LV Technology Public Co. Ltd.dcs-digital.com/setweb/downloads/2555q3/20121114_lvt.pdf · cement...

Transcript of LV Technology Public Co. Ltd.dcs-digital.com/setweb/downloads/2555q3/20121114_lvt.pdf · cement...

LV Technology Public Co. Ltd. LVT established in Thailand 1996 by HJ Nielsen as the

founder.

2004 the company listed on the Thailand Stock Exchange for alternative investment (MAI).

2012 LVT has a market share of 6% worldwide (outside of China) of all newly added clinker capacity.

LVT WORLDWIDE LNV-India

250 persons

LV-China 8 persons

LV-Latin America 7 persons

LV-Europe 3 persons

BLVT-USA 3 persons

LVT

177 persons

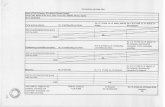

Main Achievements through 2012. Project Value (mio USD) % finished deviation

Apodi, ep 48 90% +/- 1%

Elizabeth,ep 35 80% -1%

CMS, eps has shown a loss of 5 million USD on extra works done out of contract. We have started to discuss claims for this job, and we can hopefully recover a few million USD.

Cont. Agreement Signed with Chiang Mai University for

New Developments.

1. Conversion of Plastic Waste to Coal.

2. Algae/Chlorophyle Used to Convert CO2 to Fuel.

How Does LVT Create Opportunities. LVT is a company mainly specialized in smaller and

special designed jobs, but by having done the two big jobs in Brazil, we have shown, that we can also handle big EP jobs.

History of Cement in Thailand.

First cement plant - built by Siam Cement 1914 in Bang Sue, 100 tpd wet process.

the following 50 years- very small development of the cement production capacity

the capacity in 1970 was still only about 6,000 tpd, more than 50% produced on wet or semi wet process.

Thailand as an example

Thailand, continued.

1970 to 1980 additional capacity - 6,000 tpd modification to dry process,

the total capacity of the country in 1980~ 4,000,000 MT/year~ about 100 kg/person/year.

The big boom started in 1978,

Siam Cement - 4000 tpd

Siam City Cement 4,000 tpd

Siam Cement in 1979 ...wet process kiln of 1,500 tpd at Ta Luang upgraded to 4,000 tpd as a substitution for all their combined wet process kilns at Bang Sue and at Ta Luang.

Thailand cont’d

Thailand, continued.

By 1983 there were three cement producers in Thailand. Siam Cement 4.0 million tpy. Siam City Cement 2.1million tpy. Total 6.7 Jalaprathan Cement 0.6 million tpy. More expansion 1983 to 1990 Siam Cement 11.5 million tpy. Siam City Cement 7.5 million tpy. Total 20.5 Jalapratan Cement 1.5 million tpy.

More Expansions from 1990 to 1998 Siam Cement 18 Siam City Cement 13 Total 45.5 TPIPL 8 Jalapratan/Asia 6.5

Thailand cont’d

Cement Consumption in Thailand

0

5

10

15

20

25

30

35

40

45

50

1970 1980 1990 2000

mio tpy

Column1

Column2

A Short History of Myanmar Cement Industry

- The first Cement Plant was installed in the year 1935 at THAYET MYO. - 200 TPD Wet Process Plant. (supplied by F.L Smidth Co of Denmark) - Fuel -Natural Gas Brand Name was Horse Head Brand Up to the year 1988, there were only 3 Cement Plants in Myanmar. (1) THAYET Cement Plant. 200 tpd wet process (F.L Smidth) 400 tpd wet process (Kawasaki Heavy Industries Japan) 400 tpd wet process (DIA Invest Export Company Germany) (2) KYANGIN Cement Plant 400 tpd wet process X4 Production Lines (K.H.I Japan) (3) PAAN Cement Plant 800 tpd Dryprocess S.P Kiln Line (F.C.B France)

A Short History of Myanmar Cement Industry

Ministry of Industry (1) (Government)

• THAYET CEMENT PLANT

• KYANGIN CEMENT PLANT

• KYAUKSE CEMENT PLANT

A Short History of Myanmar Cement Industry

Other Corporation (Semi - government)

• Myanmar Economic Holding Co Ltd SIN MIN CEMENT PLANT (Kyaukse Township)

• Myanmar Economic Coporation PAAN CEMENT PLANT (MYAINGGALE)

• NAYPYIDAW CEMENT PLANT (N.C.D.C)(LEWE TOWNSHIP)

• YANGON CITY DEVELOPMENT COMMITTEE (YCDC) CEMENT PLANT

• TEE KYIT CEMENT PLANT (U.S.D.A)

A Short History of Myanmar Cement Industry

Private Cement Plants • TRIPPLE A CEMENT

• MYANMAR ELEPHANT CEMENT

• TIGER HEAD CEMENT

• MAWKEINNARY CEMENT

• MAX CEMENT

• DRAGON CEMENT • MAWKEINNARY CEMENT • MAX CEMENT • DRAGON CEMENT

1. Thayet Cement Plant

2. Kyangin Cement Plant

3. Kyaukse Sin Min Cement Plant

4. Triple A Cement Plant

5. Tiger Head Cement Plant

6. Dragon Cement Plant

7. YCDC Cement Plant

8. NCDC Cement Plant

Wet Process Cement Plants

9. Max Cement Plant

10. Myanmar Elephant

11. Kyaukse Cement Plant (Ministry of Industry 1)

12. Sin min Cement Plant (UMEHL)

13. Myanmar Economic Corporation (MEC)

Wet Process Cement Plants

When valuating a cement plant there are different methods.

Asset Valuation.

A typical valuation of the assets from a replacement point of view shall be 80 - 110 USD/tpy for the entire plant production capacity from crusher to cement delivery.

Valuation of a Cement Plant.

continued For a wet plant the factory shall be divided into four

parts.

Quarry and Infrastructure. 10 - 15%

Raw Material Handling. 10 - 15%

Clinker Production 40%

Cement Production and Dispatch

of Cement. 30%

Continued. Based on this criteria, the present value of the

government plants will be

Thayet +/- 12 million USD

Kyankin +/- 25 million USD

Kyaukse +/- 15 million USD

Valuation, continued.

Valuation of Potentials.

Typically will give a higher value than asset valuation,

which means, that above values are the minimum the government shall accept.

Market Demand and Capacity. Year Production Demand

2011 2.0 m tpy 6 m tpy

2012 2.2 7

Expected Figures.

2013 2.8 8 – 9

2014 4.0 9 – 11

2015 5.0 11 – 12.5

The difference must be covered by import at a minimum price of min. 85 USD/t CIF Yangon.

Possible Solution for the Government Plants. The wet plants must be converted to dry process.

Conversion of an existing kiln for calcining process, to increase capacity to 1,600 tpd.

convert one kiln at each of the two plants at Thayet and Kyangin to 1,600 tpd, using the existing facilities as much as possible.

For Kyaukse upgrade the capacity to 1,000 tpd by using the existing facilities as much as possible.

Cont. By converting the plant as above mentioned the value

of the three plants would be increased to a total between 160 million to 180 million USD for a total investment of around 60 million USD, or an increase in value from today around 60 million USD to three times by investment of 60 million USD.

Cement Quality. the chemical Composition of clinker from the plants

are similar to cement imported from Thailand, BUT the quality is inferior.

necessary to study in details,

to optimize the cement grinding system with high efficient classifiers such as LVT, which will improve the quality comparable to imported cement.

Continued. Power consumption must be reduced by installing

waste heat recovery system, when selecting the dry process, and if the power supply is unstable, it shall be recommended to install a gas turbine to supply additional power combined with the waste heat recovery.

Continued. When preparing for competition in the market it is important to prepare for addition of third material into the cement.

MCI plants are well located, as there is pozzolane available, and in the future it is expected, that at least 20% of third material can be added into the cement, once the modifications have been implemented.

Continued Fuel to be changed to coal.

To be competitive in today’s market, it is essential to convert the kilns using coal for fuel (cost of gas)

Power consumption can be reduced -waste heat recovery system,

and if the power supply is unstable, to install a gas turbine to supply additional power.

Cont. The philosophy of LVT and its founder is that when

constructing a cement plant in a country like Muanmar it is important to use local work force to a maximum extent, as this is one of the first big industrialized projects in the country, and by using local work force this will not only create jobs for the local people, but also develop the skills of the Myanmar work force.

Continued Similar to the involvement of these two projects in

Myanmar, HJ Nielsen was involved to develop the Thai cement Industry during 1980 to 1986 and the government sector cement industry in Indonesia from 1990 to 1995, where it was also successful to utilize a big portion of local work force, at the beginning for the fabrication and installation, and later for certain engineering design.

Example from KBZI. Total Weight of Equipment 5,500 t

Imported 3,100 t

Local Manufacturing, including Silos, complete equipment in Pre Heater Cyclones Calciner, all Ducts and Chutes 2,200 t

All civil works is made by local contractors

All Erection is done by local contractors.

Continued As such a total of more than 600 persons from

Myanmar is employed during an 18 months period, and the entire job is done with less than 20 foreign supervisors.

The time period for this job is 25 months for the entire project from start to clinker production and 26 months until cement dispatch, which is one of the fastest project schedules in the country.