LED Roadway Lighting e Catalogue

-

Upload

duque201333 -

Category

Documents

-

view

533 -

download

15

Transcript of LED Roadway Lighting e Catalogue

-

Product Catalog

LRL Product Catalog EN 2012-04-17

-

Leading the LED technology wave

Table of Contents

About LED Roadway Lighting Ltd. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Introducing the SatelliteTM Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3Product Specifications SAT-24S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 SAT-48S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 SAT-72M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 SAT-96M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 SAT-120L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 SAT-144L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Catalog Numbering System: How to Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 8 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 0Light Loss Factor Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 2 Equivalency Tables HPS vs. LRL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 5 MH vs. LRL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 6 MV vs. LRL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 7Brackets and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 8Installation Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31Case Studies and Application Examples Bridge Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 7 City Mazda (Halifax, NS, Canada) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 8 Bouchard Auto (Lancaster, MA, USA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 9 10,000 fixture evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 0 South Street, Halifax, NS, Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 Asker, Norway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2 Cozumel, Mexico . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3 Sao Paulo, Brazil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 4 Canso Causeway, NS, Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 5 Armdale Rotary, Halifax, NS, Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 6 Grote Street, Adelaide, Australia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 7 Sparwood, BC, Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 8Financing Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 9Adaptive Lighting - Streetlight IntelligenceTM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 2Installation List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 8White Papers Scotopic & Photopic Considerations for Street & Roadway Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61 Incorporating Spectrum Effects for Brightness Perception and Visual Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 9 Reliability Prediction Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 8 DMD Engineering Report Summary - Nova Scotia Pilot Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 1 NOTE: All information provided in this catalog, including technical and specification data, is subject to change without notice.

-

About LED Roadway Lighting Ltd.

-

1Leading the LED technology wave

About LED Roadway Lighting Ltd.

OverviewLED Roadway Lighting Ltd. (LRL) is a leading designer and manufacturer of LED (light-emitting diode) based street and area lighting fixtures and control systems. LRL is lo-cated in Nova Scotia, Canada, with research and design facilities in Halifax and a 55,000 square foot manufacturing facility in Amherst.

LRL offers a complete range of LED based street and area lighting fixtures that meet or exceed IES (Illuminating Engineering Society), CIE (Commission Internationale de LEclairage) and IDA (International Dark Sky Association) requirements. LRLs products are RoHS compliant (free of lead and mercury), provide energy savings of up to 80%, and substantially reduced maintenance costs.

Our Mission StatementTo provide the most energy efficient and maintenance-free outdoor LED lighting so-lutions; helping our customers save money and improve their lighting with a positive impact on the environment.

LeadershipLRLs founder and CEO Chuck Cartmill has a strong track record in the creation, manage-ment, and operation of diverse businesses. His first venture, a manufacturers represen-tative firm focused on lighting products, was founded in 1974 and is still in operation today, as are his numerous other business ventures focused in the electrical and elec-tronics industries. Mr. Cartmills leadership and entrepreneurial spirit has been recog-nized by numerous organizations including Ernst & Youngs Entrepreneur of the Year Award (2006 Atlantic Region), and he has been frequently named as one of Atlantic Canadas Top 50 CEOs by Atlantic Business Magazine. Mr. Cartmills business approach, which includes being debt-averse, empowering employees, encouraging innovation, and most importantly, building strong and lasting customer relationships has been the cornerstone to his success, and the success of LRL. Mr. Cartmill is guided by a manage-ment team with a wealth of experience in diverse industries and by members of a board of directors that are highly respected in their fields.

Innovation in DesignLRLs Satellite series fixtures have been designed for maximum efficiency, performance, and reliability. Under the direction of CTO Dr. Jack Josefowicz, LRLs design team has cre-ated an LED fixture with a true 20 year design life. Drawing on his extensive experience in the aerospace field, Dr. Josefowicz determined that commercial-grade, off-the-shelf components cannot provide the life expectancy demanded by municipal and other us-ers. LRL also recognized that the most common failure point in an LED fixture is not the LEDs, but rather the power supply (driver). High failure rate components were eliminated from the fixture design (optocouplers, commercial-grade capacitors, potting, etc.) and instead, aerospace and automotivegrade components were employed. Our approach is based on the concept of reliability, rather than replaceability. The end result is that the life of the power electronics is consistent with the expected 20 year life of the LEDs.

LRLs in-house design team has developed no less than 12 articles of intellectual prop-erty related to the Satellite series fixtures. These innovations include our unique optics system, which delivers maximum target lumens to the roadway surface; our high-reli-ability power supply, and our thermal management system.

Facts and FiguresEstablished: 2002

Company Organization: Privately Held Corporation Headquarters: Halifax, NS, Canada Design Office: Halifax, NS, Canada Manufacturing Locations: Amherst, NS, Canada55,000 ft2 (5100 m2) Facility

Mooresville, NC, USA (in full compliance with Buy America requirements of ARRA)

South Wales, UK Experience: Manufacturing LED-based products since 2003

RoHS (lead-free) manufacturing certification: 2005 Number of employees: 100+ First street light installation: 2008 Number of municipal and utility installations globally: More than 300 clients in more than25 countries Local sales and technical support provided by factory representatives based in Canada, the U.S., and UK, as well as a network of more than 40 independent rep firms and dis-tributors in Canada, the U.S., Europe, Latin America, the Middle East, South Africa, and Australia Applications: Street lighting, outdoor area, pathway, building exterior, parking area, security/perimeter, outdoor retail (e.g. automotive dealership), bridges and tunnels.

-

2Leading the LED technology wave

All elements of LRLs fixture are designed to be replaceable, upgradeable and recyclable (e.g.. power supply, light engine, etc.).

ReliabilityAll power supplies and light engines used in Satellite series fixtures are designed and-manufactured by LED Roadway Lighting Ltd. to ensure reliability and total process con-trol. LRL is the only manufacturer providing LED power supplies that are independently evaluated according to Telcordia SR-332, the globally dominant standard for assessing reliability of electronics assemblies. With MTBF values of up to 3.302 million hours, LRL power supplies are the most reliable in the industry, and this is supported with inde-pendent test data.

Single Source ResponsibilityLRLs level of vertical integration is another reason to select Satellite series fixtures. All power supplies, light engines, and electronics are designed, manufactured and tested in-house. When selecting LRL for your project, you are dealing with the manufacturer, not an integrator of third-party components. We offer true single source responsibility.

PerformanceAll performance data provided by LRL is supported by independent test reports, in-cluding LM-79 and LM-80 data. We also provide our customers with a layout service, which includes detailed layout creation, as well as customer-specific requirements such as side-by-side comparisons, ROI calculations, and environmental impact reports.

Controls and Monitoring (Streetlight Intelligence) Our Streetlight Intelligence adaptive lighting controls are compatible with LED, High Pressure Sodium, Metal Halide and Mercury Vapor lighting systems. The Streetlight In-telligence system includes dimming capability, fixture outage reporting, energy con-sumption measurement (to within 1% accuracy), and Central Asset Management soft-ware. Dimming schedules can be user-defined, and programmed using a handheld device, supplied by LRL.

ResponsivenessLED Roadway Lighting Limited is small enough to be flexible and responsive to indi-vidual customer requirements, yet large enough to support your projects now and in the future. Our in-house design and manufacturing, combined with an empowering management, supports innovation and reduced time to market. Our CEO is active in the day to day operation of the business and highly responsive to customer demands.

InstallationsA partial listing of installation locations is found below:

Canada (installations in all provinces and 2 territories) U.S.A. (installations in 25 states) France (Paris) Colombia (Bogota) Australia (Adelaide, Dry Creek, Unley) Faroe Islands (Torshavn) Dominican Republic Iceland (Reykjavik) Puerto Rico (San Juan) Norway (Asker, Trgstad, Halden, Rakkestad) UAE (Dubai) South Africa (Mogale, Brachenhurst) Mexico Panama (Panama City) Switzerland (Steinmaur, Schfflisdorf) UK (numerous installations)

Email:[email protected]

LRLs SAT-S luminaire for street and area lighting applications.

Nitrogen-fed soldering process for lead-free solder joint integrity.

XRF analyzer for analysis of component chemistry.

Assembly workstation.

Independent Verification of Results: Read the third party report detailing our 1,100 fixture pilot in Nova Scotia (available on our website)

-

Introducing the SatelliteTM Series

-

Leading the LED technology wave

3

Introducing the Satellite Series

LED Roadway Lighting Ltd (LRL) Satellite series fixtures were designed for maximum efficiency, performance, reliability, and a 20 year design life.

Drawing on extensive experience in the electronics, LED and aerospace fields, our design team determined that commercial-grade, off-the-shelf components cannot provide the life expectancy demanded by munici-pal and other users. LRL also recognized that the most common failure point in an LED fixture is not the LEDs, but rather the power supply (driver). High failure rate components were eliminated from the fixture design (e.g. optocouplers, commercial-grade capacitors, potting, etc.) and instead, aerospace and automotive-grade components were employed.

Our approach is based on the concept of reliability, rather than replaceability. The end result is that the life of the power supply electronics is consistent with the expected 20 year life of the LEDs. Our design approach addresses all of the critical elements of LED fixture design (see below).

-

Leading the LED technology wave

4

Mechanical Assembly

Solid, one-piece casting for maximum heat dissipation and reliability Self-cleaning design Unique drip-edge prevents wicking of moisture No bird spikes required Accepts standard NEMA twist-lock photocontrols

LRL Satellite Series Thermal Management System

Heat Sink Fins

Aluminum Core Circuit Board

Light Emitting Diode

Reflector

Lens

Unique fin design provides a self-cleaning feature

-

Leading the LED technology wave

5

Optics

IP66 sealed light engine compartment Light engines are placed at 30 degree angles for maximum illumination of the road surface Proprietary reflective cup system Aluminum-core light engine circuit board is physically attached to the housing for increased heat dissipation Durable acrylic lens cover provides excellent light transmission and is UV resistant IES Type II, III and other distribution patterns available

Angled light engines = more light on the road surface

Proprietary reflective cup system Acrylic lens cover

-

Leading the LED technology wave

6

Light distribution at 180 ft (55 m) pole spacings

LED Roadway Lighting (LRL) Typical HPS Typical Competitor LED

Consistent Lighting (No Dark Band) Dark Band Dark Band

Light Distribution Comparison

Typical competitor LED coverage leaves dark sections between fixtures

LED Roadway Lighting (LRL) units provide uniform light coverage

Current technology High Pressure Sodium (HPS) fixtures have yellow cast

and vertical light pollution

Typical Light Distribution Comparison: LRL vs. Competing Technologies

-

Leading the LED technology wave

7

Power Supply (Driver) Electronics 20 year design life In-house designed and manufactured, purpose-built, using the highest quality aerospace and automotive grade components IP66 sealed power supply compartment: No need for potting compounds that reduce reliability Reliability analysis using Telcordia SR-332

Power Supply Design for 20 year Life Reliability

-

Leading the LED technology wave

8

Testing

LED Roadway Lighting Ltd. fixtures comply with the following standards and specifications:

ANSI C62.41 Surge Voltages in Low Voltage AC Power Circuits ANSI C136.10 Locking-type Photocontrol Devices and Mating Receptacles ANSI C136.15 Luminaire Field Identification ANSI C136.31 Roadway Luminaire Vibration ANSI C136.37 Solid State Light Sources Used in Roadway and Area Lighting ANSI C136.3 Roadway Luminaire Attachment - min. of +/- 3 tilt of luminaire about the tenon when mounting. IES/ANSI RP-8 American National Standard Practice for Roadway Lighting EN-61000-3-2 Harmonic Current Emissions IES LM-79-08 Electric and Photometric Measurements of Solid State Lighting Products NEMA IEC60529 Degrees of Protection Provided by Enclosures - IP Code Telcordia SR-332 Electronic Equipment Reliability Standard ASTM B117 Salt Spray Test Standard MIL-STD-810F Rain/Ice Test Standard CIE 115 2010 Lighting of Roads for Motor and Pedestrian Traffic Tested to Category 5 Hurricane winds (256kph/155mph) Underwriters Laboratories (UL) cULus marking is available on all products rated 120V-240V QPS (NRTL) - cQPSus mark is available on all products rated 120-240V, 277-480V NOM (Mexico) NOM mark is available on all products rated 120-240V, 277-347V

-

Leading the LED technology wave

9

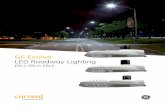

SAT-S Series (SAT-24S, SAT-48S)

Suitable for replacing conventional 70-150 watt HPS, MH or MV systems Available with 24 or 48 LEDs Drive currents: 280, 350, 450, 525, and 600 mA Input Voltages: Universal Driver 120 to 240 VAC (50Hz or 60Hz) 277V, 347V, 480V, and 12-24V DC drivers available upon request System Watts: 22-100 W (depending on model and drive current selected) Distribution Patterns: IES Type II, IES Type III, Euro wide, Euro narrow, ANZ Color Temperature (CCT): 5000K (standard), 4000K (optional), 4500K (optional)

Above: SAT-S fixture with Bronze finish (RAL 7022)

Above: SAT-S fixture with Black finish (RAL 9005) and optional wall bracket attached

-

Leading the LED technology wave

10

SAT-M Series (SAT-72M, SAT-96M)

Suitable for replacing conventional 150-400 watt HPS, MH or MV systems Available with 72 or 96 LEDs Drive currents: 280, 350, 450, 525, and 600 mA Input Voltages: Universal Driver 120 to 240 VAC (50Hz or 60Hz) 277V, 347V, 480V, and 12-24V DC drivers available upon request System Watts: 65-200 W (depending on model and drive current selected) Distribution Patterns: IES Type II, IES Type III, Euro wide, Euro narrow, Euro long Color Temperature (CCT): 5000K (standard), 4000K (optional), 4500K (optional)

Above: SAT-L fixture with Black finish (RAL 9005)

Above: SAT-L fixture with Gray finish (RAL 7035)

-

Leading the LED technology wave

11

Coming Soon!The newest addition to the Satellite Series product line

SAT-L Series (SAT-120L, SAT-144L) Coming Soon Suitable for replacing conventional 400-1000 watt HPS, MH or MV systems Available with 120 or 144 LEDs Drive currents: 280, 350, 450, 525, and 600 mA Input Voltages: Universal Driver 120 to 240 VAC (50Hz or 60Hz) 277V, 347V, 480V, and 12-24V DC drivers available upon request System Watts: 110-300 W (depending on model and drive current selected) Distribution Patterns: IES Type II, IES Type III Color Temperature (CCT): 5000K (standard), 4000K (optional), 4500K (optional)

SAT-L fixture with Gray finish (RAL 7035)

-

Product Specifications

-

Leading the LED technology wave

12

Technical Specifications: SatelliteTM Series LED Roadway LuminaireSAT-24S (24 LEDs)ElectricalAvailable Driver Currents 280mA 350mA 450mA 525mA 600mA

Power Consumption* 22W 28W 36W 44W 50W

Input Voltage: Universal Driver 120 to 240 VAC, 50Hz or 60Hz; 277V, 347V, 480V, and 12-24V DC drivers available upon request.

FixtureWeight 8.2 kg 18 lb

Width (maximum) 382 mm 15.0 in

Length (maximum) 411 mm 16.2 in

Height (maximum) 167 mm 6.57 in

EPA < 0.047m2 < 0.509 sq ft2

Cover Lens Acrylic

Housing Single piece, die-cast aluminum

Mounting 1.625 to 2.375/ 42 to 60 mm OD tenons

FinishStandard Painted Finish* * E-coat primer with durable polyester powdercoat topcoat.

Performance / PhotometricsAvailable Driver Currents 280mA 350mA 450mA 525mA 600mA

Fixture Efficacy (Type II)* 86 Lm/W 84 Lm/W 81 LmW 77 Lm/W 72 Lm/W

Fixture Output (Type II)* 1,900 Lm 2,350 Lm 2,900 Lm 3,400 Lm 3,600 LmTelcordia MTBF (in Millions)** 3.3 hrs 2.9 hrs 2.5 hrs 2.2 hrs 2.1 hrs

LED L70 @ 350mA >100,000 hoursDistribution IES Type II, IES Type III,

European wide, European narrowColor Temperature (CCT) Standard 5,000 K Other colors available upon requestColor Rendering Index (CRI) at 70 (+/-5%)

Operating ConditionsTemperature (ambient) -40C to +60C -40F to +140F

Photocell OptionsPhotocell Receptacle with shorting cap

Photocell 20 yr design life option available

No Photocell Receptacle - solid casting

LRL_SAT24S_SS_2012_01_23

167mm (6.57 in)

411mm / 16.2 in

Figure 1 Luminaire side profile*** Figure 2 Luminaire top*** Figure 3 Luminaire bottom***

382mm / 15.0 in

* Values shown are average values and are subject to +/-5% tolerance** Power supply MTBF values are based on independent labratory analysis using Telcordia SR-332. Values shown are in millions of hours.*** SAT-48S illustrated

-

Leading the LED technology wave

13

Technical Specifications: SatelliteTM Series LED Roadway LuminaireSAT-48S (48 LEDs)ElectricalAvailable Driver Currents 280mA 350mA 450mA 525mA 600mA

Power Consumption* 43W 55W 72W 88W 100W

Input Voltage: Universal Driver 120 to 240 VAC, 50Hz or 60Hz; 277V, 347V, 480V, and 12-24V DC drivers available upon request.

FixtureWeight 8.2 kg 18 lb

Width (maximum) 382 mm 15.0 in

Length (maximum) 411 mm 16.2 in

Height (maximum) 167 mm 6.57 in

EPA < 0.047m2 < 0.509 ft2

Cover Lens Acrylic

Housing Single piece, die-cast aluminum

Mounting 1.625 to 2.375/ 42 to 60 mm OD tenons

FinishStandard Painted Finish* * E-coat primer with durable polyester powdercoat topcoat.

167mm (6.57 in)

411mm / 16.2 in

Figure 1 Luminaire side profile***

Performance / PhotometricsAvailable Driver Currents* 280mA 350mA 450mA 525mA 600mA

Fixture Efficacy (Type II)* 87 Lm/W 84 Lm/W 81 LmW 77 Lm/W 72 Lm/W

Fixture Output (Type II)* 3,750 Lm 4,600 Lm 5,800 Lm 6,750 Lm 7,150 LmTelcordia MTBF (in Millions)** 3.3 hrs 2.9 hrs 2.5 hrs 2.2 hrs 2.1 hrs

LED L70 @350mA >100,000 hoursDistribution IES Type II, IES Type III

European wide, European narrowColor Temperature (CCT) Standard 5,000 K Other colors available upon request.Color Rendering Index (CRI) at 70 (+/-5%)

Operating ConditionsTemperature (ambient) -40C to +60C -40F to +140F

Photocell OptionsPhotocell Receptacle with shorting cap

Photocell 20 yr design life option available

No Photocell Receptacle - solid casting

Figure 2 Luminaire top*** Figure 3 Luminaire bottom***

LRL_SAT48S_SS_2012_01_23

382mm / 15.0 in

* Values shown are average values and are subject to +/-5% tolerance** Power supply MTBF values are based on independent labratory analysis using Telcordia SR-332. Values shown are in millions of hours.*** SAT-48S illustrated

-

Leading the LED technology wave

14

Technical Specifications: SatelliteTM Series LED Roadway LuminaireSAT-72M (72 LEDs)ElectricalAvailable Driver Currents 280mA 350mA 450mA 525mA 600mA

Power Consumption* 65W 83W 107W 131W 150W

Input Voltage: Universal Driver 120 to 240 VAC, 50Hz or 60Hz; 277V, 347V, 480V, and 12-24V DC drivers available upon request.

FixtureWeight 11.4 kg 25 lb

Width (maximum) 350 mm 13.8 in

Length (maximum) 608 mm 23.9 in

Height (maximum) 156 mm 6.14 in

EPA 0.065 m2 0.699 ft2

Cover Lens Acrylic

Housing Single piece, die-cast aluminum

Mounting 1.625 to 2.375/ 42 to 60 mm OD tenons

FinishStandard Painted Finish* * E-coat primer with durable polyester powdercoat topcoat.

156mm (6.14 in)

608mm / 23.9 in

Performance / PhotometricsAvailable Driver Currents 280mA 350mA 450mA 525mA 600mA

Fixture Efficacy (Type II)* 87 Lm/W 84 Lm/W 80 LmW 77 Lm/W 72 Lm/W

Fixture Output (Type II)* 5,650 Lm 6,950 Lm 8,600 Lm 10,050 Lm 10,750 LmTelcordia MTBF (in Millions)** 2.3 hrs 2.1 hrs 1.7 hrs 1.6 hrs 1.5 hrs

LED L70 @350mA >100,000 hoursDistribution IES Type II, IES Type III

European wide, European narrow, European LongColor Temperature (CCT) Standard 5,000 K Other colors available upon request.Color Rendering Index (CRI) at 70 (+/-5%)

Operating ConditionsTemperature (ambient) -40C to +60C -40F to +140F

Photocell OptionsPhotocell Receptacle with shorting cap

Photocell 20 yr design life option available

No Photocell Receptacle solid casting

350mm / 13.8 in

Figure 2 Luminaire top***Figure 1 Luminaire side profile*** Figure 3 Luminaire bottom***

LRL_SAT72_SS_2012_01_23

* Values shown are average values and are subject to +/-5% tolerance** Power supply MTBF values are based on independent labratory analysis using Telcordia SR-332. Values shown are in millions of hours.*** SAT-96M illustrated

-

Leading the LED technology wave

15

Technical Specifications: SatelliteTM Series LED Roadway LuminaireSAT-96M (96 LEDs)ElectricalAvailable Driver Currents 280mA 350mA 450mA 525mA 600mA

Power Consumption* 86W 110W 143W 175W 200W

Input Voltage: Universal Driver 120 to 240 VAC, 50Hz or 60Hz; 277V, 347V, 480V, and 12-24V DC drivers available upon request.

FixtureWeight 11.4 kg 25 lb

Width (maximum) 350 mm 13.8 in

Length (maximum) 608 mm 23.9 in

Height (maximum) 156 mm 6.14 in

EPA 0.065m2 0.699 ft2

Cover Lens Acrylic

Housing Single piece, die-cast aluminum

Mounting 1.625 to 2.375/ 42 to 60 mm OD tenons

FinishStandard Painted Finish* * E-coat primer with durable polyester powdercoat topcoat.

156mm (6.14 in)

608mm / 23.9 in

Performance / PhotometricsAvailable Driver Currents 280mA 350mA 450mA 525mA 600mAFixture Efficacy (Type II)* 87 Lm/W 84 Lm/W 80 LmW 77 Lm/W 72 Lm/WFixture Output (Type II)* 7,500 Lm 9,200 Lm 11,500 Lm 13,450 Lm 14,350 LmTelcordia MTBF (in Millions)** 2.3 hrs 2.1 hrs 1.7 hrs 1.6 hrs 1.5 hrs

LED L70 @350mA >100,000 hoursDistribution IES Type II, IES Type III

European wide, European narrow, European Long

Color Temperature (CCT) Standard 5,000 K

Other colors available upon request.

Color Rendering Index (CRI) at 70 (+/-5%)

Operating ConditionsTemperature (ambient) -40C to +60C -40F to +140F

Photocell OptionsPhotocell Receptacle with shorting cap

Photocell 20 yr design life option available

No Photocell Receptacle solid casting

350mm / 13.8 in

Figure 2 Luminaire top***

Figure 1 Luminaire side profile***

Figure 3 Luminaire bottom***

LRL_SAT96_SS_2012_01_23

* Values shown are average values and are subject to +/-5% tolerance** Power supply MTBF values are based on independent labratory analysis using Telcordia SR-332. Values shown are in millions of hours.*** SAT-96M illustrated

-

Leading the LED technology wave

COM

ING

SOON

16

Technical Specifications: SatelliteTM Series LED Roadway LuminaireSAT-120L (120 LEDs)ElectricalAvailable Driver Currents 280mA 350mA 450mA 525mA 600mA

Power Consumption* 110W 140W 180W 220W 250W

Input Voltage: Universal Driver 120 to 240 VAC, 50Hz or 60Hz; 277V, 347V, 480V, and 12-24V DC drivers available upon request.

FixtureWeight 15.4 kg 34 lb

Width (maximum) 458 mm 18.0 in

Length (maximum) 488 mm 19.2 in

Height (maximum) 206 mm 8.1 in

Cover Lens Acrylic

Housing Single piece, die-cast aluminum

Mounting 1.625 to 2.375/ 42 to 60 mm OD tenons

FinishStandard Painted Finish* * E-coat primer with durable polyester powdercoat topcoat.

Performance / PhotometricsAvailable Driver Currents 280mA 350mA 450mA 525mA 600mAFixture Efficacy (Type II)* 85 Lm/W 83 Lm/W 80 LmW 76 Lm/W 71 Lm/WFixture Output (Type II)* 9,350 Lm 11,620 Lm 14,400 Lm 16,720 Lm 17,750 Lm

LED L70 @350mA >100,000 hoursDistribution IES Type II, IES Type III

Color Temperature (CCT) Standard 5,000 K

Other colors available upon request.

Color Rendering Index (CRI) at 70 (+/-5%)

Operating ConditionsTemperature (ambient) -40C to +60C -40F to +140F

Photocell OptionsPhotocell Receptacle with shorting cap

Photocell 20 yr design life option available

No Photocell Receptacle solid casting

LRL_SAT120L_SS_2012_03_28

* Values shown are average values and are subject to +/-5% tolerance*** SAT-144L illustrated

458mm / 18.0 in

Figure 1 Luminaire top*** Figure 3 Luminaire side profile***Figure 2 Luminaire bottom***

206mm (8.1 in)

488mm (19.2 in)

-

Leading the LED technology wave

17

Technical Specifications: SatelliteTM Series LED Roadway LuminaireSAT-144L (144 LEDs)ElectricalAvailable Driver Currents 280mA 350mA 450mA 525mA 600mA

Power Consumption* 132W 168W 216W 264W 300W

Input Voltage: Universal Driver 120 to 240 VAC, 50Hz or 60Hz; 277V, 347V, 480V, and 12-24V DC drivers available upon request.

FixtureWeight 15.4 kg 34 lb

Width (maximum) 458 mm 18.0 in

Length (maximum) 488 mm 19.2 in

Height (maximum) 206 mm 8.1 in

Cover Lens Acrylic

Housing Single piece, die-cast aluminum

Mounting 1.625 to 2.375/ 42 to 60 mm OD tenons

FinishStandard Painted Finish* * E-coat primer with durable polyester powdercoat topcoat.

Performance / PhotometricsAvailable Driver Currents 280mA 350mA 450mA 525mA 600mAFixture Efficacy (Type II)* 85 Lm/W 83 Lm/W 80 LmW 76 Lm/W 71 Lm/WFixture Output (Type II)* 11,200 Lm 13,950 Lm 17,250 Lm 20,050 Lm 21,300 Lm

LED L70 @350mA >100,000 hoursDistribution IES Type II, IES Type III

Color Temperature (CCT) Standard 5,000 K

Other colors available upon request.

Color Rendering Index (CRI) at 70 (+/-5%)

Operating ConditionsTemperature (ambient) -40C to +60C -40F to +140F

Photocell OptionsPhotocell Receptacle with shorting cap

Photocell 20 yr design life option available

No Photocell Receptacle solid casting

LRL_SAT144L_SS_2012_03_30

* Values shown are average values and are subject to +/-5% tolerance*** SAT-144L illustrated

458mm / 18.0 in

Figure 1 Luminaire top*** Figure 3 Luminaire side profile***Figure 2 Luminaire bottom***

206mm (8.1 in)

488mm (19.2 in)

COM

ING

SOON

-

Catalog Numbering System:How to Order

-

Leading the LED technology wave

18

SatelliteTM Series: SAT-S and SAT-MCatalog Numbering System / Shop Drawing Approval

Information provided is subject to change without notice.

LRL-SHOPDRAWING-SAT-2012-01-24 LRL-SHOPDRAWING WI081D-03

MODELVOLTAGE

SAT 24 S48 S72 M96 M

SERIES # OF LEDS/BODY SIZE0678

RS

T2TWT3EWENEL

280350450525600

Satellite SmallSmallMediumMedium

120V-240V universal277V-347V universal480V12V-24V DC (solar applications)

PHOTOCELL CONTROL* OPTICS

DRIVECURRENT

c/w NEMA Photocell ReceptacleSolid Casting (No Photocell Receptacle)

Type IIType II WideType IIIEuro WideEuro NarrowEuro Long*ANZ**

280 mA 350 mA 450 mA525 mA600 mA

* Photocells and shorting caps ordered separately. See next page.

* Available on SAT-M only.** Available on SAT-S only.

1 2 3 4 5 6

SatelliteTM Series, 48 LEDs, small body fixture, 120V, c/w photocell receptacle, Type II distribution, 450mA drive current, gray painted finish, 5000K CCT, acrylic lens, CDN/US QPS certification.

Sample Catalog Number: | SAT | 48S | 0 | R | T2 | 450 | GY | 1 | A | NS | XX | 1 2 3 4 5 6 7 8 9 10 11

GYBKBZ

_ _ _ _

1

23

A NS

CENMCTUL

XX

FINISHLED COLOR

TEMPERATURE (CCT)LENS TYPE CERTIFICATION

Gray (RAL 7035) Black (RAL 9005) Bronze (RAL 7022)

4 Digit RAL#(Custom Finish)

5000K (Standard/Default)4500K (Optional)4000K (Optional)

Acrylic USA/Canada (QPS) (Standard/Default)EuropeanNOM-MexicoC-TICK (Australia)USA*

* 120-240V only7 8 9 10 11

Other color temperatures available. Please contact factory for details.

Shop Drawing Approval/Sign-off

Project Name:

Fixture Type:

Quantity:

Reviewed by:

Catalog Number:

Approved by:

Comments:

(for custom color, insert 4 digit RAL here)

| | | | | | | | ||SAT |

CONTROL OPTIONS

AN

TBA

-

Leading the LED technology wave

19

Photocell and Shorting Cap: Ordering Information

Information provided is subject to change without notice.

LRL-SHOPDRAWING-SAT-2012-01-24 LRL-SHOPDRAWING WI081D-03

SHORTING CAPS DESCRIPTION OPTIONS ORDERNUMBER

CHECK WHICH

PREFERRED

Low Profile One of the lowest profile shorting and non-shorting (open) caps in the Outdoor Lighting Control industry High Impact Thermoplastic Base UV-Stabilized Permanent Color, High Impact Resistant Polypropylene Cover Closed Cell Volara Sealing Gasket Creates weather seal, presents fixed service to luminaire, and provides surge protection ANSI Certified

SHORTING CAP GRAY 120-240V ACSHORTING CAP BLACK 120-240V ACSHORTING CAP GRAY 277-480V ACSHORTING CAP BLACK 277-480V AC

LRL65055-LF

LRL65210-LF

LRL65214-LF

LRL65215-LF

LOW VOLTAGE PHOTOCELLS DESCRIPTION OPTIONS ORDERNUMBER

CHECK WHICH

PREFERRED

Relay-assisted Triac (RAT) switching up to 1800VA, 1000W 320 Joule MOV IP67 Sealed enclosure UV Stabilized Acrylic Conical Cover

PHOTOCELL 120-277V AC 10-15 SEC 16LUX 1:1.5 ON/OFF, BLUE, 20-YEAR, UPWARD SENSING PHOTOCELL 12-48V DC 3-5 SEC 15LUX 1:1.5 ON/OFF RATIO, GREEN, 7 YEAR, SIDE FACING

LRL65223-LF

LRL65349-LF

HIGH VOLTAGE PHOTOCELLS DESCRIPTION OPTIONS ORDERNUMBER

CHECK WHICH

PREFERRED

Double-Sided, Plated Through Circuit Board (DSPT) for durability and reliability Quad-Gate Technology for precision and consistency Full Wave Rectification Dual Zener Diodes 530 Joule MOV High Impact Thermoplastic Base Solid Brass Contact Blades UV Stabilized Permanent Color, High Impact Resistant Polypropylene Cover

PHOTOCELL 480V 15LUX 3-5 SEC 1:1.5 ON/OFF, YELLOW, 20-YEAR, SIDE FACING

PHOTOCELL 347V 15LUX 3-5 SEC 1:1.5 ON/OFF, GREEN, 20-YEAR, SIDE FACING

LRL65260-LF

LRL65261-LF

-

Performance Specifications

-

Leading the LED technology wave

20

1.0 PERFORMANCE SPECIFICATIONS FOR SATELLITETM SERIES FIXTURES

1.1 Power Supply Driver Specifications Power supply must have a 3rd party independently tested Mean Time Between Failure (MTBF) Rating to international standard Telcordia SR-332 Manufacturer to provide projected failures per year per 10,000 lights based on reliability equation R = e-(time/MTBF) Minimum Mean Time Between Failure Ratings of the Following: SAT-M Series SAT-S Series i) 2,300,000 hours @ 280mA drive current i) 3,300,000 hours @ 280mA drive current ii) 1,400,000 hours @ 600mA drive current ii) 2,100,000 hours @ 600mA drive current Letter of certification from the manufacturer shall be provided which confirms that the following parts/processes are not included in the power supply driver i) Commercial-grade electrolytic capacitors ii) Potentiometers iii) Opto-couplers iv) Potting compounds Available in the following drive currents: 280mA, 350mA, 450mA, 525mA, and 600mA Rated for a minimum of 88,000 hours (approximately 20 years based on 12h/day on-time) All capacitors used must be aircraft grade and have a minimum life rating of 110,000 hours at 85C/185F Maximum 600 mA operating current RoHS compliant and lead free Surge protection devices compliant with ANSI standard C62.41-2002 Class C High (10kV, 10kA) Tested to IEC 61000-4-5 (6kV, 3kA), compliant with European Union CE requirements

1.2 LED Fixture Testing Standards - The LED fixtures shall comply with the following standards and specifications. Necessary testing shall be from an approved laboratory. Copies of qualifying reports shall be provided. ANSI C62.41 Surge Voltages in Low Voltage AC Power Circuits ANSI C136.10 Locking-type Photocontrol Devices and Mating Receptacles ANSI C136.15 Luminaire Field Identification ANSI C136.31 Roadway Luminaire Vibration ANSI C136.37 Solid State Light Sources Used in Roadway and Area Lighting ANSI C136.3 Roadway Luminaire Attachment - min. of +/- 3 tilt of luminaire about the tenon when mounting. IES/ANSI RP-8 American National Standard Practice for Roadway Lighting EN-61000-3-2 Harmonic Current Emissions IES LM-79-08 Electric and Photometric Measurements of Solid State Lighting Products IES LM-80-08 Measuring Lumen Maintenance of LED Light Sources NEMA IEC60529 Degrees of Protection Provided by Enclosures - IP Code Telcordia SR-332 Electronic Equipment Reliability Standard ASTM B117 Salt Spray Test Standard MIL-STD-810F Rain/Ice Test Standard CIE 115 2010 Lighting of Roads for Motor and Pedestrian Traffic Tested to Category 5 Hurricane winds (256kph/155mph) Underwriters Laboratories (UL) cULus marking is available on all products rated 120V-240V QPS (NRTL) - cQPSus mark is available on all products rated 120-240V, 277-480V NOM (Mexico) NOM mark is available on all products rated 120-240V, 277-347V

1.3 LED Specification LEDs shall be 5000K (500), with a minimum CRI of 65 LED LM-80 data shall demonstrate a lumen maintenance of 99% or greater at 55C/131F @ 6,000 hours with drive current testing at either 350mA, 700mA, or 1000mA LEDs shall be six (6) die chips; single die LEDs shall not be permitted

1.4 Fixture Housing Single-piece die cast aluminum alloy A360 housing Shall not contain extruded aluminum or inserts, and shall not have multiple pieces screwed, bolted, or fastened together by any other means Available in painted finish (E-coat primer with durable polyester powdercoat topcoat).

-

Leading the LED technology wave

21

Mass no greater than 11.4 kg/25 lbs EPA no greater than 0.7 ft Area between heat sink fins shall be angled to achieve a self-cleaning design and to prevent debris build-up; horizontal or flat heat sinking systems shall not be acceptable due to the lack of self-cleaning design Terminal block compartment accessible via a single trigger-latch based tool-less entry system

1.5 Thermal Management System Heat sink fins to be integral with the single-piece cast body Heat sink system shall be passive. Systems relying on venting holes, grills, or slots shall not be permitted Light engine must consist of aluminum core circuit boards clad directly to the cast aluminum housing All LEDs shall have a maximum rated junction temperature (Tj) of 135C / 275F System shall maintain minimum LED junction temperatures as per the following table (ambient T=20C/68F):

1.6 Fixture Design and Performance Dark Sky compliant IP 66 Ingress Protection for both light engine chamber and power supply chamber Operating Temperature Range -40C to +60C/ -40F to +140F Adjustable Pole Mount Connection 1.625 to 2.375/ 42 to 60 mm O.D. Power terminals sized for #14 AWG to #6 AWG wire and accessible from underside of fixture IESNA Distributions - Type II and Type III Two independent LED light engines are to be angled at 30 to a horizontal roadway in order to maximize targeted lumen output (i.e. high throwing power) for maximum energy savings LEDs must be surface-mounted to light engine circuit board; no pin through-hole LEDs shall be permitted LED fixture minimum efficacy as per the following tables (5000K, 120 V):

1.7 Manufacturing Facility - The LED fixture assembly/manufacturing facility shall have the following designations. Copies of recognized certifications shall be included with the proposal.

ISO 9001 Quality Management Systems (submit copy of certificate) Restriction of Hazardous Substances (RoHS) certification by IPC for the light engine manufacturing facility and power supply manufacturing facility (submit copy of certificates) Electrostatic Discharge (ESD) flooring throughout production area of the light engine manufacturing facility and power supply manufacturing facility (submit photographs of production floor in both facilities) Nitrogen plumbed into soldering processes to improve quality yield (submit photographs of nitrogen tank in power supply and light engine manufacturing facilities) LEDs must be stored in moisture-proof cabinets prior to production (submit photographs of cabinets in the light engine manufacturing facilities) No less than five (5) years of experience in manufacturing LED-based lighting products All production staff in power supply, light engine, and fixture assembly facilities to be certified to IPC EDU 101

LED MaxRated Tj

135C/275F

135C/275F

135C/275F

135C/275F

135C/275F

Operating Current

280mA

350mA

450mA

525mA

600mA

LED Tj(junction temperature)

42C/108F

47C/117F

55C/131F

63C/145F

69C/156F

Degrees below LEDs maximum rated Tj (135C/275F is max junction temp)

93C/167F

88C/158F

80C/144F

72C/130F

66C/119F

LED Driver Operating Current280mA350mA450mA525mA600mA

LED Fixture Efficacy*86 Lm/W 84 Lm/W80 Lm/W77 Lm/W72 Lm/W *Data based on a Type II distribution pattern.

-

Light Loss Factor Information

-

Leading the LED technology wave

22

LRL SatelliteTM Series Light Loss Factor Determination

LLD = 0.89

Lamp Lumen Depreciation (LLD). The lumen depreciation (LLD) for the LED is determined from LM-80 [1] reported data provided by the LED manufacturer. The LM-80 report gives lumen depreciation data for LEDs operating at solder pad temperatures (Ts) of 55C, 85C, and 105C.

In the Satellite Series fixtures the LEDs are operated well under the maximum drive current, as low as 280mA. In-situ temperature measurement tests (ISTMTs), performed as per UL 1598 [2] and Energy Star [3], confirm that the differ-ence between ambient (Tamb) and solder pad temperature (Ts) is 17.9C at 280mA.

For an ambient temperature of 20C and an operating current of 280mA Ts will be 37.9C

The low Ts is achieved through our unique thermal management system with cooling fins integrated into the fixture housing. The fixtures curved design is self-cleaning, preventing the buildup of dirt and debris which could adversely affect heat dissipation.

Using the methodology of TM-21 [4], an exponential curve fit to the LM-80 depreciation data and the Arrhenius Equa-tion are used to interpolate lumen maintenance at the operating temperatures seen in the Satellite Series. This yields the lumen depreciation factors for the LEDs .

For an average ambient of 20C and an operating current of 280mA, LLD = 0.89 over 20 years (12 operating hours per day).

LOD = 0.94

Luminaire Optical Depreciation (LOD). Satellite Series luminaires are IP-66 rated. This means they are impervious to dust and powerful water spray. The optical lenses are mounted at 30 angles on the underside of the fixture meaning they are protected from the elements. In extreme conditions, winds may deposit some slight dust onto the fixtures lenses, but the mounting angles make these lenses self-cleaning.

The lenses are made of UV resistant acrylic which does not discolor. Under the most extreme laboratory testing condi-tions, this material will optically depreciate by no more than 6% over 20 years based on manufacturer information.

Light Loss Factor Determination 2012-03-20

-

Leading the LED technology wave

23

EF=1.00

Equipment Factor. Our in-house designed power supply has been manufactured using high-temperature rated, vibra-tion resistant, high reliability components. The power supply has been designed to provide constant current to the LEDs over the 20 year life under normal conditions.

LLF = 0.89 x 0.94 x 1.00 = 0.83

Using this methodology total fixture Light Loss Factor (LLF) can be calculated for all Satellite Series LED Drive Currents as shown in the graph below.

Figure 1 Satellite Series LED Fixture LLF for varying drive current at an ambient temperature of 20C. Representative curves for 10, 15 and 20 years of operation are shown.

Light Loss Factor Determination 2012-03-20

-

Leading the LED technology wave

24

REFERENCES

1. Illuminating Engineering Society, Lighting Measurement (LM)-80, Approved Method: Measuring Lumen Maintenance of LED Light Sources. 2008.

2. Underwriters Laboratories (UL) 1598 Luminaires. 3rd Edition, 17 September 2008

3. ENERGY STAR Manufacturers Guide for Qualifying Solid State Lighting Luminaires Version 2.1, http:// www.energystar.gov/ia/partners/manuf_res/downloads/ENERGYSTAR_Manufacturers_Guide_v2.1.pdf 4.

4. Illuminating Engineering Society, Technical Memorandum (TM)-21, Projecting Long Term Lumen Maintenance of LED Light Sources. 2011.

Light Loss Factor Determination 2012-03-20

-

Equivalency Tables

-

Leading the LED technology wave

25

Leading the LED technology wave

High Pressure Sodium (HPS) to LED Equivalency Table

Note: This table provides suggested replacements for HPS wattages based on LED Roadway Lightings experi-ences with end clients and lighting layouts. It is the ultimate responsibility of the end client to confirm suitability for their applications, and not the responsibility of LED Roadway Lighting Ltd.

HIGH PRESSURE SODIUM (HPS)

HPS Fixture (Bulb Wattage)

50W

70W

100W

150W

200W

250W

400W

HPS Plug Wattage (Actual Fixture Consumption)

68

95

135

195

245

295

465

Equivalent LRL Product

SAT24S-350 mA

SAT24S-525 mA

SAT48S-350 mA

SAT48S-600 mA

SAT72M-450 mA

SAT96M-450 mA

SAT96M-600 mA

LRL Plug Wattage(Actual Fixture Consumption)

28

44

55

101

110

145

201

Energy SavingsLRL over HPS

59%

54%

59%

48%

55%

51%

57%

LED ROADWAY LIGHTING (LRL)

-

Leading the LED technology wave

26

Metal Halide to LED fixture Equivalency Table

Note: This table provides suggested replacements for MH wattages based on LED Roadway Lightings experi-ences with end clients and lighting layouts. It is the ultimate responsibility of the end client to confirm suitability for their applications, and not the responsibility of LED Roadway Lighting Ltd.

METAL HALIDE (MH)

MH Fixture (Bulb Wattage)

70W

100W

175W

250W

400W

MH Plug Wattage (Actual Fixture Consumption)

98

122

208

290

459

Equivalent LRL Product

SAT24S-350 mA

SAT48S-280 mA

SAT48S-450 mA

SAT96M-350 mA

SAT96M-525 mA

LRL Plug Wattage(Actual Fixture Consumption)

28

43

71.8

110

174

Energy SavingsLRL over MH

71%

65%

65%

62%

62%

LED ROADWAY LIGHTING (LRL)

-

Leading the LED technology wave

27

Mercury Vapour to LED fixture Equivalency Table

Note: This table provides suggested replacements for MV wattages based on LED Roadway Lightings experi-ences with end clients and lighting layouts. It is the ultimate responsibility of the end client to confirm suitability for their applications, and not the responsibility of LED Roadway Lighting Ltd.

MERCURY VAPOR (MV)

MV Fixture (Bulb Wattage)

100W

125W

175W

250W

400W

MV Plug Wattage (Actual Fixture Consumption)

118

137

195

285

450

Equivalent LRL Product

SAT24S-280 mA

SAT24S-350 mA

SAT24S-525 mA

SAT48S-525 mA

SAT96M-450 mA

LRL Plug Wattage(Actual Fixture Consumption)

22

28

44

87.7

148

Energy SavingsLRL over MH

81%

80%

77%

69%

67%

LED ROADWAY LIGHTING (LRL)

-

Brackets and Accessories

-

Leading the LED technology wave

28

SatelliteTM Series: Brackets & Adapters

Pole-Top Brackets (varying arm lengths are available ~ consult factory)

LED Roadway Lighting Ltd. (LRL) offers a wide range of standard and custom brackets and adapters to satisfy most mounting conditions. Our range includes pole-top brackets in a variety of configurations (single, double, or quad tenon with various arm lengths), as well as adjustable adapters that can be used in a wide variety of ap-plications. All brackets and adapters can be painted to match fixture and/or pole color.

Single Tenon Bracket

Double Tenon Bracket

Double Tenon 90 Bracket

Triple Tenon Bracket

Quad Tenon Bracket

-

Leading the LED technology wave

29

Adjustable and Other Brackets and Adapters Available:

Contact us with your mounting requirements and we will provide a solution that best meets your needs.

Quad Tenon BracketDouble Tenon BracketSingle Tenon Bracket

Brackets & Adapters: Application Examples

LRL Brackets and Adapters - 2011-06-12 - EN

-

Leading the LED technology wave

30

Technical Specifications: SatelliteTM Series LED Roadway LuminaireSAT-S Wall Mount BracketSpecificationsConstruction Material Cast Aluminum 356

Mounting Holes 4 holes: 5/16 inch / 0.794 cm diameter

Weight 2.45 kg (5.39 lbs)

Finish Standard Painted Finish*

Mounting Hardware Not included

LRL_SAT24S_Wall_Bracket_2012_03_05

DESCRIPTION FINISH CATALOG NUMBERCHECK WHICH

PREFERRED

SAT-S WALL BRACKET WITH 3/16 EDPM GASKET ALUMINUM A356.1SAT-S WALL BRACKET WITH 3/16 EDPM GASKET ALUMINUM A356.1SAT-S WALL BRACKET WITH 3/16 EDPM GASKET ALUMINUM A356.1

BRONZEGRAYBLACK

LRL 65317-01-LFLRL 65318-01-LFLRL 65319-01-LF

BZGYBK

How to Order: Catalog Numbering System

Wall Mount Bracket

Figure 1 Luminaire SAT-S (bottom) with Wall Mount Bracket

3.1/78mm

6.22/158mm

Figure 2 Luminaire SAT-S illustrated (side)with Wall Mount Bracket

3.5/90mm

3.5/90mmDiameter

6.5/165mm

6.61/168mm

15.0/381mm

16.2/411mm

* E-Coat primer with durable polyester powdercoat topcoat.

-

Installation Instructions

-

Leading the LED technology wave

31

LED ROADWAY LIGHTING LTD. DOC #: LRL65102-15-LF DATE: 2011-09-12 AUTHORS: A. CHAFFEY, T.R. LAAN

CAUTION RISK OF SHOCK DISCONNECT POWER BEFORE SERVICINGDANGER RISQUE DE CHOC METTRE HORS TENSION AVANT LINSTALLATION

PELIGRO RIESGO DE SHOCK O DESCARGA ELECTRICA DESCONECTAR LA ENERGIA ANTES DE HACER LA INSTALACION

PERIGO RISCO DE CHOQUE DESLIGUE A ELETRICIDADE ANTES DA INSTALAO.ACHTUNG STROMSCHLAGGEFAHR

UNTERBRECHEN SIE DIE STROMZUFUHR VOR DER INSTALLATION

!

SATELLITETM SERIES INSTALLATION INSTRUCTIONS IMPORTANT: READ CAREFULLy BEFORE INSTALLING FIxTURE. GENERAL: Upon receipt of fixture thoroughly inspect for any damage.SAFETy: This fixture must be wired in accordance with the National Electrical Code, National Electrical Safety Code and applicable local codes and ordinanc-es. Proper grounding is required to ensure personal safety. Overload circuit protection is recommended. MIN 75C SUPPLY CONDUCTORS. All work should be done by a qualified electrician. No serviceable parts beyond main wiring chamber. ATTENTION: See the electrical specifications on the product label.

LAMPADAIRES LED INSTRUCTIONS DINSTALLATION DE LA SRIE SATELLITETM IMPORTANT: LIRE ATTENTIVEMENT AVANT DINSTALLER LE LAMPADAIREGNRAL: rception du lampadaire, linspecter soigneusement pour viter tout dommage.SCURIT: Ce lampadaire doit tre branch conformment au Code national de llectricit, au National Electrical Safety Code (Code national de scurit lec-trique aux .-U.) et aux autres codes et ordonnances locaux en vigueur. Une mise la terre approprie est requise pour garantir la scurit du personnel. Une protection de circuit en cas de surcharge est recommande. FIL DALIMENTATION 75C MIN. Tous les travaux doivent tre effectus par un lectricien qualifi. Il ny a pas des pices remplaables lextrieur de la chambre principal des connex-ions. ATTENTION : Voir les caractristiques lectriques sur ltiquette du produit.

INSTRUCCIONES DE INSTALACION DE LA SERIE SATELLITETM IMPORTANTE: LEER CUIDADOSAMENTE ANTES DE INSTALAR LA LUMINARIA. GENERAL: Al recibir la luminaria, inspeccionar minuciosamente para ver si presenta algn dao.SEGURIDAD: Esta luminaria debe ser cableada de acuerdo al Cdigo Nacio-nal Elctrico (National Electrical Code, National Electrical Safety) Cdigos y dis-posiciones locales aplicables. Se requiere que quede debidamente aterrizada para asegurar la seguridad personal. Se recomienda proteccin de sobrecarga en los circuitos. Todo este trabajo deber ser efectuado por un electricista calificado. No hay piezas reparables fuera de la cmara principal del cableado. ATENCION: Ver las especificaciones elctricas en la etiqueta del producto.

INSTRUES DE INSTALAO DE LUMINRIAS DA SRIE SATELLITETM IMPORTANTE: LEIA COM ATENO ANTES DE INSTALAR LUMINRIAS.INSTRUES GERAIS: Ao receber a luminria, inspecione-a cuidadosa-mente, para verificar se o produto sofreu algum dano. SEGURANA: Esta luminria deve ligada fiao eltrica de acordo com o Cdigo Eltrico Nacional, com o Cdigo Nacional de Segurana Eltrica e com os cdigos e normas locais aplicveis. Aterramento adequado necessrio para garantir a segurana de pessoas. Tambm se recomenda o uso de proteo con-tra sobrecargas no circuito. Todo o trabalho deve ser executado por um eletricista profissional qualificado. No tem peas reparveis fora da cmara principal de fiao. ADVERTNCIA: Veja as especificaes eltricas na etiqueta do produto.

SATELLITETM SERIE EINBAUANLEITUNG WICHTIG: SORGFLTIG LESEN, BEVOR SIE DIE LICHTANLAGEALLGEMEIN: Untersuchen Sie die Leuchtanlage nach Erhalt sorgfltig auf Schden.SICHERHEIT: Diese Beleuchtungsanlage muss entsprechend des National Electrical Code, des National Electrical Safety Code und anzuwendenden lokalen Vorschriften und Verordnungen verkabelt werden. Eine korrekte Erdung ist fr die persnliche Sicherheit erforderlich. Ein berspannungs-schutz wird empfohlen. Jegliche Arbeiten sollten von einem qualifizierten Elektriker durchgefhrt werden. Es gibt auerhalb der Schaltkastens keine zu wartenden Teile. ACHTUNG: Entnehmen Sie die elektrischen Kenngren dem Produktetikett.

ORIENTATION: For optimum light distri-bution, install fixture parallel to the road. **ORIENTATION: Pour une rpartition op-timale de lclairage, installer le lampa-daire paralllement la route. **ORIENTACION: Para una ptima dis-tribucin de la luz, instalar la luminaria paralela al camino. ORIENTAO: Para obter a distribuio ideal da luz, instale a luminria paralelamente via. ** AUSRICHTUNG: Um eine optimale Lichtausbeute zu erhalten, installieren Sie die Beleuchtung parallel zur Strae. **

X

EN

FR

ES

PT

DE

EN

ES

FR

PT

DE

-

Leading the LED technology wave

32

Open electrical compartment door by releasing latch.Ouvrir la porte du compartiment lectrique en librant le loquet.Abrir la puerta del compartimiento elctrico soltan-do el pestillo o cerrojo.

Abra a porta do compartimento eltrico soltando a trava.ffnen Sie den Elektrobereich durch Lsen des Ver-schlussriegels.

1

2 Loosen pole clamp bolts (4 places with 9/16 hex head) sufficiently to allow insertion of 1.66 out-side diameter (42mm) or 2.375 outside diameter (60mm) pole arm as needed.Desserrer les boulons du manchon pour poteau (4 vis tte hexagonale de 9/16 po) suffisamment pour per-mettre linsertion dun poteau de 1,66 po diam. ext. (42mm) ou 2,375 po diam. ext. (60 mm) au besoin.Aflojar los pernos sujetadores del poste (en 4 ubica-ciones con cabeza hexagonal de 9/16) lo suficiente como para permitir la insercin del brazo del poste de 1.66 (42mm) de dimetro exterior o de 2.375 (60 mm) de dimetro.

Afrouxe os parafusos do fixador (4 parafusos sextava-dos 9/16 pol.) o suficiente para permitir a insero de brao de poste com dimetro externo de 1,66 pol. (42 mm) ou 2,375 pol. (60 mm), conforme a necessidade.Lsen Sie die Schrauben der Polklemmen (4 Stck mit 9/16 Sechskant) so weit, dass Sie einen Mastarm mit 1.66 (42 mm) Auendurchmesser oder 2,375 (60 mm) Auendurchmesser bei Bedarf zu einfhren knnen.

If using barrier shield, remove inner circle of shield to mount on a pole arm greater than 1.66 outside diameter (42mm). En cas doption de protection, retirer le cercle int-rieur de la protection du poteau pour monter le po-teau de 2,375 po diam. ext.Si se est utilizando la opcin con barrera protectora o de aislamiento, remover el crculo interior de la barrera protectora o de aislamiento del poste para montar un brazo de poste de 2.375 (60mm) de di-metro exterior.

Se optar por usar barreira de proteo, remova o crculo interno da vedao do poste para montar um brao de poste com dimetro externo de 2,375 pol. (60 mm).Wenn Sie die Variante mit Abdeckungsschild verwenden, entfernen Sie den inneren Ring des Mastschutzschilds, um einen Mastarm mit 1.66 (42 mm) Auendurchmesser anzuflanschen.

3

Slide fixture onto the pole, ensuring the pole barrier shield is not displaced.Faire glisser le lampadaire sur le poteau en vrifiant que la protection ne soit pas dplace.Deslizar la luminaria en el poste, asegurndose de que la barrera protectora o de aislamiento no sea desplazada.

Faa com que a luminria deslize ao longo do poste, certificando-se que a barreira de proteo no saia do lugar.Schieben Sie die Beleuchtungseinheit auf den Mast; stellen Sie dabei sicher, dass der Mastschutzschild nicht versetzt ist.

4

With the fixture approximately level, tighten bolts until clamps are snug against the pole.Une fois le lampadaire peu prs niveau, resserrer les boulons jusqu ce que les crampons de serrage soient appliqus sur le poteau.Con la luminaria aproximadamente nivelada, apre-tar los pernos sujetadores hasta que queden apreta-dos contra el poste.

Com a luminria aproximadamente nivelada, aperte os parafusos at que as garras estejam fixadas no poste.Die Vorrichtung ungefhr in Waage halten, dann die Schrauben anziehen, bis die Klammern fest am Mast ansitzen.

5

EN

ES

FR

PT

DE

EN

FR

ES

PT

DE

EN

FR

ES

PT

DE

EN

FR

ES

PT

DE

EN

FR

ES

PT

DE

-

Leading the LED technology wave

33

7

8A

6A

6B

Tighten Back Bolts

Loosen Front Bolts

6C

Loosen Back Bolts

Tighten Front Bolts

Back Bolts Front Bolts

Pole ArmTO ADJUST FIxTURE TILT: (A) If no further adjustment to fixture tilt is needed, set fixture to desired rotation about the pole then proceed to Step 7. (B) To lift the fixture nose at an upward tilt, loosen the two front bolts then tighten the two back bolts closest to the pole entry. (C) To lower the fixture nose at a downward tilt, loosen the two back bolts closest to the pole entry and then tighten the two front bolts. POUR RGLER LINCLINAISON DU LUMINAIRE: (A) Si linclinaison du luminaire na besoin daucun autre r-glage, fixez le luminaire langle de rotation souhait sur le poteau, puis passez ltape 7. (B) Pour donner une in-clinaison vers le haut lappareil dclairage, dsserrez les deux boulons avant et resserrez les deux boulons prs de lentre du poteau. (C) Pour donner une inclinaison vers le bas lappareil dclairage, dsserrez les deux boulons prs de lentre du poteau et resserrez les deux boulons avant. PARA AJUSTAR LA INCLINACION DE LA LUMINARIA: (A) Si ya no se requiere ms ajuste a la inclinacin de la luminaria, fijar la luminaria en la rotacin deseada alred-edor del poste y luego proceder al Paso 7. (B) Para levantar la punta de la luminaria con una inclinacin hacia arriba, aflojar los dos tornillos del frente y luego apretar los dos tor-nillos posteriores cercanos a la entrada del poste. (C) Para bajar la punta de la luminaria con una inclinacin hacia abajo, aflojar los dos tornillos posteriores cercanos a la en-

trada del poste y luego apretar los dos tornillos del frente.PARA AJUSTAR A INCLINAO DA LUMINRIA: (A) Se no houver necessidade de mais nenhum ajuste, fixe a luminria ao poste, girando at atingir a posio desejada, e prossiga para a Etapa 7. (B) Para inclinar a ponta da luminria para cima, solte os dois parafusos frontais e aperte os dois parafusos posteriores mais perto da entrada do poste. (C) Para inclinar a ponta da luminria para baixo, solte os dois parafusos posteriores mais perto da entrada do poste e aperte os dois parafusos frontais. WIE MAN DIE NEIGUNG DER BELEUCH-TUNGSEINHEIT JUSTIERT: (A) Falls keine weitere Ausrichtung der Neigung der Beleuchtungseinheit erforderlich ist, drehen Sie die Anlage in die gewnschte Position zum Mast und fahren dann mit Schritt 7 fort. (B) Um die Nase der Anlage zu einem Aufwrtswinkel anzuheben, lsen Sie die zwei vorderen Schrauben und ziehen dann die zwei hinteren fest, die der Mastarmhalterung am nchsten liegen. (C) Um die Nase der Anlage zu einem Abwrtswinkel zu senken, lsen Sie die zwei hinteren Schrauben, die am nchsten zur Mastarmhalterung sitzen und ziehen dann die zwei vorderen Schrauben fest.

Once fixture is set to desired tilt, tighten all pole clamp bolts to 16-18 ft-lb (21.7 24.4 Nm).Une fois le lampadaire niveau, serer tous les boulons du manchon pour Poteau de 16 18 pi-lb. (21,7 24,4 Nm).Una vez que la luminaria est nivelada, apretar to-dos los pernos sujetadores del poste a una torsin de 16-18 libras-pie (21.7-24.4 Nm).

Assim que a luminria estiver nivelada, aperte todos os parafusos de fixao com torque de 21,724,4 Nm (6-18 ps/libras).Wenn die Anlage dann die gewnschte Neigung hat, ziehen Sie alle Schrauben der Mastklammern auf 16 - 18 ft - lb (21,7 24,4 Nm) fest.

FOR AC INPUT: Route AC mains cable through strain relief; tie wrap should loop through only one side of the plastic mount. Attach AC wires to the terminal block; L1: Line (Hot) lead; N/L2: Neutral lead or Second Line lead. It is essential that proper polarity is observed or the fixture may be damaged. Attach Ground/Pro-tective Earth lead to the ground lug. Secure leads with tie wrap to 40 lb (178 N). A minimum 9mm outside diameter entry cable is recommended.ALIMENTATION CA: Tirer les cbles CA principaux au moyen dun serre-cble; lattache autobloquante doit faire une boucle dans une seule partie de la fixa-tion de plastique. Fixer les cbles CA au bornier; L1 : fil actif; N/L2 : fil neutre ou seconde ligne active. Il est essentiel de respecter la polarit au risque dendommager le lampadaire. Fixer le fil de terre la borne de mise la terre. Fixer le lampadaire avec une attache autobloquante 40 lb. (178 N). Un cble dalimentation de 9 mm diam. ext. est recommand.PARA ENTRADA DE CA: Tender los cables principales de CA libres de tensin; la banda de sujecin deber enlazarse a travs de slo un lado del montaje plstico. Conectar los cables de CA al bloque terminal; L1: Lnea conductora (Caliente); N/L2: Conductor neutro o Se-gunda Lnea conductora. Es esencial que se observe una adecuada polaridad o la luminaria podra

daarse. Conectar el conductor de Tierra/Protector a la terminal de tierra. Asegurar los cables con banda de sujecin a 40 lbs (178 N). Se recomienda una entrada de cable de 9mm de Dimetro Exterior mnimo. PARA ENTRADA DE CA: Passe a fiao eltrica pelo aliviador de tenso. A abraadeira (tie-wrap) deve passar por somente um lado do suporte plstico. Co-necte a fiao de CA ao bloco do terminal; L1: Fase; N/L2: Neutro ou segunda fase. essencial observar a polaridade correta para evitar danos luminria. Conecte o fio terra ao borne de aterramento. Prenda os fios com abraadeira (tie-wrap) com resistncia tra-o de 18 Kgf (40 libras = 178 N). O dimetro externo mnimo recomendado para a fiao de 9mm.FR WECHSELSTROM-EINGANG: Fhren Sie das Netzkabel fr Wechselstrom durch die Zugentlastung; Kabelbinder sollte nur durch eine Seite der Plastikhal-terung gefhrt werden. Befestigen Sie die Wechsel-stromkabel an der Verteilerleiste; L1: Leiter (strom-fhrend); N/L2: Nullleiter oder zweite Ader. Es ist wichtig, dass auf die korrekte Polaritt geachtet wird, da die Vorrichtung sonst beschdigt werden knnte. Verbinden Sie das Erdungskabel mit dem Bodenanschlussstck. Sichern Sie das Kabel mittels Kabelbinder mit 40 lb (178 N). Ein Eingangskabel mit mindestens 9 mm Durchmesser wird angeraten.

EN

ES

FR

PT

DE

EN

ES

FR

PT

DE

EN

ES

FR

PT

DE

-

Leading the LED technology wave

34

Install photocontrol or shorting plug (If applicable). To maintain fixture certification, these items must con-tain electrical certification appropriate for the instal-lation region (eg. UL/CSA-listed in North America; CE certified in Europe).Installer la fiche de photocontrle/court-circuit. Pour conserver la certification du lampadaire, ces lments doivent tre conformes la certification en lectricit de la rgion o il est install (par ex., certification CSA-UL en Amrique du Nord; certification CE en Europe).Instalar enchufe de fotocontrol o de corto circuito. Para mantener la certificacin de la luminaria, estas piezas deben contener una adecuada certificacin elctrica para la regin en donde se est haciendo la instalacin (por ejemplo, enlistadas en UL/CSA en Norteamrica; certificacin CE en Europa).

Instale o controle fotoeltrico ou plugue de curto-circuito. Para manter a certificao da luminria, esses itens devem ter a certificao eltrica adequada para a regio onde sero instalados (p. ex.: UL/CSA, na Amri-ca do Norte; CE, na Europa). Installieren Sie die Fotokontrolle oder einen Kurzschlussstecker (Sofern anwendbar). Um die Zu-lassung der Beleuchtungseinheit zu erhalten, mssen diese Teile eine elektrische Zertifizierung fr die Region, in der sie installiert werden, besitzen (z. B. UL/CSA-zertifiziert in Nord Amerika; CE-zertifiziert in Europa).

8B

10

9

FOR DC INPUT: Route DC input cable through strain relief; tie wrap should loop through only one side of the plastic mount. Attach DC wires to the terminal block; (+) Positive lead; (-) Negative lead. It is es-sential that proper polarity is observed or the fixture may be damaged. Attach Ground/ Earth lead to the ground lug. Secure leads with tie wrap to 40 lb (178 N). A minimum 9mm outside diameter entry cable is recommended.ALIMENTATION CC: Tirer les cbles CC principaux au moyen dun serre-cble; lattache autobloquante doit faire une boucle dans une seule partie de la fixation de plastique. Fixer les cbles CC au bornier; (+) fil positif; (-) fil ngatif. Il est essentiel de re-specter la polarit au risque dendommager le lampadaire. Fixer le fil de terre la borne de mise la terre. Fixer le lampadaire avec une attache autob-loquante 40 lb. (178 N). Un cble dalimentation de 9 mm diam. ext. est recommand.PARA ENTRADA DE CC: Tender el cable de entrada libre de tensin; la banda de sujecin deber enla-zarse a travs de slo un lado del montaje plstico. Conectar los cables CC al bloque terminal; (+) con-ductor Positivo; (-) conductor Negativo. Es esencial observar una adecuada polaridad o la luminaria podra daarse. Conectar el cable de tierra a la ter-

minal de tierra. Asegurar los cables con una banda de sujecin a 40 lbs (178 N). Se recomienda una entrada de cable de 9mm de dimetro exterior mnimo.PARA SADA DE CC: Passe a fiao de CC pelo alivia-dor de tenso. A abraadeira (tie-wrap) deve passar por somente um lado do suporte plstico. Conecte a fiao de CC ao bloco do terminal; (+) Fase positiva; (-) Fase negativa. essencial observar a polaridade correta para evitar danos luminria. Conecte o fio terra ao borne de aterramento. Prenda os fios com abraadeira (tie-wrap) com resistncia trao de 18 Kgf (40 libras = 178 N). O dimetro externo mnimo recomendado para a fiao de 9mm.FR GLEICHSTROM-EINGANG: Fhren Sie das Netzkabel fr Gleichstrom durch die Zugentlas-tung; Kabelbinder sollte nur durch eine Seite der Plastikhalterung gefhrt werden. Befestigen Sie die Gleichstromkabel an der Verteilerleiste; (+) Pluska-bel; (-) Minuskabel. Es ist wichtig, dass auf die korrekte Polaritt geachtet wird, da die Vorrich-tung sonst beschdigt werden knnte. Verbinden Sie das Erdungskabel mit dem Bodenanschlussstck. Sichern Sie das Kabel mittels Kabelbinder mit 40 lb (178 N). Ein Eingangskabel mit mindestens 9 mm Durchmesser wird angeraten.

Close electrical compartment door, ensure latch is fully closed.Fermer la porte du compartiment lectrique en vri-fiant que le loquet est compltement referm.Cerrar la puerta del compartimiento elctrico, asegu-rarse de que el cerrojo o pestillo quede bien cerrado.

Feche o compartimento eltrico e certifique-se que a trava esteja firme. Schlieen Sie die Klappe der Elektroeinheit, stel-len Sie sicher, dass der Verschlussriegel vollstndig eingerastet ist.

EN

ES

FR

PT

DE

EN

ES

FR

PT

DE

EN

ES

FR

PT

DE

-

Leading the LED technology wave

35

ENGLISH SAT-24S / SAT-48S SAT-72M / SAT-96MWeight Length Width Height Effective Projected Area (EPA) Max. Ambient Temperature (Ta)* Recommended Torque Setting for mounting bolts Recommended Force to secure strain relief Acceptable Supply Wire Sizes

8.2 kg (18 lb)411 mm (16.2 in)382 mm (15.0 in)167 mm (6.57 in)0.047 m2 (0.509 ft2) +60C (+140 F) 21.7 24.4 Nm (16 18 ft-lb) 178 N (40 lb) Ground = up to #2 AWG (33 mm2)Others = up to #6 AWG (13 mm2)

11.4 kg (25 lb) 608 mm (23.9 in) 350 mm (13.8 in) 156 mm (6.14 in) 0.065 m2 (0.699 ft2)+60C (+140 F)21.7 24.4 Nm (16 18 ft-lb) 178 N (40 lb) Ground = up to #2 AWG (33 mm2)Others = up to #6 AWG (13 mm2)

FRANCAIS SAT-24S / SAT-48S SAT-72M / SAT-96MPoidsLongeur Largeur Hauteur Zone de Projection RelleTemprature ambient max. (ta)*Couple recommand pour les boulons de fixation Force recommande pour fixer le serre-cbleTaille acceptable pour les fils dalimentation

8.2 kg (18 lb.)411 mm (16,2 po) 382 mm (15,0 po) 167 mm (6,57 po) 0,047 m2 (0,509 pi2) +60C (+140 F) 21,7 24,4 Nm (16 18 pi-lb.) 178 N (40 lb.)Terre = jusqua 13 mm2 (6 AWG)Autres = jusqua 13 mm2 (6 AWG)

11,4 kg (25 lb.) 608 mm (23,9 po) 350 mm (13,8 po) 156 mm (6,14 po) 0,065 m2 (0,699 pi2) +60C (+140 F) 21,7 24,4 Nm (16 18 pi-lb.) 178 N (40 lb.)Terre = jusqua 13 mm2 (6 AWG)Autres = jusqua 13 mm2 (6 AWG)

ESPAOL SAT-24S / SAT-48S SAT-72M / SAT-96M

PesoLargo Ancho Altura Area Proyectada EfectivaMx. Temperatura Ambiente (ta) Torsin Recomendada para pernos de montaje Fuerza Recomendada para asegurar sin demasiada tensinTamano aceptable para las lineas de alimentacion

8.2 kg (18 lbs) 411 mm (16.2) 382 mm (15.0) 167 mm (6.57) 0.047 m2 (0.509 pies2) +60C (+140 F) 21.7 24.4 Nm (16 18 libras-pie) 178 N (40 lbs)Tierra = hasta 13 mm2 (6 AWG) Otros = hasta 13 mm2 (6 AWG)

11.4 kg (25 lbs) 608 mm (23.9) 350 mm (13.8) 156 mm (6.14) 0.065 m2 (0.699 pies2) +60C (+140 F) 21.7 24.4 Nm (16 18 libras-pie) 178 N (40 lbs)Tierra = hasta 13 mm2 (6 AWG) Otros = hasta 13 mm2 (6 AWG)

PORTUGUESE SAT-24S / SAT-48S SAT-72M / SAT-96MPeso Comprimento Largura +60C (+140F)Altura rea projetada efetivaTemperatura ambiente (Ta) mxima Torque recomendado para os parafusos de montagem Fora recomendada para fixao do aliviador de tenso Dimensionamento aceitvel da fiao

8,2 kg (18 libras) 411 mm (16,2 pol.) 382 mm (15,0 pol.) 167 mm (6,57 pol.) 0,047 m2 (0,509 p quad.) +60C (+140F) 21,7 24,4 Nm (16-18 ps/libras) 178 N (40 libras) Aterramento = at 33 mm2 (2 AWG)Outros = at 13 mm2 (6 AWG)

11,4 kg (25 libras) 608 mm (23,9 pol.) 350 mm (13,8 pol.) 156 mm (6,14 pol.)0,065 m2 (0,0699 p quad.) +60C (+140F) 21,7 24,4 Nm (16-18 ps/libras) 178 N (40 libras) Aterramento = at 33 mm2 (2 AWG)Outros = at 13 mm2 (6 AWG)

DEUTSCH SAT-24S / SAT-48S SAT-72M / SAT-96MGewichtLnge Breite Hhe Effektiv beleuchteter BereichMax. Umgebungstemperatur (Ta) Empfohlene Drehmomenteinstellung zum Anziehen der Schrauben Empfohlene Kraft zur Sicherstellung der Zugentlastung

8,2 kg (18 lb) 411 mm (16,2 in) 382 mm (15,0 in) 167 mm (6,57 in) 0.047 m2 (0,509 ft2) +60C (+140 F) 21,7 24,4 Nm (16 18 ftlb) 178 N (40 lb)

11,4 kg (25 lb) 608 mm (23,9 in) 350 mm (13,8 in) 156 mm (6,14 in) 0.065 m2 (0,699 ft2) +60C (+140 F) 21,7 24,4 Nm (16 18 ftlb) 178 N (40 lb)

SatelliteTM Series LED Luminaire InformationInformation sur les Lampadaires LED de la Srie SatelliteTM

Informacin de Luminaria LED de la Serie SatelliteTM

Informaes sobre as luminrias LED da srie SatelliteTM SatelliteTM Serie LED Beleuchtung Datenblatt

EN

ES

FR

PT

DE

* UL-listed models are rated to max. ambient temperature of 50C.* Les modles lists par lUL sont certifis pour fonctionner une temprature maximale ambiante de 50C.

-

Leading the LED technology wave

36

Ingress ProtectionThe SatelliteTM Series luminaire is designed to be protected from the effects of the outside environment. The power supply and optics compartments are designed to be impervious to dust and powerful water spray, and carry an IP66 protection rating. The primary service compartment for installation of the mounting pole and electrical connections carries an IP20 protection rating.

Photobiological SafetyNOTICE: UV emitted from this product at 4.23 m (13.9ft) is 0.001 W/m2 (EN/IEC 62471 Exempt level).

Protection de pntrationLes lampadaires de la srie SatelliteTM sont conus pour tre protgs des effets de lenvironnement extrieur. Les compartiments dalimentation et doptique sont conus pour tre tanches la poussire et aux vaporisateurs deau puissants et comporte un in-dice de protection IP66. Le compartiment de service principal dinstallation du poteau de fixation et des branchements lectriques a un indice de protection IP20.

Scurit photobiologiqueATTENTION: le rayonnement ultraviolet mis par ce produit 4,23 m (13,9 pi) est de 0,001 W/m2 (niveau dexemption de la norme EN/CEI 62471).

Clasificacin de ProteccinLas luminarias de la Serie SatelliteTM estn diseadas para estar protegidas de los efectos del medio ambiente exterior. Los compar-timientos de la fuente de poder y de los elementos pticos estn diseados para ser impermeables al polvo y a fuertes chorros de agua y tienen una clasificacin de proteccin IP66. El compartimiento de servicio primario para la instalacin del poste de montaje y las conexiones elctricas tiene una clasificacin de proteccin IP20.

Seguridad FotobiolgicaAVISO: La emisin de UV de este producto a 4.23 mts. (13.9 pies) es de 0.001 W/m2 (nivel Exento para EN/IEC 62471)

Vedao A srie de luminrias SatelliteTM foi projetada para se manter protegida contra os efeitos do ambiente que as cerca. Os compar-timentos de suprimento de energia e tico so projetados para impermeabilidade poeira e pulverizao de gua, com grau de proteo IP66. O compartimento principal para a instalao do poste e conexes eltricas tem grau de proteo IP20.

Segurana fotobiolgica ADVERTNCIA: A emisso de raios UV por este produto, a 4,23 m (13,9 ps), de 0,001W/m2 (nvel isento de acordo com a norma EN/IEC 62471).

SchutzvorrichtungDie Beleuchtungsanlagen der SatelliteTM Serie wurde so entwickelt, dass sie den von auen einwirkenden Einflssen widerste-hen. Die Stromzufuhr und das Optikfach wurden so entwickelt, dass sie gegenber Staub und Spritzwasser unempfindlich sind und ber die IP66-Schutzklasse verfgen. Das Hauptwartungsfach fr die Installation auf den Montagearm und die elektrischen Verbindungen verfgen ber eine IP20-Schutzklasse.

Photobiologische SicherheitHINWEIS: Die UV-Abstrahlung dieses Erzeugnisses betrgt 0,001 W/m2 (IEC/EN 62471 ,Schwellwert) bei 4,23 m (13,9 ft.)

EN

ES

FR

PT

DE

115 Chain Lake DriveBayers Lake Business ParkHalifax, Nova Scotia, B3S 1B3 Canada

Toll-Free Tel: +1 (877) 533.5755Toll-Free Fax: +1 (888) 533.5755Email: [email protected]: www.ledroadwaylighting.comLeading the LED technology wave

** Max rotation angle less than 10 to the horizontal.** Ajustement de langle de moins de 10 par rapport lhorizontale.** No incline la luminaria ms que 10.** No incline a luminria mais do que 10. ** Der maximale Neigungswinkel betrgt weniger als 10 von der Horizontalen.

-

Case Studies and Application Examples

-

Leading the LED technology wave

37