LEADERS IN WORLD CLASS PRECISION...

Transcript of LEADERS IN WORLD CLASS PRECISION...

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

KEY CAPABILITIESGEAR MANUFACTURING

PRECISION & HEAVY MACHINING

HEAT TREATMENT

ENGINEERING & MINING EQUIPMENT

REPAIRS & MAINTENANCE

SPECIALIST TRANSMISSION REPAIRS

RESEARCH & DEVELOPMENT

SPECIALIST TOOLS & EQUIPMENT

PORTABLE MACHINE TOOLS

REPLACEMENT PARTS

ON-SITE MACHINING

DEFENCE PROJECTS

METROLOGY SERVICE

DESIGN & CONSULTING SERVICES

FABRICATION & WELDING

FIELD SERVICE

AEROSPACE

LEADERS IN WORLD CLASS PRECISION ENGINEERING

INTRODUCTION

AUSTRALIAN LEADERSHIP IN WORLD CLASS PRECISION ENGINEERING

25m high machine shop suitable for 200

tonne lifts.

Hofmann Engineering, founded by John and ErichHofmann in 1969 is a successful family owned and runengineering business. The precision and expertise thatHofmann Engineering offers in the manufacturing andrefurbishing of precision mining equipment is soughtfrom companies both locally and internationally.

Stable cash flow management has enabled HofmannEngineering to grow into one of the largest privatelyowned engineering facilities in Australia, employingover 600 people world wide. In 2003 leadership ofHofmann Engineering was passed to the secondgeneration with John’s son Erich J Hofmann nowleading the company in their continued pursuit ofexcellence.

John HofmannExecutive Director

Erich J. Hofmann B.E. (Hon)

Managing Director

Leighton WhiteTechnical Director

Erich F HofmannDirector

CONTENTS2 INTRODUCTION & CONTENTS 46 SHOVEL - SWING GEARS3 GLOBAL PREMISES 47 SHOVEL - PLANETARY GEAR BOXES5 GEAR MANUFACTURE 49 HYDRAULIC EXCAVATOR – REPLACEMENT PARTS7 BEVEL GEARS & WORM WHEELS 51 SLEW BEARINGS9 DESIGN INSPECTION MEASURMENT METALLURGY 53 TRACK PADS (4 pages)

ULTRASONICS 57 MINING TRUCK PARTS

11 MILLS & KILNS 59 EXCAVATORS & RECLAIMERS

13 GRINDING MILL SHELLS & HEADS 61 RAIL15 SELF ALIGNING DRIVES 63 HOFMANN PORTABLE MACHINE TOOLS17 MILL & KILN PINIONS 65 HOFNUTS19 LARGE MILL & KILN GEARS 67 VALVE AND PUMP21 FORGED STEEL FABRICATED GEARS 69 CRUSHER REPAIRS & SERVICE AND REPLACEMENT PARTS23 OPEN GEAR RECONDITIONING PROCEDURE 71 HPGR (HIGH PRESSURE GRINDING ROLLS)

25 GEARBOX RANGE 73 UNDERGROUND MINING

27 GEARBOX REBUILD DIVISION 74 VIBRATING SCREENS29 ONSITE SERVICE 75 DISC VACUUM FILTERS31 KILN SERVICES 77 DEFENCE33 SUGAR MILLS 79 AEROSPACE35 OIL & GAS 81 CUTTING TOOLS37 WIND TURBINE GEARBOXES 83 FOOD PACKAGING39 ENERGY POWER STATIONS 85 PRESS SHOP41 DRAGLINE – REPLACEMENT PARTS (4 pages) 87 WORLD WIDE REPRESENTATIVES & HEAD OFFICE LOCATION45 SHOVEL – REPLACEMENT PARTS

- 3 -

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

HOFMANN BENDIGO

Specialising in:

• Heavy Fabrication• Gearbox Manufacture & Overhaul• Heavy Machining• Heat Treatment• Onsite Services

Hofmann Engineering now boasts three facilities(Bendigo, Melbourne & Newcastle) on the east coastof Australia as well as a facility in Canada, NorthAmerica and Chile & Peru in South America.

HOFMANN METALTEC

Specialising in:

• Aerospace Tooling• Food Packaging• Cutting Tools • Pressing• Precision Tooling

25 Bushmaster CourtNorth Bendigo, VICTORIA 3550AUSTRALIAPhone: +61-3-5440 7400

292 Bay RdCHELTENHAM VICTORIA 3192AUSTRALIAPhone: +61-3-8585 1800

GLOBAL PREMISES

AustraliaCanada

USAChilePeruIndiaChina

Agents and Representatives

Worldwide

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

HOFMANN CANADA330 Pinebush RdCAMBRIDGE ONTARIOCANADAEmail: [email protected]: +1-903-391-0960

GLOBAL PREMISES

HOFMANN SUDAMÉRICA LTD

Av. Pedro Aguirre Cerda 5802ANTOFAGASTA CHILE Mobile: +56-9-8294 7851 Office: +56-55-441760

Hofmann Canada still retains their land and building ownership and maintains their relationship with SKF (current tenant) for special Projects.

The South American operation offers General machining and Gearbox rebuild facilities and parts storage and sales.

Specialising in:• Onsite Machining and installation service• Precision Gearbox Rebuild Centre• Shovel – Truck – Crusher – Mill Components

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

HOFMANN INDIA

16, 5th Cross, Ramakrishna Nagar Nandini LayoutBANGALOREPhone : +91-80-2319 6155Mo bile: +91-99-0008 5921

HOFMANN USA

147 FM 27 WestFa irfield Texas 75840USA (Note: This is a home office)Phone : +1-903-391-0960

HOFMANN PERU

Phone : +51-54-275644Pe [email protected]

HOFMANN CHINA

(+86) 18258782883 J [email protected]@Hofmannengineering.com

HOFMANN NEWCASTLE42 Broadmeadow RoadBROADMEADOW NSW 2292AUSTRALIASpecialising in:• Heavy Engineering to 14m dia.• Gearing to 12 dia.• Gearbox rebuilds, underground

mining, mobile mining equipment & replacement parts .

GEAR

MANUFACTURE

DESIGN AND CONSULTING SERVICES.Analyse and solve your particular gear or gearbox problem using the latest gear design sof tware to either D.I.N., A.G.M.A., B.S. or Australian Gear Standards.• Industrial Gearbox and gear design.• Onsite gear inspection and consultancy • service.• Computer aided draf ting.

TURNINGA range of lathes both conventional and computer (CNC) controlled for turning of gear blanks and shafts to 35,000mm long.• Final grinding of shafts to 8,000mm long.

FABRICATION.Complete w elding and fabrication facilities to 200 tonnes.• Fabricated gearbox casings and gears.• Rebanding w orn gears via welding ring forging • to original hub.• Qualified w elders with accredited welding • procedures.

HORIZONTAL BORING.A range of both conventional and computer controlled (CNC) borers are available to 18,000mm x 5000mm.• Machining of large gearbox housings.

1

68,000 KG DREDGE BUCKET WHEEL DRIVE GEARBOXThis gearbox operates 20m underwater for dredging mineral sands. The technical advancement of incorporating case hardened gearing throughout helped us win the order against some of the world’s leading gearbox manufacturers.

2

43

ALL MANUFACTURED UNDER ONE ROOF

- 5 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

GEAR HOBBINGManufacture of high accuracy gears and w orm w heels.• Carbide skiving of case hardened gears.• Computer (CNC) controlled accuracy • (15000mm dia).

LARGE GEAR CUTTINGInternal and external gearing to 15000mm dia. x 2500mm face.• Re-cutting of w orn girth gears and • slew rings.• Full involute form carbide finish cutting • of gears.

HEAT TREATMENTOne of Australia’s largest specialised heat treatment facilities encompassing:• Oil quench & tempering, stress relieving.• Gas carburisingvia pit furnace or f luid • bed 1800mm dia. x 5000mm.• Tool steel heat treatment.

INDUCTION HARDENINGTooth by tooth full contour induction hardening to produce a hard w ear resistant case up to 20mm deep supported by a tough impact resistant core.• Mill pinions, slew bearing races.• Traction gears.• Spin hardening of pins and splines.• 15,000mm dia. x 2500mm face.

METALURGICAL LABORATORYAn extensively equipped laboratory to facilitate both failure analysis and the inspection of test pieces heat treated w ith each and every furnace charge.

GEAR GRINDINGAustralia’s most comprehensively equipped gear grinding facilities w ith 4Höfler form grinders.• 2500mm dia. x 1500mm face x 40Mn.• Completely climate controlled area.• Prof ile and lead modif ication facilities • (tip/root relief and crow ning).• CNC Form grinding of both internal and • external gearing to 2500mm dia.

GEAR INSPECTION LABORATORYA climate controlled inspection area for the verification of all gear geometry parameters.• Lead involute and pitch inspection.• Calibrated inspection machines.• Crack detection.

GEAR BOX TEST BED FACILITY 2MW FULL LOADEvery gearbox w e manufacture or overhaul is test run and a detailed test run report compiled.• Partial load testing.• Back to back full load gearbox test • capability.• DC stepless drive system.

CO-ORDINATE MEASURING MACHINE3D machine w ith lead, involute and pitch software to enable the complete inspection of large gearing.• Climate controlled laboratory • environment.• Gears to 15,000mm dia. x 2500mm face.• Gearbox housings and complex shapes.

ALL MANUFACTURED UNDER ONE ROOF

765

1098

12 1311

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

- 7 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

BEVEL GEARSSPIRAL

HELICALSTRAIGHT

Also

WORM WHEELS&

WORMSHAFTS

CAPACITY:8 off 5-axis machines

Size ≤ ф4m• BEVEL GEARING • WORM GEARING •

DESIGNED OR REVERSE ENGINEERING & MANUFACTURED UNDER ONE ROOF

DESIGNUsing state-of-the-art engineeringcalculation programs in the hands of talentedengineers, a 3D model of your bevel gearcan be produced to DIN, AGMA or Gleasonstandards from the outputs. For replacementgears, the model of the existing design canbe acquired from a CMM and modified tosolve the problem which caused it to fail.Tooth modification can also be optimised togive quiet running gears.

INSPECTIONHofmann Engineering prides itself on producing superior quality products. The onlyway to ensure that this is achieved is by imposing a highly accurate inspectionprocess which the Spiral, Helical or Straight Bevel Gearing along with the WormGearing must pass before they can be released from the factory. All these types ofGearing are inspected on our two large CMM’s or the portable CMM arm.

CUTTINGHofmann Engineering currently has 8 new 5-axis machines for cutting spiral, helical and straight bevel gearsalong with worm wheels. It also has a unique software, crafted exclusively to obtain the optimised CAM programto machine the profile of spiral, helical and straight bevel gears plus worm wheels.

WORM MESH CONTACT INSPECTIONWorm wheel and wormshaftbeing inspected to confirm contact accuracy.

WORM GRINDINGWormshafts being ground on one of our Hofler form grinders. After grinding the accuracy is preliminary checked prior to final inspection on the CMM

HEAT TREATMENTOver the years, Hofmann Engineering has developed the technology toheat treat many different types of gears. This technology can also beapplied to spiral, helical, straight bevel gears and wormshafts to improvetheir performance and li fe. Hofmann Engineering is capable of casecarburising to a diameter of 1.87m, and full contour, tooth-by-toothinduction hardening to a diameter of 4m. Once the gears have been heat-treated, they can be hard cut to DIN 3.

TESTINGHofmann Engineering can testtheir spiral bevel gears in thegearbox on their load test cell toensure that the gearbox will bewithin the noise specificationsrequired by the customer.

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

METROLOGYINSPECTION

DESIGNMETALLURGY

SPECTROANALYSISULTRASONICS

ONSITE INSITU INSPECTION Hofmann Engineering continually improve quality and expand their library of product improved parts by pushing the frontline of inspection technology.

The tw o 6-axis Portable Co-ordinate Measuring Machines (PCMM) run a number of different softwares for general inspection and also a unique gear inspection sof tware and achieve an accuracy of 20µm (≈0.001”).

A state-of-the-art Laser Scanner attaches to the head of our PCMM’s, and produces a laser scanned point cloud from w hich a model can be created.

The tw o Laser Trackers have up to a 320m radial measuring volume producing micron accuracy on large parts such as mill heads, gearbox casings and slew gears.

- 9 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

ENGINEERING DESIGN• 2D and 3D CAD to produce

manufacturing draw ings.• 5-axis CAM to program

machining.We design all types of components including:• Aerospace tooling• HPGR’s• TrackpadsPrograms: AutoCAD, Solidw orks, Unigraphics NX CAD/CAM, PEPS, Catia v5, CADDS, and Pro_E.

GEAR DESIGN & ANALYSIS Programs: KISSsof t and TBK.Gear tooth optimisation; contact pattern and modif ication analysis to produce quiet running gearing.Shaft and bearing calculations.Typical design components: spur, helical and double helical gears and splines; planetary gear trains; straight, skew , spiral, zerol and hypoid bevel gearing; w orm gearing; special tooling; and f lexible couplings.

FINITE ELEMENT ANALYSIS (FEA)Static and dynamic FEA simulations can be performed.Special gear tooth FEA programs to analyse cracks in cast gearing.Typical applications: gearbox casings; Hofmann re-designed components; cast gearing; rope drums; and eccentrics.

METALLURGYComplete metallurgical lab for:• quality control of heat treatment

processes;• metallurgical failure analysis.Our speciality is failure analysis of gearing to AGMA and DIN standards.

SPECTROGRAPHICS ANALYSISFull chemical composition analysis of carbon and alloy steels; stainless steel; aluminium; copper; and nickel alloys.Ideal for material identif ication and Weld Procedure Specification.

ULTRASONIC NDT INSPECTIONFor quality control and defect identif ication.NATA certif ied operators.In-house and external Quality Assurance.

CMM LABORATORY INSPECTIONA state-of-the-art, climate controlled and vibrationally isolated inspection laboratory houses the f ixed CMM. With accuracy to 2µm, the CMM has the capability, software and is accredited to inspect gears to 6m diameter, pinions f rom small to large mill pinions, aerospace parts, w orm gearing, bevel gears and many other components.

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

LubricationSystems

Couplings – Rubber Flex,Gear Flex & Disengaging

Inching Drives

GearReducers

MillPinions

GirthGears

Girth Gear Guards & Sealing Systems

Heads &Shells

Onsite Inspections,Installation & Machining

Bearings: White Metal/Bronze

LubricantSupply

MILLS &

KILNS

PINIONS

1 Through-Hardened.

2 Induction-Hardened.

3 Case-Carburised.

4 HofCarb Carburised.

5 Self-Aligning.

CAPACITY

• Size - 1.6m face x 6m lg.

• Hardness - to 62 HRC

• Quality - AGMA 13 (DIN 3)

GIRTH GEARS

1 SG Iron.

2 Cast Steel.

3 Austempered SG Iron.

4 Forged Fabricated.

5 Forged Fabricated Induction Hardened.

- 11 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

CAPACITY 15m ( 50ft)

• Size - 2.5m face x 15m dia.

• Hardness - to 52HRC (500BHN).

• Quality - AGMA 10 (DIN 7).

SELF-ALIGNING DRIVES• Automatically maintains 100% gear

contact regardless of movement in foundations and/or driven component.

• Can use recirculating f iltered oil.• Reduced maintenance as alignment

checks and adjustments are eliminated.• Pow er to 10 000kW per gearbox.

GEARBOXES STANDARDCompletely designed and manufactured in

house using AGMA and DIN standards.• Standardrange of multi-stage drives.• Precision Case-carburised and ground

gearing to AGMA 14 for quiet reliable operation.

GEARBOXES SPECIALSSpecial Gearboxes can be designed to fit existing foundation as a direct replacement of your old drive. (Flender, Falk, Valmet etc.)• Pow er upgrades, ratio changes and

replacement parts available.• Torque-splitting gear drives.

INCHING DRIVESHofmann Engineering makes a range ofinching drives to f it to new and existing mill and kiln drives. Features include:• Planetary main reduction.• Hydraulic or electric.• Integral or separate brakes.• Disengaging couplings.

GEAR PROTECTION SYSTEMS• Continuous & intermittent grease spray

systems.• Re-circulating f iltered oil systems.• Infrared temperature monitoring systems. • Measures gear mesh temperature.• Sealing systems for girth gears and

trunnion bearings.

LUBRICANT SUPPLYHofmann Lubrication division has an agreement w ith Kluber Lubrication Germany AG to supply a range of products, directly formulated to Protect the Gearing that w e design and manufacture.

This forms an integral part of our Gear Protection Package used to improve the life of high performance gearing.

ONSITE MACHINING• Flange and Journal machining to 14m

dia.• Line boring and drilling to 3m dia x 6m L.• Grinding and linishing of kiln tyres.• Milling of keyw ays and surfaces.• Welding and heat-treatment.• Bolt tensioning.• Special purpose machinery design and

manufacture to suit your application.

ONSITE INSPECTION & CONSULTING SERVICE .• Inspection and assessment of your mill

and drive train.• Failure analysis including Engineering

and Gearing design review . Finite Element Analysis and Metallurgical Analysis.

ONSITE SERVICE• Laser alignments of drive trains.• Girth gear/pinion installation.• Reconditioning of w orn gearing using

case hardened pinions and chemical etchant.

• Trunnion bearing installation including scraping in of w hite metal bearings.

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

- 13 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

MANUFACTURING CAPACITY: 2 Manufacturing Sites • Bassendean – Western Australia

• Bendigo - Victoria (Australia)

• Max Shell Size: Ø13.4m (44ft)• Lift Capacity: 210 tonne (231 ton) x 17m (55.7ft) under crane hook.• Vertical Rolls: 6000 tonne (6600 ton) & 4000 tonne (4400 ton). • Sub Arc Welding using tandem head inverter technology.• Machining to Ø16m (52ft) x 6m (19.7ft) x 300 tonne (330 ton) capacity

rotary table.• Floor Borers: 15.3m (50ft) x 5.0m (16ft) & 12m (39ft) x 3.9m (12.8ft).• Heat Treatment: Stress Relieving Ø14m x 4m high.• Surface Finish: Abrasive Blast / Paint Booths / Epoxy Coating, Rubber

Lining.

GRINDINGMILL SHELLS

& HEADSTo Ø44 ft

• Fabricated Steel• Solid Stainless

Steel• Stainless Steel Clad• Bimetallic Plate• Epoxy Coated• Cast Steel• Cast SG Iron

6000 TONNER VERTICAL ROLLING PRESSMax thickness 220mm

Width 3650mm

Hardness 390BHN

FABRICATIONTypical steel plate to AS3678 Grade 250,

EN S235JR, ASTM A36.

Segments prof iled to shape w ith bevelling.

Stainless Steel Clad plate available.

FABRICATIONPlate UT examination to AS 1710

Flange plate Z property tensile tested.

Welded and tested to AWS D1.1

Stainless Steel to AWS D1.6 available.

VERTICAL BORER

Bendigo:Schiess Ø9.22m x 4.45m height 200T

Schiess Ø7.0m x 3.50m height 200T

Bassendean:Schiess Ø8.75m x 2.7m height 200T

FLOOR BORER

Bendigo: INNOCENTI CNC

15.3m x 5.0m high x 1.25m Z travel.

Floor plate area 19.50m x 6.55m

CNC Rotary Table 2.5m x 2.5m x 200T

FLOOR BORER

Bassendean:WMW BP160CNC

12m x 3.9m high x 2.0m Z travel.

Floor plate area 18.0m x 6.0m

CNC Rotary Table

LARGE VERTICAL MACHINE:Bassendean & Bendigo:Floor Borer and 200T Table to machine and drill Mill Shells up to Ø15m by 7m height.

SZIM GANTRY MACHINING CENTRE:Unique boom arrangement combined w ith a rotary table w ill allow the machine to act as vertical borer and drill on the same set up. Max capacity Ø15m.

WELDING MANIPULATOR:Adjustable to accommodate head angle. Manipulator & Boom drives synchronised. 200 tonne capacity. CNC controlled for SS cladding of heads and shells

ROAD & SEA FREIGHT

HEAT TREATMENTStress Relieving Furnace Ø14m x 4m

SURFACE FINISHAbrasive blast, paint, Epoxy Coat and rubber line as required.

PACKAGINGMachined surfaces coated with rust inhibitor. Packaged and protected for road, ocean and air freight.

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

AIRFREIGHT – ANTONOV TO 90T/PIECE

SELF ALIGNING DRIVES

HOFMANN SELF ALIGNING DRIVES always maintain 100% contact

automatically through all loading stages regardless of:• Mating gear axial run out.• Foundation movement and temperature expansion changes.• Deflections and load variations.

APPLICATIONS• Mills, Kilns, Dryers and Car Dumpers.• Dragline, Shovels, Winders and Slewing Drives.• Any gear drive where self aligning is required to reduce maintenance.

Case Hardened Gear couplings to transmit torque.

Hardened spherical bearings to enable self aligning motion.

MILL DRIVES TO 20,000KW• Using 2 off 10 000kW drives. • 4 off self aligning pinions drive the • girth gear. • Mechanical drive options to 34MW.

DIRECT MESH GEARBOXINCORPORATING TWIN TORQUE

SPLITTING SELF-ALIGNING PINIONS TO 10,000KW

- 15 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Qu ality Assurance a certification by Lloyds complements our total quality cu lture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

1) SAP - Self Aligning Pinions

2) SAOP - Self Aligning Overhung Pinion Drive 4) SASP - Self Aligning Single Pinion Drive

3) SATP - Self Aligning Twin Pinion DriveConventional Self Aligning Pinion with plummer block bearings.• Retrofit to existing mills and drives.• Pinion shaft is reversible.

• 4 standard sizes 18Mn, 22Mn, 25.4Mn & 30Mn that • covers the complete range to 10,000kW.• Single motor runs two self aligning, torque splitting • pinions direct meshed with the girth gear.• Reduced foundation, installation and running costs.• Oil re-circulating system for gearbox and girth gear.

Self-aligning pinion mounts directly to the output shaft and is integral with the main gearbox.• Reduced foundation and installation costs.• No low speed coupling or plummer bearings.• Split lube system between gearbox and open gearing is • now possible.

Self-aligning overhung pinion mounts directly to output shaft main gearbox.• Lowest foundation and installation costs.• No low speed coupling or plummer bearings.• Split lube system between gearbox and open gearing is • now possible.

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

PINIONS

1. Through-Hardened.

2. Induction-Hardened.

3. Case-Carburised.

4. HofCarb Carburised.

5. Self-Aligning.

CAPACITY

• Size - 1.6m face x 6m lg.

• Hardness - to 62 HRC.

• Quality - AGMA14 (DIN 4).

MILL&

KILN PINIONS

- 17 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

1 2 3 4 5

PINION TYPE

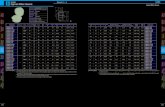

Pinion Rating Comparison Same Size But Different Hardness And Quality

SOFT INDUCTION HARD & CARBURISED & HOFCARB & CARBURISED &

QUENCH & TEMP GROUND GROUND GROUND SELF ALIGNING

Material AISI 4340

M

a

x AISI 4340

M

a

x Din 17CrNiMo6

M

a

x Din 17CrNiMo6

M

a

x Din 17CrNiMo6

M

a

x

Heat Treatment Quench & Temp Induction Hardened Gas Carburised Gas Carburised Gas Carburised

Hardness 290 BHN 420 BHN Core = 300 BHN 400 BHN Core =400 BHN 420 BHN Core =400 BHN 420 BHN Core =400 BHN 420 BHN

Case = 56 RC 60RC Cas e = 60 RC 62RC Case = 60 RC 62RC Case = 60 RC 62RC

Depth = 7 mm 10mm Depth = 5 mm 6mm Depth = 5 mm 6mm Depth = 5 mm 6mm

Quality AGMA 10 (DIN 8) 11 AGMA 12 (DIN 6) 15 AGMA 12 (DIN 6) 15 AGMA 12 (D IN 6) 15 AGMA 12 (DIN 6) 15

Machining Hobbed Ground Ground Ground Ground

Pictures depict typical

pinion types being

manufactured by

Hofmann Engineering

Example

Power De tails Power (kW) 3500

Speed (RPM) 188

Geometry Module Mn 25.4 Mn max = 100 Mn max = 32 Mn max = 32 Mn max = 32 Mn max =32

P ressure Ang 25° max = 45 ° max = 45 ° m ax = 4 5 ° max = 45 ° max = 45 °

Helix Angle 0 max = 45 ° max = 45 ° m ax = 4 5 ° max = 45 ° max = 45 °

Nos Teeth Z 25 Z max = 600 Z m ax = 6 00 Z m ax = 6 00 Z max = 600 Z max = 600

Face Widt h F 700 F max = 25 00 mm F max = 1200 m m F max = 1200 m m F max = 1200 mm F max = 120 0 mm

Overa ll Length L 320 0 L max = 12000 mm L m ax = 6 000 mm L m ax = 3 700 mm L max = 3700 mm L max = 3700 m m

Out side Dia da 701 da max = 8000 mm da m ax = 3 000 mm da m ax = 1900 mm da max = 1900 m m da max = 1900 m m

W eight (Kg) W 400 0 W max = 100 tonne W max = 20 ton ne W max = 20 ton ne W m ax = 2 0 to nne W m ax = 2 0 t onne

% Price 100% 120% 140% 140% 160%

De livery 18 weeks 21 Weeks 21 We eks 21 Weeks 24 We eks

AGMA 6004

Pitting Csf 1.21 2.77 3.53 4.27 4.72

Strength KsF 2.05 2.48 2.76 2.9 3.2

INDUCTION HARD &

GROUND

CARBURISED &

GROUND

HOFCARB &

GROUND

CARBURISED &

SELF ALIGNINGSOFT

QUENCH & TEMP

Large Pinion Rating Comparison

Strength Ksf

Pitting Csf

LARGE MILL&

KILN GEARS

TO 15M

GIRTH GEARS

1. SG Iron.

2. Cast Steel.

3. Austempered SG Iron.

4. Forged Fabricated.

5. Forged Fabricated Induction

Hardened.

CAPACITY

• Size -15m (50ft).

- 2.5m face x 15m dia.

• Hardness - to 52HRC (500BHN).

• Quality - AGMA 10 (DIN 5).

- 19 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

SG IRON CAST STEEL AUSTUF FORGING FABRICATED FORGING FABRICATED

NORMALISED NORMALISED AUSTEMPERED QUENCH & TEMP CONTOUR INDUCTION

INDIVIDUAL RISER FULL RING RISER SG IRON HARDENED

Material AS 1831-700-2

M

a

x AISI 4140

M

a

x AS 1831-700-2

M

a

x HofMod

M

a

x HofMod

M

a

xHeat Treatment Normalised Normalised Aus temperded Quench & Temp Inductio Hard

Hardnes s 280 BHN 330 BHN 280 BHN 360 BHN 380 BHN 400BHN 300 BHN 380 BHN Core =280 BHN 300 BHN

Case = 50 HRC 58 HRCDepth = 5 mm 10mm

Quality AGMA 10 (DIN 8) 10 A GMA 10 (DIN 8) 10 AGMA 10 (DIN 8) 10 A GMA 10 (DIN 8) 10 AGMA 10 (DIN 8 ) 10

Machining Hobbed Hobbed Hobbed Hobbed Hob / Hardcut

Example

Power Details Power (kW) 4500

G Speed (RPM) 14

Geometry Hofmann Hobbing (HSS) Skiving (Carbide Hob) Form Milling (Carbide) Finger Milling + Double Helic alExample Maximum Cap External Internal Gear External Internal Gear Exte rna l Internal Gear External Internal Gear

M odule Mn 2 5.4 Max Module 50 Mn 25 Mn 50 Mn 25 Mn 100 Mn 60 Mn 100 Mn 60 Mn Pressure An g 2 5° Max Press Ang 4 5° 45° 4 5° 4 5° 45 ° 45° 45 ° 45°

He lix Angle 5° 3 0' Max Helix Ang 4 5° 45° 4 5° 4 5° 45 ° 45° 45 ° 45°

Nos T eeth Z 282 Max No Tee th 700mm 700 700 700 700 700 700 700 Face Width F 860 Max Face Width 2500mm 500 2500 500 2500 600 2500 600 Outside Dia da 7247 Max Outside Dia 14000mm 14000mm 14000mm 14000mm 14000mm 14000mm 14000mm 14000mm Weight (t ) W 50 Max Weight 130 t 130 t 130 t 130 t 130 t 130 t 130 t 130 t

% Price Example 100% 130% 105% 125% 135%

Delivery Example 32 weeks 39 Weeks 34 Weeks 29 Weeks 31 Weeks

AGMA 6004 - F88 Pitting Csf 1.64 1.62 3.07 1.85 3.26

Strength KsF 1.9 2.00 2.24 2.35 2.61

MECH TESTS

Elongation (%) 3 6 3 16 16 Izod (J) 3 15 10 60 60

1.64 1.62

3.07

1.85

3.26

1.90 2.002.24 2.35

2.61

0

0.5

1

1.5

2

2.5

3

3.5

1 2 3 4 5

GEAR TYPE

Pitting Csf

Strength KsF

SA

FE

TY

FA

CT

OR

AG

MA

600

4 -F

88

FABRICATED FORGING QUENCH &

TEMPER

CAST STEELINDIVID RISERSNORMALISED

AUSTUFAUSTEMPERED SG IRON

FABRICATEDFORGING INDUCT HARD

SG IRONINDIVIDUAL RISER

NORMALISED

MECHANICAL TEST RESULTS

0

10

20

30

40

50

60

70

1 2 3 4 5

GEAR TYPE

Elongation(%)

Izod (J)

EL

ON

GA

TIO

N %

IZO

D J

CAST STEEL RING RISER NORMALISED

AUSTUFAUSTEMPERED SG IRON

FABRICATEDFORGING INDUCT HARD

SG IRONINDIVIDUAL RISER

NORMALISED

FABRICATEDFORGING QUENCH

& TEMPER

GIRTH GEAR RATING COMPARISON SAME SIZE BUT DIFFERENT HARDNESS AND QUALITY

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

FORGED STEELUse Forged Steel FabricatedGirth Gears to overcomeyour cast steel crackingproblems. Forged steelgives the highest crack andimpact resistance.

HOFALLOY FORGED MATERIALHofalloy 1 Forged Gear Rim Material conforms to:1) AGMA 2001 Grade 2

specification.2) Hardness 330 – 360

BHN.3) 3:1 Forging Reduction.4) Induction Hardenable.5) Site weld repairable in the

event of a catastrophic mishap.

STOCKED INSURANCE SPARE MATERIALUse one plate to suit a variety of gears On Site:1) FORGED HOFALLOY

plate can be used as an insurance spare to cover many different girth gears.

2) Reduces manufacturing lead time.

3) Lowers insurance premiums.

FORGED STEEL

FABRICATED GIRTH GEARS

CASTING defects and imperfections cause cracking and tooth breakout.

- 21 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

SITE AUDITSEvaluate Girth Gears and their conditions. Determine suitable forged steel rim plate –dimensions based on pitch, face w idth & Gear diameter. Order forged rim plate based on site audit. Rim plate can be ordered to suit a variety of Gears on site.

SITE GEAR INSPECTIONS• Full Dimensional inspections done onsite.• Diameters, Lengths, Hole PCD • Full Gear inspection including:

• Pitch.• Lead.• Involute.

• Hardness testing.• Crack detection.• Material chemical analysis.

DESIGN• CAD design w ith 3D modelling to

produce accurate manufacturing draw ings.

• FEA analysis to optimise the w eld sizing to keep stress levels to a minimum.

• Gear consulting.• Gear design & rating calculating to DIN

& AGMA standards.

FORGED STEEL• Rim plate can be held in stock until

required.• One plate can be purchased to suit a

variety of Gears on individual or corporate sites.

• Once forged steel is in stock, manufacture lead time can be signif icantly reduced.

OXY CUTTING• The forged steel is marked out & oxy-cut

to w idth to suit the specific gear to be manufactured.

• Purchase of material in advance (No holding fee) allow s the spread of costs over period of time.

BENDINGThe individual lengths of plate are then rolled to the specif ic radius required for your gear.• 6000 tonne roll pressing capacity.• Unlimited length.• 250mm thick x 3700mm w ide.

.

FABRICATION• Individual segments are fabricated to the

strictest of welding and inspection procedures.

• NDT Inspection including 3rd party NATA ultrasonics.

• Full penetration submerged arc w elds on critical joints.

• Stress relieved.

MACHINING• Proof Machined.• Finished machined.• Dimensionally inspected to

internationally recognised standards.• Full gear inspection including final mesh

testing.

INSTALLATION & AlignmentsExperienced team available to Plan, Manage & install your; Girth Gears, Pinion Assemblies, Gearboxes & Inching Drives.Fully Equipped w ith all tooling, for laser Aligning, Machining, Fabrication & Mill Drive Adjustments Ready for site w ork.

8 9

5 6

1 2 3

4

7

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

OPEN GEAR RECONDITIONING

PROCEDURE

1) WORN GIRTH GEARWith less than 0.5mm of involute wear.

2) WORN SOFT PINIONWith over 5mm of wear.

3) INSTALL HOFMANN CASE HARDENED PINION

4) APPLY H0FMANN PROCEDURE.1) Measure involute Wear on Gear.2) Clean and Crack detect gear using magnetic particle method.3) Install Hofmann case hardened Pinion. Case Hardness must exceed 55HRC.4) Laser align Drive Train.5) Accurately in-situ grind girth gear using the case hardened pinion as a master.6) Apply Hofmann Grafloscon A-C1 Ultra primer to pinion and gear.7) Inspect lubrication system and connect running-in lubricant Hofmann

Grafloscon B-SG00 Ultra.8) Start gear drive slowly increasing the power as the contact improves.9) Apply repair Chemical Etch Hofmann Grafloscon D-SG00 Ultra to heavy

contact areas until good contact is achieved.10) Monitor and completely document the installation procedure.

5) FINAL GEAR CONTACT 6) FINAL PINION CONTACT- 23 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

SELECTING OPEN GEAR RECONDITIONING PROCEDURE

SELECTING GEAR RECONDITIONING PROCEDURE

Measure involute wear on gear then select reconditioning procedure.

Procedure 1: If involute wear is less than or equal to 0.5mm => In-situ grind and chemical etch utilising a Hofmann case hardened pinion.

Procedure 2: If involute wear is greater than 0.5mm => Reverse open gear.

Procedure 3: If both flanks of the gear are worn => Re- cut the open gear.

Procedure 4: If insufficient material is left to re-cut the gear => Replace the open gear.

WARNING!!Do not install a new pinion against a worn open gear unless one of the above procedures (from 1 to 4) has been performed. The new involute form on the pinion would only contact the high points of the worn open gear and this can lead to:-

View of Open Gear showing substantial involute wear

• Extreme vibration and noise.• Severe wear and pitting on both pinion and gear.• High possibility of tooth breakout and destruction of • both the pinion and gear.

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

COAL CRUSHING GEARBOXES CONVEYOR GEARBOXES

CMM INSPECTION SHAFT MOUNTED ALIGNMENT FREE GEARBOXES

DOUBLE OUTPUT EXTRUDER GEARBOX

SELF ALIGNING, TWIN PINION MILL DRIVE GEARBOX

GEARBOXRANGE

STANDARD RANGE

SPECIALS

- 25 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

SELF ALIGNING DRIVES• Automatically maintains 100% gear

contact regardless of movement in foundations and/or driven component.

• Can use recirculating f iltered oil.• Reduced maintenance as alignment

checks and adjustments are eliminated.• Pow er to 10,000kW per gearbox.

GEARBOXES STANDARD• Completely designed and manufactured

in house using AGMA and DIN standards.

• Standardrange of multi stage drives.• Precision case carburised and ground

gearing to AGMA 14 for quiet reliable operation.

GEARBOXES SPECIALS• Special Gearboxes can be designed to

f it existing foundation as a direct replacement of your old drive. (Flender, Falk, Valmet etc.)

• Pow er upgrades, ratio changes and replacement parts available.

• Torque splitting gear drives.

INCHING DRIVESHofmann Engineering makes a range of inching drives to f it to new and existing mill and kiln drives. Features include:• Planetary main reduction.• Hydraulic or electric.• Integral or separate brakes.• Disengaging couplings.

BOGIE DRIVES• Complete motor, gearbox, coupling

assemblies for bogie w heel drives.• Spiral bevel gear input. These drives

are shaft mounted alignment free.

PLANETARY HIGH SPEEDPlanetary gearboxes for compact drive solutions. Case carburised gears, precision ground to ensure equal load sharing. Carbo-nitrided Internal ring gears. All gearing can be precision ground to DIN 3 (AGMA 15) to ensure quiet, smooth operation.

CONVEYOR DRIVE 3000KWConveyor drive gearboxes, shaft mounted or f loor mounted. Case carburised and ground gears. S.G. Iron Housings or Fabricated from Mild Steel.Supplied complete w ith cooling systems and condition monitoring if required.

CENTRIFUGE GEARBOX .Special purpose gearboxes designed and manufactured to meet the customer’s specification. This free f loating, inline drive replaces a complex and expensive planetary gearbox.

HIGH SPEED GEARBOXESHigh speed drives, speed increasing and speed decreasing, w ith white metal bearings w here appropriate. Gears ground to very high accuracy levels ( DIN 3). Units to 50,000 kW and 20,000 RPM input speed have been manufactured.

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

GEARBOX REBUILD DIVISION

- 27 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

ADVANCEMENT THROUGH TECHNOLOGY

using:

IMPROVED CASE HARDENED & GROUND GEARING

COMPUTERISED GEAR GEOMETRY & PROFILE OPTIMISATION

HIGH CAPACITY BEARINGS

IMPROVED SEALING & LUBRICATION

UPGRADE YOUR EXISTING GEAR DRIVES

MORE POWER & LONGER LIFE

QUIETER OPERATION

LEAK PROOF SEALING

RE-RATIO

NEW GEARBOXOLD GEARBOX

AUDITING YOUR GEARBOX REPAIR SHOP

Compare Others Hofmann

Do they have Gear Design and Consulting services? Are they members of any gear standard associations? (AGMA, DIN, ISO)

Do they have a certified Gear Inspection Laboratory to inspect gear accuracy?Can they provide computerized printouts of lead, involute and pitch?

Do they have a Co-ordinate Measuring Machine for checking bore alignment and size of gearbox housings?

Do they have gear manufacturing facilities for producing improved replacement gearing?

Do they have heat treatment facilities for replacement gearing, including qualified Metallurgists? Do they have carburizing, induction hardening, nitriding, quench & tempering and stress relieving facilities?

Do they have modern, climate controlled gear grinding facilities, capable of producing accurate gearing to DIN 3/AGMA 15?

Do they have a gearbox test bed facility for load test running gearboxes?

Do they have gearing trained site crews for installing and laser aligning gearboxes?

Do they have the equipment and know how to rebuild your gearboxes?

Hofmann Engineering has extensive experience rebuilding gearboxes, small and large, to exacting specifications. If you need your gearbox to run more efficiently Hofmann’s can help.

?

?

?

?

?

?

?

?

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

SUGAR MILL GEAR INSTALLATION & ONSITE SERVICES.• Consultation and Inspection of complete drive • train including detailed analysis and reporting.• Laser alignment and installation of the complete • drive train.

HOFMANN ONSITE GEAR RECONDITIONING PROCEDUREUsing the Hofmann case hardened pinion as the accurate master and then precision in-situ grinding and using a special chemical etchant to in-situ recondition the w orn mating gear.

DRAGLINE & SHOVEL SITE WORKHofmann Engineering completely:• Inspect,audit and condition monitor critical • dragline and shovel components.• Do complete site installation including machining • and w elding.

ONSITE MACHINING SLEW BEARING• Design, manufacture and operation of • specialized on-site machining equipment to • solve your site machining problem.• Perform large site machining projects to 14m • dia.

ONSITE SERVICE

CONSULTATIONINSPECTIONMACHINING

FITTING

WORLD WIDE MILL AND KILN SITE INSTALLATION & SERVICEInstallation by the Hofmann Site crew of Hofmann Engineering manufactured girth gear, and a tw in pinion self-align gearbox, inching drive & electric motor at a Gold mine in Ghana.

- 29 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

TRUNNION JOURNAL MACHINING AND REPAIR• Max dia: 3600mm.

• Remove/replace trunnion roller bearings

• using oil injection and specialized

• extraction and bearing installation jigs.

• Scrape in w hite-metal/bronze bearings.

RE-MACHINING TRUNNION FLANGE FACES• Max dia: 14000mm.• Onsite removal & installation of trunnion.• Onsite refurbishment & machining of mill • trunnions.

ONSITE MACHINING OF MILL SHELLS• Special trunnion journal alignment tooling • to insure that both trunnion journals are in-• line. • Mill refurbishment.• Shell crack inspection and w eld repairs • including stress relieving.

REPAIR TRUNNION BOLT AND LINER BOLT HOLES• Purpose manufactured tooling for • production drilling/boring and tapping.• Re-bore and sleeve w orn liner bolt holes • to prevent liner bolts f rom breaking.

OIL & GAS, RIG EQUIPMENT REPAIRSONSHORE & OFFSHORE• Onsite machining, f itting & laser • alignment.• Gearbox & gears manufactured and • repaired.• Pump and valves installed and serviced.

LASER ALIGNING• Laser alignments of drive trains for mills, • kilns, turbines etc. • Girth gear/pinion installation.• Gearbox bore laser alignment inspection• Engine block crankshaft bore alignment • inspection and rectification.

MACHINING GEARBOX MOUNTING FLANGE• Flange & bore refurbishment.• Site inspection and drafting.• Special purpose machinery designed and • manufacture to suit your application.• Bolt tensioning equipment.

LINE BORING ,WELDING AND ON-SITE MACHINING • Repair of bucket bores.• Onsite line boring – engine blocks, ship • propeller housings, crushers.• Line boring and drilling to 3m dia x 6m L.• Milling of keyw ays and surfaces.• Site Welding and heat-treatment.

KILN TYRE REFURBISHMENT BY IN-SITU GRINDING• Kiln roller and tyre refurbishment by • machining and grinding.• Crusher rolls in-situ grinding to remove • uneven w ear.

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

KILNSERVICES

WORLD WIDE KILN SERVICES

• Consultation

• Inspections

• Alignment Surveys

• Refurbishments

• Tyre / Roller surface Reconditioning

• Gear installations

• Maintenance Planning

RECONDITIONING:

Rollers and tyres can be machined,ground or linished to recondition tyreand roller surfaces, correcting anyuneven wear and or taper using ourpurpose built reconditioning unit.

Our purpose built reconditioning unit canbe adapted to suit most rotary kilndesigns and can be transported worldwide to meet customer requirements.

Tyre & Roller diameters are measuredprior to and after reconditioning toconfirm profiles are flat and parallel tothe centre line axis.

MAINTENANCE PLANNING:

Major maintenance projects needcarful planning to ensure timelyand correct performance.

Correct procedures and methodsrequired in order to obtainequipment performance on startup.

Alignment tolerances maintainedduring installations and repairoutages.

ALIGNMENT:

Survey carried out using hard contactand fixed datum method.

Tyre & Roller diameters are measuredduring normal operation with the aid ofelectronic measuring device that isaccurate up to 0.10mm. This allowaccurate profiling for wear conditionsand averaging for alignment

Basis of the alignment is to achievecorrect alignment of the units actualcentre line which in turn is positionedin relation to the meshingcharacteristics of the main drive girthgear and pinion.

- 31 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

1. KILN ALIGNMENT SURVEYINGSurvey by hard contact method.• Check alignment of the kiln.• Re-align kiln to ensure smooth running.

2. KILN CENTRELINE SETTINGThis enables datumns to be established from w hich future measurements can be taken.

3. ROLLER ALIGNMENTRollers are aligned using hard contact method from direct centre lines.

4. ROLLER & KILN TYER MEASUREMENTElectronic measuring of diameters accurate to 0.10mm.This is critical as part of the information needed to give correct kiln alignment.

5. MACHINING TYERS & ROLLERSMachining of roller by tool to obtain optimum material removal.Both kiln tyers and roller can be machined or ground on-site.

6. SHELL CHANGE-OUTShell change-out and straightening.• Shells can be site measured and then manufactured by us up to

15m in dia.• Site shell change out and straightening including in-situ sub arc

w elding can be performed by the Hofmann site team.

7. GIRTH GEARSGirth gear manufacture, installation, reversal, reconditioning and alignment.• Site measure pinions and gears.• Manufacture complete gearing in house.• Install and align w ith our site crew.• Site gear reconditioning available.• Hofmann open gear lubrication and lubricants also available.

SUGAR MILLS

PARTSAND

SERVICE

LOW SPEED PINIONS

• Through hardened (to 360 BHN).

• Induction hardened (to 55 HRC).

• Case-carburised (to 62 HRC).

• HofCarb carburised (to 62 HRC).

CAPACITY• Size: 1.6 m face x 2.0m dia.

• Quality: AGMA 12 (DIN 5).

LOW SPEED GEARING• SG Iron.• Cast Steel (to 320 BHN).• Austempered SG Iron (to 450 BHN).• Forged fabricated (to 360 BHN).• Forged fabricated induction

hardened (to 55 HRC).

CAPACITY• Size: 1.6 m face x 15 m dia.

• Quality: AGMA 10 (DIN 5).

RE-RIMMED GEARS• Remove old rim and weld new rim to

hub with full penetration welding.

Hofmann Engineering has the experience and technology to provide you with all of your sugar mill drive train needs. High & low speed gearing, shafts, lubrication and sealing solutions, crush roll pinions, planetary drives, consulting, onsite service and more.

- 33 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

HIGH SPEED GEARBOXES• Replacement gearing and new gearboxes.• Ratio changes and pow er upgrades.• Case-carburised to 62 HRC and precision • ground to AGMA 12 (DIN 5).• White metal bearing manufacturing and • reconditioning.

CRUSH ROLL PINIONSCast to 300 BHN.Forged to 300 BHN and CNC cut to AGMA 6 quality. Eliminates casting inclusions that can cause fatigue fracture.Induction hardened to 55 HRC and CNC hard cut to AGMA 6 gives 200% improvement in pitting and 70% improvement in bending strength.

CRUSH ROLL PLANETARYPlanetary drives, use electric motors and eliminate crush roll pinions w hile still allow ing centre distance adjustmentPrecision gears, case hardened and ground to AGMA 12 quality.Standard modular design minimises spare parts capital and can be changed out in less than one shift.

GEARBOX SPECIALSSpecial Gearboxes can be designed to fit existing foundations as a direct replacement of your old drive. (Flender, Falk, Valmet, David Brow n etc.)• Pow er upgrades, ratio changes and • replacement parts available.• Torque-splitting gear drives.

LUBRICANT SUPPLYHofmann Lubrication division has an agreement w ith Klüber Lubrication of Germany AG to supply a range of products, directly formulated to Protect the Gearing that w e design and manufacture.

This forms an integral part of our Gear Protection Package.

LOW SPEED JOURNAL BEARINGS• White metal• Bronze• Pedestals and caps• High tensile studs and nuts• Full reconditioning and installation • available.

GEAR RE-RIMMING• Old gear material tested to ensure material • compatibility• Rim machined off leaving bare diaphragm.• New forged rim w elded to diaphragm by • submerged arc full penetration w elding.• Full contour induction hardening to 55 HRC • and hard cutting to AGMA 10• Full NDT to ensure integrity.

ONSITE INSPECTION & CONSULTING SERVICE• Inspection and assessment of your mill • and drive train.• Failure analysis including Engineering • and Gearing design review . Finite • Element Analysis and Metallurgical • Analysis.

ONSITE SERVICE• Laser alignment of gear trains.• Gear and pinion installation.• Reconditioning of w orn gearing using • Hofmann Engineering’s reconditioning • procedure.• White metal and bronze bearing • installation including scraping.

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

OIL & GAS

PARTS AND

SERVICE

SUB-SEA BALL CHECK VALVESLarge 1500mm dia. Borsig Sub-sea Ball Check Valve completely overhauled and tested by Hofmann Engineering.

GAS LIQUIFYING PUMP MANUFACTURED AND TESTED UNDER LICENCE TO STORK.Hofmann Engineering continue to havelicensing agreements w ith recognisedOEM’s for the manufacturing, assembly,and shop testing of precision valves andpumps.

- 35 -

With Western Australia's largest heavy engineering facility operating 24 hours per day, 7 days per weekHofmann Engineering is able to offer an unparalleled range of services to its clients. Emergencyrepairs and rapid rebuilds can be conducted on a w ide range of machines, components and specialtools, complete w ith compliance documentation to most international codes and standards.

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

SUBMERGED ARC WELDING OF SUB-SEA BALL VALVEThe ball v alve is submerge arc welded and heat treated in an electric furnace (stress reliev ed). Welding performed to detailed w eld procedure.

BALL VALVE FULLY MACHINEDBall precis ion machined to giv e 100% clean up. Full magnetic particle and ultrasonic crack detection.

BALL VALVE FINISH GROUNDThe ball is Hard Chromed and then finish ground to a 0.02mm roundness tolerance and polished to a 0.4 micron surface finish.

BALL VALVE ASSEMBLYAssembly is handled by our specialist valve technic ians. Where required the assembly is carried out in a purpose built clean room.

BALL VALVE PRESSURE TESTINGDue to safety requirements many high pressure v alves are pressure tested in a below ground concrete w alled pit. Certification for the testing is prov ided.

SWAGING TOOL REBUILT AND MODIFIEDPile Reforming Tool for Goodwyn A Platform for straightening bent py lons. This tool w as re-engineered, part manufactured and then tested by Hofmann Engineering.

TOP DRIVE DRILLING SYSTEMSWe supply replacement parts including all gears as w ell as rebuild services.Gearing case hardened and ground to DIN 5 quality .

WINDLASSWe supply replacement parts including all gears as w ell as rebuild services.This includes both the capstan, brakes and gearbox driv e system.

TRIPLEX SLUSH PUMPSReplacement parts for common makes like National including gears, crankshafts, etc. Rebuild and repair serv ice.

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

• Standard Helical.• Planetary.

All makes overhauled and rebuilt after marketwith improved high performance casehardened precision ground gearing. Thisensures smooth, quiet, reliable operation.

• Flender.• Renk.• Valmet.• Hansen.• L&S• Metso• Clipper.• Gamesa.• Eickhoff.• Zollern.

WIND TURBINE

GEARBOXES

Slew Bearings - Induction hardened and precision ground..

WIND TURBINE GEARBOXES - New and Rebuilt.

- 37 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

ONSITE MACHINING & MEASURINGPrecision portable co-ordinate measuring machine for checking bore alignment and accuracy insitu.Portable line boring for remachining worn gearbox housing insitu.

HofmannCompare

SITE INSTALLATION AND SERVICEDo they have gearing trained site crews for installing and laser aligning gearboxes? Are they able to provide on-site machining services?

GEARBOX BACK TO BACK LOAD TESTINGDo they have a gearbox test bed facility for load test running gearboxes? Hofmann Engineering has full load gearbox test running to 2000kW.

GEAR GRINDING – PRECISION – EXTERNAL & INTERNAL

Do they have modern, climate controlled gear grinding facilities, capable of producing accurate gearing to DIN 3/AGMA 14 required to produce quiet running wind turbine gearing?

HEAT TREATMENTDo they have heat treatment facilities for replacement gearing, including qualified Metallurgists? Carburizing, induction hardening, nitriding, quench & tempering and stress relieving facilities? Gas carburising to 1800mm dia for the output stage gearing for wind turbines.

MACHINING / FABRICATION

Do they have gear manufacturing facilities for producing improved replacement gearing? Hofmann Engineering also fabricate and machine many of the wind turbine components.

CO-ORDINATE MEASURING MACHINE

Do they have a Co-ordinate Measuring Machine for checking bore alignment and size of gearbox housings? This is required for the planet carrier of the planetary stage on wind turbine gearboxes and components.

GEAR INSPECTION

Do they have a certified Gear Inspection Laboratory to inspect gear accuracy? Wind turbine gearing requires very high gear accuracies of DIN 3 or better.Can they provide computerized printouts of lead, involute and pitch?

GEAR DESIGNDo they have Gear Design and Consulting services and a full metallurgical laboratory for carrying out failure analysis? Are they members of any gear standard associations? (AGMA, DIN, ISO)

AUDITING YOUR WIND TURBINE GEARBOX REPAIR SHOPDo they have the equipment and know how to rebuild your gearboxes?

?

?

?

?

?

?

?

?

?

Others

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

COMPLETE TURBINE WORKSHOP OVERHAUL• 200 Ton Crane Facilities

• Bead Blasting Facilities

• Metrology Laboratories

• Turning to 4m dia x 35m long

• 6 x Floor borers up to 18m travel

• 9 x Vertical Borers (4 CNC)

• 5 x Co-ordinate Measuring Machines

• 2 x Portable Measuring Machines

• 2 x Laser Tracker

• Largest Heat Treatment Facility in Australia

• 7 x 5 axis machines including hard machining of titanium

- 39 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

ENERGY POWER

STATIONS

Steam Turbines

Coal Pulverising

Gas Turbine Gearboxes

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

MANUFACTURE• New seals from castings (including S/S)

or forgings. Re-engineering from samples.

REFURBISHING• Re-caulking of seal strips to refurbish

diaphragm seals.

MACHINING• Machining a casing on a floor borer.

Check split face for distortion and remachine if necessary.

MACHINING• Rotor of approx Ø3m. Removal of

blades and finish machining of new blades.

INTERNALS OF A GAS TURBINE GEARBOXAbility to fully inspect, manufacture and refurbish all components.• Precision Grinding of the gearing to Din

3 quality.

REFURBISHINGGas turbine gearbox that is being stripped, assessed, completely refurbished and load tested.

COAL MILL GEARBOX REFURBISHMENTS• Onsite removal• Manufacture of components• Worm & w heelmanufacture• Total refurbishment• Onsite installation

ONSITE SERVICESOnsite measuring using our portable coordinate measuring machine. This can measure in a single set up Ø2.4m to an accuracy of 0.025mm (0.001”). Photo show s performing f latness check on a low er casing. Compliments our Laser Tracker w hich can span 25m in one setup.

SPARE PARTS

• Studs from High Temp Steel

• S/S Springs

• Governor valves, rollers, positioner etc

• Cylinder locking strips

• Control shaf ts

OVERHAULING A COMPLETE TURBINE ARRANGEMENT

• Total overhaul w ithin the one premises

• Customer off ice available on request.

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

UDD MECHANICAL CONVERSIONSHofmann Engineering Pty Ltd completely designed, manufactured and installed the mechanical drive for the UDD (Universal Dig & Dump) dragline.

Our concept provided a free-floating, alignment-free, shaft-mounted, modular gearbox that bolts to the side of the rope drum. This gearbox contains HofCarb carburized and precis ion ground gearing with a filtered oil recirculation system.

Being shaft-mounted and modular enables this gearbox to be pre-test run and changed out in under one shift without requiring any re-alignment.

INPUT MOTOR PINIONS• Double Helical Hard Cut Narrow

Gap. Case Carburised to 60-62HRC & finished to AGMA 12 quality.

• Single helical case hardened. These are fitted with eccentric cartridges and spherical roller bearings. This assembly fits straight into the Bucyrus hois t or drag gear case bore. The eccentric cartridges enable simple mesh adjustment without having to re-bore the gear case.

• Quench & tempered to 360 BHN and cut to AGMA 10 quality as per OEM design.

• Carb Bearing Alignment Technology with Eccentric Cartridges can also be used on Bucyrus machines to give over a 200% improvement in bearing life.

SWING RACK ASSEMBLIES• Alloy Steel Forged Rack Rims Q&T to

330BHN Combined with fabricated construction.

• High performance racks with a unique heat treatment procedure that increases the hardness to 450BHN.

• Swing Pinions are full contour induction hardened.

OEM Design

Hofmann increased face w idth narrow gap

DRAGLINE

REPLACEMENT PARTS

BUCYRUSMARION

P&HPAGE

UDD MECHANICAL CONVERSIONS

- 41 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

DRUM GEARS• New Forge Fabricated Gears 330 to

360BHN precision cut to AGMA 10.• M echanically Re-RimmedGears

Replace only the gear teeth to save time and money.

• Re-Rimmed GearsRemove old rim and w eld new rim to hub w ith submerged arc full penetration w eld.

INTERMEDIATE ASSEMBLY• Intermediate Gear Forge fabricated,

staggered tooth, double helical, through hardened 330 to 360BHN, precision cut to AGMA 10 quality.

• Intermediate ShaftForged, spline coupling carburized to 60-62HRc, Precision cut to AGMA 12 quality.

• CARB Bearingsincrease bearing life by up to 200%.

SELF ALIGNING PINONS• Self-aligning Gearing technology

maintains 100% contact in operation.• Double helical zero-gap 19” face width,

carburized to 60-62HRc and precision ground to AGMA 12 quality.

• Spherical Bearingscarburized to 60-62HRc and lapped for 100% contact, oil lubricated.

PROPEL GEARS• New or Reclaimed hub. • Reversible gear rim on the same side

hub thus doubling the life of the gear.• Mechanically Fastened Rim can be

replaced independently of hub.• Gear Rim Forge fabricated, through

hardened gear 330 to 360BHN, precision cut to AGMA 10.

PROPEL SHAFTS• New Shafts of high quality alloy forging

w ith a higher forging reduction.• Quench & Tempered to achieve

hardness of 320-360 BHN.• Pol ished & Shot Peened Radii &

Transitional areas to increase strength.

PROPEL ECCENTRIC• Eccentr ic casting fully machined in-

house• Forged fabricated version from

AS1444-4330 steel• Full refurbishment by welding and re-

cutting of splines

ROPE SHEAVES• New forged fabricated full contour

induction hardened to 55HRC for a case depth of 6mm.

• Repaired sheavesby full penetration submerge arc w elding the w orn groove and then induction hardening.

8200 HOIST ARRANGEMENT• M odular Design allows quick and easy

change out.• Rigid constructionreduces distortion

and gear misalignment.• Interchangeability between gearboxes

and gearing.• Self-aligning technology maintains

100% contact during floor deflection.

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

SHAFT MOUNTED GEARBOX• M odular Design allows quick and easy

change out in one shift.• Rigid Construction reduces distortion

and gear misalignment.• Free Floating isolated from dragline floor

distortion.• Alignment Free gearbox bolts directly to

the hoist drum.

ROPE DRUM DESIGN• Fini te Element Analysishas been

conducted in order to eliminate the inherent OEM rope drum internal stiffener cracking problem

• Hofmann Engineering Pty Ltd designremoves all internal lateral stiffeners and increases the drum shell forging thickness to reduce stress.

ROPE DRUM MATERIAL• Hofalloy2 Forged Plate has been

specifically formulated by Hofmann Engineering Pty Ltd to accommodate industry requirements. The result is a Quench & Tempered high alloy steel suitable for induction hardening, machining and fabricating. Stocked quantities are maintained in order to reduce lead-times

ROPE DRUM ROLLING• The stocked Hofalloy forged plate rolled

into a perfect cylinder using Hofmann Engineering Pty Ltd.'s, 5000 ton Vertical Rol l Press.

• The above drum is 150mm thick 1900mm long and w ith an OD of 2947mm, in its rolling condition it is approx. 300 BHN.

ROPE DRUM MACHINING• All Rope Drums are fully machined in-

house from the initial fabrication preparations right through to cutting of the rope grooves, turning of the flanges and drill and tapping of the holes. This ensures that complete control of the project is maintained and the highest standards of quality are guaranteed.

GEARBOX MODULE• M aintenance and testing of gearbox can

be done in a clean w orkshop rather than inside the dragline.

• Installation requires less skill and accuracy with the self aligning pinion.

• Gearing forged, HofCarb carburised to 60-62HRc, precision ground to AGMA 12

INDUCTION HARDENING • New Forge Steel drums fully fabricated

using full penetration w elds and then full contour induction hardened to 55 HRC for a case depth of 6mm.

• Worn Drums. All cracks removed before building up w ith 30mm of submerged arc w elds and then induction hardening

ROPE DRUM CLAMPS• Unique design developed by Hofmann

Engineering Pty Ltd.• Clamp is integrated into the rope drum

center f lange.• Precision machined.• Case Hardened. • Optimized for w eight. • Greater clamping force.

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

1 2

3 4

OEM Drum Hofmann Drum

5 6

PROPEL CAMSHAFT/ASSLY• New quality high alloy forgings either

in 4340 or EN26 Quench & Temperedw ith transition areas polished & shot peened.

• The propel cam can be w eld repaired to improved hardness or manufactured as a new casting.

SWING SHAFTS• New shaftsof high alloy forged steel• Repair Worn out splines and bearing

Journals to as-new condition using a technically advanced, individual w eld & Heat Treatment procedure.

SWING PLANETERY

• The swing gears are manufactured from high quality alloy forgings and heat treatment to increase load carrying capacities.

• All the gearings are ground to higher AGMA quality

RACK SEGMENTS.

• Swing Racks Forged fabricated design w ith High Alloy steel forged segment.

• Induction Hardened full contour induction hardened to 45-49HRc 8mm thick case.

• Impact Resistant Core hardness of 280-310BHN.

SWING RAILS & ROLLERS• Upper and Lower Rails High Alloy steel

forging Q&T to 340-360BHN and precision CNC machined.

• 3rd Rail Design.• Rol lersHigh Alloy steel forging Q&T to

410-415BHN and precision CNC machined & Flangeless Roller design

• The rails & rollers are trial assembled using our laser tracker.

. SWING PINIONS• Forged High Alloy steel precision

ground to AGMA12.• Induction Hardened full contour

induction hardened to 54-58HRc 8mm thick case.

• Impact Resistant Core hardness of 280-310BHN.

CENTRE PINTLE• Designed using FEA modeling to

reduce magnitude of stress and reduce stress concentrations.

• New forged steel construction to overcome cast steel cracking problems.

• Forged steel Centre Pintle used on P&H 9020 in operation since 2002.

SWING BASE (TUB)

• Full onsite measure, in-house 3D modelling and design of the complete Tub, Racks, Rails, Rollers & Centre Pintle

SWING BASE (TUB)

• The five individual modules are fully assembled in our w orkshop for your inspection prior to transporting to site & erection into your one piece Base

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Internet: Email:

HOFMANN ENGINEERING PTY LTD3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

HOIST GEARBOX PINIONS• Forged alloy steel• Case Carburised Pinion, 58-62HRc,

precision ground to AGMA 12.• As per above examples of P&H 4100A

Hoist Input Pinion, and Bucyrus495 Hoist Intermediate Pinion.

SWING PINIONS• Pinion Shaft Quenched & Tempered• Induction HardenedGear teeth & Spline

before f inally shot peening the stressed shaft area. The F.E.A. performed on this re-design confirms a 50 x life improvement.

• Pinion can also be supplied fully assembled w ith Bearing & Cartridge ready to install.

HOIST ROPE DRUMS• New Forge Fabricated alloy steel rope drum,

Induction hardened 56-58HRc.• Induction hardeneddrum seal.• New Forged Alloy Steel Drum Shafts

through hardened.• Service Exchange and re-lagging available.

HOIST DRUM GEARS• New Forge Fabricated Drum Gear 330-

360BHN core hardness.• One piece T-section construction.• Full Contour Induction hardenedgear teeth

to 54-58HRc and precision ground to AGMA 10 quality.

SHOVEL

REPLACEMENT PARTS

BUCYRUSMARION

P&HPAGE

- 45 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

SPLIT SWING GEAR ADVANTAGES: • Shovel only need be separated not de-decked• Replaceable thrust rail• Universal bolt pattern• Stronger, harder teeth

FULL CONTOUR INDUCTION HARDENINGalong full involute without tempering back the tooth tip.

The effective case depth is varied from 8mm at the tooth tip to 10mm to eliminate a hard brittle tooth tip.

SWING SHAFT ASSEMBLIESImprove the life of your Swing Shafts with Hofmann

Engineering Pty Ltd positive stop shoulder design that prevents the sleeve moving during thermal expansion thus

eliminating loss in bearing preload.

10mm

8mm

Positive stop

Sleeve design Shaft design

Fitted bolting sleeve also helps retain the split joint.

2 Fitted Dowel Bolts with Hofnuts secure the split line with 190T of clamping force.

HOFMANN BOLTED SPLIT LINE DESIGNthe solution to split line tooth cracking

Positive shoulder on shaft prevents the bearing sleeve moving during operation

thus bearing preload is maintained

Tapered joint face and Hofnuts prevent tangential separation force and hence fatigue cracking

Replaceable Thrust Rail

SHOVEL SWING GEARS

& PINION SHAFT

ASSEMBLIES

P&HMARION

BUCYRUS

- 46 -

+61 8 9279 5522+61 8 9279 9386

Telephone:Facsimile:Net: Email:

HOFMANN ENGINEERING PTY LTD

3 ALICE STREET, BASSENDEAN, PERTH, WESTERN AUSTRALIA 6054

Since 1969 Hofmann Engineering has p rovided specialist engineering services t o Australia’s industry leaders.

Quality Assurance certification by Lloyds co mplements our total quality culture.

Ou r commitment to continuous quality-improvement touches every aspect of o u r products, services and customer su pport.

1. Second reduction sun pinion eccentric thrust kit to reduce wear and prevent damage to pinion.

2. Induction hardened 43Tooth propel shaft to 54-56HRc to give substantial fatigue cracking resistance.

3. 43Tooth output spline is upgraded to 47Tooth spline for higher load carrying capacity.

SHOVEL PLANETARYGEARBOXES

P&H 2800XPAP&H 2800XPB

P&H 4100AP&H 4100XPBBUCYRUS 495B

BUCYRUS 495HR

PROPEL&

SWING

HOFMANN UPGRADED PLANETARY TRANSMISSIONSNew or Service Exchange. Gain more life from your transmissions

SERVICE EXHANGE PROGRAM:

1. Full strip and assessment.

2. Replacement of bearings and seals.

3. NDT inspection of all components.

4. “Failed Steel” repair/replacement.

5. Reassembly and test run.

6. Comprehensive service reports.

1. Higher quality materials and heat treatment to increase load carrying capacity.

2. SKF bearings for superior quality and life.