Lubrucation Engineers SA - Marine Applications

-

Upload

nicholas-kominos -

Category

Engineering

-

view

490 -

download

1

Transcript of Lubrucation Engineers SA - Marine Applications

-

Welcome to Lubrica/on Engineers SA

-

Who are we ?

Producer of high performance industrial lubricants, oil analysis services & reliability solu/ons

Expert in maintenance cost reduc/on

-

Who are we ?

Based in more than 60 countries

-

State of the art plant based in Kansas USA

-

Interna/onal Headquarters based in UK

-

Who are we?

-

What is the main differences of LE, compared with other lubricant

producers ?

-

Studies shows that the lubricant

cost, represents only 2-3 % of the total maintenanc

e cost

-

LE uses 100 % Paraffinic base oil

Synthe/c Base oil

-

LE adds unique-proprietary addi/ves to reduce fric/on, heat, wear, increase water separa/on, tachiness, heat resistance etc.

-

Almasol Monolec Duolec Quinplex

DUOLEC is the newest LE proprietary additive incorporating revolutionary technology designed specifically for use in LE gear lubricants. It is a temperature activated, dual acting, liquid additive that imparts special properties and synergies to the LE Products in which it is used. DUOLEC increases lubricant film strength and protects metal surfaces outperforming at

Under normal to light conditions of speed and load, two metal surfaces are effectively separated by a lubricant film. This is known as hydrodynamic lubrication. An increase in load or a decrease in speed reduces the lubricant film allowing metal to metal contact and raising the temperature of the contact zone due to frictional heat. As a result, the EHD and mixed film antiwear components of DUOLEC

-

Solid Additive

Almasol

Maximum Service

Temperature

1,038C (1,900F) 400,000 psi(28,123 kgf/cm)

Inert None

MolybdenumDisulfide

343C (650F) 400,000 psi(28,123 kgf/cm)

Some Oxidizes in air above 343C (650F), forming abrasive molybdenum trioxide. Tendency to build up on itself, affecting machinery with close tolerances. Cannot tolerate hydrochloric and nitric acid, especially when heat, water and air are present.

Graphite 426C (800F) 80,000 psi(5,625 kgf/cm)

Some Known to exhibit galvanic corrosion problems. Tendency to build up on itself, affecting machinery with close tolerances.

Fluorocarbon (PTFE)

260C (500F) 5,000 psi (352 kgf/cm)

Inert No load-carrying capability. Tendency to build up on itself, affecting machinery with close tolerances.

Load Carrying Capacity

Acid Resistance

Drawbacks When Used in Industrial Lubricants

A

B

C

DEMO

-

Quinplex

1

2

3

4

5

Water Resistance

Tackiness

Cohesion

Mechanical Stability

Corrosion Resistance

BEFORE AFTER

-

Quinplex Demonstra/on

Impact Tester Water Separa/on

-

Gear Box Demonstra/on

-

Gear Box Live Opera/on

-

Oil Analysis Services ''''''Lubrica@on'Engineers'Hellas

Lubrica(on+Engineers+Leaders+in+lubricants

www.le9greece.gr++30+210+5152+040

''''''''':'

1)######2)######3)###.

':+:++(Fe),+M+(Pb)+X+(Cu)+,++(Cr),++(Mo)+,++(l),++(Ni)+,++(Ag),++(Sn)+..+

+++++++++.+++++++++++++.+H++++++++,+++++++++++.

'(P),''(n),''(Ca),''(),''(Mg):++++++++++++++++++++++++.++++++++++++,+++,+++++++++++.++++++++++,+++++++++++++++.+++++++++++++++++++.

'()',''(),''():+++++++++++.++++++++++++++++++++++.+++,+,++++++++++++.

'(Si'b'Silica):++,++,++++++++++++"".++++++++++++.+++(silicone)++++++++.

''''''Lubrica@on'Engineers'Hellas

Lubrica(on+Engineers+Leaders+in+lubricants

www.le9greece.gr++30+210+5152+040

-

Audits & Inspec/ons

-

Audits & Inspec/ons

-

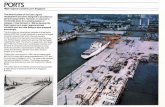

LE SA & Marine Applica/ons

Marine lubrica/on maintenance improvements

-

Vessel+3d+H+Deck+Applica(ons

www.le%greece.gr))+30)210)5152)040

12

76

5 43

1

56

34

2

1. Anchor)winch)windlasses)%)Almagard)3752)2. Mooring)winches)%)Almagard)3752,)Wire)ropes)%)Earthwise)EAL)3353)3. Cranes)%)Gearboxes:)Duolec)1600,)Grease)points:)Almagard)3752,)Hydraulics:)Monolec)6520

Bulk)curriers)cranes)%)Slewing)bearings:)Almagard3752)or)Almaplex)1299)(auto)systems))4. Accommoda6on)ladders)%)Gearboxes:)Duolec)1600,)Grease)points:)Almagard)3752)5. Lifeboats)%)Engines:)Monolec)Ultra)15W%40,)Gearboxes:)Duolec)1600,)Grease)points:)Almagard)

3752)6. Provision)cranes)%)Gearboxes:)Duolec)1600,)Grease)points:)Almagard)3752,)Hydraulics:)Monolec)

6520)7. Mooring)winches:)Almagard)3752,)Wire)ropes:)Earthwise)EAL)3353)

Lubrica6on)Engineers)SA)Leaders)in)lubricants

Deck Applica/ons

-

Windlass lubrica/on

Cover opened a[er 6 months. Frequent relubrica/on reported. Lubricant starva/on, wear & oxida/on

monitored

-

Use of Alamagard 3752. Cover opened a[er 6 months. No re-lubrica/on for 6 months. Excellent lubricant film

concentra/on, no wear or oxida/on.

Windlass lubrica/on

-

Wire rope lubrica/on

-

Wire rope lubrica/on common prac/ces

-

Wire rope lubrica/on common prac/ces

-

Wire rope lubrica/on - rust lube wash out

-

Wire rope lubrica/on - rust lube wash out

-

Wire rope lubrica/on LE Recommends

Proudly manufactured and supplied by: Lubrication Engineers Pty Ltd

How it Works! o Grease is delivered to the Aluminum collar via a high volume

grease pump that can deliver lubricant at pressures up to 5000PSI.

o The Collar contains polyurethane seals which seal against the wire rope allowing the grease time to penetrate.

o Scrapers at each end of the collar remove old lubricant while also flattening broken wires and protecting the seals.

o Grease application is adjusted via a lubricant control valve which adjusts the grease volume.

o Wire ropes are pulled through the collar. o Excess lubricant is collected. o Use of a Viper rope cleaner pre-cleans ropes prior to them entering the collar.

Superior Protection for Wire Ropes www.viperwrl.com phone: +61 (2) 9636 5655

Viper recommend that wire ropes be physically measured prior to ordering seals and scrapers as ropes in service may vary in size. Scrapers are supplied slightly larger than the actual wire rope size to allow for rope flexing.

Viper seals are designed to have some interference with the rope, depending on its size and type, with an interference of up to 3mm allowable for standard 6 & 8 strand ropes. For compact, non-rotating or wireline type ropes which do not have valleys, a maximum interference of 1mm is recommended as these ropes do not allow for the same amount of seal deflection within the collar.

Seals Selection

Scraper Selection

Wire Rope Measurement GuideIt is recommended that wire ropes be physically measured prior to ordering seals and scrapers as ropes in service can stretch and sizes may vary. correct incorrect

Viper Mini MkII - Mid Mk II - Maxi Mk IISeal - Scraper - VRC - Selection Guide

1.

Rope Cleaner (VRC) Selection Viper Rope Cleaners enable the removal of contamination or built up old lubricant from the wire rope prior to lubrication, improving the effectiveness of the lubrication process via the Viper WRL.

It is critical that all ropes be physically measured prior to selecting and ordering the VRC, as ropes size may vary in service.

Available for 6 and 8 strand ropes in a wide range of sizes, the following tables allow for the quick and easy selection of the correct VRC to suit your specific requirements.

Right Lay - Clockwise Rotation Left Lay - Counter Clockwise Rotation

LEFT: The Viper Wire Rope Cleaner in place as the rope enters theViper Mid Mk II WRL.

RIGHT: Smooth Bore Rope Cleaner

For certain types of wire ropes where the standard Viper Rope Cleaner is not suitable, the Viper Smooth Bore rope cleaner is available. The Smooth Bore Rope Cleaner would typically be used on those ropes with a large number of outer strands, some non-rotational ropes, ROV cables, etc, where the valleys between the strands are minimal and do not readily facilitate a standard Viper Rope Cleaner.

The illustrations show how to measure a wire rope correctly.

REV D.06.15

Superior Protection for Wire Ropes www.viperwrl.com phone: +61 (2) 9636 5655

Viper recommend that wire ropes be physically measured prior to ordering seals and scrapers as ropes in service may vary in size. Scrapers are supplied slightly larger than the actual wire rope size to allow for rope flexing.

Viper seals are designed to have some interference with the rope, depending on its size and type, with an interference of up to 3mm allowable for standard 6 & 8 strand ropes. For compact, non-rotating or wireline type ropes which do not have valleys, a maximum interference of 1mm is recommended as these ropes do not allow for the same amount of seal deflection within the collar.

Seals Selection

Scraper Selection

Wire Rope Measurement GuideIt is recommended that wire ropes be physically measured prior to ordering seals and scrapers as ropes in service can stretch and sizes may vary. correct incorrect

Viper Mini MkII - Mid Mk II - Maxi Mk IISeal - Scraper - VRC - Selection Guide

1.

Rope Cleaner (VRC) Selection Viper Rope Cleaners enable the removal of contamination or built up old lubricant from the wire rope prior to lubrication, improving the effectiveness of the lubrication process via the Viper WRL.

It is critical that all ropes be physically measured prior to selecting and ordering the VRC, as ropes size may vary in service.

Available for 6 and 8 strand ropes in a wide range of sizes, the following tables allow for the quick and easy selection of the correct VRC to suit your specific requirements.

Right Lay - Clockwise Rotation Left Lay - Counter Clockwise Rotation

LEFT: The Viper Wire Rope Cleaner in place as the rope enters theViper Mid Mk II WRL.

RIGHT: Smooth Bore Rope Cleaner

For certain types of wire ropes where the standard Viper Rope Cleaner is not suitable, the Viper Smooth Bore rope cleaner is available. The Smooth Bore Rope Cleaner would typically be used on those ropes with a large number of outer strands, some non-rotational ropes, ROV cables, etc, where the valleys between the strands are minimal and do not readily facilitate a standard Viper Rope Cleaner.

The illustrations show how to measure a wire rope correctly.

REV D.06.15

Superior Protection for Wire Ropes www.viperwrl.com phone: +61 (2) 9636 5655

Viper recommend that wire ropes be physically measured prior to ordering seals and scrapers as ropes in service may vary in size. Scrapers are supplied slightly larger than the actual wire rope size to allow for rope flexing.

Viper seals are designed to have some interference with the rope, depending on its size and type, with an interference of up to 3mm allowable for standard 6 & 8 strand ropes. For compact, non-rotating or wireline type ropes which do not have valleys, a maximum interference of 1mm is recommended as these ropes do not allow for the same amount of seal deflection within the collar.

Seals Selection

Scraper Selection

Wire Rope Measurement GuideIt is recommended that wire ropes be physically measured prior to ordering seals and scrapers as ropes in service can stretch and sizes may vary. correct incorrect

Viper Mini MkII - Mid Mk II - Maxi Mk IISeal - Scraper - VRC - Selection Guide

1.

Rope Cleaner (VRC) Selection Viper Rope Cleaners enable the removal of contamination or built up old lubricant from the wire rope prior to lubrication, improving the effectiveness of the lubrication process via the Viper WRL.

It is critical that all ropes be physically measured prior to selecting and ordering the VRC, as ropes size may vary in service.

Available for 6 and 8 strand ropes in a wide range of sizes, the following tables allow for the quick and easy selection of the correct VRC to suit your specific requirements.

Right Lay - Clockwise Rotation Left Lay - Counter Clockwise Rotation

LEFT: The Viper Wire Rope Cleaner in place as the rope enters theViper Mid Mk II WRL.

RIGHT: Smooth Bore Rope Cleaner

For certain types of wire ropes where the standard Viper Rope Cleaner is not suitable, the Viper Smooth Bore rope cleaner is available. The Smooth Bore Rope Cleaner would typically be used on those ropes with a large number of outer strands, some non-rotational ropes, ROV cables, etc, where the valleys between the strands are minimal and do not readily facilitate a standard Viper Rope Cleaner.

The illustrations show how to measure a wire rope correctly.

REV D.06.15

Viper Applications

o Crane Wire Ropes Static overhead cranes Mobile cranes Tower cranes Ship cranes Wharf Cranes

o Marine Applications Ship deck winches Ship Cranes Mooring lines Dredge cables Anchor cables Tug Boat winches Remote Operated Vehicles (ROVs) umbilical cables Dam sluice gate lubrication

-

31

Mini MkII collar with seals weighs only 2.5 kgs making

Viper Mini MkII Wire Rope Lubricator

Superior Protection for Wire Ropes www.viperwrl.com phone: +61 (2) 9636 5655

Vipe

r Min

i MkII

Viper Mini seals are designed to have some interference with

the rope, depending on its size and type, with an interference

For compact, non-rotating or wireline type ropes which do not

have valleys, a maximum interference of 1mm is

recommended as these ropes do not allow for the same

amount of seal deflection within the collar.

Seals Selection

It is recommended that wire ropes be

physically measured prior to ordering

seals as ropes in service can stretch

and sizes may vary.

correct incorrect

The illustrations show how to measure a wire rope correctly.

Rope Cleaner (VRC) Selection built up old lubricant from the wire rope prior to lubrication,

improving the effectiveness of the lubrication process via the

Bore rope cleaner is available.

following tables allow for the quick and easy selection of the

SEAL & ROPE CLEANER SELECTION GUIDE

used on those ropes with a

large number of outer strands,

some non- rotational ropes,

valleys between the strands

are minimal and do not readily

facilitate a standard Viper

Seals for 6 or 8 Strand

Seals for Armoured

or Multi Strand

IMPORTANTCHOOSE CORRECT ROPE TYPEPRIOR TO ORDERING

Viper

Smooth Bore

Seal art No. Seal art No. ope leaner ight ay eft ay ight ay eft ay

8mm to 10mm5/16 to 3/8

11mm to 12mm7/16 to 15/32

13mm to 14mm to 9/16

15mm to 16mm19/32 to 5/8

17mm to 18mm21/32 to 11/16

19mm to 20mm to 25/32

21mm to 22mm13/16 to 7/8

23mm to 24mm29/32 to 15/16

25mm to 26mm1 to 1 1/32

27mm to 28mm1 1/16 to 1 1/8

29mm to 30mm1 5/32 to 1 3/16

31mm to 33mm1 to 1 5/16

34mm to 35mm1 11/32 to 1 3/8

VMISEAL33 VRC-SB34 VRC34-6R VRC34-6L VRC34-8R VRC34-8LVMISEAL35

High Speed Kit Only

VMISEAL30 VRC-SB32 VRC32-6R VRC32-6L VRC32-8R VRC32-8LVMISEAL33

VMISEAL28 VRC-SB29 VRC30-6R VRC30-6L VRC30-8R VRC30-8LVMISEAL30

VMISEAL26 VRC-SB27 VRC28-6R VRC28-6L VRC28-8R VRC28-8LVMISEAL28

VMISEAL24 VRC-SB25 VRC26-6R VRC26-6L VRC26-8R VRC26-8LVMISEAL26

VMISEAL22 VRC-SB23 VRC24-6R VRC24-6L VRC24-8R VRC24-8LVMISEAL24

VMISEAL20 VRC-SB21 VRC-22-6R VRC22-6L N/A NAVMISEAL22

VMISEAL18 VRC-SB19 VRC20-6R VRC20-6L N/A NAVMISEAL20

VMISEAL16 VRC-SB17 VRC18-6R VRC18-6L N/A NAVMISEAL18

VMISEAL14 VRC-SB15 VRC16-6R VRC16-6L N/A NAVMISEAL16

VMISEAL13 VRC-SB13 N/A N/A N/A NAVMISEAL14

VMISEAL10 VRC-SB11 N/A N/A N/A NAVMISEAL13

VMISEAL8 VRC-SB9 N/A N/A N/A NAVMISEAL10

Actual ope Size

Viper ope leaner Viper ope leaner

6 Strand opes Strand opes

Viper ope Seals for

"6 " Strand opes

Viper ope Seals for Armoured

Multi Strand opes

Kit Components

Supply Hose

Wire rope lubrica/on LE Recommends Viper Applications

o Crane Wire Ropes

Static overhead cranes Mobile cranes Tower cranes Ship cranes Wharf Cranes

o Marine Applications Ship deck winches Ship Cranes Mooring lines Dredge cables Anchor cables Tug Boat winches Remote Operated Vehicles (ROVs) umbilical cables Dam sluice gate lubrication

-

Viper Applications

o Crane Wire Ropes Static overhead cranes Mobile cranes Tower cranes Ship cranes Wharf Cranes

o Marine Applications Ship deck winches Ship Cranes Mooring lines Dredge cables Anchor cables Tug Boat winches Remote Operated Vehicles (ROVs) umbilical cables Dam sluice gate lubrication

Viper Applications

o Crane Wire Ropes Static overhead cranes Mobile cranes Tower cranes Ship cranes Wharf Cranes

o Marine Applications Ship deck winches Ship Cranes Mooring lines Dredge cables Anchor cables Tug Boat winches Remote Operated Vehicles (ROVs) umbilical cables Dam sluice gate lubrication

-

Viper Applications

o Crane Wire Ropes Static overhead cranes Mobile cranes Tower cranes Ship cranes Wharf Cranes

o Marine Applications Ship deck winches Ship Cranes Mooring lines Dredge cables Anchor cables Tug Boat winches Remote Operated Vehicles (ROVs) umbilical cables Dam sluice gate lubrication

-

What is VGP?

11

Deck applications EPA has not

mandated vessels must use EALs,

but is encouraging use.

Below the water line

In all oil-to-sea interfaces, unless

technically not feasible

Wire rope lubrica/on EAL requirements

-

1. Biodegradability >60% in less than 28 days

2. Low aqua/c toxicity

3. Minimal bioacumula/on

35

EAL Characteris/cs Dec 2013 VGP

-

Available in pails to start Product is available and ready to ship;

will ship out of Wichita to start.

International has been using sincelate May approximately.

40

Availability & Pricing

Earthwise EAL Wire Rope Grease

Earthwise EAL Wire Rope Grease

Self-certified EAL that meets specifications required by the EPAs VGP

Soft, semifluid formulation designed to coat wire rope, chains, and cables

Semi-tacky & readily biodegradable Exhibits minimal aquatic toxicity and will not

accumulate in the cells of fish and other aquatic life Seals out water, protecting against rust Protects against wear, corrosion, impact,

rust & oxidation

Earthwise EAL Wire Rope Grease (3353)

Contains LEs proprietary additives Almasol & Quinplex

34

Overview

Available Grade | NLGI 0

Earthwise EAL 3353 is the only EAL product that contains the non toxic addi/ve Quinplex, which makes

it tacky and water resistant. It will stay much longer in the wires vs any other EAL

product.

-

- Highly reduced volume consump/on

(Around 10 Kg / mooring wire rope)

- Quinplex will reduce water wash out & will seal out moisture contamina/on

37

Earthwise EAL 3353 &

Viper MK II - MK II Mini

-

- Highly reduced volume consump/on

(Around 10 Kg / mooring wire rope)

- Quinplex will reduce water wash out & will seal out moisture contamina/on

38

Earthwise EAL 3353 &

Viper MK II - MK II Mini

How it Works! o Grease is delivered to the Aluminum collar via a high volume

grease pump that can deliver lubricant at pressures up to 5000PSI.

o The Collar contains polyurethane seals which seal against the wire rope allowing the grease time to penetrate.

o Scrapers at each end of the collar remove old lubricant while also flattening broken wires and protecting the seals.

o Grease application is adjusted via a lubricant control valve which adjusts the grease volume.

o Wire ropes are pulled through the collar. o Excess lubricant is collected. o Use of a Viper rope cleaner pre-cleans ropes prior to them entering the collar.

-

Slewing Bearings

-

Marine Industry - Slewing BearingsAlmaplex Ultra Syn 1299 (automatic lubrication)

Almagard 3752

Protect your investmentPremature failure is a common fate for large-diameter (e.g., 8 to 10) bearings in heavy-duty applications where rotations are frequent. In big rotating equipment such as cranes, excavators and tunnel boring machines, a slewing ring bearing must simultaneously handle a complex load spectrum that covers diverse combinations of thrust, radial and tilting moment loading.

Fortunately, theres an easy way to protect your investment in these custom-engineered bearings. Its called regular maintenance, and it can prevent 96% of slewing ring bearing failures. To maximize bearing life, simply follow these tips raceway and gear lubrication, torque checks on bolts, and seal inspection and be alert for four warning signs of potential bearing problems.

Seals

Bearing Lubrication Bolts

Gear Lubrication

Bearing lubricationA bearing should be lubricated at regular intervals with heavy-duty, extreme-pressure grease. Apply a liberal shot to the fittings around the bearings circumference at the interval recommended in the operators manual.

Slowly-rotating equipment or oscillating applications (e.g., backhoes, excavators, cranes) should be re-lubricated about every 100 hours of operation. More frequent lubrication every day or even every eight hours may be needed on equipment that moves rapidly or rotates continuously, such as trenchers and boring machines.

While adding grease, the bearings should be rotated to spread the grease throughout. Pump it in until you see the old grease squeeze past the seal; this is called purging. Purged grease carries contaminants out of the bearing. Rub some between your thumb and forefinger if you feel grit or metal chips, you may have a bearing problem.

Grease tends to dry out over long periods of time, allowing condensation to form within a bearing. You can avoid this by introducing grease at least every six months, even when the equipment is sitting idle.

White Paper

How to extend the life of your slewing ring bearings- Ronald Shaw, Bearing Remanufacturing Manager, Kaydon Bearings Division

-

Crane gearboxes

-

Hangar's Hatch Rollers

-

www.le%greece.gr))+30)210)5152)040

Lubrica6on)Engineers)SA)Leaders)in)lubricants

Vessel+3d+H+Applica(ons

10

9 Turbocharger

11

8

Turning gear

Main engine

8.))Steering)rudder)%)Gearbox:)Duolec)1600,)Bearings:)Almagard)3752)9.)ShaB)bearings:)Monolec)GFS)8430)10.)Main)engine:)Turbochargers:)Mul6lec)6800,)Turning)gear:)Pyroshield)5180)11.)Air)compressors)%)Mul6lec)6800,)Fuel)&)Oil)purifiers:)Duolec)1600,)Refrigera6on)compressors:)Monolec)6723,)Electric)motor)bearings:)Almaplex)1275

Below deck Applica/ons

-

An/pollu/on Oil Spill Eater II, enzyme that converts oil to CO2 & water. EPA approved, fully non toxic. Usages: - Oil spill cleaning - Fuel & cargo tank cleaning - Engine room & deck cleaning

-

Thank you!