LIFTING STATION EB-705 English - DUX NZ · ventilation system if this is not possible). - The...

Transcript of LIFTING STATION EB-705 English - DUX NZ · ventilation system if this is not possible). - The...

MMAINTENANCE AND INSTRUCTION MANUAL - 3

En

glis

h

TABLE OF CONTENTS1. SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .032. MAIN COMPONENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .043. INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .054 GENERAL DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .05

4.1. Operation.5. SYSTEM SETUP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .06

5.1. Installation recommendations.5.2. Power supply connection.5.3. Starting up.

6. INDICATIONS FOR END USERS. . . . . . . . . . . . . . . . . . . . . .087. MAINTENANCE OPERATIONS. . . . . . . . . . . . . . . . . . . . . . . . .09

7.1. Cleaning.7.2. Troubleshooting guide.7.3. Motor disassembly and extraction.7.4. Replacement/cleaning of non-return valve.

8. TECHNICAL SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . .129. LAYOUT AND SECONDARY VENTILATION

SYSTEM DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1310. EXPLODED VIEWS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

10.1. Lifting station assembly.10.2. Caset assembly.

11. BASIC INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1512. EC DECLARATION OF CONFORMITY. . . . . . . . . . . . . . .16

.

1. SAFETY INSTRUCTIONSIn order to reduce the risk ofelectric shock, do not open thetop covers. Do not handle theinterior of the macerator; alwaysrefer servicing to qualifiedpersonnel.

In order to reduce the risk of fireor electric shock, do not exposethis appliance to rain or flooding.

DETAILED SAFETY INSTRUCTIONS.

Please read all the safety and operatinginstructions before using the appliance. Keepthem for future reference.

All the user safety indications, instructions andoperations included in this manual must beobserved.

LIFTING STATION EB-705

MMAINTENANCE AND INSTRUCTIONMANUAL

1en English

DETAILED SAFETY INSTRUCTIONS (continued).

This appliance must be installed in such a way that air is allowed to enter and leave the top part. If theappliance is installed inside a cupboard or another piece of furniture, ensure there is enough space forair to circulate around the unit.

Keep the unit away from heat sources such as: radiators, stoves or any other appliances that gener-ate heat.

This appliance must be connected to a power source of the kind indicated in these instructions or onthe sticker on the appliance.

This unit MUST be connected with an earth connection. Check that the earth connection is effective.

The supply cable must be placed so that it cannot be stepped on, or perforated or damaged by anyobject nearby.

Always clean the appliance with a wet cloth and mild soap. Do not use solvent or acidic cleaning prod-ucts.

Unplug this apparatus when unused for long periods of time and make sure the stopcock for any sani-tary fixture connected to it is turned off before disconnecting the lifting station.

Prevent the entry of any kind of foreign object which is not admitted by the unit, such as: cotton wool,cotton buds, hair, food waste, etc.

If problems occur that requires technical service, such as damage to the supply cable, obviouschanges in the normal performance of the unit or when it seems that the unit is not workingproperly, maintenance operations should be carried out by specialised personnel, unlessexpressly indicated otherwise in these instructions.

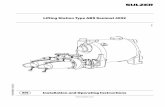

2. MAIN COMPONENTS .

4 - MODE D’EMPLOI ET ENTRETIEN

LIFTING STATION EB-705

En

glis

h

1.- Deposit body.2.- Covers.3.- Discharge outlet.4.- 40/32 auxiliary inlet.5.- Power supply cable with earth connection.6.- Deposit aeration grill.7.- Motor ventilation cover

3. INTRODUCTION.The CICLON LS lifting station allows the pumping of waste water from: washbasins, bidets, showers,bathtubs, sinks, urinals, washing machines and dishwashers, in uncommon locations, at a distanceand/or at a different level from a downpipe, as long as there is a downpipe available at a maximumdistance of 72 m horizontally or 7 m vertically, or a combination of both, as described in this manual.

The CICLON LS lifting station is the solution to problems with renovating and creating secondaryinstallations in places such as: lofts, basements, garages, stairwells, offices, factories, restaurants,pubs, gyms, businesses, terraces, etc. which are characterised by their low noise level.

Its attractive and practical design has been created so that it integrates perfectly in small spacessuch as inside pieces of furniture, unused spaces, etc, facilitating installation, and, if necessary, disas-sembly for maintenance, given that, in case of a fault, the independence of the motor section from therest of the unit (Caset), allows quick and clean intervention in the unit, avoiding an “out of order” situ-ation while it is repaired.

4. GENERAL DESCRIPTION.The CICLON LS lifting station allows the installation and drainage of up to 5 sanitary fixtures andappliances located at the same level (washbasin, bidet, shower, bathtub, sink, urinal, washingmachine, dishwasher).

Each sanitary fixture can be connected to the lifting station through the 40 mm. inlet with the conicaljoint and the nut supplied. The total flow drained to the lifting station must not be more than thetotal flow pumped by this station.

The lifting station includes two main parts:

- The deposit body �, which receives the drainage connection from the sanitary fixtures.

- The motor assembly, which contains all the mechanisms: the pressure switch and the turbine.

4.1. OPERATION.

Once installed, the lifting station is automatically activated when any connected sanitary fixture isdischarged. Likewise, it automatically disconnects when the water stops coming.

The water and the waste matter enter the unit, raising the level inside it, triggering the microswitch ofthe pressure switch which activates the motor and the pump.

The turbine pumps the grey water that is received through the side or top inlets � turning at 2.700 rpm.The water is propelled by the pump through the drainage outlet � to a sanitary pipe or downpipe.

Depending on the height of the vertical drainage pipe, a working cycle will last between 7 and 12seconds.

If the lifting station operates for an excessive length of time, or continuously starts up (once the wateris no longer arriving), it should be checked to see whether there are any leaks from the sanitary fixturesconnected to the side or top inlets.

MMAINTENANCE AND INSTRUCTION MANUAL - 5

LIFTING STATION EB-705

En

glis

h

5. SYSTEM SETUP- Put the CICLON LS in the desired place and connect the inlets and outlet. (See connection diagram

on page 13). Leave a minimum distance of a meter from the downpipe to the lifting station, so thatthis works for an adequate length of time.

- Bring the desired connecting pipes to the lifting station, remove the necessary flat caps and connectthe smooth pipe to the side and top inlets, affix-ing the 40 mm (1 ½”) pipe using the nut andconical joint supplied.

- The lifting station is supplied with 3 non-returnvalves, which we recommend be installed in thelower side inlets and, if necessary, in the upperside inlet. A non-return discharge valve is alsosupplied and this must always be installed inthe outlet of the lifting station.

- Additionally, if necessary, they can be installed inthe top inlets (non-return valves not supplied).

- The unit receives water from the connected sani-tary fixtures by means of gravity. The sectionstowards the unit must have a vertical lift thatallows drainage when the pump has stopped.

- When a shower basin is connected, a minimumheight of 180 mm between the lowest part ofthe shower basin and the base of the liftingstation must be allowed for when installing it, inorder to provide enough of a height differencetowards the drainage inlets.

- The use of non-siphoned outflows is recom-mended for the installation of shower basins orbathtubs (see connection recommendations onpage 13 for the installation of a secondaryventilation system if this is not possible).

- The CICLON LS lifting station has a female Ø32mm PVC connection, provided with a non-returnvalve. In case of an obstruction, it is recom-mended that a stopcock be installed in the verti-cal discharge pipe that stops it from emptying.

- Connect the drainage pipe and the downpipe.The lifting station propels, through the Ø 32 mmdrainage pipe, up to a maximum height of 7 mor as far as a horizontal distance of 72 m, or a combination of the two (see diagram). A constant mini-mum slope of 1% must always be maintained as far as the discharge point.

- In combined installations (vertical and horizontal) it must be kept in mind that a 1 metre vertical lift isapproximately the equivalent of a 10 metre horizontal stretch.

- All those installations that must be lifted vertically must have this lift carried out directly over the liftingstation. The installation of bends or directional changes creates a loss of load that must be subtractedfrom the maximum pumping distances (reduce approx. 1 m from the maximum distance for each bend).

6 - MODE D’EMPLOI ET ENTRETIEN

LIFTING STATION EB-705

En

glis

h

1

2

VOLUME MNIMO FREES FORDISASSEMBLING CASETE

5.1. INSTALLATION RECOMMENDATIONS.

PIPING – Use Ø 32 mm PVC piping for discharge propulsion. Avoid curved sections (siphons) thatcould retain certain solids and create obstructions.

PIPE SUPPORTS – The drainage pipes must be supported with the right accessories, according tothe manufacturer’s instructions.

BENDS – Do not use 90º elbows, use bends instead. If bends are not available, it is possible to usetwo 45º elbows instead.

AVOID DIAGONAL SECTIONS – The installation sections must always be vertical or horizontal, neverinstall diagonal sections.

PROTECTION AGAINST FROST – In areas where there is a risk of frost due tolow temperatures, all stretches of pipe that are at risk of freezing mustbe protected with thermal insulation.

CONNECTION WITH THE DOWNPIPE – Carry out the connection with the down-pipe by means of a 45º bypass. If the joint with the downpipe is below thebase of the lifting station, a ventilation valve (Jimten A-69 type) must beconnected at the highest point of the installation to stop it emptying.

DISCHARGE – The discharge section must always be connected to thedrainage network or grey water tank. It is not recommended that thewater go into open drains or similar.

VENTILATION – The lifting station must not be enclosed by walls or in such away that the motor is prevented from being correctly ventilated bymeans of the ventilation system incorporated.

SANITARY FIXTURES – The lifting station is prepared for the connection of up to5 sanitary fixtures and appliances (washbasin, bidet, shower, bathtub,

MMAINTENANCE AND INSTRUCTION MANUAL - 7

LIFTING STATION EB-705

En

glis

h

7 m.

6 m.

5 m.

4 m.

3 m.

2 m.

1 m.

0 m.

Up to 2 m.

Up to 12 m.

Up to 22 m.

Up to 32 m.

Up to 42 m.

Up to 52 m.

Up to 62 m.

Up to 72 m.

HORIZONTAL RANGE

VE

RTI

CA

L R

AN

GE

sink, washing machine, dishwasher). It is necessary to check that the total flow drained fromthese fixtures at any given time is never more than the total flow pumped by the lifting station.

5.2. POWER SUPPLY CONNECTION.

Connect all the sanitary elements and the drainage network before carrying out the connection of thepower supply.

When the unit is installed in a bathroom, put a distance of at least a metre between the macerator anda bathtub or shower.

It is necessary to have an electricity supply of 220/230 V, 10-16 A European standard, with two polesand an earth connection exclusively for connection of the unit.

Place the lifting station in such a way that the plug is accessible, since before any maintenance oper-ation it will have to be disconnected before proceeding with disassembly.

The lifting station must be connected to a network that is protected by a differential switch.

5.3. STARTING UP.

In order to start up the unit:

- Verify that the connected pipes are free of any foreign elements.

- Open the stopcock of the sanitary fixtures connected to the unit, and check that the flow drained doesnot exceed the maximum permitted flow for the unit.

- Check the connection of the electricity supply.

- Open the taps of the sanitary fixtures connected in order to check that the drainage is workingcorrectly, bearing in mind that during the startup, the unit will not begin working until a minimum levelof water is reached in the tank and a residual level of water will always remain inside the unit.

6. INDICATIONS FOR END USERS.Once the lifting station is installed and connected to the electrical network, it does not require specialmaintenance under normal conditions of use.

Each time any of the sanitary fixtures connected to it is activated, the water coming from this fixturemakes the unit function automatically and it stops when water is no longer being pumped in, withoutany action by the user.

For the smooth running of the lifting station, only discharge wastewater into it, and prevent any foreignelements from entering it.

Preventative information.

- Do not put in solid foreign matter such as: sanitary towels, cotton wool, cotton buds, sponges, hair, foodleftovers, lit cigarettes, other flammable materials, etc, since these can damage or block the lifting station.

- Do not pour in corrosive liquids such as: acid, solvent, oil, paint or paint stripper since these mayaffect the ability of the lifting station to work correctly.

- In these cases, the damage is not covered by the guarantee.

- If the device is used intensively, is can accumulate fats that make it necessary to clean the unit occa-sionally, therefore ensure that there is sufficient space to disassemble it.

- Do not use any of the sanitary fixtures connected to the unit if there is a power cut.

- The lifting station allows very hot water (this can be up to 60ºC, for example washing machines on a

8 - MODE D’EMPLOI ET ENTRETIEN

LIFTING STATION EB-705

En

glis

h

high-temperature washing programme) to be pumped for short periods of time. However, hot watercannot be drained for long periods of time.

- When you expect to be away, or if the unit is for use with installations that are onlyused occasionally, we recommend that you turn off the stopcocks feeding theconnected sanitary fixtures to avoid the risk of leaks.

- In areas that are at risk of frost, it is recommended that the pipes beprotected with thermal insulation, and that the whole system (drainage pipesand lifting station) be prepared by:

- Turning off the stopcock feeding the sanitary fixtures.

- Pouring special plumbing antifreeze into connected sanitary fixtures (wash-basins, bidets, etc.)

- The guarantee does not cover damage caused to the lifting station by freezing.

7. MAINTENANCE OPERATIONS.The Jimten lifting station has been designed to be highly reliable and to provide years of operation.Below are listed the most common maintenance operations and there is a quick troubleshooting guidefor problems that the user can easily fix.

7.1. CLEANING.

In order to clean the sanitary fixtures connected to the lifting station, we recommend the use of anyquality cleaning product on the market, as long as it is not acid-based.

In areas that have very hard water, and with the aim of removing limescale deposits, it is recommendedthat a cleaning be carried out periodically following these steps:

Disconnect the lifting station from the electrical network.

Pour a mixture of 1 litre of vinegar and 3 of water (approximately) into any of the connected sanitaryfixtures (washbasin, bidet, etc).

Let this act for a few hours.

Connect the lifting station again and activate it.

7.2. TROUBLESHOOTING GUIDE.

Before carrying out any action, check the following points:

Check that the taps of the connected sanitary fixtures or appliances are in good condition and do not leak.

Check that the lifting station is connected at the plug, and that there is a current. (Check that the differ-ential switch has not tripped and the magnetothermic switch is connected)

Check the lifting station’s thermal protection (this incorporates an automatic disconnection system forexcess temperatures). After approximately 20 minutes (this can vary depending on the room temper-ature conditions) the unit will reactivate automatically.

If the lifting station is activated for too long a time period, or if it starts up continuously, a check shouldbe made to see that the connected fixtures are not leaking.

If water is returning to the macerator from the drainage pipe through the non-return valve, check thatthe valve closes correctly (verify that the flapper sits correctly) and replace it or clean it if necessary(see page 12).

MMAINTENANCE AND INSTRUCTION MANUAL - 9

LIFTING STATION EB-705

En

glis

h

10 - MODE D’EMPLOI ET ENTRETIEN

LIFTING STATION EB-705

PROBLEM REASON SOLUTION

En

glis

h

- The lifting station does not start - It is disconnected.- The electricity supply is not the correct

one. - The electrical protection has been acti-

vated.

- Connect the appliance correctly.- Check the electrical connection.- Wait about 20 minutes until the motor

cools.

- The differential switch trips - The motor’s earth connection is defec-tive.

- Motor is broken. Contact TechnicalAssistance

- The motor works but it does notdischarge or it does so slowly.

- Blockage in the drainage pipe - Clean the drainage pipe

- The motor buzzes but does not turn - Turbine blocked by foreign matter. - See maintenance operations (disas-sembly and extraction of the motor,page 11)

- After draining, the motor starts up andstops indiscriminately.

- Leak from the non-return valve, loss ofwater from one of the connected sani-tary fixtures

- Clean the discharge pipe’s non-returnvalve.

- Check and replace the joints of the tapsof the connected sanitary fixtures

- The motor does not stop - Excess height or length of the drai-nage pipe.

- Loss of power because of too manyelbows.

- Blockage in the discharge pipe.- Obstruction of the drainage pipes due

to limescale.- Malfunction of the microswitch.

- Reconsider the drainage installation.- Reconsider the drainage installation.- Clean the discharge pipe.- Carry out the descaling process (clean-

ing 7.1)- Contact Technical Assistance

- The motor does not work with thewater of one of the sanitary fixturesconnected.

- The auxiliary connections are obstruc-ted or the non-return valve is blocked.

- Lack of aeration or gradient in the auxil-iary connection.

- Malfunction of the microswitch.

- Clean the auxiliary connection sectionof pipe.

- Provide the installation with secondaryventilation, or install an aeration valve(Jimten A-69 type). / Reconsider theinstallation.

- Contact Technical Assistance

- After draining, the motor starts uprepeatedly before stopping for good

- Water returning to the lifting station.The non-return valve does not workproperly

- Carry out a number of discharges withclean water and clean the non-returnvalve.

- Water returns to the shower basin. - The minimum necessary gradient hasnot been allowed for in the drainageinstallation. (See shower basin height)

- Malfunction of the auxiliary connec-tion’s non-return valves.

- Reconsider the installation (raising theheight of the shower basin).

- Cleaning and/or replacement of theside connection’s non-return valve

- Strange noise when the motor isworking

- Obstruction/blockage because foreignmatter has fallen into the unit.

- Extract the matter from inside the unit.(See motor disassembly and extrac-tion 7.3)

- Smells come from the lifting station - Wear of the active carbon filter. - Replacement of the filter (ContactTechnical Assistance).

- The shower basin does not drain well - Possible obstruction of the drain.-Siphonic shower basin drain, creates

plunging of air during drainage

- Cleaning of the drainage piping.- Remove the siphon from the shower

basin valve

7.3. MOTOR DISASSEMBLY AND EXTRACTION.

Before opening the lifting station it is very important to check that the power cable has beendisconnected from its plug.

- Remove the protective cap from the caset coverscrew, remove the screw �. Remove the cover ofthe Caset �

- Remove the cable gib from the caset assembly,by pressing from the ends and freeing the stub,disconnect the connections (faston) from the elec-trical cable to the motor and the pressure switch.

- To remove the caset assembly (motor, pressureswitch, rotor, pump, capacitor) remove the 7screws bracing the main body. �. Manuallyextract the whole caset assembly, pulling themotor upwards. �

Safety notice: Pay attention to the motor, whichafter a period of use can be hot.

- Replace the caset assembly with the spare � andassemble it again, following the steps in reverseorder. (see electrical connections page 9), screwin and replace the caset cover. �

The whole process can be carried out in only 10minutes.

DIAGRAM OF ELECTRICAL CONNECTIONS(motor – pressure switch – power cable).

Network cable � – Made up of Live (brown),Neutral (blue) and Earth (Yellow/Green).

Live (brown) � �, faston female connectionwith 6A protection sheath.

Neutral (blue) � and Earth (Yellow/Green) �,faston male connection with 6A protectionsheath.

Connection to the pressure switch � of thenetwork Live (brown) � position 3 of thepressure switch and motor Live (brown) �

position 1 of the pressure switch.

* If power supply cable is damaged, it mustbe replaced by the manufacturer, its tech-nical assistence service or a qualified tech-nician to prevente any danger.

LIFTING STATION EB-705

32 1

�

�

�

�

�

MMAINTENANCE AND INSTRUCTION MANUAL - 11

En

glis

h�

��

��

�

7.4. REPLACEMENT / CLEANING OF THE DISCHARGE NON-RETURN VALVE.

Before beginning the replacement / cleaning,carry out a number of discharge cycles and (ifone has been installed) close the vertical drainagepipe’s throttle valve and disconnect the unit fromthe electricity supply.

- Remove the cover � and the 1 ¼” nut �.

- Loosen the clips of the discharge pipe brace inorder to be able to move the tube and thus enableits disassembly.

- Prepare a container to collect the water, emptythe discharge pipe, activating the flapper of thenon-return valve.

- Remove the clip nut �

- Check or replace the seal holder + non-return joint� assembly.

- Follow the steps in reverse order to assemble thevalve.

Carry out a number of discharge cycles of the unitbefore putting it back in service in order to eliminatethe air from the discharge installation.

8. TECHNICAL SPECIFICATIONS.Inlets:Top: 2 1½” x 40 mm inlets for Ø40 / 32 mm * smooth pipesLower side: 2 1½” x 40 mm inlets for Ø40 / 32 mm * smooth pipes

with non-return valveUpper side: 1 1½” x 40 mm inlet for Ø40 / 32 mm * smooth pipes with

non-return valve.* Five 40 to 32 conical reducing joints are supplied.

Outlet:Discharge: Ø32 mm for PVC pipe.Non-return valve: 1¼” x 32 mm removable.

Pump:Voltage: ~ 220/230 V, AC, 50 Hz.Fuse: Thermal.Power: 0.39 kW.Capacitor: 10 µFElectrical connection: For IEC standard Maximum discharge height: 7 m

Maximum horizontal discharge distance: 72 Dimensions and weight:Dimensions: 413 x 180 x 270.5 mmWeight: 7.6 KgWeight including packaging: 8.9 Kg

12 - MODE D’EMPLOI ET ENTRETIEN

LIFTING STATION EB-705

En

glis

h

NOTE: As a result of the constant improvement and development of our products, the data provided in thismaintenance and instruction manual may be modified without prior notice. This maintenance and instruc-tion manual has no contractual value and all the information is given in good faith.

�

�

� �

TO RETIRE EMBELLECEDOR

NON-RETURN JOINT

RENOVE CLIP NUT

REMOVE 1 ¼”NUT

9. LAYOUT AND SECONDARY VENTILATION SYSTEM DIAGRAM.

CICLON LS, WC Y WASHBASIN.

.

RECOMMENDEO FREE VOLUME OF INSTALLATION.

MMAINTENANCE AND INSTRUCTION MANUAL - 13

LIFTING STATION EB-705

En

glis

h

A – CONNECTION TO EXISTING VENTILATION PIPE.

B – Ø 32 DISCHARGE PIPE WITH 1% GRADIENT.

C – DRAINAGE INLET PIPE 1% GRADIENT.

Ø 32 or 40 MM

D– ACCORDING TO LOW VOLTAGE ELECTROTECHNICAL REGULATION MI-BT 024 PLACE ATLEAST 1 M AWAY FROM THE WASHBASIN OR SHOWER BASIN.

�

�

�

�

�

10. EXPLODED VIEW OF THE MACERATOR AND CASET ASSEMBLY.

MACERATOR ASSEMBLY

LIST OF MACERATOR PIECES.

14 - MODE D’EMPLOI ET ENTRETIEN

LIFTING STATION EB-705

En

glis

h

(1) TANK BODY.(2) BODY CROSSPIECE.(3) 1½” NUT(4) 1½” OBTURATOR CAP(5) 1½” BLUE JOINT(6A) NON-RETURN VALVE JOINT(6B) NON-RETURN VALVE SEAL.(7A) AERATION FLOAT(7B) AERATION FLOAT JOINT(8A) TANK ENCLOSURE COVER(8B) BODY GASKET(9A) ACTIVE CARBON DEPOSIT(9B) ACTIVE CARBON DEPOSIT COVER(10) DEPOSIT COVER(11) CASET COVER(12) CIRCULAR COVER(13) CIRCULAR COVER FIXING SCREW

(14A) CASET(14B) CASET GASKET(15) 1½” NUT(16) DISCHARGE TUBE(17) PLASTIC BRACE(18) SCREW HOUSING CAP(19) FIXING SCREW(20A) NON-RETURN VALVE CLIP NUT(20B) NON-RETURN VALVE UPPER PART(20C) 31 X 2 O-RING(20D) NON-RETURN VALVE LOWER PART(20E) FLAT GASKET(20F) SLIDING NUT LINK(21) LOWER BODY STUBS

CASET ASSEMBLY

11. BASIC INFORMATION.

MMAINTENANCE AND INSTRUCTION MANUAL - 15

LIFTING STATION EB-705

En

glis

h

IST OF CASET PIECES

(1) DEPOSIT BODY

(2) CASET GASKET

(3) CAPACITOR

(4) THREE WIRE HOSE

(5) BUSHING JOINT

(6) MOTOR

(7) MOTOR INSULATION DISK

(8) PRESSURE SWITCH

(9) PRESSURE SWITCH PIPE

(10) 22 X 3 O-RING

(11) MOTOR SCREW CAPS

(12) MOTOR FIXING SCREWS

(13) CERAMIC ENCLOSURE

(14) ROTOR

(15) ROTOR FIXING SCREW

(16) CASET ROTOR COVER.

(17) MOTOR COVER SCREW

(18) CABLE BUSHING

12. EC DECLARATION OF CONFORMITY CE DECLARACION DE CONFORMIDAD JIMTENDECLARACÃO DE CONFORMIDADE CE JIMTENEC CERTIFICATE OF CONFORMITY JIMTENEWC KONFORMITATÄTSERKLÄRUNG JIMTENCE DÉCLARATION DE CONFORMITÉ JIMTEN

Declara que el producto designado como: ESTACIÓN DE BOMBEO EB-705Declara que o produto designado como: ESTAÇÃO DE BOMBAGEM EB-705Declares in sole responsibility that the product: LIFTING STATION EB-705Bestätigen, dass die Produkte: HAUSHALTSPUMPE EB-705

Cumple con las directivas siguientes:- Directiva de Baja Tensión (73/23/CEE + ENMIENDAS)- Directiva de Compatibilidad Electromagnética (89/336/CEE + ENMIENDAS)

Está em conformidade com as seguintes directivas:- Directiva (73/23/CEE e com as respectivas aterações introduzidas) respeitante ao material

eléctrico destinado a ser utilizado dentro de certos limites de tensão.- Directiva (89/336/CEE e com as respectivas aterações introduzidas) respeitante à compati-

bilidade electromagnética.

Complies with the following directives:- The low voltage directive (73/23/EEC including amendments)- The electromagnetic compatibility directive (89/336/EEC including amendments)

Folgende Richtlinien erfillt:- Niederspannungsrichtlinie (73/23/EWG + ABÄNDERUNGEN)- Elektromagnetische verträglichkeit (89/336/EWG + ABÄNDERUNGEN)

Est conforme aux directives:- Directive Basse Tension (73/23/CEE + amendements)- Directive Compatibilité électromagnétique (89/336/EEC + amendements)

Las condiciones de instalación, funcionamiento y mantenimiento están detalladas en el:- Manual de instrucciones y mantenimiento de la Estación de Bombeo EB-705.

As condições de instalação, funcionamento e manutenção são fornecidas pormenorizadamente no:-Manual de instruções e de manutenção do Estação de Bombagem EB-705

Installation, working and maintenance conditions are contained within the:-Instructions and maintenance guide of the Lifting Station EB-705.

Die Installierungs, Betriebs und Wartungsbedingungen sind zu ersehen aus den:- Gebrauchs und Wartungsbedingungen des Haushaltspumpe EB-705

Les conditions d’installation, fonctionnement et entretien sont détaillées dans le :- Manuel d'instructions et entretien du Broyeur EB-705

Alicante a, 11 de abril de 2007 / Alicante, em 11 de abril de 2007 / Alicante 11 April 2007 / Alicante, den 11. April2007 / Alicante, le 11 avril 2007.

Alejandro Perales TerolResposable de Calidad / Gerente de Controlo de Qualidade / Quality Control Manager / Qualitätsmanager / Responsable qualité.

El fabricante Jimten S.A.O fabricante Ctra. de Ocaña 125The manufacturer 03114, AlicanteWir EspañaLe fabricant

16 - MODE D’EMPLOI ET ENTRETIEN

LIFTING STATION EB-705

En

glis

h