Lime Manual

-

Upload

ho-ngoc-thanh-quang -

Category

Documents

-

view

266 -

download

14

Transcript of Lime Manual

Lime Handling

Systems

Executive Summary Lime Handling Systems is a general article dealing with the storage and feeding of lime slurries. Design considerations involved in selection of equipment are discussed in addition to general information on lime. Recommendations for system designs are discussed with information presented on equipment options. The article is designed to acquaint the reader with the considerations involved in achieving an efficient and practical lime system.

CHAPTER 1: GENERAL INFORMATION ON LIME 4 Lime 5 Lime Uses 5 Types of Lime 6 Quicklime 7 Hydrated Lime 8 Selecting what type of Lime to use 10 Lime Deliver 11 CHAPTER 2: FACTORS AFFECTING LIME SLAKING 13 Factors Affecting Lime Slaking 14 Lime Slaking 14 Quicklime Properties 14 Water Properties 15 Water to Lime Ratio 16 CHAPTER 3: LIME SYSTEM COMPONENTS 18 Bulk Storage 19 Typical Silo Configurations 21 Dust Control 22 Silo Flow Promotion 23 Flooding Control 25 Chemical Feeders 26 CHAPTER 4: LIME SLAKERS 30 Lime Slakers 31 Paste Type Slakers 31 Detention Slakers – Conventional 32 Detention Slakers – Grinding Mill Type 33 Factors Affecting Slaker Selection 34 CHAPTER 5: SYSTEM ACCESSORIES 37 Slaker Accessories 38 Grit Removal 38 Slurry Tanks 38 Slurry Pumps and Piping 39 CHAPTER 6: CONTROL PANELS & INSTRUMENTATION 42 Control Panels 43 Instrumentation 43 Silo Level and Inventory Controls 43 Slurry Measurement 44 CHAPTER 7: LIME ADDITION CONTROL 45 Lime Addition Control 46 Good Design Practices 49 Other Considerations 49 CHAPTER 8: SMALL FEED SYSTEMS 50 Small Feed Systems 51 Pre-Made Lime Slurries 53 CHAPTER 9: OTHER CHEMICALS 54 Other Chemicals 55 Soda Ash 55 Powdered Activated Carbon (PAC) 57

Chapter 1: General Information on Lime

CHAPTER 1: GENERAL INFORMATION ON LIME

Page 4 of 60

Chapter 1: General Information on Lime Lime The term lime is used to refer to a variety of calcium based substances, which include or may be derived from limestone. Except for sulfuric acid, limestone and its derivatives are the most widely used chemicals in the United States. Approximately 25 million tons of lime is used each year for a variety of different applications such as steel making, acid neutralization, water treatment, wastewater treatment, and air pollution control. Lime Uses

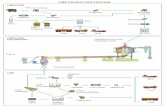

FIGURE 1 Currently lime usage is growing rapidly with the major investments being made upon acid rain control and environmental protection, both of which use lime in large quantities. In addition, new leaching processes for certain types of mineral ores and new sludge composting requirements will require large new quantities of lime.

Page 5 of 60

Chapter 1: General Information on Lime This introduction to lime handling equipment is intended to acquaint users with the design considerations involved in setting up a lime handling facility for maximum efficiency and minimum maintenance considerations. Types of Lime The two most common derivatives of limestone are quicklime and hydrated lime. For substances, properties such as particle size, purity, and chemical reactivity vary considerably between grades. Following is a more complete definition of each lime type:

Limestone: Limestone is a naturally occurring substance, which consists primarily of calcium carbonate (CaCO3). Limestone is typically quarried for use in its native form or for further processing to produce derivative substances such as quicklime. One form of limestone is marble. Figure 2 shows the types and properties of limestones.

FIGURE 2. Limestone Names, Grades, and Properties

Common Name and Formula

Grades or Forms Available 1

Appearance and Properties

Bulk Density

High Calcium Limestone CaCO3

Large Lump Pebble or Crushed

Ground, Screened or Granular

Pulverized

White rock with intermediate hardness [Mohs hardness of 3-5], product is quarried, typical purity is 95% CaCO3

90-115 lbs/cf

Dolomitic Limestone CaCO3 & MgCO3

Large Lump Pebble or Crushed

Ground, Screened or Granular

Pulverized

White rock with intermediate hardness [Mohs hardness of 3-5], product is quarried.

90-115 lbs/cf

1 Limestone is available in a large range of sizes often specified as percentages passing standard sieve sizes. Sizes listed in the table are defined by ASTM C 51 as Large Lump [8” and smaller], Pebble or Crushed [2.5” and smaller], Ground, Screened or Granular [1/4” and smaller], and Pulverized [100 % Passing a No 20 sieve]. The purity of limestone varies widely. The purity is measured by the percentage of available CaCO3 and MgCO3. Limestone is primarily used for flue gas desulfurization, acid neutralization, and to produce quicklime. Limestone delivery is available in barges, dump trucks, rail car and bulk trucks.

Once mined and processed for size, purity, and chemical constituents, the raw material is subjected to a variety of mechanical processes to produce various grades of lime.

Page 6 of 60

Chapter 1: General Information on Lime

Aerial photo compliments of Graymont Lime

ExshawExshaw

Lime Kiln

FIGURE 3: TYPICAL PRODUCTION PLANT Quicklime: Quicklime consists primarily of calcium oxide (CaO) and is produced from limestone in a process known as calcining as defined below: High Calcium Quicklime CaCO3 (Calcium Carbonate) + Heat ⇒ CaO (Calcium Oxide) + CO2↑ (gas) Dolomitic Quicklime CaCO3 • MgCO3 (Calcium Carbonate and Magnesium Carbonate) + Heat ⇒

CaO • MgO (Calcium Oxide and Magnesium Oxide) + CO2↑ (gas)

Page 7 of 60

Chapter 1: General Information on Lime

Figure 4 below defines the different types of quicklimes and the basic properties of each type:

FIGURE 4. Quicklime Types, Grades, and Properties

Common Name and Formula

Grades or Forms Available

Appearance and Properties

Bulk Density

High Calcium Quicklime CaO

Pebbled [3/4 – 1/4” φ] Granular [1/4” minus]

Pulverized [100 % Passing # 20 sieve]

Soft [Moh hardness less than 3], white pebbles to powder, typical purity is above 90% available CaO

48-70 lbs/cf

Dolomitic Quicklime CaO & MgO

Pebbled [3/4 – 1/4” φ] Granular [1/4” minus]

Pulverized [100 % Passing # 20 sieve]

Soft [Moh hardness less than 3], yellowish white pebbles to powder, contains 5 to 40% MgO

49-72 lbs/cf

The quality of quicklimes varies greatly. The quality of the lime is determined by the purity and reactivity of the quicklime. Purity is a measurement of the quantity of calcium oxide (CaO) in a given sample that is chemically available. The purity of commercially available quicklime in the United States typically ranges from 85% to 95% available CaO. Reactivity is a measurement of the heat released in the reaction between quicklime and water. This reaction is commonly known as lime slaking or hydration, the product of which is hydrated lime. As noted in Figure 5 below, reactivity is determined by slaking quicklime (at specific ratios of water to quicklime) and measuring the rate at which the product temperature rises. It should be noted that while purity and reactivity are related, they are not the same; that is, a high purity does not always indicate a highly reactive quicklime. Quicklime is shipped via in barges, railcar, bulk truck, sea containers, bulk bags and paper bags. The most common delivery is in 25 Te bulk trucks. Quick lime is either sold as quick lime containing approx 85-95% CaO or is further treated by hydration to produce hydrated lime Ca(OH)2 which contains approx. 72-74% CaO Hydrated Lime: Hydrated lime consists primarily of calcium hydroxide, Ca(OH2) and is the product of the reaction between quicklime and water as defined below: High Calcium Hydrated Lime

CaO (Calcium Oxide) + H2O ⇒ Ca(OH)2 (Calcium Hydroxide) + Heat

Page 8 of 60

Chapter 1: General Information on Lime Dolomitic Hydrate (type N) CaO • MgO (Calcium Oxide, Magnesium Oxide) + H2O ⇒ Ca(OH)2 • MgO (type N hydrate) + Heat

Dolomitic Hydrate (type S)

CaO•MgO (Calcium Oxide, Magnesium Oxide) + 2H2O ⇒ Ca(OH)2 •Mg(OH)2 (type S hydrate) +Heat Each pound of calcium oxide will react with 0.32 pounds of water to form 1.32 pounds of calcium hydroxide. Commercial hydration of quicklime occurs in hydrators, which control the water to lime ratio precisely to this ideal ratio to produce a dry powdered product. Where quicklime is reacted with water in excess of the ideal ratio, the process is known as lime slaking which produces a slurry of water and solid hydrated lime particles. Figure 5 below defines the different types of hydrated limes and the basic properties of each type:

FIGURE 5. Hydrated Lime Names, Grades, and Properties

Common Name and Formula

Grades or Forms Available

Appearance and Properties Bulk Density

High Calcium Hydrated Lime Ca(OH)2

Powder [80% passing 200 mesh

size}

Soft [Moh hardness less than 3] white powder, dusty, typical purity is 97% Ca(OH)2

25-40 lbs/cf

Normal Dolomitic Hydrated Lime (Type N) Ca(OH)2 & MgO

Powder [80% passing 200 mesh

size}

Soft [Moh hardness less than 3] white powder, comes from dolomitic quicklime, typical composition is 46 to 48% CaO, 33 to 34% MgO and 15 to 17% Ca(OH)2

30-40 lbs/cf

Pressure Dolomitic (Type S) Hydrated Lime Ca(OH)2 Mg(OH)2

Powder [80% passing 200 mesh

size}

Soft [Moh hardness less than 3] white powder, comes from dolomitic quicklime, typical composition is 7% CaO and MgO and 90% Ca(OH)2 and Mg(OH)2

30-40 lbs/cf

The properties of hydrated lime from different sources in the United States are fairly consistent with those properties described previously. The purity of the hydrated lime is expressed as a percentage of the material that is calcium hydroxide (Ca(OH)2). The typical range of purity in the United States is above 95% calcium hydroxide (Ca(OH)2). Hydrated lime is available in bulk trucks, bulk bags, and paper sacks.

Page 9 of 60

Chapter 1: General Information on Lime Selecting what type of Lime to use The type of lime is to be utilized in the process is dependent on a variety of factors, chiefly the anticipated consumption of lime (as CaO) to be used. As consumption increases the overall savings in chemical costs will justify cost increases in capital equipment. Keep in mind that if quick lime is used it has to be converted to hydrated lime prior to its use in the process in almost all cases.

Pebbled Crushed Pulverized

HYDRATED LIMEHYDRATED LIME

QUICKLIMEQUICKLIME

Choice of Lime to Use Lime Particle Size

Quicklime available in variety of particleQuicklime available in variety of particlesizes from pulverized to pebble limesizes from pulverized to pebble lime(usually 3/4”minus)(usually 3/4”minus)

Hydrated Lime - usually pulverizedHydrated Lime - usually pulverized

2 x 3/4 3/4 x 3/8 3/8 minus

FIGURE 6 FIGURE 7

Lime in either form is available in either bags or in bulk. As a rule of thumb the following differentials apply to the various types of lime. Cost difference between bagged hydrated lime and bulk hydrated lime Approx. $ 90.00 per ton (Based on unit costs, trucking, unloading, housekeeping, space requirements and labour costs for batch makeup) Cost difference between bulk hydrated and bulk quicklime Approx. $ 40.00 per ton (Based on unit costs and the differential between CaO content in hydrated and quick lime plus trucking and storage costs).

In general the use rate will dictate the form of lime used as illustrated in the following (Figure 8)

Page 10 of 60

Chapter 1: General Information on Lime

Lime Delive Lime is shipprailcars (100type, which uPD car, whicpneumatic ucfm of conve

Recommended Selections

0

1

4

Approximate Savings

TonsperDay

> $90/Ton

> $40/Ton

Lime Types

FIGURE 8

ries

ed in a variety of containers as illustrated below. Bulk deliveries are either in tons) or in self-unloading bulk trailers (20-25 tons). Rail cars are either the hopper nload by dumping by gravity to a storage pit (See Fig.10) or unloading device or a h is unloaded by pneumatic transfer. Truck trailers are usually equipped with a nload system which will unload 15 - 20 TPH through a 4" line using up to 600-1100 y air. (See Fig.11)

S h ipm en t C h o ice s

B u lk T r u c k

B a g

R a il C a r

T ote

Page 11 of 60

FIGURE 9

Chapter 1: General Information on Lime

Page 12 of 60

Rail Car Unload

FIGURE 10

Truck Delivery

FIGURE 11

Chapter 2: Factors Affecting Lime Slaking

CHAPTER 2: FACTORS AFFECTING LIME SLAKING

Page 13 of 60

Chapter 2: Factors Affecting Lime Slaking Factors Affecting Lime Slaking The lime slaking process and product quality depend on three primary factors: quicklime properties, water properties, and water to lime ratio. In most applications, water to lime ratio is the single most important factor in lime slaking; as this ratio is decreased, product quality increases. Lime Slaking The term “lime slaking” refers to the reaction between calcium oxide (as a component of quicklime) and water to form calcium hydroxide. This process is represented by the following equation:

CaO + H2O ⇒ Ca(OH)2 + Heat (Calcium Oxide) (Water) (Calcium Hydroxide)

In this reaction, each 1.0 lbs of calcium oxide combines with 0.32 lbs of water to yield 1.32 lbs of calcium hydroxide. The reaction releases heat (490 btu/lb of CaO) and is the same as that which takes place in a lime hydrator to produce commercial hydrated lime. Commercial hydration processes typically yield a dry product, whereas lime slaking occurs with an excess of water to produce a slurry of hydrated lime solids in water. Quicklime Properties Three properties of quicklime: type, purity, reactivity, and particle size should be considered in lime slaking. Type: The grade of quicklime, high calcium or dolomitic effects the slaking rate. A dolomitic lime will slake at a slower rate than high calcium quicklime. In the United States, the most common form of quicklime is high calcium quicklime. Purity: Purity describes of the amount of quicklime that is chemically available as Calcium Oxide (CaO). The purity of quicklime affects the reactivity and determines the purity of the hydrated lime product. The purity of commercially available high calcium quicklime in the United States typically ranges from 85% to 95% available CaO. Reactivity: Reactivity describes the relative capacity of quicklime to reciprocate chemical change with water. Reactivity is a function of purity, particle size and other factors such as particle porosity. The slaking rate is a measurement of the time for the slaking process to reach completion. Thereaction is considered complete when the temperature of a given sample reaches a maximum. As reactivity increases, the slaking rate, ultimate temperature rise, and surface area of hydrated lime increase also.

Page 14 of 60

Chapter 2: Factors Affecting Lime Slaking

Page 15 of 60

Particle size: Quicklime particle size and mixing methods have a significant affect on slaking rate. Commercial grade quicklime is available in a variety of sizes including pulverized (powder), granular (1/4” minus), pebble (1/4”-3/4” minus) and lump (2” minus). When adequately mixed with water, quicklime reactivity increases as particle size decreases. Ultimate temperature rise and product quality are not significantly affected by particle size with pebble or finer grades. The smaller the size of quicklime the more susceptible the lime is to air slaking. Water Properties Two properties of water: dissolved solids and temperature should be considered in lime slaking. Dissolved Solids: Water containing sulfites or sulfates in excess of 400 ppm should not be used for lime slaking as they inhibit the slaking process. Water containing bicarbonate hardness will not affect the slaking process, however it should be noted that bicarbonate ions will precipitate (scale) as calcium carbonate on contact with slaked lime. Softened process water or potable water is recommended for lime slaking.

FIGURE 12 FIGURE 13 Temperature:

Chapter 2: Factors Affecting Lime Slaking In general, higher incoming water produces better product quality. Water that is too cold may “drown” the quicklime and slow the slaking reaction down. Water that is too hot may boil during the slaking reaction. For reliable slaking with most lime types and slakers, water temperature should be between 55 deg F and 70 deg F. Water to Lime Ratio In most applications for slaked lime, surface area of the hydrated lime particles is of paramount importance. Water to lime ratio is the principal determinant of product surface area; as this ratio is decreased, surface area increases. The water to lime ratio is defined as the ratio of water mass to quicklime mass. This ratio does not include dilution or process water, which may be added to slaked lime downstream of the slaking compartment. In conventional lime slakers, water to lime ratio varies from 2.5:1 (for paste type slakers) to 6.0:1 (for detention type slakers). The water should be evenly distributed into the slaker. Surges or pulsating of the water flow may cause improper slaking. As shown in Figure 14, specific surface area of slaked lime particles is highly dependent on the water to lime ratio, with surface area increasing as water to lime ratio decreases. As the graph shows, this increase is greatest when water to lime ratio varies in the region between 2.5:1 and 6.0:1.

Figure 8. - Specific Surface of Calcium Hydroxide with Different Water to Lime Ratios [68 Deg. F Water]

35000

40000

45000

50000

55000

2 4 6 8 10 12 14Water to Quicklime Ratio

Bla

ine

Spec

ific

Surf

ace

(sq

cm /

g) Paste

Detention

Source: A Study of the Reaction Between Calcium Oxide and Water, T.C. Miller, Published by the National Lime

FIGURE 14

Page 16 of 60

Chapter 2: Factors Affecting Lime Slaking

FIGURE 15 illustrates the temperature rise of varying Water to Lime Ratios

Page 17 of 60

Chapter 3: Lime System Components

CHAPTER 3: LIME SYSTEM DESIGN

Page 18 of 60

Chapter 3: Lime System Components Bulk Storage Storage silos are generally vertical cylindrical units with a straight side to diameter ratio of between 3:1 and 4:1 for best flow characteristics. A conical bottom is generally supplied with a minimum cone angle of 60 degrees. Sizing the silo is a function of the usage rate. A 7-10 day minimum storage is typically used up to a maximum of 6 months. The minimum storage time may be altered depending on lime availability, transportation constraints or special problems. Minimum recommended silo size is 1-1/2 truckloads to allow delivery of a full truckload while still maintaining function of the lime system during the re-order process. Silo design should account for local seismic, wind and snow loadings as well as potential mass flow of the product. For quicklime 65 pcf is commonly used for structural calculations and 55 pcf for volumetric calculations. For hydrated lime use 35 pcf structurally; 25 pcf for volumetric purposes. An allowance should be made for some freeboard in the silo; typically 3’ to account for the angle of repose of the product. This freeboard also increases the efficiency of the bin vent filter operation. Material of construction for the silos include welded or bolted steel, concrete, or stainless steel. In all cases the material of construction for the silo must be compatible with the material stored. Steel construction is the most popular for these systems. Shop fabricated welded steel silos are economic up to 14’ diameter. Beyond this size shipping constraints preclude their use and field fabricated silos are used. Bolted steel factory coated steel silos offer an attractive option at diameters >12’. They are shipped knocked down and can be quickly erected on site with local labour. Steel silos are generally supplied with epoxy or inorganic zinc coated exteriors. Interior product areas can be left uncoated but are more commonly coated with an epoxy primer. For difficult products the cone area can be coated with special superslick Teflon based coatings, which greatly improve flow in this area. The silos can be supported in a variety of methods. Typical supports include skirt supported, leg supported or using structural steel. Some of these are illustrated below.

S ilo D es ignS ilo sup p ort

S k irt, s tru c tu re o r leg

Page 19 of 60

Chapter 3: Lime System Components A variety of discharge arrangements can be used depending on the application. For systems requiring duplicate trains for the lime make down equipment, silos can be equipped with a bifurcated cone outlet which provides dual outlets or a splitter valve can be installed on the cone discharge to direct product to two or more trains. Some examples are shown below.

Silo Cone Design In the case of a duplicate train system, if it is anticipated that both sides will be in use most of the time, then either a splitter valve arrangement or a bifurcated cone arrangement can be used. If only one side is in use, as is the case of a backup system, then it is recommended to use the splitter arrangement. In this case the idle side will tend to compact in the silo discharge and create flow discharge problems. Silo accessories should include the following:

• Access ladder (caged) with rest platforms (if required) and perimeter guard rail • Vacuum pressure relief hatch • 4" fill line with long radius elbows typically of Sch. 40 or 80 carbon steel c/w compression

couplings and grounding strips. Pipe restraints are recommended for operator safety. • High and low level probes (capacitance type) • Knife gate shut off valve for maintenance • Other accessories as desired for inventory control. • With regard to silo coatings we recommend that the silo interior be epoxy primed after

surface preparation to SSPC-SP6 with special anti friction coatings applied to assist in flow promotion. The exterior and skirt interior area are usually epoxy primed with an acrylic finish coat.

Page 20 of 60

Chapter 3: Lime System Components

Typical Silo Configurations

PARTIALLY INSULATED DRIVE THROUGH INTERMEDIATE WALKWAY

MULTIPLE SYSTEMS STRUCTURE SUPPORTED STAND ALONE

INSIDE BUILDING

Page 21 of 60

Chapter 3: Lime System Components Dust Control It is necessary to provide dust control on the silos to enable the conveying air to exit the silo during offloading. Bin vent filters of the reverse air purge type are recommended with 150-250 sq. ft of filter area, which will handle the average truck delivery system. For quick lime with larger particle sizes a filter of this type with 150 sq. ft. is satisfactory. For hydrated lime or pulverized quick lime the filter area should be approx. 250 sq. ft. which results in an acceptable surface to air ratio of < 4:1. Shaker type filters can also be utilized if compressed air is not available. With this type of filter additional filter area is required as the dust builds up on the filter bags during the off-load cycle thereby increasing the pressure drop across the bags. This type of filter is generally mechanically cleaned at the end of the of unload cycle. A minimum of 400 sq. ft. of filter area is recommended in addition to an exhaust fan to assist air flow. In rail car unload systems additional filter capacity will be required sized to match the conveying air flow.

FIGURE 16 Shown: WAM Reverse Pulse Bin Vent Filter

Page 22 of 60

Chapter 3: Lime System Components

Silo Flow Prom Once the lime idownstream eqflooding as illussilo structure. Every bulk prod

FIGURE 16A

Dust Filters

Need to vent and clean the Need to vent and clean the pneumatic convey air pneumatic convey air

Usually located on roof of silo Usually located on roof of silo

Design for 3-4 Design for 3-4 cfm cfm / / sq sq . ft. filter area . ft. filter area • • i.e. Truck 200 - 250 i.e. Truck 200 - 250 sq sq .ft. filter area .ft. filter area • • Rail 300 - 500 Rail 300 - 500 sq sq .ft. filter area .ft. filter area

Mechanical shaker or reverse air Mechanical shaker or reverse air pulse type pulse type

otion

s in the silo it is necessary to ensure a continuous smooth flow from the silo to the uipment. Bulk products stored in silos can be subject to bridging, rat-holing and trated below. If not addressed, these problems can cause catastrophic failure of the

uct stored in cylindrical silos will have its own unique flow promotion characteristic.

N ecessary to avoid bridging or rat-holingN ecessary to avoid bridging or rat-holingEfficient use of silo volum eEfficient use of silo volum e

Silo F low Prom otion

FIGURE 17

Page 23 of 60

Chapter 3: Lime System Components

Bin activatorBin activatorImparts vibration energy Imparts vibration energy to product to product Excellent for coarse Excellent for coarse productsproductsInterlock with feederInterlock with feederDo not use for continuous Do not use for continuous feed of small amountsfeed of small amounts

Silo Flow Promotion

FluidizationFluidizationFluidizes product with air Fluidizes product with air pads, air cone, impactors to pads, air cone, impactors to promote flow promote flow Excellent for powdered Excellent for powdered productsproductsUsed only on refilling feeder Used only on refilling feeder hopperhopperNecessary to control floodingNecessary to control flooding

Silo Flow Promotion

FIGURE 19

FIGURE 18

For pebble lime and other products shipped as a larger particle size, a vibrating bin activator sized at a minimum of 1/3 the diameter of the silo is recommended.(See Figure 19) These devices impart vibration energy to the product and promote smooth flow. Caution is required when using these devices in situations where a small quantity of product is removed continuously as in a direct feed application. In these cases it is recommended to use a transition hopper above the feeder and refill this hopper periodically. For hydrated lime, pulverized quick lime and other powdered products, a fluidization system works very well. This system consists of an aeration cone on the hopper outlet plus air pads assisted by low frequency, air operated impactors on the cone. (See Figure 18) Both of the above flow promoters can be used on either type of lime but some restrictions apply depending on particle size, air dryness, etc.

Page 24 of 60

Chapter 3: Lime System Components

These devices should be interlocked with the feeding equipment to allow operation only when feeding. Flooding Control Flooding of the material can be a problem with hydrated lime due to material size or excess aeration. An anti-flood system should be used which generally consists of a rotary valve above a transition feed hopper. The rotary valve is used to maintain the level in the feed hopper between two set points. This arrangement prevents flooding of the product through the feeder and provides a constant head of product on the feeder for repeatable flow characteristics. (Figure.20) An electromagnetic vibrator is generally installed on this hopper to provide flow promotion to the feeder. (See Figure 21)

Page 25 of 60

Chapter 3: Lime System Components

Typical Feed Hopper Setup

FIGURE 20

Feed Hopper Flow Problems

Used on Hoppers

Electric Vibrator

FIGURE 22 FIGURE 21 Chemical Feeders A variety of feeding devices is available for controlled metering of lime to the slurry tank. For lime service a volumetric screw feeder provides an economical, accurate device with minimum maintenance requirements. The accuracy of this device is approx. +/- 2%, which is normally satisfactory on lime service. Alternately a loss-in-weight feeder can be used which will give accuracy to +/- 0.2- 0.5% and also provide instantaneous and totalized product usage for inventory control. Other types of feeders include gravimetric belt feeders and rotary airlock feeders.

Page 26 of 60

Chapter 3: Lime System Components Feeders with accuracy to +/- 0.2% (FIGURE 23)

B E L TS P E E DP IC K U P

IN F E E D

S H E A R G A T EM O T O R

M O T O RS P E E D

C O N T R O L L E R

D IS C H A R G E

B E L T

S IN G L E L O A D C E L L

M IC R O -C O M P U T E RC O N T R O L L E R

C O U N T E R B A L A N C E DW E IG H P L A T F O R M

G ra v im e tr ic F e e d e r

FIGURE 26 Belt Feeder Shown: Merrick Belt Feeder

Page 27 of 60

Chapter 3: Lime System Components

Volumetric Screw Feeder

FIGURE 25 Volumetric Screw Feeder

Shown: Metalfab DB-1 Screw Feeder

L o s s -In -

W e ig h tF e e d e r

Feeders with accuracy of +/- 2% (FIGURE 24)

Page 28 of 60

Chapter 3: Lime System Components

LossLoss--InIn--Weight Weight FeederFeeder

FIGURE 27

Rotary Valve

FIGURE

Page 29 of 60

Chapter 4: Lime Slakers

CHAPTER 4: LIME SLAKERS

Page 30 of 60

Chapter 4: Lime Slakers Lime Slakers The objective in slaking quick lime is to thoroughly hydrate the CaO to form Ca(OH)2 and produce a very small particle size with a large surface area. The slaking reaction produces a great deal of heat, which is useful in sustaining and initiating further reactions. There are two types of lime slaker commonly used today: paste type slakers and detention type slakers. The principal difference between paste slakers and detention slakers is the ratio at which water and lime are mixed during the reaction phase of the slaking process; paste type slakers react quicklime with water at a ratio of approximately 2.5:1 whereas detention slakers react quicklime with water at ratios of 3.5:1 or greater. Paste and detention type slakers come in a variety of different configurations and sizes, each suited to specific applications. Paste Type Slakers Paste slakers automatically control the water to quicklime ratio and rely on the heat released from the reaction as energy to complete the slaking. By controlling this ratio the slakers are able to effectively handle frequent changes in the quicklime feed rate for both batch and continuous process applications. Optimum paste slaker performance is designed for short reaction times and maximum utilization of the lime. For these reasons, the paste slaker is best suited for applications using high quality quicklime. Paste slakers also consume substantially less power than comparably rated detention type slakers.

Paste Slaker(.5, 1, 2, 4 TPH)

1000, 2000, 4000, 8000, Lbs./Hr.1000, 2000, 4000, 8000, Lbs./Hr.Operate by mixing lime & water in Operate by mixing lime & water in 1:2 ratio1:2 ratioHeat of reaction breaks particles Heat of reaction breaks particles apartapartVery efficient slakingVery efficient slakingLow hp, low speed, minimal Low hp, low speed, minimal maintenancemaintenanceAble to operate without additional Able to operate without additional water heatingwater heating

FIGURE 28 Shown: Merrick Paste Slaker

Page 31 of 60

Chapter 4: Lime Slakers The paste slaker consists of two horizontal paddle shafts, which counter-rotate to mix water with quicklime. The mixture is driven toward the discharge (weir) end by means of pitched paddles attached to the shafts. Water to lime ratio in the slaking compartment is automatically maintained at an user adjustable ratio between 2.5:1 and 2.8:1. Beyond the weir end, slaked lime is further diluted by means of manually controlled spray jets integral to the slaker assembly. Grit (inert material in quicklime) is removed either by screening or inclined classifier. Paste type slakers are available in quicklime slaking capacities of 500, 1000, 2000, 4000 and 8000 lbs/hr. They operate at water to lime ratios (in the slaking compartment) between 2.5:1 and 2.8:1 which produces specific surface area (hydrated lime) of approximately 53,000 cm2 per gram. Typical operating temperature rise of a paste type slaker is approximately 140 deg F above the temperature of the incoming water and steady state is usually reached within 5 minutes of startup. Standard slurry discharge is 18-20% solids at the slakers rated maximum capacity. Detention Slakers - Conventional Conventional detention type slakers are best suited to applications in which the lime quality is medium to high and the lime feed rate changes neither frequently nor automatically. They are the least expensive of the slaker types and are well suited for batch type operations where lime quality is reliable. As shown in Figure 29, a typical detention slaker consists of two slaking compartments, each agitated by a conventional slow speed mixing impeller. Water and lime are fed into the first compartment and then overflow a weir into the second compartment. Additional agitation takes place in the second compartment after which the product discharges into the grit removal system. The water to lime ratio in the slaking compartment is adjusted and monitored manually with the hand valves and flowmeters integral to the slaker assembly. Grit is removed either by screening or inclined classifier. Conventional detention type slakers are available in a variety of quicklime slaking capacities up to 16,000 lbs/hr. They operate at water to lime ratios (in the slaking compartment) between 3.5:1 to 6.0:1which produces specific surface area (hydrated lime) of approximately 47,000 cm2 per gram. Typical operating temperature rise of a detention type slaker is approximately 100 deg F above the temperature of the incoming water and steady state operation is usually reached within 15 minutes of startup. Standard slurry discharge is 18-25% solids at the slakers rated maximum capacity. With slakers of this type it is necessary to incorporate heating of the slaking water for efficient operation in cold weather locations.

Page 32 of 60

Chapter 4: Lime Slakers

Detention S laker500, 1250, 2500, 5000,500, 1250, 2500, 5000,10,000 10,000 LbsLbs . . / / H r.H r.O perated by m ixing ratioO perated by m ixing ratioof 1:3.5 - 4.0of 1:3.5 - 4.0M echanical agitation atM echanical agitation athigh speed drives Slakinghigh speed drives Slakingreaction.reaction.H igher H P, higher speedH igher H P, higher speedR equires additional heating of m akeup w ater inR equires additional heating of m akeup w ater inw inter conditionsw inter conditions

FIGURE 29 Shown: BIF Slurry Slaker

Detention Slakers - Grinding Mill Type Grinding mill type detention slakers are best suited to applications where the lime quality is poor, grit handling is costly or when the processing rate exceeds that achievable in a conventional slaker. Grinding mill slakers operate on the same principle as conventional detention slakers, however they have the ability to grind inert materials (grit) contained in the quicklime and generally require little or no grit removal or disposal facilities. Grinding mill slakers are horizontal or vertical ball mills (as commonly used in the mineral processing industry) modified to withstand the temperature of lime slaking. They have the advantage of being relatively simple and rugged. However, grinding mill slakers are the most expensive of the slaker types, have limited capacity for turndown, and consume the most energy. As shown in Figure 30, a typical grinding mill slaker (horizontal type) consists of a rotating drum supported by external rollers. The mill contains a grinding media (typically steel balls) agitated by means of horizontal lifting bars attached to the interior of the drum assembly. Slaked lime product discharges from the drum and is pumped to a hydrocyclone, which classifies the slurry to recirculate oversize particles to the mill inlet. As with a conventional detention slaker, water to lime ratio in the slaking compartment is adjusted and monitored manually with hand valves and flowmeters. Grinding mill type detention type slakers are made to order in quicklime slaking capacities up to 60,000 lbs/hr. Operating parameters and characteristics are similar to conventional detention slakers.

Page 33 of 60

Chapter 4: Lime Slakers An alternate version of the ball mill is a Vertimill which is basically a ball mill operated in a vertical manner. This type is useful where very fine grinding is desired. (Figure 31)

Ball Mill1 TPH and up1 TPH and upOperates as aOperates as aslurryslurryslakerslakerBall impacts andBall impacts androtation drivesrotation drivesslaking reactionslaking reactionVery High HPVery High HPRequires water heating for winter operationRequires water heating for winter operationEspecially suitable for poor quality limes &Especially suitable for poor quality limes &High use ratio > 2- 4 TPHHigh use ratio > 2- 4 TPH

FIGURE 30 Shown: Svedala SRR Ball Mill Slaker

Factors Affecting Slaker Selection Many factors other than price and operating costs will influence the selecof the factors are outlined in the following: Product Quality Surface area of the hydrated lime product is of paramount importance in mshow a correlation between the diameter of slaked lime particles and theduring slaking. As the water to lime ratio is reduced, the diameter is redsubstantial increase in surface area of the slaked lime product. Due to tlime ratios, paste type slakers deliver more neutralizing capacity (as titration) than comparable detention slakers. For certain applications, thisubstantial improvements to the process as well as chemical cost saving

Page 34 of 60

FIGURE 31

tion of a slaker. Some

any applications. Tests water to lime ratio used uced also, resulting in a he difference in water to measured by free base s difference can result in s.

Chapter 4: Lime Slakers Grit Disposal Costs The cost of grit disposal can be a significant factor in the selection of lime slakers. The inert portion of quicklime which is captured by a screen or inclined classifier is relative to the purity and particlesize quicklime. This grit must be transferred from the grit removal device to a bin, which is emptied periodically. While the grit itself is not a hazardous material (as defined by EPA), however, the pH exceeds 12.0 and caution must be exercised in handling and disposal. The grinding mill slaker eliminates the grit disposal problem by grinding the grit to very fine particles, which are carried along with the lime slurry. This type of slaker should be considered where grit disposal costs are high. Slaking Water Quality For reliable operation of any lime slaker type, water used for lime slaking should be at a temperature not less than 55 ° F / 12° C. For slakers, which are expected to start and stop frequently, the time to reach operating temperature (with associated hydrated lime quality) may be a factor. Paste type slakers reach their steady state operating temperature in approximately 1/3rd the time required by comparable detention type slakers. In general, paste slaker performance is less susceptible to cold slaking water (less than 55° F / 12° C) than detention and grinding mill slakers. Water heaters may be added to raise the temperature of the slaking water for all types of slakers. Space Constraints Like all process equipment, lime slakers require regular cleaning and maintenance. They are often placed within the skirt support structure of the quicklime storage vessel where space is at a premium. The size and shape of the slaker may be a determining factor in slaker selection; in general, paste slakers are the most compact (in plan view). Some conventional slakers are configured with vertical mixing chambers and require less horizontal space, however headroom requirements are greater. For grinding mill slakers, the vertical type require the least space in plan view, however they can be up to 30 ft in height depending on the processing capacity. Capital Cost Budget constraints frequently determine slaker selection. Conventional detention type slakers are the least expensive of the three type considered, with paste slakers priced approximately 15% higher for comparable capacities. The higher price of the paste slakers can often be recovered quickly by the more efficient slaking and lower chemical usage. Grinding mill slakers are typically 3-5 times the price of comparable conventional slakers, however this premium can also be offset by the reduction in grit disposal cost. Operator Experience

Page 35 of 60

Chapter 4: Lime Slakers The user’s level of experience with lime slaking and prior experience with specific types of slakersshould be a factor in slaker selection. For safe and effective lime slaking, operators should have knowledge of the theory and practice of lime slaking. In general, detention type slakers are more forgiving of inaccuracies in lime and water feedrate; however manual slaking water control requires calculation of slaking/dilution water flowrates each time the lime feed rate is changed. In cases where quicklime feed rate is changing frequently, the automatic water proportioning system in pasteslakers should be considered. In addition to knowledge of lime slaking, grinding mill slakers require a knowledge of the grinding process and related equipment. For this reason; grinding mill systems require more operator knowledge than conventional slakers and appropriate consideration should be made in the selection process. A summary of selection criteria and comparative features is presented in Figure 32 below.

FIGURE 32 Lime Slaker Selection Criteria and Comparison

Condition Paste Type Detention Type Conventional

Detention Type Grinding Mill

Maximum Quicklime Slaking Rate (lb/hr) 8000 16,000 60,000

Minimum Quicklime Quality

85% CaO with high reactivity OR 80% CaO with medium reactivity

85% CaO with medium reactivity

75% CaO with low reactivity

Process Applications Batch or Continuous Batch Only Batch or Continuous Water to Lime Ratio (Typical) 2.5:1 4.5:1 4.5:1

Slaking Water Control Method Automatic Manual Manual

Turndown Ratio (Typical) 20:1 5:1 2:1

Horsepower Required 0.5 Hp per Ton/hr of Quicklime

1.7 Hp per Ton/hr of Quicklime

10 Hp per Ton/hr of Quicklime

Percent Free Base (Typical) 81% 75% 75%

Ca(OH2) Product Surface Area (Typical)

53,000 Cm2/Gram 47,000 Cm2/Gram 47,000 Cm2/Gram

Capital Expense Typically 15% higher

than conventional detention type slakers

Least 2-5 times higher than

conventional detention type slakers

Grit Disposal Screen or Inclined Screw

Screen or Inclined Screw Not normally required

Operator Experience

Important

Important

Critical

Page 36 of 60

Chapter 5: System Accessories

CHAPTER 5: SYSTEM ACCESSORIES

Page 37 of 60

Chapter 5: System Accessories Slaker Accessories For efficient operation of the slaker additional equipment is required to monitor and control the system. These include the following:

Grit removal devices •

• • • • •

Vent exhaust fans Dust control devices Temperature controls and alarms Warning devices In line water heaters

Grit Removal In order to extend the life of slurry piping, valves and pumps it is recommended that grit be removed from the lime slurry. This is accomplished in either a screen type, screw type of conveyor type grit remover. Slurry Tanks Sizing: In batch makeup systems, slurry tanks should be sized for a minimum of 15 minutes retention time of the lime slurry to allow the slurry to stabilize and complete the softening precipitation with the dilution water. This will minimize scaling on slurry pipelines. The slurry tanks should be circular with integral baffles and an adequately sized low speed agitator. For optimum mixing the tank diameter to height ratio should be kept close to 1:1. For continuous feed applications, smaller tanks are used to minimize the lag time when lime feed settings are changed. These tanks are generally 50-100 usg capacity and are quipped with high speed agitators. The water level in the tanks is maintained by either float valves or with a control valve reacting to tank level indication. Tanks can be fabricated of Carbon steel, FRP or polyethylene construction. Agitation: Agitators for lime service can be either belt or gear drive units designed for low speed operation with radial flow impellers. For hydrated lime service the agitators need to be designed for wetting service and generally are of the two blade design. Suspension applications common in quick lime slaking service are usually of the single prop design.

Page 38 of 60

Chapter 5: System Accessories

Page 39 of 60

Agitation

Low speed agitator ( 350 rpm)Low speed agitator ( 350 rpm)Gear or Belt DriveGear or Belt DriveDual prop for WettingDual prop for WettingSingle prop for SuspensionSingle prop for SuspensionCS or SS materialCS or SS material

FIGURE 32

Slurry Tank Level Controls: Non-contacting devices are strongly recommended for lime and/ or slurry service as they avoid the build up problem common with any item immersed in the slurry. Ultrasonic level controls, air bubblers or load cells have all given excellent service. Slurry Pumps and Piping Pump selection is critical in lime service. A properly designed lime slurry addition system will operate virtually maintenance free whereas poorly designed systems will create extensive maintenance and control problems. Pumps should be designed for slurry service. Gland seals should be avoided as the seal water creates scaling problems in the packing. Recessed impeller pumps with expeller options have given excellent service. Other choices include peristaltic hose pumps, progressive cavity designs and air operated diaphragm pumps.

Wilfley Pump

Centrifugal slurry pump

FIGURE 33

Chapter 5: System Accessories Lime slurry piping should be designed to ensure a minimum flow velocity of 4’/sec. with a minimum line size of 1-1/2”. Care should be taken to eliminate short radius elbows. Avoid in line dilution of the lime slurry. Pump suction lines should be as short as possible with no bends. Piping materials can be PVC, ABS or carbon steel. Valves should be chosen with care to avoid problems. For pump isolation valving straight through diaphragm valves are recommended. Lime slurry take off valves should be of the pinch valve type, (Fig 33) which are self-cleaning with a 1” minimum diameter. Pinch valves can be of the straight through, reduced port or tapered style operating in a timer controlled on-off manner. Alternately they can be operated in a modulating manner provided an intermittent fully open pulse is provided by the control scheme.

TY

FIGURE 34

PICAL BATCH SYSTEM SHOWING FEEDER SURGE HOPPER, SLURRY TANK, RECYCLE PUMP

FIGURE 35

Shown: Red Valve Pneumatic Pinch ValvePage 40 of 60

Chapter 5: System Accessories

Page 41 of 60

Pressure gauges should be of the isolation sleeve type, as shown below, to avoid plugging problems.

Pressure Gauge

Isolation Sleeve TypeIsolation Sleeve Type

Housing

SensingFluid

Integrally Molded Flange Gasket

Flexible Elastomer Element

Where possible lime slurry should be added to the process with an air gap to avoid scaling problems at the injection point. If this is not possible (i.e. Injection into a pipeline) then a retractable injection lance assembly should be used to allow periodic cleaning.

Adding Lim e to Process

FIGURE 35A

Note: Addition of lime to process using an air gap to minimize scaling.

Chapter 6: Control Panels & Instrumentation

CHAPTER 6: CONTROL PANELS & INSTRUMENTATION

Page 42 of 60

Chapter 6: Control Panels & Instrumentation Control Panels Generally the lime system supplier will supply a complete control panel to control and monitor the lime slurry preparation process. These panels can be supplied utilizing either relay logic or programmable controllers. Panels should be designed to NEMA 4 or 4X standards and a separate truck fill panel should be incorporated for the silo filling process to avoid having the truck driver access the main control panel. In cases where the silo bin vent filter is of the mechanical shaker type, the motor starters for this device should be located in the main panel or in an MCC section for overall economics.

Control PanelsNEMA 4 or 4XNEMA 4 or 4XdesigndesignUsually withUsually withintegral PLCintegral PLCCan haveCan haveintegral MCCintegral MCCsectionsection

Control Panels

RecommendRecommendseparate truckseparate truckfill panelfill panel

FIGURE 36 FIGURE 37

Instrumentation A variety of instrumentation is available to suit individual plant requirements. Silo Level and Inventory Controls

Digital point sensors Capacitance, radio frequency and vibrating tuning fork probes have all been used successfully. Rotating paddle type sensors, although the most economical devices, have resulted in higher maintenance costs than the other types.

Analog level sensors Radar reflex units, capacitance cable probes and retractable Yo-Yo probes have given good service. These devices all react to the shape of the product stored in the silo and hence are subject to some inaccuracies relating to the varying profile of the chemical as it is withdrawn from the silo.

Page 43 of 60

Chapter 6: Control Panels & Instrumentation

Load cells or strain gauges installed on the silo supports avoid this problem and will give accurate total weights.

Another method of accomplishing inventory control is by means of loss-in-weight feeders, which will give instantaneous as well as totalized usage readouts, which can be used to calculate inventory levels. Slurry Measurement In general, lime slurry concentrations and flows are not measured. Instrumentation for this purpose that works effectively is limited and is quite expensive. It is usually preferable and easier to measure the dry product feed rather than the liquid feed. If absolutely necessary for process control measurement of slurry density can be accomplished with nuclear density meters and flow with coriolis meters.

Page 44 of 60

Chapter 7: Lime Addition Control

CHAPTER 7: LIME ADDITION CONTROL

Page 45 of 60

Chapter 7: Lime Addition Control Lime Addition Control Lime can be added to the process in a dry form direct from the silo or as a slurry. For most applications a slurry feed is preferred as it ensures higher reactivity, better dispersion and the most efficient use of chemical. For slaking systems it is advisable to control the lime slaking process as follows:

• Set slaking rate at approx. 120% of maximum process requirements • Operate the slaker as required to maintain the level of slurry in the slurry tank between the

high and low set points • Re-circulate the lime slurry in a recycle loop with the lime being added to the process

through a pinch valve takeoff • Adjust lime slurry feed by varying the timer cycle of the feed line pinch valve ON time

Note: It is not advisable to vary the feed rate of quick lime to the slaker as a means of controlling the lime addition rate to the process as the lag time through the slaking process is too long for effective response time.

Page 46 of 60

Chapter 7: Lime Addition Control For hydrated lime systems either of the following methods can be used:

A) Variable Volume, Constant Strength (Batch Method)

• Make up batches of hydrated lime slurry to pre -set concentrations as required and adjust the slurry feed rate as above for the slaking systems.

B) Constant Volume, Variable Strength (Direct Feed)

• Feed a constant volume of dilute slurry to the process through a gravity, pump or eductor system.

• Maintain a constant level of slurry in the slurry tank by introducing water through a modulating control valve or float valve.

• Vary the feed of dry lime to the slurry tank in response to the process demands through a variable speed feeder.

Note: 1. Method A is useful when using an eductor feeding mechanism. 2. Method B should only be used when makeup water hardness and alkalinity are low.

FIGURE 38 METHOD A

Batch Makeup Process

Constant solution strengthConstant solution strengthVariable volumeVariable volumeUsually 5 Usually 5 -- 20% slurry20% slurryFeed to Process through Feed to Process through recirculating loop system.recirculating loop system.

Page 47 of 60

Chapter 7: Lime Addition Control

Page 48 of 60

FIGURE 39

METHOD B

Continuous Makeup Process

Variable lime feedVariable lime feedConstant lime slurry feedConstant lime slurry feedUse only with softened makeupUse only with softened makeupHigh water requirements ~ min. 30High water requirements ~ min. 30--35 usgpm35 usgpmVery low slurry strength 0.1 Very low slurry strength 0.1 -- 1%1%

Chapter 7: Lime Addition Control Good Design Practices Good design practices dictate that lime slurry piping and pump facilities be duplicated to ensure continuous operation. The level of this redundancy is predicated on the actual plant process requirements. Other Considerations A large variety of accessories can be incorporated into the lime system package to suit customers’ individual requirements and other process needs such as remote instrumentation and alarms, inventory control, heating and insulation of the silo skirt area, etc. As a minimum a safety shower and eyewash should be incorporated at the working level for operator safety when using quick lime in addition to safety glasses and protective clothing as recommended when using any chemical. Safety showers should be equipped with a flow switch to alarm in the event of use to protect workers working alone. Lime preparation areas should be equipped with wash down provisions and a sump area with pump. In summary, if careful attention is given at the design stage to the lime handling and feeding system, then an efficient, automated, low maintenance facility can be provided for the end user at an economical cost.

Page 49 of 60

Chapter 8: Small Feed Systems

CHAPTER 8: SMALL FEED SYSTEMS

Page 50 of 60

Chapter 8: Small Feed Systems

Page 51 of 60

Small Feed Systems Bulk Bag Systems For intermediate use applications lime may be purchased in 1 ton bulk bags. We have developed a system to handle these effectively as shown below to avoid the common flow problems associated with using these bags as storage bags for a feeder. The bulk bags are dumped into the hopper and chemical is withdrawn as required to make up batches. Flow promotion equipment is incorporated into the design. These skid mounted systems are shipped completely assembled and are custom designed for each application.

FIGURE 40 Shown: Stanco Prepackaged Skid System

Bulk Bag Systems

For small to medium use applications

Chapter 8: Small Feed Systems Bag Systems For low use applications utilizing 50# bags of chemical, a system illustrated below can be supplied to handle these effectively. The chemical bags are dumped into the sack dump system and then transferred to a batching system. The resulting slurries/solutions can be added to the process through a variety of pumping methods. Shown in the slide are metering pumps typically used for adding solutions.

Bag Systems

For small applications

Page 52 of 60

Chapter 8: Small Feed Systems Pre-Made Lime Slurries For smaller use applications several lime manufacturers have developed delivery systems to handle high strength lime slurries approaching 35% solids. These slurries are shipped in bulk from the manufacturer to liquid tanks at the use point. This method of delivery saves on the expense of a dry lime makedown system at the cost of the higher freight costs involved in shipping water. An illustration of a typical system from Chemical Lime is outlined below.

FIGURE 41

Page 53 of 60

Chapter 9: Other Chemicals

CHAPTER 9: Other Chemicals

Page 54 of 60

Chapter 9: Other Chemicals Other Chemicals All chemicals have their own particular design considerations that should be addressed in order to provide trouble free feeding systems. Some design aspects are addressed for common water treatment plant chemicals in the following sections. Soda Ash Special considerations for soda ash include its tendency to form hard lumps if exposed to moisture and its complex phase diagram in water. When designing soda ash systems special care should be taken to avoid long, complex pneumatic fill lines. Soda ash is vulnerable to product size degradation if handled extensively or off loaded at too high a pressure. The resultant fine powder is especially sensitive to moisture and will cause flow problems in the silo. Designers should note that there are two common forms of soda ash in industrial use. Light soda ash is generally used as a filler in compounds and will have a product weight of 25-35 pcf. Dense soda ash is generally used in water treatment and has a bulk density of 65 pcf. The storage silo size and design should take the form of soda ash into account. Consideration should also be given to the use of a lump breaker at the discharge of the silo cone. This can be used in conjunction with or in place of bin activators and will reduce any lumps that form in storage. Soda ash dissolves in water to form a variety of compounds depending on the strength of the solution and the temperature. The phase diagram is quite complex. Special care should be taken to ensure that the decahydrate form of soda ash cannot form as it forms a hard glassy solid that is difficult and dangerous to remove from pipelines and pumps. By maintaining the temperature and solution concentration within defined limits to ensure an unsaturated solution, this situation can be avoided. A phase diagram is shown below which illustrates the various forms that can be produced. Feeding soda ash solutions to the process can be accomplished using a batch tank makeup system with the solution fed to the process with metering pumps. Alternatively soda ash can be metered continuously in dry form using a volumetric feeder. This feeder adds the soda ash to a wetting cone/eductor system for direct feed to the process using the transport water as a carrier. Control over the addition is maintained by controlling the feeder speed in response to plant flow/ph signals. A typical flow diagram is shown below to illustrate the direct feed system

Page 55 of 60

Chapter 9: Other Chemicals

Page 56 of 60

E------------EA---------------------A

F---------------------------------------------F

G----------------------------------------------G

D------------------------------------D H-------------------H

B-------------------- C-----------------------C

A-------

B-------

C-------

D-------

--------E

--------F

--------G

--------H

Chapter 9: Other Chemicals

Page 57 of 60

Chapter 9: Other Chemicals Powdered Activated Carbon (PAC) Special considerations for PAC include the type of carbon used and the flow promotion in the silo. Designers should note that there are two common forms of PAC in water treatment plant use. PAC used in water treatment is produced from coal or wood each with its own characteristics. Coal based PAC is generally heavier with a bulk density ranging from 25-35 pcf. Wood based PAC is lighter with a bulk density ranging from 15-25 pcf. The storage silo size and design should take these ranges into account. Flow promotion devices are required to ensure smooth even flow form the silo. Fluidization systems are very effective when using intermediate feed hoppers above the feeding device. The use of bin activators is not recommended as these devices tend to compact the PAC and create additional flow problems. Many jurisdictions also require that any electrical devices used in feeding or storing PAC be rated for explosion potential. Local regulations should be checked to determine their applicability. The cost impact of this requirement can be minimized by locating many of the devices such as control panels in an adjacent building as shown below. Feeding PAC to the process can be accomplished using a batch tank or continuous makeup system with the slurry fed to the process with slurry pumps. Alternatively PAC can be metered continuously in dry form using a volumetric feeder to a wetting cone/eductor system for direct feed to the process using the transport water as a carrier. Control over the addition is maintained by controlling the feeder speed in response to plant flow signals. Note that the volumetric feeder design should incorporate a conditioning screw around the feed screw to avoid bridging and arching flow problems. Care should be taken to ensure that flooding of the PAC through the feeder is effectively prevented. A typical direct feed system utilizing a loss-in-weight feeder is shown in the following pictures. This system also has a separate building to house some of its electrical equipment.

Page 58 of 60

Chapter 9: Other Chemicals

Page 59 of 60

Chapter 9: Other Chemicals

Page 60 of 60

Summary In conclusion, if the potential hazards and problems of feeding lime and other chemicals are recognized and dealt with at the design stage, then effective, efficient and minimal maintenance systems can be provided to the end users.

![Kaffir lime kaffir lime (Citrus × hystrix, Rutaceae) is also known as combava, kieffer lime, limau purut,[2] jeruk purut or makrut lime, Kabuyao (Cabuyao).[1] It is a lime native](https://static.fdocuments.in/doc/165x107/5d055daf88c99375438bc1b1/kaffir-lime-kaffir-lime-citrus-hystrix-rutaceae-is-also-known-as-combava.jpg)