Lithium Battery UN38.3 Test Report - AccuPower...

Transcript of Lithium Battery UN38.3 Test Report - AccuPower...

WXP

~~T5~$6%(Repmt ID): MZIPBAQA88798721

Pony Testing International Group

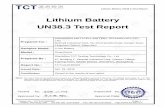

Lithium Battery UN38.3 Test Report

Sample Description

& Model

Applicant

Manufacturer

Lithium-Ion Battery ?SlOP ICR18650

AccuPower Forschungs-Entwicklungs-und Vertriebs-GmbH.

AccuPower Forschungs-Entwicklungs-und Vertriebs-GmbH.

PO No.: MZIPBAQA88798721

Code: blhjh3d0lx

DCNY

PCNV Report ID: MZIPBAQA88798721 Page I of 11

Pony Testing International Group

L SAMPLE DESCRIPTION

Sample Description Lithium-Ion Battery Sample Model 7S I OP ICR 18650

Applicant AccuPower Forschungs-Entwicklungs-und Vertriebs-GmbH.

Manufacturer AccuPower Forschungs-Entwicklungs-und Vertriebs-GmbH.

Nominal Voltage 25.9V Rated Capacity 29000mAh Limited Charge

29.4V Voltage

Maximum End Charge Charge Current lOA Continuous 27.5A 290mA

Charge Current Current

Maximum Electronic Cut-off Voltage 21V Discharge Current 27.5A Use

inspection device

Cell Number 111 70PCS Cell Model lCRI8650-29E Cell Capacity 2900mAh Each Battery

Manufacturer of cell SAMSUNG

Entrust date 2015-9-17 Finished date 201 5-10-9

IL TEST METHOD

«United Nations Recommendations On The Transport Of Dangerous Goods, Manual Of Tests And Criteria))

(ST/SG/AC. I 0/ 11 /Rev.5, amend. l & amend.2, 38.3).

ill, TESTITEM 1. Altitude simulation 5. External short circuit

2. Thermal test 6. Impact

3. Vibration 7. Overcharge

4. Shock 8. Forced discharge

IV, CONCLUSION

JTEM SAMPLE NUMBER STANDARD CONCLUSION

Altitude simulation PASS

Thermal test NI~N4

PASS

Vibration Cl~4

PASS

Shock PASS UN38.3

External short circuit PASS

lmpact N9- NI3 PASS

Overcharge N5-N8C5~8 PASS

Forced discharge N1 4-N23 C~18 PASS

The Samples has passed the test items of UN ITED NATIONS "Recommendations on the

TRANSPORT OF DANGEROUS GOODS" Manual of Tests and Crite ria, ST/SG/AC.IO/ II /Rev.5

amend. I & amend.2, 38.3.

Prepared by: ~vJ eA Issue Date: October 9, 2015

www.ponytcs l.com (OHotlinc 400-819-5688

Jti.t 'J;f4'1\: (010) R~til~ll6 Kt.;i:'l(l·.;r, (().l\1) 851SO'JOS hlt',l;~·;t, (021) 648519?9 t:\:Jitl~th(: C0755) 260WJ09

t't~"J<JP'{{: (OB2)8R706866 ki11:~:{;, (0-lll )l\46S0820 'i'lf'<:l:~)'\<, COS74)87731>49'1 r-.fW:Ii~'{t, <020)&9224310

JdC'l:!fi'1h (Ol2l27JI\07JO XSit!Jl:~~·,;r, COJ71)69JS0070 Ltlli''l:~'i<, (0571) X72 1QOQ6 ..t~·n~'if, C027)8l'I971H

DCNY

PIJNV Report ID: MZIPBAQA88798721 Page 2 of 11

Pony Testing International Group

Notes:

Nl~N8: Batteries at first cycle in fully charged states;

N9~N 13: Cells at first cycle at 50% of the design rated capacity;

N1 4---N23: Cells at first cycle in fu lly discharged states;

Cl~C8: Batteries after 50 cycles ending in fully charged states;

C9~Cl8: Cells after 50 cycles ending in fully discharged states.

V, PHOTO OF THE SAMPLE

Sample Number: A8879872 1

Authenticate the photo on original report only

www. ponytest.com ~Hotli ne 400-8 J 9-5688

:ltJ;(:,k!Jrt~(, (010) 826 18116 K1F:Xf<l!i' : (0431) X5150908 J:~J'!};!~;{( , (021 ) 64851999 t.lWI:!J<!l!l':'K : (0755)26050909

ff~:,kl),~~ ' (OS32)H8706866 kit;);~'{,, (0411)84650820 'J•J.:i~~:i£ , (0574) 87736499 s-ili!l;~ '-1{ : (020)89224310

7dllll<ll't{(, Wl2l 273607.JO Jl!#l':t.fl:{L (0371 )69350670 tttii?);!Jil'i( , (0571)87219096 li:tiJtlli~'t> : (027)83997127

Report ID: MZIPBAQA8879872 1 Page 3 of 11

Pony Testing Internationa l Group

VI, TEST METHOD Tests T.1 to T.S shall be conducted in sequence on the same cell or battery. Tests T.6 and T.8 shall

be conducted using not otherwise tested cells or batteries. Test T.7 may be conducted using

undamaged batteries previously used in tests T.1 to T.5 for purposes of testing on cycled batteries.

In order to quantify the mass loss, the following procedure is provided:

Mass loss(0/0) = (M1-MJ) I M, X 100

Where M 1 is the mass before the test and M2 is the mass after the test. When mass loss does not

exceed the values in Table blow, it shall be considered as "no mass loss".

Mass M of cell or battery Mass loss limit

M<lg 0.5%

1~95g 0.2%

M>75g 0.1 %

T.l Altitude simulation

Test cells and batteries shall be stored at a pressure of 11.6 kPa or less for at least six hours at

ambient temperature (20 ± 5 °C).

Cells and batteries meet this requirement if there is no leakage, no venting, no disassembly, no

rupture and no fire and if the open circuit voltage of each test cell or battery after testing is not less

than 90% of its voltage immediately prior to this procedure. The requirement relating to voltage is

not applicable to test cells and batteries at fully discharged states.

T.2 Thermal test

Test cells and batteries are to be stored for at least six hours at a test temperature equal to 72 ± 2 °C,

followed by storage for at least six hours at a test temperature equal to - 40 ± 2 °C. The maximum

time interval between test temperature extremes is 30 minutes. This procedure is to be repeated until

1 0 total cycles are complete, after which all test cells and batteries are to be stored for 24 hours at

ambient temperature (20 ± 5 °C). For large cells and batteries the duration of exposure to the test

temperature extTemes should be at least 12 hours.

Cells and batteries meet this requirement if there is no leakage, no venting. no disassembly, no

rupture and no fire and if the open circuit voltage of each test cell or battery after testing is not less

than 90% of its voltage immediately prior to this procedure. The requirement relating to voltage is

not applicable to test cells and batteries at fu lly discharged states.

www.ponytcst.com <l>Hotlinc 400-819-5688

DCNY

JtJl!'J:ff\! , (0!0) 8lo1RII6 !((,)i;t'l'{', 104.11) ~51'(~1Q8 J ,1j',j;~·¥, COli) 048$1999 ~~~J\1.:~~·¥, 107$5) 2c.050'109

i'r.lt>;J.;~i.'~! , (0532)8870(,&66 J\Ji·~~·{(, \O-l ii )~~650S20 ·j';l('J.:fl:ir, C0574)~773049'l I' ltt',l;~'-il• IO!Ol89ll4310

X;r.::l;'ll:'''• (022)!7360730 l:l:ffl:.l:~'''• (0371l<•9lSill.70 !'LIW~!()·i•, (0571)N72190'16 11\:iX;J.;,~·.;c, (027)83997 127

Report ID: MZLPBAQA88798721 Page 4 of 11

Pony Testing International Group

T.3 Vibration

Cells and batteries are firmly secured to the platform of the vibration machine without distorting the

cells in such a manner as to faithfully transmit the vibration. The vibration shall be a sinusoidal

waveform with a logarithmic sweep between 7 Hz and 200 Hz and back to 7 Hz traversed in 15

minutes. This cycle shaiJ be repeated 12 times for a total of 3 hours for each of three mutually

perpendicular mounting positions of the cell. One of the directions of vibration must be

perpendicular to the terminal face.

The logarithm ic frequency sweep shall differ for cells and batteries with a gross mass of not more

than 12 kg (cells and small batteries), and for batteries with a gross mass of more than 12 kg (large

batteries).

For cells and small batteries: from 7 Hz a peak acceleration of I gn is maintained until 18 Hz is

reached. The amplitude is then maintained at 0.8 mm (1.6 mm total excursion) and the frequency

increased unti I a peak acceleration of 8 gn occurs (approximately 50 Hz).

A peak acceleration of 8 gn is then maintained until the frequency is increased to 200Hz.

For large batteries: from 7 Hz to a peak acceleration of I g" is maintained until 18Hz is reached. The

amplitude is then maintained at 0.8 mm (1.6 mm total excursion) and the frequency increased until a

peak acceleration of 2 gn occurs (approximately 25 Hz). A peak acceleration of 2 gn is then

maintained until the frequency is increased to 200 Hz.

Cells and batteries meet thjs requirement if there is no leakage, no venting, no disassembly, no

rupture and no fire during the test and after the test and jf the open circuit voltage of each test cell or

battery directly after testing in its third perpendicular mounting position is not less than 90% of its

voltage immediately prior to this procedure. The requirement relat ing to voltage is not applicable to

test cells and batteries at fu lly discharged states.

TA Shock

Test cells and batteries shall be secured to the testing machine by means of a rigid mount which will

support all mounting surfaces of each test battery. Each cell or battery shall be subjected to a

half-sine shock of peak acceleration of 150 gn and pulse duration of 6 milliseconds. Each cell or

battery shall be subjected to three shocks in the positive direction followed by three shocks in the

negative direction of three mutually perpendicular mounting positions of the cell or battery for a

total of 18 shocks.

However, large celJs and large batteries shall be subjected to a half-sine shock of peak acceleration

of 50 gn and pulse duration of 11 mi lliseconds. Each cell or battery is subjected to three shocks in the

positive direction followed by three shocks in the negative direction of each of three mutually

perpendicular mounting positions of the cell for a total of 18 shocks.

www.ponytcst.com <l> Hotl inc 400-8 19-56 88

DCNY

~th1~~S£ , (010) 82618116 ~~f,;;~¥. , (0431) 85150908 J:iW:k~·¥._ , (021) 6~85 1999 «!#11~~ ·;,~ , (0755) 26050909

l'f .%~:~:~, , <os32lss7o6s66 :ki1:lt~~·1,, (04 11 l846soszo 'i'\()d;~:sr , <os74l87736499 r-/li:;~%4( , co2ol892243 to '.l<il\~~·~~ , (021) 17360730 Xli!W;i;!i'<.'i'! , Co371l6935067o ~tffl'k¥1.'-il:, (0571} 87219096 ,f\:~Jilli'1' ' (027)839Q7 127

-z

( -

Report ID: MZIPBAQA8879872 1 Page 5 of 11

Pony Testing International Group

Cells and batteries meet this requirement if there is no leakage, no venting, no disassembly, no

rupture and no fire and if the open circuit voltage of each test cell or battery after testing is not less

than 90% of its voltage immediately prior to this procedure. The requirement relating to voltage is

not applicable to test cells and batteries at fully discharged states.

T.5 External short circuit

The cell or battery to be tested shall be temperature stabi lized so that its external case temperature

reaches 55 ± 2 °C and then the cell or battery shall be subjected to a short circuit condition with a

total external resistance of less than 0.1 ohm at 55 ± 2 °C. This short circuit condition is continued

for at least one hour after the cell or battery external case temperature has returned to 55 ± 2 °C.

Cells and batteries meet this requirement if their external temperature does not exceed 170 °C and

there is no disassembly, no rupture and no fire during the test and within s ix hours after the test.

T.6 Impact I Crush

Impact (applicable to cylindrical cells not less than 18 mm in diameter)

The sample cell or component cell is to be placed on a flat smooth surface. A 15.8 mm ± 0.1 mm

diameter, at least 6 cm long, or the longest dimension of the cell, whichever is greater, Type 3 16

stainless steel bar is to be placed across the centre of the sample. A 9. 1 kg± 0. 1 kg mass is to be

dropped from a height of 61 ± 2.5 cm at the intersection of the bar and sample in a controlled

manner using a near frictionless, vertical sliding track or channel with minimal drag on the falling

mass. The vertical track or channel used to guide the falli ng mass shall be oriented 90 degrees from

the horizontal supporting surface.

The test sample is to be impacted with its longitudinal axis parallel to the fl at surface and

perpendicular to the longitudinal axis of the 15.8 mm ± 0. 1 mm diameter curved surface lying across

the centTe of the test sample. Each sample is to be subj ected to only a s ingle impact.

Crush (applicable to prismatic, pouch, coinlbullon cells and cyli ndrical cells less than 18 mm in

diameter)

A cell or component cell is to be crushed between two flat surfaces. The crushing is to be gradual

with a speed of approximately 1.5 cm/s at the fi rst point of contact. The crushing is to be continued

until the first of the three options below is reached.

(a) The applied force reaches 13 kN ± 0.78 kN;

(b) The voltage of the cell drops by at least I 00 m V; or

(c) The cell is deformed by 50% or more of its original thickness.

Once the maximum pressure has been obtained, the voltage drops by I 00 m V or more, or the cell is

deforn1ed by at least 50% of its original thickness, the pressure shall be released.

www.pony tcs t.com (l) llo tlinc 400-8 19-5688

DCNY

Jtl;( <).:~"{(: (010) H~tiiM I Ih K(;I.J:'j:)"\{, (0~11) KS ISOQ08 bW:l;~"{(: lOl l ) 648S i q9Q U.llil'~:*l·<l{, 10155) 26050Q09

r'l .'i~";;l;~'~(, (0532) K8706~66 A.il~~·':, (IN 11 ) K•l650820 i"<'~::l:'lllo\o (057~) 87136499 I" ffl:sti~"'' ' (0!0)89224310

A.;r··J:~·,,, (022)~7J60730 )f.fW<l.:'»"'~' (0371)1,9JS0670 1/i.i!f;:ill·i•, coml87219096 ot&·~~·¥. (027)83997 127

... '· ~

Report ID: MZIPBAQA88798721 Page 6 of I I

Pony Testing International Group

A prismatic or pouch cell. shall be crushed by applying the force to the widest side. A button/coin cell

shall be crushed by applying the force on its flat surfaces. For cylindrical cells, the crush force shall

be applied perpendicular to the longitudinal axis.

Each test cell or component cell is to be subjected to one crush only. The test sample shall be

observed for a further 6 h. The test shall be conducted using test cells or component cells that have

not previously been subjected to other tests.

Cells and component cells meet this requirement if their external temperature does not exceed 170

oc and there is no disassembly and no fire during the test and within six hours after this test.

T. 7 Overcharge

The charge current shall be twice the manufacturer's recommended maximum continuous charge

current. The minimum voltage of the test shall be as follows:

(a) When the manufacturer's recommended charge voltage is not more than 18V, the minhnum

voltage of the test shall be the lesser of two times the maximum charge voltage of the battery or

22V.

(b) When the manufacturer's recommended charge voltage is more than 18V, the minimum voltage

of the test shall be 1.2 times the maximum charge voltage.

Tests are to be conducted at ambient temperature; the duration of the test shall be 24 hours.

Rechargeable batteries meet this requirement if there is no disassembly and no fire during the test

and within seven days after the test.

T.8 Forced discharge

Each cell shall be forced discharged at ambient temperature by connecting it in series with a l2V

D.C. power supply at an initial current equal to the maximum discharge current specified by the

manufacturer.

The specified discharge current is to be obtained by connecting a resistive load of the appropriate

size and rating in series with the test cell. Each cell shall be forced discharged for a time interval (in

hours) equal to its rated capacity divided by the initial test current (in ampere).

Primary or rechargeable cells meet this requirement if there is no disassembly and no fire during the

test and within seven days after the test.

www.ponytest.com <l>Hotlin e 400-819-5688

PCN Y

.!i:.G(;;J;~:{;: , (OlO) 82618 11 6 *U-'9<~~~\ , (0431 ) 85150908 J:~;J;!l"!:.i'. , (021) 64851999 i:tl»ll "'~ ·~ , (0?55} 26050909

t'f.%:ll:1FH!' <om>ss;o6&66 :1;:i1i9:;@:i;, (0411)~46sos2o ·ril!<3l<~:r.~ , <os?4J87736499 r"ffl~!!;"; ·~ , <o2oJ&9224Jio

;ldli'J<~·~, (0!2) 27360730 tllJI!'!li~'{{, (0371)69350670 liCIW!l;~j_(, (0571)&7219096 JJ.-1:&));¥!~ , (027)83997127

Report ID: MZIPBAQA8879872 1 Page 7 of 11

Pony Testing International Group

VII, TEST PROCEDURE

I Marking

~

I Pretreatment

+ + +

Nl- N4 N9- N13 CI...C4

~ Altitude simulation

~ Thermal test

t Vibration Impact

l Shock

l External short circuit

+ +

I Analysis

VIII , MAIN TEST APPARATUS I E-0 I 21 Rechargeable battery test system

IE-0294 DC regulated power supply

I E-0434 Vacuum chamber

I E-0219 Rapid temperature

l

I

I l 1

N5- N8 N14-N23

c5-c8 C9...Cl8

Overcharge -~ ~ Forced discharge I

'

I

IE-01 78 BALANCE

IE-0090 Digital rnultimcter

IE-0287 Shock test instrument

I E-0 185 Thermoelectric pair (housing)

I E-0506 Battery impact test instrument IE-0281 Battery anti-explosion chamber

I E-0077 TPR series high precision DC regulated power supply

I E-0503 Electrodynamamic type vibration test instnnnent

I E-05 14 Rechargeable battery test system

I E-0 128 Electrodynamam ic type vibration test instrument www.ponytcst.com (O IIotlinc 400-!! 19-56!!8

OCNY

JtU.Jiit~·<r, 1010) A~tii81W (olrltr.t'<i<, <0431) ~~~~<Nil~ Ut!t5~'1t: toW 64851999 • .:.11~1:~·~, (075~> ~!'050'109

i'f.l:!::J;~-i': (0531)~8706866 ),;~;·n~·.;r, (().l!llNU•~U~lll 'i'v.ll':l:~'i'• (0574)87736499 J-iW4<~·11, Cn:o)8Q2241111

Xi'l'':l:ii' r, (022) ~7360730 •Jitt1l;t)'ir, (0)1l>t•9Wll•71l tJdft':l:~ \1, (0~71)872190')6 Jl:f(ll:~·;r, (017)M39Q71l7

' .t

PIJNT Pony Testing International Group

IX, DATA

I. Altitude s imulation

Pre-test

No. Mass Voltage

(g) (V)

NI 3741.1 29.23

N2 3705.5 29.27

N3 3734.0 29.24

N4 3745.9 29.29

Cl 3742.1 29.26

C2 3743.9 29.24

C3 3742.3 29.26

C4 3745.3 29.27

2. Thermal test

Pre-test

No. Mass Voltage

(g) (V)

N I 3740.1 28.71

N2 3703.5 28.72

N3 3733.0 28.72

N4 3743.9 28.74

C l 3740.9 28.70

C2 3740.9 28.71

C3 3741 .3 28.69

C4 3744.6 28.71

DCNY

Report ID: MZ1PBAQA88798721 Page 8 of 11

After test Whether leakage, Mass loss Voltage

Mass Voltage venting, disassembly,

(g) (V) (%) loss(%)

rupture, fire (Y IN)

3740.1 28.71 0.027 1.779 N

3703.5 28.72 0.054 1.879 N

3733.0 28.72 0.027 1.778 N

3743.9 28.74 0.053 1.878 N

3740.9 28.70 0.032 1.914 N

3740.9 28.71 0.080 1.813 N

3741.3 28.69 0.027 1.948 N

3744.6 28.71 0.019 1.913 N

After test Whether leakage, Mass loss Voltage

Mass Voltage venting, disassembly,

(g) (V) (%) loss(%)

rupture, fire (Y IN)

3740.1 28.51 0.000 0.697 N

3703.5 28.51 0.000 0.731 N

3733.0 28.57 0.000 0.522 N

3743.8 28.03 0.003 2.470 N

3740.9 28.54 0.000 0.557 N

3740.9 28.51 0.000 0.697 N

3741.3 28.53 0.000 0.558 N

3744.5 28.56 0.003 0.522 N

www.ponytcst.com <tlHotlinc 400-8 19-5688

Jt.!XS:tj'i'• <otol 82o1SIIo ¥-:if~t:."if, I04.l1 ) ~5 15090~ 1:/r:l:~¥. <ow 6-IM519~ ;:;:t4'l;~·~~. !0755) 26050909

r'i'~:l<'H"i! : (OSH)8l\706S66 A4:l:~'i!: (041 1 )8~650820 j·~~;J:~~·.;<, (0574)g77J6-199 /" lti't!ll'\i: (020)89224.110

A.~?i<·~·-(: (022)27360730 1lilff~~·o11 , 10371)69350670 t~l!!'t~·-·, (0571lR7219{)96 ~til1"4.:11!'.;~, (027)83997127

) )

DCNY

Report ID: MZLPBAQA88798721 Page 9 of 11

Pony Testing International Group

3. Vibration

Pre-test After test Whether leakage, Mass loss Voltage

venting, disassembly, No. Mass Voltage Mass Voltage (%) loss(%)

(g) (V) (g) (V) rupture, fire (Y IN)

NI 3740.1 28.51 3739.6 28.32 0.013 0.666 N

N2 3703.5 28.51 3702.6 28.32 0.024 0.666 N

N3 3733.0 28.57 3733.0 28.41 0.000 0.560 N

N4 3743.8 28.03 3743.3 28.02 0.013 0.036 N

Cl 3740.9 28.54 3739.1 28.38 0.048 0.561 N

C2 3740.9 28.51 3739.8 28.50 0.029 0.035 N

C3 3741.3 28.53 3739.7 28.36 0.043 0.596 N

C4 3744.5 28.56 3744.5 28.41 0.000 0.525 N

4. Shock

Pre-test After test Whether leakage, Mass loss Voltage

No. Mass Voltage Mass Voltage venting, disassembly,

(g) (V) (g) (V) (%) loss (%)

rupture, fire (Y IN)

Nl 3739.6 28.32 3739.1 28.15 0.013 0.600 N

N2 3702.6 28.32 3701.5 28.30 0.030 0.071 N

N3 3733.0 28.41 3733.0 28.31 0.000 0.352 N

N4 3743.3 28.02 3743.3 28.00 0.000 0.071 N

Cl 3739.1 28.38 3739.1 28.16 0.000 0.775 N

C2 3739.8 28.50 3739.2 28.45 0.016 0.175 N

C3 3739.7 28.36 3739.1 28.36 0.016 0.000 N

C4 3744.5 28.41 3743.1 28.32 0.037 0.317 N

www.ponytest.com Cl>Hotline 400-819-5688

;ftjj(;J:;~'{(o (010) 82618116 L<.#:~;:~'{(, (0431 ) 85150908 J:ilf9:;lJ!i.·~~' (021) 64SSiq99 i*»W·n~"¥.: (0755) 26050909

t/.\i,::Jif,t~~ ' (0532)88706866 .k~';i;!liUI., (0411}84650R20 'i'~~::li!Jil'il • (0574)87736499 J"ili:;t~·,;; , (020)89224310

Rii:?tiJil~, (022)27360730 .tlliii:9<~".1, (0371}69350670 IIC.Itl':t;¥.<'\(, (0571)87219096 i>ttl{~~~{f , (027)83997127

DCNY

Report ID: MZIPBAQA88798721 Page 10 of 11

Pony Testing International Group

5. External short circuit

No. Peak temperature (C) Whether disassembly, rupture, fire (Y IN)

Nl 55.8 N

N2 55.5 N

N3 55.1 N

N4 55.3 N

Cl 55.2 N

C2 55.0 N

C3 55.4 N

C4 55.1 N

6. Impact

No. Peak temperature (C) Whether disassembly, fire (Y IN)

N9 38.2 N

N IO 26.4 N

Nil 27.8 N

N12 117.4 N

N13 26.9 N

7. Overcharge

No. Whether disassembly, fire (Y /N)

NS N

N6 N

N7 N

N8 N

CS N

C6 N

C7 N

C8 N

www.ponytest.com <0 Hotline 400-819-5688

.itJ::l>);~~·{i , (010) 826181 lfi K./Fj;~:£ , (0431) 85150908 1:11i'9;~~ . (021) 64X5 1999 tli!ij I~;J~~. (0755) 26050909

l't.%::l:~:r~. <o532l887o6s66 xili:-t~.~{, (04t llS46sos2o ·J'~>J;!l!,t~, , <os74lsnJ6499 ,-~~~~:~¥. . <o2o)s92243IO ~ill~~·~ , <Ol2J27J60730 J:ll~H:~·f! , (0371)69350670 tillti:9<!Ji'''i~· (0571)872 19096 JltiJOI.:~':\( , (027183997127

)

1 .Q

?~ . . . I 1

~ ~

IJCNY

Report ID: MZIPBAQA88798721 Page 11 of 11

Pony Testing International Group

8. Forced discharge

No. Whether disassembly, fire (Y IN)

Nl4 N

NlS N

Nl6 N

Nl7 N

N18 N

Nl9 N

N20 N

N21 N

N22 N

N23 N

C9 N

CIO N

Cl! N

CI2 N

CJ3 N

CJ4 N

CIS N

C16 N

C17 N

Cl8 N

*** End of report ***

www.ponytcst.com CO II otlinc 400-819-5688

Jt~·,x;~·i;, (010) S2618116 K{i-'t-~·.;,, !O~Jll K~ 1 5090~ r~l":l;<~'\<, toZll 6-l851Q9? f,(l/11';;.""{1, (0755) l60SO'XN

t'r.l~li:~'i!• (0532)~~706~1.6 J...ii'i.:V.!'<<, (ll411H4650S20 ;·;!';;);~~(, (0574)~7736-19'1 ( ~~~~·-t, (O~O)SQ2!~310

J<ir;J:1~ "-i\:, (022)!7360730 I'Ji~W:i:~~t, (0371J69JSil670 litffl"'i:f<i"¥• (OS71)H7l l9091> litJ:{!lin'-if, (027)8)99712"1