Determination of sulphur trioxide in the presence of sulphur

Lime Sulphur Introduction

-

Upload

mmiirroo-oo -

Category

Documents

-

view

216 -

download

0

description

Transcript of Lime Sulphur Introduction

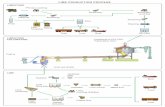

Hello Thanh,Best way to reduce acidity is adding lime (Quick lime or Dehydrated lime) on the conveyor feed belt. This in combination with a good sulphur melter design, with good agitation and contact time, will neutralise the acid and herewith solves you acidity problem throughout the process..If you think of adding NaOH we inform you that this is not a good idea.NaOH dissolves the precoat layer and all ash will pass the filter!Jan Hermans; Sulphurnet HoangHoang T.chemical enginering at DAP2 Join stock company* Thanks for your advises. I known that using lime is very good for neutralise acid in sulfur feed. but it cause filter problem, all lime supplies will be keep on filter surface, so we need to clean it often. sometime, quick lime was clotted when they combine with moisture or it not good distribute in surfur melting tank . I think using NaOH to help reduce time to clean filter. NaOH also combines and reacts with acid better than Ca(OH)2 because it is liquid phase. thanks your advise again because you remin me the dissolving of NaOH, Na2SO4, precoat layer and ash through filter.

- I have a question about: how does NaOH dissolve the precoat layer and all ash through filter. Can you explain it clearly for me, or give me some reference to read. JanJan H.Director and owner of SULPHURNETThanhSodium Hydroxide (NaOH) reacts with the Si02 in the filter aid. It forms a Sodiumsilicate derivate, a kind of waterglass. This is a liquid product and will pass the filter. So the ashes and non-reacted lime will pass the filter resulting in high ash levels in the filtered sulphur, polluting the convertor (and maybe you WHB)In beer filtration they use Kieselguhr a filter aid related product. They use the Sodium Hydroxide to CIP the filters and remove the remains of Kieselguhr.

Your problem is the melter design. This is not designed well. In the melter the lime should be reacting with the acid and after the melter the pH of the sulphur should be pH 6 or higher. Also the melter should keep the solids in suspension so they end up in the filter.A good pre-coat layer in the filter protects the mesh and facilitates the cleaning of the filter plates.Sulphurnet can help you to improve the operations. ([email protected])JAN HoangHoang T.chemical enginering at DAP2 Join stock company* Thanks you. The matter is NaOH react with SiO2 in coat filter layer.

I think there is no problem with melter design, it has an agitator to mix sulfur liquid and lime. - But the problem is adding lime on the conveyor feed belt. We add lime discontinuously then we doesn't neutralize acid in sulfur liquid well.* Now we want design a automatic and continuous adding lime. I think we can apply modern adding sulfur to design modern adding lime. It means using the speed of conveyor to control weight of lime adding.

* Could you support me some ideal for make a modern adding lime. I will very appreciate your help.

You could contact me by email: [email protected].

http://www.sulphurnet.com/http://www.devcousa.com/technologies/high-capacity-sulfur-melting/http://www.sulphuric-acid.com/techmanual/sulphur/melting.htm

Lime Sulphur IntroductionLime Sulphur is and excellent insecticide and pesticideLime Sulphur solution, diluted in water, is a well known insecticide and fungicide.It was originally used to protect grape vines from fungus and there are references to it as early as the 1800's.It is also an old and effective dip to cure sarcoptic mange on dogs.

Lime Sulphur can be bought ready made and diluted or made at home and diluted. There is a recipe on Wikipedia that I add here in case I am ever in a position where I need it.

The two ingredients of Lime Sulfur are:

1.

Sulphur

and2.

Calcium Hydroxide (Hydrated Lime)

They are good to have on hand because:

- readily available- have a wide range of uses- have a long storage life- are deemed non toxic themselves, (just combined together they make a lethal - in a good way :) - insecticide and fungicide cocktail. This cocktail also stinks!)

Recipe from Wikipedia

A standard recipe for the concentrate usingCalcium Hydroxide (Hydrated Lime)

is :

80lb. (36kg)

Sulphur,48lb. (22kg)pure

Calcium Hydroxide (Hydrated Lime)

50 gallons (189Litres) of water.

If impure

Calcium Hydroxide (Hydrated Lime)is used, increase its quantity by a generous 2 lb. per each 5% less than 100% pure.

Avoid using lime that is less than 90% pure.

Start boiling water.

Mix Calcium Hydroxide with Sulphur together.

Add to boiling water slowly, dont get in flames as Sulphur is flammable.

Stir.

Boil for an hour (until the mixture becomes dark red), stirring and adding small amounts of hot water to compensate for evaporation.

Sieve through a stocking and use. It is in its concentrated form so you will need to dilute it 3 to 10 parts per hundred depending on use.

Here is a video of Eugenio Gras on You Tube making it. He is using a 2kg Sulphur, 1kg Lime, 10L Water (if you do the maths this is the same ratio as the Wikipedia recipe above.