LEADERS IN CORROSION PREVENTION & Denso Protal liquid...

Transcript of LEADERS IN CORROSION PREVENTION & Denso Protal liquid...

LEADERS IN CORROSION

PREVENTION &

SEALING TECHNOLOGY

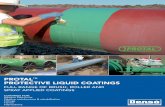

Denso Protal liquid

coating for the

rehabilitation of

pipes, valves, welds,

bends and tees

Volume 14 Number 11 - NOVEMBER 2014

®

SPILLS

A quick response to

Barry Cleveland and

Linda Henning, Elastec/

American Marine, USA,

discuss the use of oil

spill response systems to

clean up pipeline spills

quickly and efficiently.

In a perfect world, pipelines never fail. But ours is

an imperfect world. Leaks from ageing pipelines,

corrosion, the type of material being transported,

vandals and even oil terrorism can cause significant

environmental and economic damage. If material escapes

from a pipeline and is not properly contained, it may

travel to inland watercourses damaging sensitive habitats.

Residential neighbourhoods have even been threatened by

pipeline spill emergencies. Coastal and offshore pipeline

spill incidents can also threaten harbours and oceans

causing millions, and in some cases, billions of dollars

in lost production, lawsuits, fines, and response and

restoration operations. Beyond dollars, the negative public

SPILLS

Figure 1. The Rapid River Response System (R3S) was conceived by

responders for use in the shallow and fast moving river systems.

perception of the pipeline company’s reputation, integrity

and goodwill can take years, even decades, to restore.

Pipeline companies are committed to being proactively

response-driven by having trained, employee-dedicated

responders, reliable, reputable spill response contractors,

current emergency response plans and oil spill recovery

equipment that is designed for site-specific situations –

equipment that is simple to use, easy to deploy and lives

up to its performance claims.

Elastec, headquartered in Carmi, Illinois USA, is

the largest manufacturer of pollution control and oil

spill response equipment in the Western Hemisphere.

The company has products in more than 145 countries,

offices in China, India and Turkey, and a network of

dealers spanning the globe. The company’s passion is to

understand the challenges oil spill responders face in

various inland and offshore scenarios. Elastec’s dedication

to support responders and protecting the environment

inspires a constant quest to improve and develop new and

innovative oil spill response systems, from deployment to

recovery.

Oil spill response systemsElastec is perhaps best-known for its line of smooth- and

grooved-drum skimmers. The patented or pneumatic-

powered units can recover a variety of oil viscosities

with very little water pickup. The diesel or electric

power units used to operate them and the pumps to

transfer the recovered oil for storage or disposal are also

manufactured by Elastec.

And Elastec is currently bringing to market the first

of its much-anticipated X SKIMMER line, an advancing

offshore oil spill response system, featuring the patented

grooved disc technology that captured the US$ 1 million

top prize in the 2011 Wendy Schmidt Oil Cleanup X

CHALLENGE international competition.

Elastec has had substantial success in manufacturing

oil response systems for inland incidents, which is where

the majority of pipeline spills occur. The company builds

a range of trailer-mounted vacuum systems capable of

removing liquids, solids and sludge from land or water.

Smaller mobile, portable vacuum systems such as the

Elastec MiniVac and the All-Terrain Vac are also available,

and all are well-suited for cleaning up pipeline spills.

Elastec’s product line also includes multipurpose

crawler carriers and all-terrain vehicles, amphibious

crawlers, a variety of portable incinerators for onsite

waste disposal and a range of floating barriers, oil

containment booms, dispersant spray systems, temporary

storage tanks, workboats and accessories.

And if a pipeline ruptures at sea and requires

controlled burning of the oil, Elastec manufactures

American Fireboom and Hydro-Fire™ Boom Systems. Both

were used extensively in the wake of the 2010 Deepwater

Horizon spill in the Gulf of Mexico, when Elastec was

contracted by BP America to supervise the controlled

burn operation.

“We are very familiar with the challenges of pipeline

spill response, and we manufacture equipment to meet

those challenges,” said Chief Executive Officer Donnie

Wilson.

One of those is the Rapid River Response System (R3S),

a towed sweep and recovery system, specifically tailored

Figure 2. Donnie Wilson, Elastec/American Marine Chief

Executive Officer, led a team of responders during the 2010

Gulf of Mexico oil spill. His team spearheaded the controlled

burn operations.

Figure 3. The ELASTEC MiniVac (shown here with optional

All Terrain Tracks) can easily be towed by small vehicles to

help respond to remote locations that larger vacuum systems

cannot access.

REPRINTED FROM NOVEMBER 2014 / World Pipelines

to provide responders with all the tools necessary to

clean up pipeline spills quickly and efficiently in wide,

fast, shallow waters. It includes a workboat and skimming

vessel, a BoomVane™ or two, containment boom, towable

bladder(s), hoses and rigging. An oil spill aerial surveillance

system is even available.

Challenging environmentsRiver widths and isolation, limited access, the amount

of channelling around islands, sand bars and inaccessible

shorelines make locating effective control points

extremely difficult, sometimes impossible, especially in

remote areas. A control point is a predetermined location

to deploy spill containment and recovery operations with

a pre-calculated high degree of success. Rapids and falls

can further limit adequate response locations, and the

sheer size of the territory and width of the rivers makes

establishing control point sites impractical.

The Elastec R3S is mobile, transportable by road,

water, rail or air and is capable of being transported

quickly to the site of the incident and then deployed at

once. Operable by just a few trained personnel, having

the potential to recover and store large volumes of the

contaminant, and be largely independent of control points

and shore facilities, pipeline emergency responders are

finding that the R3S is a necessity when incidents occur

near wide, fast and shallow rivers.

At the front of the system is a towboat or workboat,

on each side of which a 0.5 m BoomVane is attached.

Each of the BoomVanes has 150 ft (50 m) of Elastec

OptiMax boom in tow, sweeping a wide path of water

and funnelling oil to the collection system

incorporated into a Kvichak (Kwee-jack)

rapid response skimming (RRS) vessel in

the apex of the boom. The Kvichak RRS is

a 30 ft, self-propelled skimmer boat with

an integral MARCO Filterbelt oil and debris

recovery system. Its high recovery efficiency

and ability to collect spilled products

ranging from jet fuel to emulsified crude

oil performs well in either stationary or

advancing mode.

Trailing the Kvichak RRS skimmer vessel

is a reusable, 3.8 m3 Elastec storage bladder,

capable of accepting up to 1000 gallons

of fluid and, when full, drawing less than a

metre of water. What is unique about this

system is the use of the BoomVanes to keep

the mouth of the sweep open behind a

single towing vessel. By adjusting towlines,

control lines and forward speed, the crew of

the towing vessel can control the width of

the sweep opening: wide open for skimming,

closed to avoid obstacles or for transit to a

different site, or anything in between.

Elastec builds workboats ideal for

this system, but any vessel capable of

manoeuvring at a slow speed can be

Figure 4. Over 400 burns were conducted during the 2010 Gulf

of Mexico oil spill, some lasting up to 12 hours.

Figure 5. Jeff Cantrell, co-founder of Elastec, monitors an oil burn in the Gulf.

The performance of Elastec’s Hydro-Fire® Boom and American Fireboom in the

Deepwater Horizon oil spill in the Gulf of Mexico has been officially recognised.

The company set a GUINNESS WORLD RECORDS® title for the “Longest

Continuous Burn of Oil Spill at Sea”.

World Pipelines / REPRINTED FROM NOVEMBER 2014

employed to tow it. The vessel must also have adequate

deck space to accommodate the BoomVanes and boom

enroute to the site.

The system works well in shallow water: the Kvichak

RRS draws 0.79 m empty and 1.09 m full, and the

BoomVanes draw just 0.55 m.

Effective in fast water, the skimming and towing vessels

operate together, drifting downstream with the river while

maintaining a one knot relative velocity. This alternative

approach to conventional fixed control point operations

also permits the response to move downstream, with

the spill, while continuing recovery operations. The

alternative, a fixed shore-based deployment, has one shot

at intercepting the oil – and if the oil gets by, the fixed

installation fails.

The R3S can be trailered to any feasible waterside

launch point and, if required, placed in the water at a

boat launch or lowered into the stream by crane from a

riverbank, road bridge or rail car.

The system is designed to be operated by just five

responders, providing a significant saving in labour costs,

training and remote logistics. Each component is also

available separately, and new systems can be configured

for specific needs.

Elastec works closely with pipeline environmental

and emergency response managers and consultants to

determine equipment engineering designs for specific

situations. Based upon experienced tactical knowledge

and innovative scientific technologies, for over 20 years,

Elastec continues to grow by developing innovative

response systems and response equipment training.

One major pipeline company recently purchased boats,

drum skimmers, power units, ATV tankers, amphibious

crawlers, reels, containment boom, a BoomVane, bladders,

pillow tanks, water barriers and absorbents from Elastec to

standardise equipment across all response locations and

to synchronise training and familiarity of the equipment.

Safety: the overarching goalPipelines are the energy arteries of the world, transporting

oil, natural gas, gasoline, jet fuel and chemicals which

connect the activities of our daily lives across continents.

Pipeline safety is the overarching goal, superseding all

ambitions, by any reputable pipeline company. The safety

and protection of the public, response personnel and the

environment are at the very heart of pipeline integrity.

Even with established pipeline safety precautions,

inspection and maintenance best practices, accidents,

caused by man, nature or time, will happen. The mission

at Elastec is to design, engineer and manufacture oil

spill response systems to contain, recover and assist the

responders who fight to protect our environment and

those who live with in it.

REPRINTED FROM NOVEMBER 2014 / World Pipelines