LIVE.WORK.GROW. Volume 3, Issue 1 - Central Illinois Ag

-

Upload

central-illinois-ag -

Category

Documents

-

view

221 -

download

6

description

Transcript of LIVE.WORK.GROW. Volume 3, Issue 1 - Central Illinois Ag

m m

www.centralilag.com · Volume 3, Issue 1 1

Live.Work.Grow.

CENTRAL ILLINOIS AG

Volume 3 Issue 1

ATLANTA · CLINTON · FARMER CITY · MASON CITY

m1 · Central Illinois Ag · www.centralilag.com

Have an article suggestion or would like to advertise?Contact Abby at (217) 648-2307 or [email protected]

Live.Work.Grow.4 A Letter from Steve and Michael Schmidt5 Chad Colby, General Manager

9 Measuring Data from the Case IH 215012 Heavy Usage Seed Tenders

15 Top Quality for Top Growers18 Never Going Back19 Sales Team

20 Inventory25 A Grower’s Review of the Landoll 855027 Destination: Monsanto for the City Moms30 Potential for More32 & The Winners Are...

34 Growers Need Same Day Data

36 Largest Track Loader38 Employee Spotlight

7Rethinking Productivity

13For the Love of Farming

19Sales Team

33Aerial Imagery

33Compact Machines

A note from abbymarketing coordinator, central Illinois agThank you - farmers, customers, business representatives, and employees - for allowing me to visit your farm/job site and to share your story throughout the pages of this magazine. Your story, from equipment to technology, is valuable to the thousands of readers across the nation. Be sure to connect with Central Illinois Ag online to stay informed on what we are doing year-round through Facebook, Twitter, Instagram, and YouTube.

*All articles in this issue were written by me, Abby Coers, unless otherwise noted.

Steve Schmidt Chief Executive Officer

Michael Schmidt President

Brian Reeser Vice President

Tim Evans Chief Financial Officer

Chad Colby General Manager

Abby Coers Marketing Coordinator

Abby C oers

m m

www.centralilag.com · Volume 3, Issue 1 2

Live.Work.Grow.

The most people, on the ground, in Illinois, covering Illinois

agriculture for you.

CLICKLISTEN READ

Richard Verdery

Gary White

Nan Fannin

Bob Standard

Mobile/App Advertising on FarmWeekNow.com

FW467T5

BUY BUSH HOG

When PERFORMANCEMATTERS!

With over 60 years of experience and a reputation for quality and durability, Bush Hog® is truly the brand you can count on!Bush Hog® was built from the innovation of farmers needing rugged performance and durability in a cutting implement. The first ever rotary cutter was built in the 50s by Bush Hog,® and from that one machine has grown a full line of heavy-duty rotary cutters. Bush Hog® now offers construction implements, commercial turf, and professional landscape, and lawn care equipment, all built with the same standards and innovations that made the first Bush Hog® synonymous with quality and dependability. Bush Hog® is performance you can count on!

in Selma Alabama

MadeBUSHHOG

www.bushhog.com

Central Illinois Ag is proud to be your Bush Hog dealer!

Abby C oers

m3 · Central Illinois Ag · www.centralilag.com

All rights reserved. Case IH is a trademark registered in the United States and many other countries, owned by or licensed to CNH Industrial N.V., its subsidiaries or affiliates. www.caseih.com

BE READY.

SEE US TODAY.

For nearly 20 years, we’ve left the competition with some pretty big tracks to fill. But in the rush to keep up, there are a few things the copies have missed. Like our exclusive five-axle design. It gives our Steiger® Quadtrac,® Steiger Rowtrac™ and Magnum™ Rowtrac tractors a smoother ride and more power to the ground with less berming and compaction. Which is one of the advantages of paying your dues, instead of paying homage. Learn more at caseih.com/tracks.

CENTRAL ILLINOIS AG, INC.200 SHARON STREETP.O. BOX 506ATLANTA, IL 61723217-648-2307

m m

www.centralilag.com · Volume 3, Issue 1 4

Wow! The past year has been nothing but non-stop fun at Central Illinois Ag. As fourth and fifth

generation owners of Central Illinois Ag, we look back on the ‘good old days’ fondly; but more importantly we focus on each day, moving forward to the best days ahead. Because after all, everyday is a good day.

On June 2, 2015 we moved into the new building for our dealership in Atlanta with a heated/air conditioned shop, a showroom to display the latest equipment, and a conference and training room equipped with the latest technology to provide you with educational meetings throughout the seasons. The past year since we moved in has been great- and we can’t thank you enough for the support!

It was an honor to host Case IH President Andreas Klauser at Central Illinois Ag, along with numerous Case IH corporate employees this past summer. We’ve also welcomed many individuals and business owners from around the world, including Germany to Russia. If you haven’t visited the new dealership, stop by and we will gladly show you around!

Chad Colby joined our team as General Manager in April 2016. His previous professional experiences fit in perfectly with the goals and visions of Central Illinois Ag. We look forward to the expertise he brings to the family-owned business. Read about Chad on page 5.

The ever-changing technology leads to new equipment, and with that Case IH released the new 2000 series planter. We had the opportunity to test the planter on several different fields and the results are unbelievable!

See what our test results revealed on page 9.

Most of you who know that we’re more of a ‘hands-on’ dealership so be sure to connect with us on social media. Stay updated with what we’re up to and view photos/videos straight from the field.

With all this excitement, it’s important to focus on the employees of Central Illinois Ag. Our family has been in business since 1898 because of them. Thank you for the hard work, ever-changing times, and excitement as we move forward to another season.

We hope you had a great planting season and we look forward to a smooth harvest. As always, please contact us if you need anything. As a family-owned business, YOU are also part of the Central Illinois Ag family.

moving forwardA letter from Steve Schmidt and Michael Schmidt, Owners @MPSchmidtAg

Photo (L to R): Owners of Central Illinois Ag Tim Evans and Steve Schmidt, Case IH Senior Director of Harvesting Eric Schuman, Case IH President Andreas Klauser, Owner of Central Illinois Ag Michael Schmidt, and Case IH National Account Manager Marty Chamberlain

Photo (Back L to R): Steve Schmidt, Gov. of Illinois Bruce Rauner, Michael Schmidt, Owen Schmidt, and Kara SchmidtFront (L to R): Collin Schmidt, Alec Schmidt, and David Schmidt

Steve and Michael

m5 · Central Illinois Ag · www.centralilag.com

Chad Colby, a first-one-in-the-cab kind of guy, social media expert, and industry advisor joined

the Central Illinois Ag team in April 2016. As General Manager of Central Illinois Ag, Chad works closely with each department to help best serve you, the farmer.

His prior experience in sales, marketing, and product support create a solid background for the general manager role at Central Illinois Ag. Chads’ business and practical understanding, along with technical knowledge, will advance the Case IH dealership into the future.

He founded ColbyAgTech.com, where he has worked with progressive farmers, leading companies and government agencies to provide a more thorough understanding of the use and the practical applications of new technologies. As a well-known speaker and agricultural technologist, Chad has been a keynote speaker hundreds of times from Washington, D.C. to Australia. Chad is also a frequent contributor to the popular ag television program “This Week in Agribusiness” hosted by Max Armstrong and Orion Samuelson.

“Educating farmers is job one” Chad says. “There is so much to learn in this latest flush of technology; it’s a real challenge. But technology will be critical in doubling global food production by 2050.”

From technology to tractors, Colby has served farmers and growers with his expertise and experience.

Chad was attracted to Central Illinois Ag because of the strong and stable foundation formed by owners Steve Schmidt, Michael Schmidt, Brian Reeser, and Tim Evans.

“Chad’s one-of-a-kind strengths in ag technology prepare our family owned company to serve our customers as never before. His knowledge and commitment will serve this business and our customers not just in the near term, but also for the next 20 plus years,” said Michael Schmidt.

Chad grew up on his family farm in Tiskilwa, IL. The Colby family farm always had red equipment. In fact, Chad says, they had one of the first Case IH Axial-Flow® combines — a 1440 they purchased in 1978. “Today, Case IH has a machinery lineup like it’s never had before.”

Chad currently resides in Goodfield, IL with his wife Karen Corrigan who is a business partner in McGillicuddy Corrigan Agronomics, and their two daughters Mara and Bristol.

Contact Chad at [email protected]

Chad ColbyGeneral Manager, Central Illinois Ag @TheChadColby

Photo: Chad Colby began his career as General Manager of Central Illinois Ag in April 2016.

m m

www.centralilag.com · Volume 3, Issue 1 6

m7 · Central Illinois Ag · www.centralilag.commm7 · Central Illinois Ag · www.centralilag.com

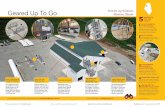

RETHING PRODUCTIVITY: Track Technology, AFS RTK+ Boost

CASE IH CELEBRATES 20 YEARS OF TRACK TECHNOLOGY

In 1996, Case IH introduced a new tractor that changed the industry: the 8370 Steiger® Quadtrac® tractor. And

while others have entered the field since, we’ve spent decades expanding the track horizon. Building on 20 years of field-proven technology, today’s lineup includes a track model for any application, any width and any cropping need.

Ultimate row crop flexibility: As the newest member of the Case IH track lineup, the MagnumTM RowtracTM tractor combines the benefits of tracks with the maneuverability of mechanical front-wheel drive. This combination of low compaction, high traction and ease of handling make the Magnum Rowtrac well- suited to a variety of crops. Narrow track widths and row spacings match your specific cropping system, including easier travel for side-dress applications.

Most horsepower available: The original five-axle design of the Steiger Quadtrac tractor minimizes compaction through even weight distribution, providing a balanced and continuous footprint for maximum traction. This system reduces berming, improves operator control and delivers consistent power to the ground — even through the tightest turns. A 682-peak horsepower handles the largest implements, helping cover more acres in less time.

Power, comfort and flexibility: A longer tractor combined with a narrower frame help the Steiger Rowtrac provide a smoother ride with more power to the ground. Better traction reduces compaction by minimizing slippage on the soil surface. Plus, each track drive oscillates up and down up to 10 degrees to maintain consistent ground contact no matter the field conditions.

NEW AFTERMARKET AUTOGUIDANCE SOLUTION AND AFS RTK+ BOOST EFFICIENCYLATEST AFS ADVANCEMENTS PROVIDE

From field preparation through to harvest, the latest Advanced Farming Systems (AFS) capabilities

make precision farming technology more attainable to producers of all sizes. Two new upgrades, ElectriSteer and AFS RTK+, will be a welcome addition to current AFS offerings this spring.

ElectriSteer

If you haven’t already taken advantage of autoguidance capabilities, ElectriSteer offers an affordable

aftermarket option. Quickly clamping onto the steering wheel, this component connects with your AFS Pro 700 monitor and can be easily transferred from one vehicle to the next. Within minutes of installation, ElectriSteer provides high torque and a positive drive with whisper-quiet operation. Additional features include guidance patterns and swath algorithms, nudge and remark functionality, plus added aggressiveness during guidance line acquisition. ElectriSteer is available for more than 800 vehicle makes/models.

AFS RTK+

Make the most of all your inputs with AFS RTK+. Offered through AFS ConnectTM and available

for purchase through your participating Case IH dealer, a Case IH AFS RTK+ network subscription allows you to achieve pass-to-pass accuracy. Cellular guidance correction signals alleviate line-of-sight issues, including hills, valleys, trees, buildings or other structures — extending your distance of travel from a cellular base. Seamless connectivity reduces application overlaps and skips, improves field efficiency and allows for more accurate placement of inputs, such as fertilizer and herbicides. This helps achieve repeatability — even in the most narrow rows — keeping tire tracks on the same path to reduce compaction.

Ask Central Illinois Ag about how to sign up for a free one-year subscription to AFS Connect — available for a limited time.

m m

www.centralilag.com · Volume 3, Issue 1 8mm

NEW 2000 SERIES INTEGRATES ALL-NEW RUGGED ROW UNIT WITH LEADING SEED PLACEMENT TECHNOLOGY

From the all-new rugged row unit to the integration of the industry’s most accurate planter technologies,

Case IH redesigned the new 2000 series Early Riser planter to ensure faster, more uniform emergence. Whether you’re planting at 10 miles per hour or at a slower pace for your conditions, the new Early Riser planter is consistently accurate.

AGRONOMICALLY DESIGNED ROW UNIT

Heavy-duty cast components — including the row unit frame, lower parallel arms and maintenance-

free gauge wheel arms — help the new Early Riser planter stand up to high speeds and tough, fast- changing conditions. A 26-inch toolbar clearance, plus 16 inches of vertical row unit travel, accommodate uneven terrain without sacrificing accurate seed depth and consistent closing. Larger, heavier Earth Metal® offset opener blades are agronomically designed to slice through tough crop residue, while exclusive pulled gauge wheels and their soil relief grooves help eliminate sidewall compaction.

Integrated technology delivers precise placementDeveloped just for the new Early Riser planter, the new vSet® 2 meter and vDrive® electric drive systems deliver accurate and consistent seed singulation, populations and in-row spacing. DeltaForce® automatically provides the required up-or-down pressure necessary to achieve consistent weight on the gauge wheels. The hydraulic down force delivers the ultimate row-by-row control across varying soil conditions and speeds. Not to

mention, Overlap Control and Curve Compensation allow each row unit to function like an independent planter, minimizing inputs and eliminating the need for clutches, cables and chains.

Tailored, flexible and dependableEach new Early Riser planter can be configured direct from the factory to meet the needs of any operation based on soil type, terrain, fertilizer/ chemical preferences and residue management. A streamlined design makes service access easy and simplifies adjustments. Plus, tool-free crop changes and adjustments ensure you can hit critical planting windows with confidence

CENTRAL ILLINOIS AG TESTS PLANTEROur Precision Planting team at Central Illinois Ag along with Precision Planting Representative Eric Huber found results of how the planter performed. View the results and findings on the next page.

Learn more at: www.centralilag.comwww.caseih.com/rethink.

*Articles on page 7 & 8 excerpted from “Case IH News: 2016 Winter Farm Show Edition”

2000 Series Early Riser Planter

m9 · Central Illinois Ag · www.centralilag.com

The research and development team at Precision Planting begins with a theoretical problem. How

do you solve this problem? Measurements. Ever since Precision Planting began developing products, they’ve used measurements for tests and therefore have gotten results. Greg Sauder started with the test stand to visually see the meters work, creating the 20/20 monitor placed in the cab to measure performance in high definition. Now, we understood the down force which led into AirForce®, before then measuring data for DeltaForce™.

“We measure to get a better understanding and now we can tackle challenges,” said Eric Huber, Precision Planting Specialist.

Eric, Central Illinois Ag Precision Planting Specialist Rush Olson, and Central Illinois Ag owner Michael Schmidt had the opportunity to measure crops planted with the Case IH 2150 and analyze the results using the Pogo Stick.

POGO STICKThe pogo stick came from the late engineer Derek Sauder as he would evaluate closing systems. Instead of measuring spacing and typing in numbers by hand, the Pogo Stick is a tool that automatically measures the distance between plants, specifically looking at emergence issues.

“The faster we can gather data, the more complete information we have to make a better product,” said Eric.

The Pogo Stick can be used any time during the season to take data from the 20/20 and visually see what the ground actually looks like. While the 20/20 monitor says singulation is near perfect, we are now able to test the results and validate the performance. Singulation issue? Emergence? Spacing? Let’s look at the problem and find a way to correct it.

As an equipment dealer, we can use the Pogo Stick to show weak spots with equipment. The placement was great, but was the closing set exactly where we would like? Let’s look at how your planter can fix the problem.

The Pogo Stick is also very efficient to collect a myriad of data compared to hand sampling. Within two to three hours, we were able to collect data from 2100 plants.

MEASURING DATA FROM THE CASE IH 2150

Photo: Rush Olson using the Pogo Stick and digging to find either late emergence or a missed seed.

m m

www.centralilag.com · Volume 3, Issue 1 10

We compared four Case IH planters (955, 1255 stock, 1250 with SpeedTube™ (beta), and a 2150) specifically looking at speed passes to see how the evolution of technology has impacted planter placement accuracy.

RESULTS

CONCLUSIONTwo planters lined up with the best results: the Case IH 1250 with SpeedTube™ (beta) and the Case IH 2150. We saw amazing placement and accuracy at 10 miles per hour for the Case IH 1250 with the current technology of SpeedTube™. The Case IH 2150 had better spacing , over the Case IH 1250 with SpeedTube™ (beta), but a slight decrease in singulation.

*Tillage practices were different in the fields, anytime planting occurs in wetter conditions it creates a challenge to place and close the trench.

As technology has developed so has plant

placement - not only that, but we can also maintain that accuracy

with higher speeds.

Case IH 955 at 6 mph vs. Case IH 2150 at 10 mph to show how the planter at 10 mph compared to 6 mph on the Case IH 955.

Case IH 955

94%Singulation 6 miles per hour

Case IH 2150

98%Singulation 10 miles per hour

vs.Case IH 1250 with SpeedTube™ at 6 mph, 8 mph, & 10 mph vs. Case IH 1255 stock at 6 mph, 8 mph & 10 mph to show how the planters compared with SpeedTube™ vs. stock.

Case IH 1250w/ Speed Tube™ (beta)

99%Singulation

Case IH 1255Stock

97%Singulation

vs.

There was amazing placement potential from 5-10 mph. Planting conditions were a bit marginal and overall we struggled with the disc closer in less than ideal conditions. Planting conditions are critical to emergence success, and a planter that can push 50% higher production allows the grower to wait for the right window because of his increased efficiency.

90% Spacing 79.5% Spacing

81% Spacing 94.7% Spacing

*Note: Spacing values due to populations in these fields the true comparison is standard deviation. Case IH 1250 with the aftermarket SpeedTube™ (beta) was a 1.22 standard deviation. Case IH 2150 was a 1.32 standard deviation. Statistcally, the results were very similar.

m11 · Central Illinois Ag · www.centralilag.comJ&M Manufacturing, Co, Inc284 Railroad Street • Fort Recovery, Ohio 45846 • (419) 375-2376 • fax: (419) 375-2708www.jm-inc.com

AtlantaClintonFarmer CityMason City

510 SpeedTender™ 275/375 SpeedTender™ c4•50 SpeedTender Pro™ 2•50/4•50 SpeedTender Pro™

Convenient Open 11 HP

Honda Engine PlacementGentle on Seeds for

Maximum YieldsNew Kingpin Hitch available on 510ST Models Trouble Free Belt Alignment Patented Tru-TrakConveyor Design

BULK TENDERS 275 | 375 | 510

• X-tra Long Conveyor• Patented V-Belt Design• Easy To Use Self-Filling Design• Low Center of Gravity• Full 180º of Motion• Larger Tank Opening for Easy Complete Fills

PRO BOX TENDERS 2•50 | 4•50

• X-tra Tall Auger with 3-Stage Telescoping Spout• Easily Fills Tall Bulk Planters or Wide Planter Boxes• Gentle Plastic Poly-Cupped Auger• 11 HP Honda Engine with Electric Start• Two (2) 7,000 lbs. Axles with Electric Brakes (4•50 Model)• Two (2) 4,400 lbs. Axles with Electric Brakes (2•50 Model)• Convenient Open Engine Placement

PRO BOX CONVEYOR TENDERS C4•50

• X-tra Long Conveyor• Patented V-Belt Design• Easy To Use Self-Filling Design• 11 HP Honda Engine with Electric Start• Two (2) 7,000 lbs. Axles with Electric Brakes• Convenient Open Engine Placement

PATENTED TRU-TRAK™ V-BELT DESIGNA patented V-Belt and skirting design keeps the belt centered, reducing seed damage and chance of premature wear due to misalignment. Competitor conveyor designs feature crowned rollers that allow the belt to “walk” back and forth, making it difficult to maintain alignment, causing premature wear.

V-Guided Belt

Grooved End RollerSkirting

New!

P A T E N T E D

SeedTender_Full_Page_central_illinois.indd 1 5/20/16 3:28 PM

m m

www.centralilag.com · Volume 3, Issue 1 12

Beginning in 1960 J&M Manufacturing has developed leading edge equipment to haul grain including a

full line-up of ‘Speed Tenders’ (seed tenders) including pro box and bulk fill designs.

Jason Schmidt, owner of Illini Ag and a Channel Seedsman in Lincoln, IL has first-hand worked with a variety of seed tenders. As a Channel Seedsman Jason includes a seed tender complimentary to his clients. He chose J&M seed tenders due to the amount of heavy usage each season.

From farmer recommendations and personal experience, Jason believes the 375ST, 510, and 450 (4 box) are the best for his client and business needs.

“J&M is built heavier and has a better finish,” Jason said, “I’m impressed with the capacity of the 500’s and how nice they pull on the road.”

The 500’s are Jason’s favorite seed tender because of the capacity, speed of the conveyor, and the hydraulic swing. When there are a lot of features on a machine, one would think something would go wrong - but that’s not the case with J&M, in fact, the opposite is true. With minimal problems, Illini Ag and his Channel clients are able to get through the planting season smoothly.

CENTRAL IL AG IS MORE THAN A BUSINESSUntil a couple years ago, Central Illinois Ag was just an agricultural equipment dealership to Jason but his business relationship with the company has developed into a close-knit friendship. As part owner of leading edge UAV company, Flying Ag, and a farmer himself, Jason has attended several of the same conferences as Central Illinois Ag.

He understands that your ag dealership shouldn’t just be about business, but it should be about a company who is there for you and cares for your operation like family. “The feeling of confidence when walking through the doors at Central Illinois Ag in Atlanta is indescribeable. As a farmer and business owner myself, they are always

watching out for my needs,” Jason said.

Michael Schmidt, Salesman and owner of Central Illinois Ag, has helped Jason succeed with his seed business by presenting him with equipment that would be best for his clients.

“Central Illinois Ag is a family business, not just the owners generation of family, but this family business includes the customers,” Jason said.

TO LEARN MOREJ&M Manufacturing: www.jm-inc.comJason Schmidt, Channel Seedsman, (217) 737-5354

HEAVY USAGE SEED TENDERSm

www.centralilag.com · Volume 3, Issue 1 12

Photo (top): Seedsman Jason Schmidt, allows customers to use his seed tenders as a thank you for purchasing Channel seed from him.Photo (bottom): A farmer weighs seed using the J&M 375ST.

m13 · Central Illinois Ag · www.centralilag.com

for the love of farmingShe’s a wife, mother of two, and a farmer. Jennifer

(Heck) Jacobs from McLean, IL grew up on the family farm, where she learned the value of hard work. It was ‘just another day’ to be in the field with her dad, jeans covered with dirt and hands slimed with grease.

Jennifer may not have been aware of it at the time, but the values her parents displayed on the farm would stay with her forever. With a strong work ethic she graduated from Illinois State University in 2004 with a Bachelor of Science with a Agriculture-AgriBusiness degree. The skills and knowledge learned led her back to the farm and the life she enjoyed most.

“My family is my support system. If it wasn’t for my family I wouldn’t have the opportunity to be a farmer,” said Jennifer.

Jennifer’s husband, Andy, is also a farmer. Their two children, Kaleb and Kaitlin, enjoy riding along in the tractor. Just as Jennifer was taught a strong work ethic, she hopes the same for their children.

To the outside world, being a woman farmer may seem different. To Jennifer, it’s her career choice. While she attends agriculture-related meetings, it’s not a room full of men and one woman. To her, it’s a room of farmers.

“My mother and grandmother were always in the field running the tractors, hauling wagons, and helping load the planter. I grew up not even thinking this isn’t normal

because I had two awesome women doing it before me,” said Jennifer.

Her dad never set a limit on his two daughters. He knew a woman was capable of doing what she put her mind to. Still today, Jennifer has no limits.

“You need to work hard at whatever you do,” said Jennifer, “that’s what really matters.”

Would she recommend her daughter to follow in her footsteps? “Absolutely! Just as much as I would my son.” Jennifer is proud of the hard work needed to plant and harvest her crops, and to have a rewarding career where she can help feed the world.

Follow your heart, set goals, and don’t limit yourself on what can be done.

Photo (left): Jennifer and Kaleb working togetherPhoto (below): Jennifer and Kaitlin checking seed counts

m13 · Central Illinois Ag · www.centralilag.com

m m

www.centralilag.com · Volume 3, Issue 1 14

Farmer TodayIllinois Practical.

Weekly.Timely.

Useful.

Meet the Team

If you’d like to place an ad or have a story idea we would love to hear from you.

www.IllinoisFarmerToday.com

Northern ILField EditorPhyllis CoulterBloomington, IL(309) 660-5701

Northern ILAccount ExecutiveKaren ParsonsWashington, IL(309) 241-7270

Southern ILAccount ExecutiveShannon VerdeyenToledo, IL(217) 317-9487

Southern ILField EditorNat WilliamsWest Frankfort, IL(618) 932-3041

Follow us on Facebook & Twitter.m

m15 · Central Illinois Ag · www.centralilag.com15 · Central Illinois Ag · www.centralilag.com

“Quality is Huge!” Those are the words of Jeremy Wolf, 5th generation operator of Wolf Farms, when asked why he operates with Case IH equipment on his family farm in Homer, Illinois.

In 1983 Jeremy’s grandfather Dale, 3rd generation of Wolf Farms and former realtor, paved a successful future for farmers in Central-Eastern, Illinois as he worked with Frito-Lay to acquire land in Sidney, Illinois for use of a corn receiving plant. He knew this opportunity would benefit the farmers allowing them to grow food grade corn for years to come.

What he didn’t know was the machinery on his farm wouldn’t stand a chance with the neighboring International farmers who were growing much cleaner and whole kernels.

Wolf Farms have always been, and continue to strive to be, ahead of technology. “In 1985 the top quality and cleanest whole kernals of corn came from International equipment, so it was obvious to make a change,” said Terry Wolf, 4th generation of Wolf Farms said.

“There are always improvements available whether it’s technology, equipment, or seed and if you can get to that level of perfection, it’s time to see what is next..always be looking ahead,” said Jeremy Wolf.

Dale and son Terry purchased their very first International 1680 rotary combine in 1986 for it’s superior gentler threshing with the rotor and fewer moving parts (belts).

“The ever increasing technology made it possibly for us to secure a spot the very next year in the top growers for Frito-Lay,” said Terry.

At the time Case and International merged, Wolf Farms visited the Case IH plant to see what was being developed, and how it could help their operation. Terry Wolf was one of the first farmers to test and evaluate the very first combine. The next year, a prototype Case IH 7010, was brought to Wolf Farms to see how it would work for their food grade crop.

“The engineers would test the combine, change out parts, and test again. It was an amazing process to see how they developed a new high capacity combine from the ground up,” said Terry.

Over time every piece of equipment had turned to Case IH. In 2009, Terry traded two competitor planters for one Case IH Early Riser.

With the new faster planter, we increased our productivity by 50%. The yields were higher and the quality of corn showed improvements.

Wolf Farms continues to be on the front line of technology, still today, their loyalty and belief in Case IH equipment stands firm. “We’re always searching for the best,” Jeremy said, “and for the past 29 years we haven’t found anything that can beat Case IH equipment.”

Top Quality top growersFOR

m m

www.centralilag.com · Volume 3, Issue 1 1616 · Central Illinois Ag · www.centralilag.com

FAMILY FARMWolf Farms began in Lewisville, IL and moved in 1924 to the Homer and Sidney areas. Today, the family farm has grown to be six generations strong.

Jeremy’s son Jake Wolf joined the farming operation in 2015 after gaining experience off the farm, but still within the agriculture industry. His other son, Jordan, is studying Ag Business and Farm Management at the University of Illinois.

“Being away from the farm for school and/or work has allowed the opportunity for each of us to experience diverse personalities and life on the outside of our farming operation,” said Jeremy.

Each generation of the family farm holds knowledge of a business background prior to joining the farm.

Being together and sharing the strong work ethic has made Wolf Farms very close to one another. The challenges from a business perspective show the true value of each individual involved.

Wolf Farms is a great example of a family farm, their loyalty to one another, and the value of family land and the history behind it.

CENTRAL ILLINOIS AGJust as it took time to find the right equipment, it also took time to find the right Case IH dealership. Wolf Farms was referred to Central Illinois Ag in 2014 from a former CNH employee and friend of Wolf Farms and Central Illinois Ag.

Terry, Jeremy, and Jake (4th, 5th, and 6th generations of Wolf Farms) met with owner of Central Illinois Ag Michael Schmidt, and instantly there was a connection formed between the two businesses.

As an equipment dealership on the leading edge of technology, Wolf Farms knew this is where they belonged.

Business with Wolf Farms and Central Illinois Ag has developed in to more than a practice, but a relationship. The trust and friendships formed have cultivated opportunities to test products, share results, and in turn share this knowledge to various farmers nationwide.

“Central Illinois Ag is a different kind of Case IH dealership. Michael (salesman/owner) showed interest in my operation to help my needs. He wants to help make Wolf Farms successful.” -Jeremy Wolf

Photo: Jake Wolf, sixth generation, filling their Case IH 1255 planter in Spring 2016.

Photo (above): Loren Wolf on the tractor and Dale Wolf on the Case combine in 1941. (2nd & 3rd generations.).

Photo (left): Jake Wolf, Jeremy Wolf, and Terry Wolf stand by their Case IH 8240 combine in 2015 (4th, 5th, & 6th generation).

m17 · Central Illinois Ag · www.centralilag.comm17 · Central Illinois Ag · www.centralilag.com

ILSOYADVISORSM

FIELD DAYSIF YOU GROW SOYBEANS, THEN YOU CAN’T MISS OUTField days are free and include lunch and refreshments. Additionally, each field day will offer four CEUs.

TOPICS INCLUDE:

REGISTER AT ILSOY.ORG/FIELDDAYS

AUGUST 3SEYMOUR

WEDNESDAY

AUGUST 4BENTON

THURSDAY

HINCKLEYAUGUST 2TUESDAY

8 A.M. – NOON

8 A.M. – NOON

8 A.M. – NOON

ISASOY05161547-3

Soybean Agronomics

High Yields Require Full-Season Management

LibertyLink® Soybeans and Liberty® Herbicide

Growth Stimulants and Why They Increase Yield (Hinckley Event Only)

Planting Date and Maturity Group Selection (Seymour Event Only)

Soybean Fertility (Benton Event Only)

m m

www.centralilag.com · Volume 3, Issue 1 18mMacDon: Used Combine Market Source: Central Illinois Ag Live.Work.Grow., 1/2 page, 8.5" x 5.5", CMYK, April/June Issue

Publication

One season..that’s all it took for Jim Lederbrand, fourth generation farmer with Lederbrand Farms

in Pawnee, IL, to find value in a draper head.

Transitioning from a platform to draper head in 2014 has allowed Lederbrand to work longer hours due to the dew having no effect on the head. He saves time and energy by not having to clean the head while in the field, and more flexibility as the draper head is capable of following through hills and waterways. His MacDon FD75 - 30’ draper head also runs much faster through the field while harvesting soybeans without error.

“All of these factors help to increase productivity during harvest, essentially, the draper head is paying for itself,” Jim said.

A feature that Lederbrand especially enjoys is the ability of fine tuning to the draper head. The draper head adjusts to angle up and down to feed better, a feature

not available on a platform. “Once you go to a draper head,” Jim said, “you’ll never go back.”

Lederbrand Farms has been loyal to Central Illinois Ag since 2009. Although his farm is an hour from the dealership, the service doesn’t change.

NEVER GOING BACK

“My salesman (Andrew Elder) adjusts his schedule to fit mine. He’s worked on the farm with me on a Saturday at 10:30pm.” -Jim Lederbrand

ILSOYADVISORSM

FIELD DAYSIF YOU GROW SOYBEANS, THEN YOU CAN’T MISS OUTField days are free and include lunch and refreshments. Additionally, each field day will offer four CEUs.

TOPICS INCLUDE:

REGISTER AT ILSOY.ORG/FIELDDAYS

AUGUST 3SEYMOUR

WEDNESDAY

AUGUST 4BENTON

THURSDAY

HINCKLEYAUGUST 2TUESDAY

8 A.M. – NOON

8 A.M. – NOON

8 A.M. – NOON

ISASOY05161547-3

Soybean Agronomics

High Yields Require Full-Season Management

LibertyLink® Soybeans and Liberty® Herbicide

Growth Stimulants and Why They Increase Yield (Hinckley Event Only)

Planting Date and Maturity Group Selection (Seymour Event Only)

Soybean Fertility (Benton Event Only)

m19 · Central Illinois Ag · www.centralilag.comm19 · Central Illinois Ag · www.centralilag.com

Steve SchmidtAtlanta, IL(217) 737-7445

Michael SchmidtLincoln, IL(217) 737-8669

Dallas KaufmanDanvers, IL(309) 613-0556

Clay WithamStanford, IL(217) 519-4346

Brandon HendelGlasford, IL(309) 212-1656

John CoersNew Holland, IL(217) 737-5674

Joe FisherPetersburg, IL(217) 303-1754

Ryan CurryLincoln, IL(217) 671-5296

Brian ReeserClinton, IL(217) 519-4341

Mike O’NeilArrowsmith, IL(309) 275-8158

Mike BarringerDecatur, IL(217) 519-2918

Andrew ElderTaylorville, IL(217) 306-4621

Doug FranzenFarmer City, IL(309) 275-8556

Jim SpicerFarmer City, IL(309) 275-8545

Jeff CopleyLeRoy, IL(217) 871-4097

Locations

Atlanta200 Sharon St.Atlanta, IL 61723(800) 762-2325

Clinton1000 State Route 10 EastClinton, IL 61727(800) 362-3866

Farmer City792 U.S. Hwy 150 EastFarmer City, IL 61842(800) 334-8942

Mason City130 Tonica St.Mason City, IL 62664(217) 482-9760

cia Sales Team *Numbers listed are cell phone numbers

m m

www.centralilag.com · Volume 3, Issue 1 20mtractors

live.work.grow. showcaseBrowse our ‘lot’ of equipment chosen exclusively for this issue of Live.Work.Grow. to bring you the best deals.

Call Central Illinois Ag owner Steve Schmidt at (217) 737-7445, or your respectable salesman.

Inventory is added daily at: www.centralilag.com

m

www.centralilag.com · Volume 3, Issue 1 20

2013 Case IH 500 QuadTracZDF135616 $293,000

2011 Case IH 550 QuadTracZBF126354 $245,000

2011 Case IH 550 HDZBF125613 $230,000

NEW! 2016 Case IH Maxxum 135ZFEE03771 CALL

2013 Case IH Magnum 340ZDRD06181 $189,000

2015 Case IH Magnum 280ZERF07000 $195,000

WWW.CENTRALILAG.COM

m21 · Central Illinois Ag · www.centralilag.com

live.work.grow. showcaseBrowse our ‘lot’ of equipment chosen exclusively for this issue of Live.Work.Grow. to bring you the best deals.

Call Central Illinois Ag owner Steve Schmidt at (217) 737-7445, or your respectable salesman.

Inventory is added daily at: www.centralilag.com

m21 · Central Illinois Ag · www.centralilag.complanters

NEW! 2017 Case IH 2150IN ATL SHOWROOM! CALL

2014 Case IH 1255 24/30 YDS042082 CALL

2009 Case IH 1250 16/30Y9S007667 $49,000

NEW! 2015 Kinze 3600 16/30 106667 $109,000

NEW! 2014 Kinze 3700 24/30 104555 $149,000

NEW! 2015 Kinze 3600 12/30 106667 $115,000

Interplant 23/15

WWW.CENTRALILAG.COM

m m

www.centralilag.com · Volume 3, Issue 1 22combines

live.work.grow. showcaseBrowse our ‘lot’ of equipment chosen exclusively for this issue of Live.Work.Grow. to bring you the best deals.

Call Central Illinois Ag owner Steve Schmidt at (217) 737-7445, or your respectable salesman.

Inventory is added daily at: www.centralilag.com

m

www.centralilag.com · Volume 3, Issue 1 22WWW.CENTRALILAG.COM

2015 Case IH 7240 YFG227616 $340,000

2014 Case IH 7230 YEG225097 $285,000

2014 Case IH 8230YEG223186 $249,000

2007 Case IH 2588 HAJ300203 $84,500

2009 Case IH 8120 TracksY8G205333 $199,900

m

2011 Case IH 8120YAG210359 $169,900

m23 · Central Illinois Ag · www.centralilag.com

live.work.grow. showcaseBrowse our ‘lot’ of equipment chosen exclusively for this issue of Live.Work.Grow. to bring you the best deals.

Call Central Illinois Ag owner Steve Schmidt at (217) 737-7445, or your respectable salesman.

Inventory is added daily at: www.centralilag.com

NEW! 2015 ECOLO-TIGER 875 YFD080665 CALL

2013 ECOLO-TIGER 870 YDD067126 $59,900

2013 BLU-JET SUB TILLER 4 018185 $23,500

2012 KRAUSE 4850-21 3923 $45,000

2011 TRUE TANDEM 330T JFH0054137 $28,000

2015 NEW TRUE TANDEM 335VT 31’ NEW! 10 IN STOCK

m23 · Central Illinois Ag · www.centralilag.comtillage WWW.CENTRALILAG.COM

m m

www.centralilag.com · Volume 3, Issue 1 24

m

www.centralilag.com · Volume 3, Issue 1 24m

m25 · Central Illinois Ag · www.centralilag.com

Loeffler Farms in Stanford, Illinois was one of the first operations in Central Illinois to purchase and test the

Landoll 8550-43’ soil finisher before planting their crop for the 2016 season.

Brian Loeffler, third generation farmer of Loeffler Farms, trusted Landoll to develop a high-end product and he never doubted the field performance of the 8550. Many features of this unit left Loeffler Farms with an worry-free and smooth surface to begin planting corn.

“The shields set up higher, allowing the dirt to break up into finer pieces making quick and smooth passes,” said Kent Osland, Loeffler Farms employee.

Loeffler Farms have been loyal to Landoll since 2000. The tillage company makes it known that the farmers are a key part of the business. Landoll engineers have visited with Brian and his team to test equipment and allow input into the product.

A Landoll engineering team member, owner of Central Illinois Ag Michael Schmidt, Salesman Clay Witham, and Landoll Representative Arch Kohl worked together in Loeffler’s field to prepare and ensure the 8550 worked to its full potential.

It’s a simple answer when asking Brian why he chooses Landoll: “Hands down, they make the best finishers.”

Photo (right): A Landoll engineer and representative, Central Illinois Ag team members, and Loeffler Farms performing tests in the field.

Benefits of a Landoll 8550

Central Illinois Ag has become a valuable part of our farming operation. Clay Witham (salesman) is quick to the farm when we need him, whether for parts delivery or extra help.” -Brian Loeffler

▶ Hydraulic disc gangs -Saves time and allows fine tuning of depth adjustments▶ Smooth and ultra low concavity disc blades -Allows operation in more adverse conditions and prevents soil slabbing▶ Longer shanks -Creates more residue clearance and soil flow throughout the machine▶ Higher shields -Creates better soil flow▶ Multiple Harrow Configurations -Customize to your soil types and conditions▶ Easier and safer to transport - Double fold brings greater visibility on the road

Photo: Brian Loeffler, Steve Johnson, and Kent Osland after-season with the Landoll 8550.

From the Field: A Grower’s Review of the Landoll 8550

m m

www.centralilag.com · Volume 3, Issue 1 26

...The Company Who Knows You BestN

ext

Genera

tion

Vert

ical Ti

llage

Engin

eere

dSim

plici

tyEx

pect

a

Perf

ect

Seedbed

2410/2430 Series Weatherproofer (WP1)

7400 Series VT Plus (Vertical Tillage)Vertical tillage is a popular term heard today. The Landoll VT Plus was developed with input from producers’ issues on competitive tools they were using. The 7400 VT Plus Series, available in 14’ through 49’ working widths, is designed to anchor residue, accommodate shallow working depths, mix more soil, handle better weed kill across the machine and level small ruts left by the previous operation. The smooth blades allow the unit to work in wetter conditions when needed and stay sharper over time when compared to fluted blades used by competition.

Manage residue and compaction in a single pass with the Weatherproofer 1 from Landoll. Available in 6 through 13 shank models, the WP1 features disc gangs on 10 1/2” spacing that quickly resize and mix the toughest residue. Auto-reset shanks on 24” centers provide much better soil fracture than traditional 30” spacing. This allows you to run at shallower depths at higher speeds, saving on both fuel and labor while leaving an impressively level field. The WP1 is a true “set it and forget it” type of tool as the entire machine is set with a single adjustment.

Time is more important in farming today than it’s ever been, and it plays a major role in how good the crop yield will be. The 8530 Finisholl will help producers meet their timeline during the crucial spring and fall planting seasons. Outstanding quality is designed and manufactured into every part and this keeps it performing without costly delays season-after-season. Available in seven working widths from 19’ to 48’, the 8530 will increase your return on investment by creating the perfect seedbed and eliminating costly downtime.

8530 Finisholl

Marysville, KS 66508785.738.6613www.landoll.com

®

m27 · Central Illinois Ag · www.centralilag.com

By Linda Olson, Illinois Farm Bureau®, on behalf of Illinois Farm Families®

I don’t know if Monsanto would be the destination of your choice on a picture-perfect Saturday in late May,

but for 18 Chicago City Moms and influentials, it was an opportunity to see in person this entity they’d heard so much about. Illinois Farm Families defines ‘influentials’ as people who have specialized knowledge and who help others make decisions about food. (Think registered dietitians, nutritionists and nurses.)

Research tells us that consumers want transparency. Our hosts at Monsanto did their best to be open and answer all questions.

City Moms saw the greenhouse, the growing rooms, and the labs. The guides, retired Monsanto research scientists, explained how and why they do the things they do. They patiently, respectfully, and, in some cases, humorously, responded to all questions.

Following the 2-hour tour of the research facilities, panels of scientists and farmers answered more of the City Moms’ questions.

No one was offended by the questions their city guests asked ... questions about glyphosate and designer genes and stories they’ve heard about GMOs destroying the good bacteria in our guts.

No one rolled their eyes when asked about guaranteeing GMO safety and colony collapse disorder among hives of bees.

No one responded defensively when the moms wanted to know how Monsanto recoups their cost of research and, “what about those farmers being sued by Monsanto?”

The questions were not asked maliciously or with the intent to intimidate. They just wanted to know the “rest of the story.”

This was an opportunity for those of us in ag to hear the concerns our city friends have. And it was an opportunity for our city friends to hear the ag story directly from the toxicologist, the entomologist, the biochemist, the nutritionist, and the farmer.

Interested in reading what insights the City Moms had about their trip to Monsanto? Watch for their blogs on www.watchusgrow.org. Illinois Farm Families are Illinois farmers who support Illinois Farm Bureau, Illinois Pork Producers Association, Illinois Corn Marketing Board, Illinois Soybean Program Operating Board, Illinois Beef Association, and Midwest Dairy Association through farmer-funded checkoff or membership programs. We are committed to having conversations with consumers, answering their questions about food, farmers and farming, and sharing what really happens on today’s Illinois family farms. More than 97 percent of Illinois farms are family owned and operated. We are passionate about showing consumers how we grow safe, healthy food for their families, and ours.

Destination: Monsanto for the City Moms

Photo: Janice Person of Monsanto shows the City Moms one of their greenhouses.

Photo: Farmer Larry Miller, moderator Renea Heinrich, and farmers Chad Schultz and Michele Aavang responded to mom’ questions about how they farm.

m27 · Central Illinois Ag · www.centralilag.com

m m

www.centralilag.com · Volume 3, Issue 1 28

FEEL THE MyRIDE DIFFERENCE. DEMO ONE TODAY!LEARN MORE AT TORO.COM/MYRIDE

Long days will feel shorter with the all-new, amazingly comfortable MyRIDE™ suspension system on select Toro® Z Master® mowers. The fully suspended, adjustable operator platform isolates bumps and vibrations so you don’t feel the rough terrain. It’s the Toro toughness you expect with a ride you won’t believe.

© 2015 The Toro Company

HARD-CORE COMFORT

Toro z6000 MyRide Turf V2.indd 1 6/5/15 11:07 AM

m

m29 · Central Illinois Ag · www.centralilag.com

Potential for More

m m

www.centralilag.com · Volume 3, Issue 1 30

How much time could you save during harvest by switching cornheads? Better yet, what if your

cornhead had the potential of increasing your yields?

Four years ago, Cox Farms in Mason City were ready for something ‘different’. A cornhead brand they could trust and one that would have a lot of potential during harvest. Andy and Olin Cox found it, a Geringhoff Northstar 1230.

“We’ve run Geringhoff for four years without any downtime in the fall. This is a big step up from our past heads,” said Andy. The Northstar cornhead has automatic chain tensioners, which eliminate wear and resist damage from foreign objects. The parrellel knife rolls cut aggressively through stalk reducing it to a manageable level. Another benefit is the light weight and durable gear box, along with a low profile head which is beneficial when harvesting down corn, minimizing shatter and bounce.

Olin is true to Geringhoff because they stand out from other brands due to their comittment to high-quality products. Andy noted that in 2015 the company took it upon themselves to update their cornhead. Showing a huge commitment to the customers.

Each season their head runs through a thousand plus acres of corn. Central Illinois Ag salesman John Coers, knew they needed a reliable product. It’s no doubt they made the right decision with a Geringhoff Northstar.

Throughout Olin’s 42 years of farming and Andy’s 14 years of farming, the trust of their equipment dealership and salesman has been imperative.

During harvest 2011, the unfortunate event of a combine fire left these two with crops in the field and down a combine. “All it took was one phone call to John, and he took care of the rest,” Andy said, “we had a replacement combine and were back running within four hours.”

Cox Farms continue to see the value in Central Illinois Ag. “It’s more than a parts and sales department, they work with us as a team,” said Andy.

“John Coers is much more than a salesman, it’s clear to us that he values our farming operation as much as we do. He goes above and beyond to see that we are taken care of.” -Andy Cox

Potential for More

Photo: Andy Cox and Olin Cox stand by their Geringhoff Northstar 1230 cornhead.

m31 · Central Illinois Ag · www.centralilag.comm31 · Central Illinois Ag · www.centralilag.com

m m

www.centralilag.com · Volume 3, Issue 1 32m

A little over two years ago, we received this 1948 Farmall Cub and 1953 International Super M on

trade-in. Owners of Central Illinois Ag Steve & Michael Schmidt saw this as an opportunity to give back to Illinois FFA Chapters.

The antique tractors were restored through the Parkland Diesel Program at Parkland College in Champaign, IL where CASE IH technicians are trained. Central Illinois Ag technician Garret Maxheimer helped in the restoration process. The tractors were then painted locally by Darin Schemmp of Atlanta, IL.

Central Illinois Ag and the Illinois Association FFA have teamed up over the past year to sell raffle tickets for a chance to win the tractors. 100% of the money raised from tickets sales go toward your choice FFA chapter.

Two tickets were drawn on stage during the 5th General Session of Illinois FFA State Convention on Wednesday, June 15th.

The International Super M goes to Jess Slager of Hopedale, and the Farmall Cub to Garrett Hartke of Teutopolis. Thank you for supporting your local FFA Chapters.

& the winners are...

m

www.centralilag.com · Volume 3, Issue 1 32

Over $17,100 raisedtoward local illinois ffa chapters

Photo: 1953 International Super M and the 1948 Farmall Cub restored to raise money for Illinois FFA programs.

@LiveWorkGrowCIA

m33 · Central Illinois Ag · www.centralilag.com

Aerial imagery

As excitement and enthusiasm continues to grow around UAS, and the regulatory framework

continues to take shape, more consumers are looking to buy UAS for personal use and more businesses are looking to use UAS too. These prospective operators want to fly, and fly safely, but many don’t realize that, just because you can buy a UAS, doesn’t mean you can fly it anywhere, or for any purpose. Know Before You Fly provides prospective users with the information and guidance they need to fly safely and responsibly.

We, at Central Illinois Ag, stand for relationships with our customers. Central Illinois Ag has put

together an Unmanned Aerial Vehicle (UAV) based on the farmers needs and then back the technology with personalized education and product support. When you buy a system from Central Illinois Ag, it comes with private instruction and continued education to help you utilize your UAV system.

Now farmers can take advantage of cutting-edge technology in unmanned aerial vehicles (UAVs) to scout crops.

▫UAVs save time by allowing farmers to cover more acreage quicker and from a bird’s eye view.▫UAVs save money by identifying potential problems earlier so farmers can identify problems like weeds or pest infestations.▫UAVs increase profits by identifying areas where inputs, like nutrients, need to be applied, decreasing costs and increasing yields. ▫UAVs provide immediate data so farmers and growers can react quickly to changing conditions and opportunities.▫UAVs provide unencumbered access to assess plant conditions and animal health.

growers need same-day data

Contact Abby Coers to get set up with your Central Illinois Ag/Flying Ag drone!

[email protected] or (217) 828-0081

*Note: Article written by FlyingAG.com & Central Illinois Ag

*Note: Article taken from www.KnowBeforeYouFly.com

*In-stock at Atlanta, kits starting at $2,400. See your salesman for more information.

m m

www.centralilag.com · Volume 3, Issue 1 34

m

www.centralilag.com · Volume 2, Issue 2 34

Time is your most valuable resource. During the growing season, you need to be able to detect and solve problems.

DroneDeploy makes it quick and easy to fly your drone and capture imagery, view and annotate maps, and then share those maps and insights with others to help them take action.

Learn more, and read about how farmers are using DroneDeploy in their fields at www.dronedeploy.com.

*Note: Information from www.DroneDeploy.com

growers need same-day data

m35 · Central Illinois Ag · www.centralilag.com

Prairie View Landscaping from Bloomington, IL trusts Takeuchi in their business operation. The

heavy duty yet compact size has a 8,102 pound tipping load for the TL12.

“Our landscaping business requires us to work in smaller areas, but a larger machine to move heavy objects is required. Takeuchi machines are perfect for that,” said Tyler Pilchard, owner of Prairie View Landscaping.

Prairie View Landscaping has projects ranging from small and large scale landscaping, forestry, roadwork, and grading.

Tyler has found the tracks to be one of the best features on the Takeuchi machines. Due to the excessive amount of down pressure while working mostly on dirt, the tracks don’t disturb the ground. The 13,760 pounds of traction force is distributed throughout the whole track, not just in certain areas, causing the machine to stay flat on the ground.

“It’s like a mini bulldozer,” said Tyler.

Prairie View Landscaping transitioned to Takeuchi nine years ago and have since purchased a TL12 and two TL230’s.

COMPACT MACHINES

“Mike (O’Neil) has gone one step further than a salesman, he’s become a friend. Not someone who shows up just to sell.” -Tyler Pilchard

Photo: Prairie View Landscaping, using his TL12 to mulch a tree.

Photo: Tyler Pilchard, owner of Prairie View Landscaping with his TL12.

m35 · Central Illinois Ag · www.centralilag.com

m m

www.centralilag.com · Volume 3, Issue 1 36

Powerful and stable are two words to describe the new Takeuchi TL12V2 High Flow track loader. S&S

Landscaping and Excavating from Decatur, IL had the first chance to run the machine on tree removal and landscaping projects.

“The Takeuchi TL12V2 has better lift capacity and the ergonomics in the cab make it more comfortable,” said Scott Stallard, owner of S&S Landscaping & Excavating.

The cab is much quieter with the new track design the machine travels with less vibration noise. The pilot control system allows for smooth operation. The new color display and arrangement of the cab controls makes it more comfortable for the user.

With the various projects Scott’s company takes on, his inventory of machinery includes more than Takeuchi. He points out that Takeuchi machines compared to his others are more reliable.

“The power and torque is better with Takeuchi,” Scott

said when comparing his machines. “They’re the best out there.”

S&S Landscaping and Excavating’s clientele range from a variety of businesses. They offer professional service including: tree line cleanup, forestry, drainage, landscaping, excavating and more.

It’s important for Scott and colleague Jason Vaughn, head operator, to use the most durable machines.

The Takeuchi TL12V2 is the largest track loader in the industry with an 11,737 pound tipping load. It has an EPA final tier 4 Kubota engine, running 111.3 horsepower. The high flow option allows S&S Landscaping & Excavating to run 40.4 gallons per minute (GPM) to their attachments.

Scott turns to Central Illinois Ag as his Takeuchi dealer because of the trusting relationship he has formed with Takeuchi Sales Manager, Jim Spicer.

“Instead of handing me a manual when delivering a machine, Jim (Spicer) will visually show me features of the machine.” -Scott Stallard

Largest track loader

COMPACT MACHINESPhoto: Scott Stallard, owner of S&S Landscaping & Excavating with his TL12V2

mPhoto: S&S Landscaping & Excavating use their Takeuchi TL12V2 with a mulching head for forestry work.

m37 · Central Illinois Ag · www.centralilag.comFIND OUT WHAT OTHERS KNOW. VISIT TAKEUCHI-US.COM

about the largest vertical track loader in the industry.GET IN THE KNOW

New ModelTL12V2

Those in the know, know Takeuchi

m m

www.centralilag.com · Volume 3, Issue 1 38

George H. Dunn hired me in 1979

I began my career as a technician because I came from a farm, and I always knew growing up I wanted to help farmers.

My focus is planters and older equipment.

You can usually find me in the country, I’m on the road 99% of the time.

Bob Zimmerman, former service manager in Farmer City, taught me a lot about being a technician. I really looked up to him.

Thirty-seven years ago, I wanted to be doing just as I am today. Being a technician is a blessing to me, I really enjoy helping the farmers.

Rick HardwickTechnician, Farmer City

George H. Dunn hired me in 1982

Working on equipment has always been a passion of mine.

My focus is combines and older equipment.

Central Illinois Ag is a great place to work. The environment is relaxed and we’re all a family.

George H. Dunn, was a great example of leadership.He taught me the value of working hard.

Thirty-four years ago, I didn’t think my career would be the same today. The farmers and Central Illinois Ag employees make this a great place to work.

Dave prestonTechnician, clinton

employee spotlight

Photo: Dave Preston has been serving farmers for 34 years.

Photo: Rick Hardwick has been serving farmers for 37 years.

m m

www.centralilag.com · Volume 3, Issue 1 39

200 Sharon StreetAtlanta, IL 61723

Connect with us online

@Liveworkgrowciawww.centralilag.com