M CONNELL DOWELL FTP2 PROJECT …...•Scope: • 70 km of 42” x70 high pressure gas pipeline •...

Transcript of M CONNELL DOWELL FTP2 PROJECT …...•Scope: • 70 km of 42” x70 high pressure gas pipeline •...

www.mcconnelldowell.com

MCCONNELL DOWELL

FTP2 PROJECT – SHOWCASING

AUSTRALIAN ONSHORE PIPELINE

EXPERTISE ON THE WORLD STAGE

OCTOBER 2015

Presented to APGA Convention 2015

by Rod Blackwell

CORPORATE VISION

Leaders in infrastructure development.

CLIENT VALUE PROPOSITION

We are the Creative Construction company building better communities through safe, smart, efficient infrastructure.

Group Summary

• Average annual revenue of

$2.5 billion

• Strong balance sheet, negligible

debt

• Deliver individual infrastructure

contracts up to $1 billion in value

• Experienced in all contract delivery

models, including PPP projects and

equity participation

• Employ over 8,500 office and

project staff

• Operate in 23 locations – Australia,

Asia, New Zealand, Pacific Islands

and the Middle East

• Over 50 Years of Creative

Construction – since 1961

1. Committed and visible leadership

2. Everyone takes ownership of

HSEQ and all are held

accountable

3. All risks associated with high

consequence activities can be

eliminated or reduced

4. Risks arising from changed

circumstances are recognised

and controlled

5. Consistent understanding and

application of systems and

contract requirements

6. Measurement and success

7. A one team approach with

customers and business

stakeholders

HSEQ Pillars

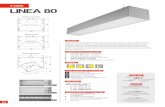

Fourth Transmission Pipeline Stage 2

• Client: PTT Public Company Ltd

• Value: AU$270 million

• Location: Rayong to Kaeng Khoi,

Thailand

• Scope:

• 70 km of 42” x70 high pressure

gas pipeline

• 3 km of thrust bores

• 20 km of horizontal directional drills

and direct pipe installation

• 18 block valves

• 2 end-line facilities

• Mid-line scraper station

FTP2 PROJECT

Project challenges

• Work spread over 300 km across 50

discrete worksites

• Multi-cultural workforce peaked at 2,800

direct employees and subcontractors

• Significant safety, logistical and

stakeholder challenges

• Aggressive fast-track, one-year completion

target required rapid mobilisation of large

and specialist resources

FTP2 PROJECT COMPLEXITY

Project challenges

• Concurrent construction involving six HDD

rigs, two direct pipe rigs and six thrust boring

rigs, plus pipeline installation and facilities

construction teams

• Brownfield environments adjacent to busy

highways, utility services, watercourses and

residential and commercial dwellings

• Restricted and environmentally sensitive

worksites with poor ground conditions

• Site rehabilitation requirements

FTP2 PROJECT COMPLEXITY

Project challenges

• Pipe had been abandoned for 15 months

• Inadequate attention to closing of ends

• Debris and soil ingress

FTP2 PROJECT COMPLEXITY

Resourcing

• All structural, mechanical and piping fabricated

and installed by McConnell Dowell

• Extensive resources mobilised including

multiple thrust bore, HDD and Direct Pipe

spreads

• Majority of specialist pipeline plant and

equipment supplied by McConnell Dowell

and CCC

• Peak workforce of more than 2,800 personnel

worked on multiple fronts simultaneously with

majority being direct employees

• Staff included highly experienced McConnell

Dowell employees from Australia and Thailand

FTP2 PROJECT RESOURCING

Advantages of the HDD method

• Less disturbance to community

• Reduced damage to surfaces

• Increased safety in populated areas

• Ideal when passing many properties which

require continuous access

FTP2 PROJECT HDD METHOD

Advantages of the Direct Pipe method

• Combines advantages of microtunnelling

and HDD technology

• Prefabricated pipeline installed and

borehole excavated in one step

• Fast and highly economical

• Suits practically any ground condition with

the environment remaining largely

unaffected

• Suits densely populated areas with

minimum footprint and maximum efficiency

• Expensive shaft construction not required

• Direct installation of a pre-welded and pre-

inspected pipeline possible

• Precise steering possible on upward and

downward slopes and in curves

FTP2 PROJECT DIRECT PIPE METHOD

Facilities construction challenges

• Spools fabricated by others defective

• Determining status of spool fabrication

• Multiple sites constructed concurrently

• Many underground systems

FTP2 PROJECT FACILITIES

4 million man hours completed LTI free

• Safety Leadership Team led safety

management by example

• Strong safety culture-building program based

on understanding of Thai culture

• Bilingual and pictorial HSE field documentation

FTP2 PROJECT SAFETY

4 million man hours completed LTI free

• Comprehensive safety induction program and

ongoing training for all personnel

• Regular pre-start and toolbox meetings

• Consistent application and monitoring of safety

hazard controls across multiple worksites

FTP2 PROJECT SAFETY

4 million man hours completed LTI free

• Focus on continuous improvement

• Program recognising and celebrating safety

success

FTP2 PROJECT SAFETY

Outstanding project outcomes

• More than 4 million man hours

completed LTI free

• No significant reportable environmental

incidents

• Project completed ahead of schedule

and within budget

• Satisfied client and community

stakeholders

• Minimal disruption to the community

• Sensitive worksites rehabilitated

effectively

FTP2 PROJECT OUTCOMES

![PHYSICO-CHEMICAL PROCESSES FROM THE X70 STEEL … · 2020. 3. 12. · Variation of mechanical strength of X70 microalloyed steels according to API-5L / 95 Yield Strength [MPa] Tensile](https://static.fdocuments.in/doc/165x107/6130a4bb1ecc515869443a56/physico-chemical-processes-from-the-x70-steel-2020-3-12-variation-of-mechanical.jpg)