Logical Sequence Approach

-

Upload

v-balasubramaniam -

Category

Documents

-

view

125 -

download

0

description

Transcript of Logical Sequence Approach

LOGICAL SEQUENCE APPROACH TO SAFETY

Introduction:

In any progressive nation the manufacture, processing, handling, storage,

transportation of toxic, flammable, corrosive and explosive chemicals

is a way of life.

But Hi-tech, changes in environmental and social conditions,

community awareness and legislative requirements have brought in a complexity of

factors that make Safety a vital factor to reckon and factor.

Hi-tech:

Modern industries are big and complex. Giant machinery and intricate processes

handle high pressures, high temperatures, corrosive, flammable and toxic

substances. Composition details of many patented materials are well guarded

particularly those covered by Intellectual Property Rights.

Environment :

Environmental factors include ecological pollution and degradation that may

cause community and industrial worker sickness leading to permanent disability and

long-term adverse impact.

Social factors :

Social factors and domestic stress have a direct bearing on a person’s

concentration to err on the job, he/she performs, and can affect safety and quality

of the work turned out.

1

Chemical industry :

The small capacity multi-stream plants have yielded way to giant size single

stream units to obtain economy of scale . Compact size plants, new processes ,

high-speed equipment , and microelectronics is the feature of the day. Even though

exotic metals like chrome-nickel, moly-steels, zirconium , titanium and tantalum etc

are being used to combat corrosion , failures due to corrosion, erosion , metal fatigue,

creep failure and such , resulting due to greater stress and strain of the modern plants

has not been fully overcome. These factors further reinforce the essentiality of safety.

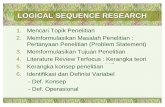

Logical Sequence Approach (LSA):

The logical sequence approach is perhaps worth pursuing for safety . In this approach

the risk analysis commences from conception stage of the plant and progresses to

Design stage- material selection–fabrication- inspection- layout-

safe storage , handling , transportation and on to emergency preparedness

planning and disaster management .

Having slotted, LSA helps to focus on to what to look for.

Design:

There are several standards/codes/regulations available for reference such as BIS,

IBR, IPR, IER, ASME, ASTM, API, DIN, JIS, BS, NFPA, NEC, Canadian and many

European standards including AFNOR, UNI and EU directives etc. In general, each

country or economy has a single recognized National Standards Body (NSB). The

advantage of incorporating built –in safety devices at this stage are immense and

should not be viewed an option for cost reasons.

Material selection :

Selection should be compatible to process fluids and plant process parameters.

As mentioned earlier choice of exotic materials facilitate a wide spectrum selection.

Fabrication:

The use of these materials has also created a compelling need for special welding,

fabrication, heat –treatment and weld inspection techniques. Even a minor lapse in

any one of these stages offsets the benefits derived by selection of such costly

materials. Bi –metal/exotic metal welding is another aspect requiring knowledge,

skills and perfection.

2

Inspection:

After fabrication, work inspection is to be carried out. Besides in-house inspection,

Statutorily required and recognised third party inspections as are

called for, ensure conformance to the codes. This stage is used for correcting

noted deficiencies if any, instead of rejection and costly rework or failures

subsequently.

Several known inspection methods are adopted like hydrotest, pressure test,

magnetic particle, dye-penetrant, radiography, ultrasonic flaw detection,

metallography and wet fluorescent test, just to cite a few . The importance of the

correctness of the calibration of the measuring instruments reflects on the accuracy of

the readings. Methods should suit specific application needs.

Layout:

Land availability, prohibitive land costs, economic considerations of project

costs(capital outlay), and need for piping compactness have also resulted in

close spacing of hazardous units and storage.

The insistence of plan approvals from statutory authorities and safety certificates

from recognised third parties are motivated by the objective of an independent

scrutiny. Statutory requirements and recommendations should be viewed as a source

of valuable input and advantage is to be gained by the inputs.

Layout should avoid hazard cascade effect. While standards specify minimum

distances, other built-in safety features should be given due importance

3

Some Key Statutory Regulations—Indian context

(Illustrative)-- Refer current versions.Batteries ( Management & Handling ) Rules

Biomedical Waste Rules (Management and Handling)

Central Motor Vehicles Rules

Chemical Accidents (Emergency planning, preparedness & response ) Rules

Declaring coastal stretches under Coastal Regulation Zone (CRZ)

NOC from District Authorities as defined

Environment (Siting for industrial projects) Rules

ESI Act

Factories Act/State Factories Rules

Gas cylinder Rules

Indian Electricity Act / Rules

Indian Petroleum Rules

Static and Mobile Pressure Vessels rules

The Air (Prevention and Control of Pollution) Rules

The Environment (Protection ) Act

The Environment (Protection ) Rules

The Hazardous Waste (Management & Handling) Rules

The Manufacture, storage and import of hazardous chemicals Rules

The Noise pollution ( Regulation & Control ) Rules

The Ozone Depleting substances (regulation & Control) Rules

The Public Liability and Insurance Act

The Public Liability and Insurance Rules

Cross-reference with other codes mentioned under “DESIGN” in partnership with the

process and technology provider is beneficial.

4

Safe storage :

It is by intent this part of the subject has been dealt with at this stage of the

handout. The aspects of LSA applicable to plant equipment and process for safe

handling of chemicals is relevant to the storage area and transport Safety as well.

Examples of storage design :

Single wall tank

Double wall tank(cup-in tank)

Double integrity tank

Fixed roof

Floating cum fixed roof

Spheres

Bullets

Rubber lined tanks

Underground tanks

Mounded storage

Deep sea Caverns

The storage design should be compatible to the substance stored and volumes. This is

the primary stage in LSA.

Besides the code referenced earlier. Engineer’s Tank Manual and the booklets

on Health and Safety series from HMSO are useful reference.

Some tanks are insulated and others heated or cooled. Some atmosphere pressure

tanks are mounted direct and in services like anhydrous Ammonia storages the

mounting is on piled pillars to avoid frost heaving by facilitating passage of air

currents.

5

Built-in safety-Design safety

At the design stage itself , the built-in features should be integrated . Some of the

factors include.

-filling pipe location (top or bottom filled).

-flow velocity considerations.

-flush mounted on ground or piled pillar mounted.

-flanged , threaded bolted, instantaneous connected , or welded.

-design of vents, drains, overflows pipes, pressure relief, vacuum breaker, spark

arrestor.

-bundwall construction and capacity.

-overflow catchments, safe containment recovery, transfer or safe disposal.

-routing of drains.

-protection against stray currents, static and lightning.

-bonding and grounding connections.

-earthing strips/earth pits.

-pressurised/non-sparking/increased safety/intrinsically safe/flame proof/explosion

proof or other specified special protection electrical wiring, fittings and receptacles.

-excess flow check valves, remote operated valves

-fail-safe instrumentation with redundancy

-structural fireproofing and low smoke fire retardant cables

-fire-cable insulation

-gas –leak detectors, alarms, trips, interlocks.

One has to review to come up with the required design.

6

Foundations

Soil test is prime requirement to ensure foundation stabilities. The characteristics to

be analysed are listed below depending on the terrain.

Sample testing

Soil fraction sieve analysis as per IS 460-1962

Liquid limit determination

Natural moisture content determination—as per IS 2720 Part II 1969

Bulk Density as per IS 2720

Triaxial tests as per IS 2720

Consolidation tests

Chemical Analysis

Obtain Foundation recommendation based on the test results validated by a certified

Chartered Civil Engineer.

Civil engineers may insist more

Drains:

Interdependent drains of caustic, acid and hydrocarbon liquids are harmful.

Accidental mix of caustic/acid or hydrocarbon entry into storm water drains is

disastrous. Spillage recovery system and oil/water seperators should be of approved

design.

Overflow:

Similarly volatile liquid storage tanks do not have open overflow while on sulphuric

acid tanks they are not an unusual sight.

Bundwalls:

Bundwall design should ensure minimum ten percent (10%) excess capacity hold upto

the full tank capacity and should be resistant to tank contents. Leaching and seepage

tests are essential.

7

Metallurgy for storage tanks :

Metallurgy suitable for one substance need not be for another. While carbon steel is

suitable for concentrated sulphuric acid , some other acids can corrode it

even at low concentrations . Though ammonia at positive temperatures is

transported /stored without additional refrigeration in carbon steel tanks, Ammonia at

–33 degree centigrade requires special steel to avoid low temperature, caustic

embrittlement and creep failures. Dilute sulphuric acid evolves hydrogen with steel

and aqua ammonia can attack brass, copper and gunmetal components.

Contamination with Air (excess oxygen) can promote stress corrosion cracking in

ammonia storages and presence of water can cause solidification and crack failures of

valve bodies and Low temperature (freezing point) in pipelines/ accessories.

Sometimes even air used for passivation of exotic metal liners of reactors

(to retard corrosion) has been known to have contributed to accidents .

Engineering inspection/ Condition monitoring and

Predictive maintenance.

Despite various measures, corrosion is a significant issue. From pitting to external

scaling it can assume many forms. In a typical carbon steel concentrated sulphuric

acid storage tank this can vary as:-

-Uniform corrosion

-Hydrogen grooving

-Horizontal grooving

-Weld corrosion and defects

-Galvanic corrosion- dissimilar metals

-Erosion corrosion

-End-grain attack

-Corrosion of tank internals

-Crevice corrosion etc

Attention spots

Inlet pipes, nozzles, roof, edge of shell plate, shell plate weld seams, between

tank bottoms and foundations, behind reinforcing pads for manholes or nozzles

or behind fillet-welded repair patches are area to watch

8

Changes/Condition monitoring

Any modifications or deviation to codes should have the endorsement of plant

Senior Management review team and the Designer.

Condition monitoring by qualified personnel well versed with codes and calibrated

monitoring instruments facilitates identification of problem in advance and,

prevention of catastrophic failures by resort to predictive maintenance.

Following standards are valuable reference.

API/OISD/DIN/JIS/EU/National standards etc

9

Operational phase

Basic elements of Pre–commissioning checks should include (Illustrative)

Blinds.

Calibration of instruments and process control devices.

Check for ice-formations under valve seats in low temperature services.

Check of loading arms and transfer hoses for ship to shore transfer, gantries.

Functional checks of electrical instrumentation and failsafe devices.

Functional integrity checks of fire protection system such as pumps, system

components and network.

Functional integrity checks of gas leak sensors and related interlocks, manual fire call

points, manual and emergency fire sirens, plant fire siren, one-touch emergency push

button.

Functional integrity checks of valves, alarms, trips, interlocks, set points.

Gaskets, bolts, nuts, washers, threads

Level gauges

Line blowing, purging, displacement and evacuation procedures

Operational permits introduction

Pipeline tracing checks to ensure continuity

Pressure gauges

Pressure leak tests

Punch list generation for safety items and addressing of any deficiencies

Purge status

SOPs and Special PPE

Valves

Vents, drains, elbows, flanges

10

The following Drawings /Documentation /Calculation sheets should be preserved

( Illustrative )

Statutory Approved Layout drawings

Fabrication drawings

Soil Survey reports/Foundation recommendations

Pipelines sectionalised drawing/Isometrics

HAZOP Reports

Load calculation sheets for structurals

Structural stability reports

Pipeline routing drawing

Hazard Area classification drawing

Earthpit layout drawing

Lightning protection coverage drawings

11

Post-commissioning phaseGeneral Hazards can also arise from: Causative Factors (Illustrative)

Abnormalities in operation/ initiating event.

Equipment upset condition.

External fire damage.

Failure of pipe due to erosion or corrosion.

Failure of pumps seal.

Failure of fill/transfer lines.

Flange/gasket leaks.

Higher-pressure transfer.

Human error.

Improper procedures.

Improper selection of equipment for hazard classified areas.

Leaks to atmosphere, passing of valves, relief release.

Level/Flow/Temperature Control failures, Bye-pass condition.

Line fracture due line feed to tank being closed, overpressurization.

Line reverse flow protection valves malfunction.

Malfunction /failure of control valve.

Overflow/ spill, leak due to passing valves into collection sump.

Physical impact.

Pumping continues when tank already on high level

Pump seal leak Fire.

Rapid pumping of product causing Static charge build up

Relief valves/rupture discs faulty.

Uncontrolled hot work, maintenance activity/ inactivity.

Unsafe conditions.

Valves in the line closed.

Weather conditions.

Weld failure.

Rapid pump out with vent blocks can cause Storage to buckle.

12

Ignition sources may be:

Cutting and welding flames

Electrostatic discharge sparks

Friction heating or sparks

Hot surfaces

Impact sparks

Lightning strikes

Sparks from electrical equipment

Use of cigarettes/matches etc

Warm Surfaces, Flames

Static electricityGenerally Static Electricity is an issue in the following Unit Operations:

Sampling

Pumping

Ullaging

Flange joints

Environmental/NaturalLandslide/Upheaval

Earthquake

Storm/Flood

Subsidence

Lightning

13

Consequences and Nature of Fires:

Bulk Storage fires

Pool fire due to rupture and outflow

Flash fire

Jet Fire

Torch Fire

Vent fires

Vapour cloud explosion due to leakage and accumulation

Vapour cloud ignition/explosion, if unburnt

Flash backs

BLEVE (Boiling Liquid Expanding Vapour Explosion)

In case of storage to process equipment routing, the following can be valid.

Containment failure

Instantaneous release

Continuous release

Leaks/overflow

Pipeline leaks

Pump Mechanical seal leak

Fill/transfer lines failure

The release of Hazardous substance can result in any of the following scenarios.

Instantaneous release:

This will occur in case storage tank fails. The source strength is equal to contents of

the capacity of the storage tank.

Continuous release:

In this category, continuous release from process vents and fugitive emissions like

storage tank breather vents are not generally factored.

The gas/vapour otherwise discharged will spread in the surrounding area under the

influence of atmospheric turbulence.

14

Broad category of hazard/risk/harm control measures

Layout--Inter distances.

Engineered—Built-in Safeguards.

Operational/instrumentation controls.

Procedural controls.

Fire and emergency combat, control and containment.

Special PPE like Fire proximity suit, Gas tight chemical suit etc.

Explanatory note:

Equipment Controls--- Built-in fail-safe controls

Instrumentation controls—DCS/PLC/SCADA

Temperature/Pressure sensitive reactions merit close attention.

Procedural Controls –SOP, work instructions, checklists, Batch logs etc

Fire protection—Fixed, Portable, Fire classification specific wet networks

Job Safety Analysis:

A comprehensive pre-commission Operational and Safety checklist should be

prepared based on HARA and HAZOP study done.

Developing a plant operation and safety specific checklist using the logical sequence

approach will be beneficial.

The implementation of Job Safety Analysis will facilitate hazard identification and

safe work methods.

Summary of the steps for JSA is reproduced below:

Assess the present job method correctness

Enlarge details

Correct/Eliminate hazard conditions

Introduce Safety Do’s and Don’ts checklist

Issue Work instructions card

Conduct refresher training for change

PDCA--Observe/Correct

Change physical condition /Job procedure, Issue New /revalidated procedure

15

Transportation:

The LSA can be put to good use inside the plants. But when the time comes to move

the material from storage to consumer destinations outside the plants after processing,

a variety of different safety issues emerge.

The common mode of transport is road tankers though movement of hazardous

cargo is also done by rail cars and ships . Regulations for the movement of

Dangerous Goods by ships/rail are covered under IMO, IRS, IBC and DGM

regulations

Confining to the topic of movement by road tankers, the ICMA booklet on

“Code For Safe Transportation Of Hazardous Substances By Road” is a good

reference.

Plant checklist should not be limited to, but include:

-Verification of tankers fitness/roadworthiness/licences to haul designated cargo.

-Hazchem labels on panel and Tremcards are available.

-Tanker fitness ensured to avoid incompatible chemical mix.

-Spark arrestors and anti-static chains fitted.

-Approved PPE, fire fighting and first aid equipment carried.

-Wheel chocks available and driver qualified and trained to communicate incidents.

-Basic training imparted to the driver.

-Level gauges, relief valves, vacuum breakers, non-return valves and, excess flow

check valves are in good working condition.

-Tanker master isolation valve fitted and in working order.

-Ladders and platforms are in good condition.

-Unloading hoses are tested and leak tight condition.

-Standard operating procedures detailing sequence of valve operation and safe

recovery of residual vent during hose disconnect and tanker loading is published and

used.

-Safe height venting.

-Loading areas access restricted, and plant safety regulations enforced.

-Tanker entry and exit routes clearly defined and understood by all.

-Portable leak detectors kept handy at site.

-Loading operations or even unloading operations not carried unattended.

-Public Liability Insurance cover taken by the plant as per requirement.

16

Contingency Management Plans :

Clearly documented, easily referenced and well-rehearsed spillage and disaster

contingency management plans are to be kept ready for easy access any time to

authorised personnel.

Monitoring and measurement

Evolve a Management SHE Planner calendar (Illustrative)

The calendar items can include:-

Licences status.

Pollution samplings frequency.

Pressure vessel/Lifting appliances checks.

Statutory inspections follow up status.

Internal audit schedule.

Other audits programme.

Electrical audit.

Open issues review.

Earthpit checks.

Lightning protection checks.

Electrical relays checks.

Transformer oil checks.

Environmental audits.

Environment Statement submission.

PM Plan compliance/deviations.

Condition monitoring programmes –Pipelines in a planned and progressive manner, including the Painting programme.Non-Destructive tests.

Fire & Safety Equipment inspection status.

Safety committee meeting.

Mock drills.

Training.

Medical examinations.

World/National Safety day/Environment day.

Continual improvement measures, Objective setting based on Key Focus area

17

Internal /External audits based on standard templates

Audits well structured and scheduled periodically will enable timely detection of

potential hazards and proactively take preventive actions from incidents emerging.

Illustrative contents of well structured audits

5-Star

AUDIT ELEMENTS:

Safety Organisation:

Policy, Strategy, EHS Training & development, Inspection systems,

Contractors’ safety, Permits system, Internal safety audits, Safety organisation,

Committees, Safety promotional and publicity activities.

Management control systems:

Equipment control systems, Engineered controls/Built-in safety,

Pressure vessels/Lifting appliances, Hazardous material control,

Electrical installation safety, Personal safeguards, Hand & power Tools.

Fire control systems :

System integrity and certification, Proactive fire prevention measures, Emergency

planning, communication and response, Hydrocarbon storage area safeguards.

Measurement control systems:

Reporting systems, Incident investigation procedures, Performance measurement

systems and display

Workplace implementation:

Industrial Hygiene—Lighting, Ventilation, Noise, Heat, Fumes/Vapour Containment,

Housekeeping, Waste Management.

18

Process Safety Management: (Code of Federal Regulations 1910-119 USA)

Process safety information

Process hazard analysis

Standard operating procedures

Training

Contractor control

Pre-start up safety review

Mechanical integrity

Non-routine work authorisation

Management of change

Investigation of incidents

Emergency preparedness

Compliance audit

Employee participation

If the Organisation Safety culture is at a stage to adopt Audits under International

Safety Rating System, it enables reference benchmarking The elements of OSH:

BIS 14489Occupational Safety and Health PolicyOS & H Organisation set

upEducation and trainingEmployees’ participationMotivational & promotional

measuresSafety Rules & manualCompliance with statutory requirementsRisk

Assessment including hazard identificationSafety inspectionsHousekeepingMachine

guardingElectrical and Personal

safeguardingVentilation/Illumination/NoiseEnvironment monitoringMedical

examinationsSafe operating proceduresWork PermitsFire Prevention/protection/and

fire fighting systemsEmergency preparedness planManagement of

changeTransportation of hazardous substancesWaste treatmentStorage area

safetyContractor safety systemsSafety for customersAccident reporting and

analysisFirst aid facilitiesPPEImprovement PlansConclusionIt is rather strange but

true that the High-risk industry particularly those handling Toxics, Flammables,

Corrosives, Explosives, Radioactive, Biohazard boast of some of the best-known

safety records in relation to the hazard involved. But the performance is sometimes

obscured by adverse publicity, particularly when it involves genuine community

concerns of Safety/Health and Environment.Reliance on information data banks, in-

house and external expertise and applying a logical approach to incident prevention

can only bring cheer.Despite the risk analysis by any method, incident free operation

involvinghazardous substances still remains a challenge.Safety is an on-going

19

process. Regular audits using standard risk analysis methods and build up of a

Database (MIS-Management Information System) will ensure that, the quest for

betterment is never ending. Credits: Statutory regulationsStandards and CodesCode

of Federal RegulationsPublicationsWikipediaAIChEEngineers Tank

ManualHMSONational Safety CouncilsEvents and occurrencesBest industrial

practicesProfessional handshakes List of abbreviationsAFNOR Association

française de normalisation (French Standards)AIChE American Institute of Chemical

EngineersAPI American Petroleum InstituteASME American Society of

Mechanical EngineersASTM American Society of Testing MaterialsBIS Bureau

of Indian StandardsBSI British Standards InstitutionDCS Distributed Control

SystemDGR Dangerous Goods RegulationsDIN Deutsches Institut für

Normung German StandardsEU European DirectivesHARA Hazard Analysis

and Risk AssessmentHAZOP Hazard OperabilityHMSO Her Majesty’s Stationery

OfficeIBC International Bulk Cargo IBR Indian Boiler RegulationsICMA

Indian Chemical Manufacturers AssociationIER Indian Electricity RulesIMO

International Maritime OrganisationIPR Indian Petroleum RulesIS Indian

StandardsJISC Japanese Industrial Standards CommitteeJSA Job Safety

AnalysisLSA Logical Sequence ApproachNEC National Electric CodeNFPA

National Fire Protection AssociationNOC No Objection CertificateOISD Oil

Industry Safety DirectoratePDCA Plan, Develop, Check and ActPLC Programme

Logic ControllersPPE Personal Protective EquipmentSCADA Supervisory Control

and Data AcquisitionSOP Standard Operating ProcedureUNI Ente Nazionale

Italiano di Unificazione (Italian)

20