETWEEN .001" and .005". IF THESE TOLERANCE LIMITS ARE EXCEEDED, REMOVE BEARING PLATE, AND ADD OR REMOVE SHIMS TO ACHIEVE CORRECT END PLAY.

INSTALL ROTOR GEAR, CAM, AND CONTACT POINTS

,Assemble and adjust contact points. When installing breaker points use complete kit No. ls-48A. To adjust points, turn rotor shaft until cam lobe has raised the rub bar to its highest position. Use feeler gauge and set point gap at .008" to .012" as shown in Figure 11. Cam oiler should touch the cam lightly. Use SAE 70oil.._) Do not over oil the cam oiler.

8

All rights reserved. No part of this book may bereproduced in any form whatsoever without writtenpermission from the copyright owner.Jensales Inc. • 200 Main St. • Manchester, MN 56007-5000www.jensales.com • 800-443-0625 • 507-826-3666

American Bosch:AT, BA, DU, FB, FO, FY, FY-2, MJA4/2,MJA4C, MJA6C, MJB4/2, MJB4A, MJB6A,MJC1B, MJC4/2, MJC4C, MJC6/2, MJC6C,MJK, MVA1A, MVA2A, U-4, ZEV, ZR.

Apollo:2-cylinder: 4/2 FR, 4/2 FL, 4/2 VL, 4/2 VR.4-cylinder: 4 FL, 4 FR, 4 MFL, 4 MFR,

4 MVL, 4 MVR, 4 VL, 4 VR.6-cylinder: 6 FL, 6 FR, 6 VL, 6 VR.

Case:4-CAMA, 4-CMA, 4-JMA, 41, 601,Robert Bosch FU4, Robert Bosch FU-4-A,Bosch FU-4-BR.

Dixie: 235 Oscillating.

Eisemann: RC-2Q, RT-2H, RT-4, RT-6, RT-2Q.

Fairbanks Morse: 273-E, FM-B2B6, FM-B2B6D, FM-B4B, FM-B4B11, FM-B4B11A, FM-B4B11B, FM-B4B3, FM-B4B3A, FM-B4B5, FM-B4B9,FM-E, FM-J4A, FM-J4B, FM-JH2B70, FM-X1-2B7, FM-X1A2, FM-X1A39A, FM-X1A52B, FM-X1A7, FM-X1A79, FM-X1A7E, FM-X1B2B, FM-X1B7E, FM-X2A, FM-X2A39B, FM-X4A, FM-X4B,FM-X4B16B, FM-X4B7A, FM-XAB2A, FM-XC1B7, FM-XC1B7D, FM-XCE1B7P, FM-XD1B7, FM-XD1B7D, FM-XDE1B7P, FM-XE1-2B7C, FM-XE1A7F, FM-XF2B7, FM-XOR, FM-XR, FM-XV4B7, FM-XV4B70,FM-XV4C73, FM-XVE4B7G, FM-XZE4B7,FM-ZV4B7, FM-ZVE4B7, RV 4-B, V.

Henricks: Comet J6, Comet J6X, Comet L, Comet LX, Comet M, Comet MX, Comet S6, Comet S6C, Comet S6X, Eureka BC-1, BC-2, D.C., LC, LD1, LD2, S, S4.

International Harvester: E4A, F-4, F-6, H-1, H-4, J-4, AH Wico, AP Wico, EK Wico, H Wico, Dixie and Aero Splitdorf

International & McCormick-Deering:Low Tension - Rotating: A, B, L, M, R. Oscillating: O, OL, U.

John Deere Applications by: Edison CD, RM. Fairbanks-Morse RV-2-A, Fairbanks-Morse RV-2-B. Wico AP477B, C.

K-W Ignition Co.:High Tension, Low Tension, A, AL, A-M, C-M, D, DL, E, EL, F, FL, H, HT, J, M, ML, O, OC, Special, U, UL.

Webster:JY, JZ, K, L, M, MM, PY.

Wico: AP-1, AP-2, AP-3, AP-4, AP-6, AP-G, AP-R,EK, FW-1718, FW-1781, Series C, XB-2, XB-4, XB-6, XH, XH-1, XH-2, XH-2D, XHD,XHD-1, XHD-2, XHD-4, XHD-6, XHG-2,XHG-4, XHG-6, XV-2, XV-2065, XV-4, XV-6 automatic adv., XV-6 minus auto-adv.

Wizard:Oscillating.

American Bosch Automotive Manual Page 229/102

AMERICAN BOSCH CORPORATION, SPRINGFIELD, MASS., U. S. A.

errs instruction book will provide information in this regard--generally in terms of a mark on the flywheel.

B. Rotate the impulse coupling (5) by hand and thr'ough the window (9) in the distributor plate observe the movement of the rotating electrode (8) until it points to cable outlet No.1 as shown in Figure 3. This operation is best performed by turning the impulse coupling in the rotation OPPOSITE to that in which it will be driven by the engine, thus eliminating the engagement of the impulse coupling weights.

C. If paragraphs A and B above have been properly carried out, the impulse coupling drive tongues will engage the slot in the engine drive member when the magne~o is flanged into position. APPROXIMATE timing to the! engine is now obtained.

D. Tighten the flange fastening screws by hand but not to the extent that the magneto cannot be moved toward or away from the cylinder block.

E. Remove the distributor plate (7) by loosening the four screws. This will expose the interrupter (12).

F. To obtain the EXACT timing, the contact points (10) must just begin to open. It may be necessary in order to get that position to turn the magneto slightly toward or away from the cylinder block.

G. Re-insta11 the distributor plate and insert the cable between outlet No.1 and cylinder No.1 which is

r 3 then timed to fire correctly. Note that the rotating Ig. electrode (7) visible through the window (9) moves in

the direction of the arrow on the distributor plate (7), tberefore the cables leading from the distributor plate outlets in that direction must be connected with the cylinders according to their firing order. The firing order of an engine is generally marked on the cylinder block.

HOW TO CHANGE ROTATION OF MAGNETO

A. Changing rotation from clockwise (right) to anti-clockwise (left)

1. Remove the following parts:

a. Distributor plate complete (7) b. Rotor gear fastening screw, lock washer and plain washer c. Rotor gear (20) d. Cam (13)

The slots of the rotor gear (20) and the edge of the distributor gear (21) are marked with letters "A" for anti-clockwise rotation and !lC" for clockwise rotation. NOTE: A limited number of 6 cylinder rotor gears (part number GE 52100), both on magnetos and as spare parts, were shipped into the field prior to January 1, 1942 with the letters !lA" and "c" stamped· between the slots and in some cases, adjacent to the opposite rotation slot. However, when magnetos were assembled here at the factory, the cam was correctly engaged in the slots- of the rotor gear. In order to select the proper slots in the rotor gear, we advise that you check with the illustration at the right-Figure 4. The magneto will not function properly if the cam is incorrectly engaged.

2. Engage slots marked "A" on rotor gear (20) with ears on cam (13). Fig. 4

Automotive Manual Page 237/200

AMERICAN BOSCH CORPORA TION, SPRINGFIELD MASS, USA

SERVICE INSTRUCTIONS

for American Bosch Type "MJH Edition C" Magneto

TABLE OF CONTENTS

PAGE PAGE PAGE

General Descr~ption 237/200 Trouble Shooting 237/205 Disassembly of Magneto 237/200 Inspection after Disassembly 237/202

Performance Specification 237/204 Lubrication Specification 237/204

Plug Gap too Wide 237/205 Plug Short Circuited 237/206

Remagnet~zing 237/203 Changing the Rotation 237/204 Faulty Spark or No Spark 237/206 Reassembly of Magneto 237/203 Timing 237/204 Contact Breaker Faults 237/206

GENERAL DESCRIPTION

The American Bosch ~UH Edition IC' Magneto is a small, compact, dependable unit employing the induction princirle of current generation. It is espec.iallY ~pplicable to Marine, Farm and IndustrIal EngInes of small and medium size and is available for base or flange mounting applications.

The Magneto is of simplified design with rotating parts limited to the magnet rotor with integral cam, the distributor rotor and, in the thrpe, four and six cylinder types, the magnet rotor gear and the distributor rotor gear.

The magnet rotor (13) for the three, four and six cylinder models revolves on ball bearings (10 and 16) located in the magneto housing and breaker plate. In the. one and tw~ cylinder models, the ball bearIng located 1n the breaker plate is. replaced by a sel.f-lubric~tjng bronze bushIng (16A). The h1gh tens10n

coil (5) is seated on top of the pole shoes and is secured by two screws (4). The breaker assembly (19 and 19A), including the condenser (21), is securely fastened to the open end of the magneto housing by three fastening screw~ lockwashers (34) and plain washers (33). lne cam is constantly lubricated by a felt strip wick (30) which has been saturated with a special lubricant. The distributor rotor (41) and gear (40) revolves on a large self-lubricating bronze bushing (39) located in the upper part of the breaker plate (19).

The open end of the magneto is enclosed by a bakelite distributor plate (43A, 43B, 44B or 440) which contains the high tension conductor and contact brush (45), grounding terminal (43), cable outlets and, on the three, four and six cylinder models, labyrinth ventilators (43H) centrally located on each side of the plate.

DISASSEMBLY OF MAGNETO

To facilitate the reassembly of the Magneto, it is suggested that parts be placed on a clean bench, or in a clean pan, In the order in which they are removed. Always remove the impulse coupling before proceeding to disassemble a Magneto. 1. Remove the woodruff key (15).

2. Withdraw the distributor plate fastening screws, lockwashers and washer (46 and 46A), and remove the distributor plate. Remove the ventilator fastening screws (431) and ventilators (43H). Do not remove the distributor plate from a radio shield assembly.

- See Service Letter A-44 NOTE; On the two cylinder models, removal of the distributor plate is accomplished in the following order. a. Distributor plate cap (44F) and gasket

(44E) . b. Distributor rotor (41A). c. Distributor plate (44B) and gasket (44C).

REVERSE THIS PROCEDURE WHEN REASSEMHLING

3. Remove the spring ring (36) and magnet rotor gear (35).

Form No. 237/200 CKH 947

4. Disconnect and remove the coil lead (6) from the breaker assembly. This also applies to the grounding cable (49), if present.

5. Withdraw the breaker plate fastening screws, lockwashers (34) and plain washer (33), and remove the breaker assembly by inserting screw drivers in the slots provided on each side of the breaker plate and and carefully prying upward.

. If necessary, the condenser (21), wick (30) and contact point assembly (24) can be removed from the breaker plate (20) by withdrawing their respectIve fastening screws and lockwashers.

6. Remove the spring ring (37) and washer (38) from the dIstrIbutor gear shaft and withdraw the distributor rotor (41) and gear assembly (40). If necessary, the distributor rotor (41) can be removed from the shaft by firmly holding the gear and shaft in one hand and pulling on the distributor rotor with the the other hand.

Automotive Service Manual

MAGNETOS MRD Edition A Service Instructions

A MER I CAN B 0 S C H COR P 0 RAT ION S P R I N () FIE L D 7, MAS SUS A

SERVICE INSTRUCTIONS For

AMERICAN BOSCH Type

MRD EDITION A MAGNETOS

Table of Contents

Page

GENERAL DESCRIPTION......... .... 2

DISASSEMBLY. . . . . . . . . . . . . . . . . . . . . 2

INSPECTION. . . . . . . . . . . . . . . . . . . . . . 4

REMAGNETIZING .••................ 5

LUBRICATION....... ......... ..... 5

REASSEMBLY. . . . . . . . . . . . . . . . . . . . . . 5

CONTACT POINT OPENING....... .... 5

"E" GAP......................... 5

VENTILATION .................... . 6

CHANGING ROTATION........... .•.. 6

PERFORMANCE TESTS........ ....... 6

Printed in U. S. A. .~

Page

TROUBLE SHOOTING................ 7

TIMING. . •. . . . . . . • . . . . . . . . . . . . . . . 9

ENGINE. . . . . . . . . . . . . . . . . . . . . . . . 9

BASE MOUNTED MAGNETO WITHOUT IMPULSE COUPLING ................ 9

BASE MOUNTED MAGNETO WITH IMPULSE COUPLING............. 9

FLANGE MOUNTED MAGNETO WITH IMPULSE COUPLING.... .... 9

MAGNETO WITH IMPULSE COUPLING BY COUPLING RELEASE .......... 10

PERIODIC INSPECTION ............. 10

SERVICE TOOLS................... 11

Page 1

SERVICE INSTRUCTIONS & PARTS LIST

WICO MAGNETO MODELS

XH & XHD

INDEX

Page Service Instructions •••••••••••••••••••••••••• ~ •••••••• 2 - 6

Illustrations

Stop Devices •••••••••••••••••••••••••••••• Exploded View - Distributor End ••••••••••• Exploded View - Impulse End •••••••••••••••

7 8 8

Impulse Parts •••••••••••.•••••••••••••••••• 9 Adjustable Drive Cups ••••••••••••••••••••• 9 Oust Cover Un it •••••••••••• '............... 9 Covers and Distributor Cap Unit. •••••••••• 10 Distributor Arms and Pinion Gears. •••••••• 10

Table of Variable Parts •••••••••••••••••••••••••••••••• 11 - 16

,.;

Form S~2IW

File in XH Parts Section of your Service Manual

Pages 11 thru 16 Revised July 1959 Printed in USA