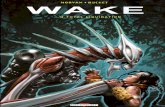

Liquidation Sale - Ford Genk

-

Upload

hilco-industrial -

Category

Documents

-

view

219 -

download

0

description

Transcript of Liquidation Sale - Ford Genk

IN CONJUNCTION WITH

DUE TO THE CLOSURE OF

GENK VEHICLE OPERATIONS

LIQUIDATION SALE

COMPLETE PRESS SHOP WITH WHEEL PLANT

FOR SALE BY

PRIVATE NEGOTIATIONASSET LOCATION: GENK, BELGIUM

(4) TRANSFER PRESSES, (4) BLANKING LINES, (11) TANDEM PRESS LINES, (2) SHEARS,

(2) CUT-TO-LENGTH LINES, (2) DIE PRESSES

www.hilcoind.com

LIQUIDATION SALE

INSPECTION:Strictly By Prior Appointment

ASSET LOCATION:Henry Fordlaan 8, Genk, Belgium

Machinery & Equipment Ernst Rost Onnes +31 20 470 0989 [email protected]

Machinery & EquipmentChip Thornton+1 313 839 [email protected]

Customer Service Hilco Industrial +31 20 470 0989 [email protected]

MAIN CHARACTERISTICS OF THE PLANT: Capacity: 500.000 cars/year Site Size: 600.000 square meters

IN CONJUNCTION WITH

WWW.PRESSESFORINDUSTRY.COM

SALE STARTING DATE:16th NOVEMBER 2015

REMOVAL:

Only Ford qualified and approved companies are allowed to work at Ford Genk.We have met with a number of companies and selected following companies to work on an exclusive basis, they quoted the best prices and conditions.• Schollp Montage GmbH; www.scholpp.de.Only Scholpp is allowed and certified to dismantle the Stamping-, Blanking and Wheel Presses.

Scholpp has quoted very competitive prices, which are available on request from Mr. D. Asch; [email protected]• Vanguard Shipping Ltd. Is the only qualified packer allowed on the Ford site; For any packing quotations please contact: John Summer [email protected] • Shipping Enquiries can be directed to Keld Rübner Pedersen [email protected]

Customer Service Hilco Industrial +31 20 470 0989 [email protected]

TRANSFER PRESSES

• 6.200 Ton, CROSS BAR TRANSFER PRESS LINE “MUELLER WEINGARTEN” S-6200.06.230; Siemens Press Control; Cap. Rams 1-6: 1800/800/1000/800/1000/800 Ton; 1 x 6 Moving Bolsters, Station 1: 2400 x 4500, Stations 2-6: 2000x4500 mm; (6) Rams, each with Injector; (6) Draw Stations; (2) Moving Pallets for Blanks; Blank Cleaning Unit• 3.200 Ton TRI-AXIS TRANSFER PRESS LINE “SCHULER” TBS 3-3200-6-1828-8; Siemens Press Control; Cap. Ram 1:1800 ton, Ram 2: 1400 Ton Two Rams, with Six Draw Stations; 2 x 2 Moving Bolsters 5.500 (5460) x 2.500 mm each; Destacker NSM-Magnettechnik; Blank Cleaning Unit Schleifstein

• MODERNIZED EARLY 2000 •

3

TRANSFER PRESSES

• (2) 2.200 Ton TRI-AXIS TRANSFER PRESSES LINES “SCHULER” TBS 2200-6-1200 with Siemens Press Control; Cap. Ram 1: 1200 Ton, Ram 2: 1000 Ton; (2) Moving Bolsters and Rams 3600 x 2500 mm; Destacker Neuhauser- Magnettechnik4

• MODERNIZED EARLY 2000 •

COMPLETE LINES OR INDIVIDUAL PRESSES

TANDEM PRESS LINES

• 1.000 Ton Tandem Press Line “WEINGARTEN/KRUPP”; Bed 4.500 x 2.400 mm; with Automation and Siemens S-7 Press Control; Olafström Automation:* 1600 Ton Double Action Press WEINGARTEN ZS 1600.48* (4) 1.000 Ton Single Action Presses KRUPP PDqV4-1000

(2) 600 Ton Tandem Press Line “WEINGARTEN”; Bed 3.600 x 2.200 mm;

with Siemens S-7 Press Control.* 1000 Ton Double Action Press

WEINGARTEN ZK 1000.34* (5) 600 Ton Single Action Presses

WEINGARTEN VK 600.39.60

5

• MODERNIZED EARLY 2000 •

TANDEM PRESS LINES

500 Ton Tandem Press Line “KRUPP”; Bed 3.100 x 1.300 mm;

(2) 600 Ton Tandem Press Line “WEINGARTEN/SCHULER”; Bed 3.050 x 1.800 mm; with Siemens S-7 Press Control.• 1000 Ton Double Action Press WEINGARTEN ZK 1000.31• (4) 600 Ton Single Action Presses WEINGARTEN VK 600.34.55• (1) 600 Ton Single Action Press SCHULER P4E2SQ/600/3.05/0.55

• MODERNIZED EARLY 2000 •

6

TANDEM PRESS LINES

• 500 Ton Tandem Press Line “SCHULER”; Bed 2.700 x 1.500 mm; with Siemens S-7 Press Control.• 900 Ton Double Action Press SCHULER PZKnbs 900/2,8/0,75• (4) 500 Ton Single Action Presses SCHULER P2E2Sqs 500/3,1/0,5

• MODERNIZED EARLY 2000 •

7• 500 Ton Tandem Press Line “RASKIN”; Bed 2.800 x 1.300 mm; with Siemens S-7 Press Control.• (7) Single Action Presses RASKIN Sphinx 5028.AE.2

TANDEM PRESS LINES

(2) 400 Ton Tandem Press Line “SCHULER”; Bed 2.650 x 1.000 mm; with Siemens S-7 Press Controls • 700 Ton Double Action Press SCHULER PZKnbs 700/2,8/0,6• (3) 400 Ton Single Action Presses SCHULER P2E2Sqs/400/2,6/0,4• (4) 400 Ton Single Action Presses RASKIN Sphinx 4025.AE.2

400 Ton Tandem Press Line “SCHULER”; Bed 2.600 x 1.000 mm; 8

• MODERNIZED EARLY 2000 •

BLANKING LINES

“WILHELMSBURGER/RASKIN/NSM” Blanking Line, Cap. 2000 x 0,5-2,0 mm; with Siemens S-7 PLC. Coilweight 25 Ton; Blanking ress; Coilcar, Decoiler, Coil Opener and Feeder, Looping Pit, Straightener, 400 Ton “Raskin” Blanking Press; Bed 4340 x 2300 mm, Stacker “NSM-Magnettechnik”

“WEINGARTEN/SCHLEICHER/RASKIN/ASM” Blanking Line, Cap. 1300 x 0,6-2,0 mm. Siemens S-7 PLC. Coilweight 25 Ton; Coilcar, Decoiler, Coil Opener and Feeder, Cropping Shear, Looping Pit, Straightener, Roll Feeder, 400 Ton “Raskin” Blanking Press, bed 3300 x 1800 mm; Stacker “ASM” 9

COMPLETE LINES OR INDIVIDUAL PRESSES

• MODERNIZED EARLY 2000 •

BLANKING LINES

“WEINGARTEN/RASKIN” Blanking Line, Cap. 1.300 x 0,6 - 2,0 mm; with Siemens S-7 PLC.

Coilweight 25 Ton; Coilcar, Decoiler, Coil Opener and Feeder, Looping Pit, Straightener,

400 Ton “Raskin” Blanking Press; Bed 3300 x 1800 mm

“WILHELMSBURGER/WEINGARTEN” Blanking Line, Cap. 1.300 x 0,5 – 2,0 mm; with Siemens S-7 PLC. Coilweight 25 Ton; Coil Car, Decoiler, Coil Opener and Feeder, Looping Pit, Straightener with Feeder; 300 Ton “WEINGARTEN” Blanking Press, Bed 3.000 x 1.800 mm10

• MODERNIZED EARLY 2000 •

CUT - TO - LENGTH LINES

“MULLER-WEINGARTEN” Universal Straight and Angel Cut-to-Length Line,Cap. 2100 x 2,0 mm, with Siemens S-7 PLC. Coilweight 25 Ton; Coil Car, Decoiler, Coil Opener and Feeder; Straightening Machine, Looping Pit; Roll Feeder; Elect. Straight- and Angle Shear; Magnetic Stacker, Stacker, Scrap End Store with Quick Changing of tools

“WILHELMSBURGER/SCHULER” Cut-To-Length Line, Cap. 2.000 x 2,5 mm with Siemens S-7 PLC. Coilweight 25 Ton; Coil Car, Decoiler, Coil Opener and Feeder, Straightener “SCHULER” RPA 48/205-2000 (2003), Looping Pit, Shear, Stacker “ASM” 19711871-00-0 (2008) 11

FOR ANY ENQUIRIES PLEASE CONTACT:ERNST ROST ONNES

+ 31 20 470 0989 • [email protected] •

OR VISIT OUR WEBSITE AT WWW.HILCOIND.COM

• MODERNIZED EARLY 2000 •

SHEARS

• “NSM MAGNETTECHNIK/ALTEK” FULLY AUTOMATIC CUTTING -and STACKING LINE, Cap. 2.500 x 2.500 x 0,6-2,0 mm with Siemens S-7 PLC. Year 2005. Destacker NSM with Robot Kuka, (2) Aut. Pallet Tables with Positioning Altek, Roller Table, (2) Robots Kuka, Guillotine Shear NSM, Sheet Transport, Overhead Magnetic Sheet Transport, Stacker with (2) Pallet Tables

• “WIEGER” Model 4/0 Guillotine Shear with Run-Out Table and Scrap Coveyor.Cap. 2.000 x 4,0 mm.

12

• MODERNIZED EARLY 2000 •

(2) SCHULER DIE PRESSES

13

• MODERNIZED EARLY 2000 •

WHEEL PLANT & ROBOTS

14

• Hub- and Rim Line For Wheels dimensions: 12” – 16” , Width 3,5”– 7”, Min. diameter 265 mm, Max.diameter 470 mm, Output approx.. 5.000 wheels per shift Decoiler “PULCH”, Bowl forming, 2000 Ton 7 Station Die Press “SCHULER” PSt – 2000/7/600, Control: PLC SIEMENS S7* CLAYS Horizontal Bowl Calibration Press, Deburring. * Wheel Ring Bending, Welding and Rim Profiling WEAN DAMIRAY-SIEMAG* Assembling Bowl and Rim, Welding and Calibration OTTENSER EISENWERKE and SCIAKY* Cleaning, Phosphating, Painting, Duerr, Alstom Packing Ring-Rim & Bowl Production

• MODERNIZED EARLY 2000 •

SPARE PARTS & ROBOTS

SPARE PARTS & ROBOTS

15

DISMANTLING, PACKAGING AND TRANSPORTATIONOnly Ford qualified and approved companies are allowed to work at Ford Genk.We have met with a number of companies and selected following companies to work on an exclusive basis, they quoted the best prices and conditions.

Only Scholpp is allowed and certified to dismantle the Stamping-, Blanking and Wheel Presses. Scholpp has quoted very competitive prices, which are available on request from Mr. D. Asch; Detlef Asch [email protected]

Vanguard Shipping Ltd. Is the only qualified packer allowed on the Ford site;For any packing quotations please contact Mr. John Summer - [email protected]

Shipping Enquiries can be directed to Mr. Keld Rübner Pedersen - [email protected]

* We are also giving the opportunity to arrange your own transport!Dismantling of Presses and or Press Lines by Prior Appointment with Detlef Asch, [email protected]

IN CONJUNCTION WITH

WWW.PRESSESFORINDUSTRY.COM

DUE TO THE CLOSURE OF

GENK VEHICLE OPERATIONS

COMPLETE PRESS SHOP WITH WHEEL PLANT

WWW.HILCOIND.COM

LIQUIDATION SALE