lcd

-

Upload

abhishek-upadhyay -

Category

Engineering

-

view

700 -

download

4

Transcript of lcd

1

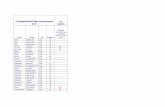

TABLE OF CONTENT

Certificate ……………………………………………………………..i

Acknowledgement……………………………………………………..ii

Abstract ……………………………………………………………….iii

CHAPTER 1: INTRODUCTION TO PROJECT

1.1 Brief Description of Project..........................................................2

1.2 Scope of project………………………………………………….2

1.2 List of Applications........................................................................2

CHAPTER 2: PROJECT DETAILS

2.1 Detailed Description of the Project..............................6

2.2 Working principle with the help of circuit diagram.......6

CHAPTER 3: METHODOLOGY

3.1 Process followed ......................................................15

3.2 Programming..............................................................16

CHAPTER 4: TESTING AND VALIDATION OF RESULT….20

CHAPTER 5: FUTURE SCOPE...............................................................21

CHAPTER 6: CONCLUSION.................................................................22

REFERENC

APPENDIX

2

CHAPTER 1:

INTRODUCTION TO PROJECT

1.1 Brief Description of Project

This is an interesting idea in which a message is displayed on an LCD screen whenever a

sound is produced. The message remains on LCD for a short duration of time and then

disappears. This topic demonstrates the interfacing of a sound operated circuit and LCD

display with the pic microcontroller (16f73). The circuit can be used to display welcome

message at entrance; or warning messages at public places. It can also be used to aid

communication for deaf and dumb people.

1.2 Scope of Project

In a future we can modify sound activated massage display as sound operated massage

display a what we are saying that all are display on the lcd screen by advancing and

connecting it sound module and memory in the present circuit of project.This can be help in

to produce smart notice board at school, collage, railway station, hospital etc. where the

immediate announcement are required after very small interval of time.

1.3 List of Applications

This system has various following application

a. Used to display welcome massage at entrance.

b. Warning massage at public place.

c. It can also be used to aid communication for deaf and dumb people.

3

CHAPTER 2:

PROJECT DETAILS

2.1 Detailed Description of the Project

It is LCD sound activated display using pic microcontroller (16f73) in which we use

microphone to sense any type of sound and the massage is display on the lcd

screen.The message remains on LCD for a short duration of time and then disappears..

2.2 Working principle with the help of circuit diagram

4

The circuit consists of four major modules, namely, a sound sensor, an amplifying circuit, a

control circuit and a display module. A switching circuit is also employed after the amplifier.

Any sound, say clap, is detected by a microphone (condenser mic) which acts as the sound

sensor. This mic is connected to a two stage transistor amplifier. The mic output is thus

amplified to a suitable level so that it can be detected at the TTL logic.

The output of the amplifier is coupled with a transistor switch. Whenever a high voltage

output is received from the amplifier, it generates a pulse. The transistor switching circuit

also ensures that a high TTL logic is not received at the microcontroller due to noise signals.

The pulses, from the switching circuit, are fed to the microcontroller 16f73's pin which is

programmed to detect the pulses. Whenever a high pulse at microcontroller input is detected,

a message ‘MAHARISHI MARKENDESHWAR UNIVERSITY’ is sent to a 16x2 LCD. The

message remains on the LCD display for a short duration after which it is cleared again. The

message is repeated whenever a high pulse (due to clap sound) is received by the controller.

The data pins of the LCD are connected to port P2, while the control pins (RS, R/W & EN)

are connected to pins 1-3 of port P1, respectively. The microcontroller receives sound pulses

through the first pin of port P0.

6

Power Supply Circuit:-

A power supply is an electronic device that supplies electric energy to an electrical load. The

primary function of a power supply is to convert one form of electrical energy to another and,

as a result, power supplies are sometimes referred to as electric power converters. Some

power supplies are discrete, stand-alone devices, whereas others are built into larger devices

along with their loads. Examples of the latter include power supplies found in desktop

computers and consumer electronics devices.

Every power supply must obtain the energy it supplies to its load, as well as any energy it

consumes while performing that task, from an energy source. Depending on its design, a

power supply may obtain energy from various types of energy sources, including electrical

energy transmission systems

7

Transformer:-

Electrical power transformer is a static device which transforms electrical

energy from

one circuit to another without any direct electrical connection and with the

help of mutual induction between two windings. It transforms power from one

circuit to another without changing its frequency but may be in different

voltagelevel.

1. Bridge Rectifier:-

The four diodes labelled D1 to D4 are arranged in “series pairs” with only two diodes

conducting current during each half cycle. During the positive half cycle of the supply,

diodes D1 and D2conduct in series while diodes D3 and D4 are reverse biased and the

current flows through the load.

8

Capacitor:-

A capacitor (originally known as a condenser) is a passive two-terminal electrical

component used to store energyelectrostatically in an electric field. The forms of

practical capacitors vary widely, but all contain at least two electrical

conductors(plates) separated by a dielectric (i.e. insulator). The conductors can be thin

films of metal, aluminum foil or disks, etc. The "nonconducting" dielectric acts to

increase the capacitor's charge capacity. A dielectric can be glass, ceramic, plastic

film, air, paper, mica, etc. Capacitors are widely used as parts of electrical circuits in

many common electrical devices. Unlike a resistor, an ideal capacitor does not

dissipate energy. Instead, a capacitor stores energy in the form of an electrostatic

field between its plates.

Resistor:-

The electrical resistance of a circuit component or device is defined as the ratio of the voltage

applied to the electric current which flows through it. If the resistance is constant over a

considerable range of voltage, then Ohm's law, I = V/R, can be used to predict the behavior

of the material. Although the definition above involves DC current and voltage, the same

definition holds for the AC application of resistors.

9

Voltage Regulator:-

A voltage regulator is designed to automatically maintain a constant voltage level. A voltage

regulator may be a simple "feed-forward" design or may include negative feedback control

loops. It may use an electromechanical mechanism, or electronic components. Depending on

the design, it may be used to regulate one or more AC or DC voltages.

Electronic voltage regulators are found in devices such as computer power supplies where

they stabilize the DC voltages used by the processor and other elements. In

automobile alternators and central power station generator plants, voltage regulators control

the output of the plant. In an electric power distribution system, voltage regulators may be

installed at a substation or along distribution lines so that all customers receive steady voltage

independent of how much power is drawn from the line.

Led:-

A light-emitting diode (LED) is a two-lead semiconductor light source. It is a basic pn-

junction diode, which emits light when activated.[7] When a fitting voltage is applied to the

leads, electrons are able to recombine with electron holes within the device, releasing energy

in the form of photons. This effect is called electroluminescence, and the color of the light

(corresponding to the energy of the photon) is determined by the energy band gap of the

semiconductor.

An LED is often small in area (less than 1 mm2) and integrated optical components may be

used to shape its radiation pattern.

10

INTERFACING DIAGRAM OF LCD WITH 16f73

A 16x2 LCD means it can display 16 characters per line and there are 2 such lines. In this LCD each

character is displayed in 5x7 pixel matrix. This LCD has two registers.

1. Command/Instruction Register - stores the command instructions given to the LCD. A command

is an instruction given to LCD to do a predefined task like initializing, clearing the screen, setting the

cursor position, controlling display etc.

2. Data Register - stores the data to be displayed on the LCD. The data is the ASCII value of the

character to be displayed on the LCD.

PIC 16F73

fig :- 16f73/72

11

PIC is a family of modified Harvard architecture microcontrollers made by Microchip

Technology, derived from the PIC1650 originally developed by General Instrument's

Microelectronics Division. The name PIC initially referred to "Peripheral Interface

Controller" now it is "PIC" only.

PICs are popular with both industrial developers and hobbyists alike due to their low cost,

wide availability, large user base, extensive collection of application notes, availability of low

cost or free development tools, and serial programming (and re-programming with flash

memory) capability.

LCD Display

Fig :- lcd diplay

A liquid crystal display is a special thin flat panel that can let light go through it, or can

block the light. (Unlike an LED it does not produce its own light). The panel is made up of

several blocks, and each block can be in any shape. Each block is filled with liquid

crystals that can be made clear or solid, by changing the electric current to that block. Liquid

crystal displays are often abbreviated LCDs.

Liquid crystal displays are often used in battery-powered devices, such as digital watches,

because they use very little electricity. They are also used for flat screen TV's. Many LCDs

work well by themselves when there is other light around (like in a lit room, or outside in

daylight). For smartphones, computer monitor, TV's and some other purposes, a back-light is

built into the product.

14

CHAPTER 3:

METHODOLOGY

3.1Process followed with the help of block diagram

IF NO

Fig no 3.1.1:process follow(pcb designing)

COLLECTION OF

COMPONENT/RESOURCES

COMPONENT PLACEMENT

SOLDERING+ ROUTING

PROGRAMING

TESTING

POWER SUPPLY BLOCK

CONTROLLER BLOCK

DISPLBLOCK

VALIDATION

PROJECT COMPLETED

15

PCB Board

We created a circuit that enabled our robot to follow taped lines based on the light reflected

off the ground. The robot is capable of following the lines by comparing light on either side

of the different colored tape using light sensors. Through this experience we have learned the

basics of circuits, motors,sensors, comparators, and gears.A printed circuit

board (PCB)mechanically supports and electrically connects electronic components using

conductive tracks, pads and other features etched from copper sheets laminated onto a non-

conductive substrate. PCBs can be single sided (one copper layer)

Fig no 3.1.2:pcb board

Component Placement

After the component and board have been cleaned, you are ready to place the components

onto the board. Unless my circuit is simple and only contains a few components, i will

probably not be placing all the components onto the board and soldering them at once. Most

likely i will be soldering a few components at a time before turning the board over and

placing more. In general it is best to start with the smallest and flattest components (resistors,

ICs, signal diodes, etc.) and then work up to the larger components (capacitors, power

transistors, transformers) after the small parts are done. This keeps the board relatively flat,

making it more stable during soldering. It is also best to save sensitive components

(MOSFETs, non-socketed ICs) until the end to lessen the chance of damaging them during

assembly of the rest of the circuit.

16

Soldering

Soldering is defined as "the joining of metals by a fusion of alloys which have

relatively low melting points". In other words, you use a metal that has a low melting point to

adhere the surfaces to be soldered together. Consider that soldering is more like gluing with

molten metal, unlike welding where the base metals are actually melted and combined.

Soldering is also a must have skill for all sorts of electrical and electronics work. It is also a

skill that must be taught correctly and developed with practice.

Routing

In electronic design, wire routing, commonly called simply routing, is a step in the

design of printed circuit board(PCBs) and integrated circuits (ICs). It builds on a preceding

step, called placement which determines the location of each active element of an IC or

component on a PCB. After placement, the routing step adds wires needed to properly

connect the placed components while obeying all design rules for the IC.

Programing

For the programing I have used the software names as Keil. The Keil C51 C Compiler for the

8051 microcontroller is the most popular 8051 C compiler in the world. It provides more

features than any other 8051 C compiler available today.The C51 Compiler allows you to

write 8051 microcontroller applications in C that, once compiled, have the efficiency and

speed of assembly language. Language extensions in the C51 Compiler give you full access

to all resources of the 8051.The C51 Compiler translates C source files into relocatable object

modules which contain full symbolic information for debugging with the µVision Debugger

or an in-circuit emulator. In addition to the object file, the compiler generates a listing file

which may optionally include symbol table and cross reference information.

Testing

An Actual-size, single sided PCB of the microcontroller-based digital alarm clock is shown in

fig and its component layout. Use IC base for microcontroller AT89S52. Also use a heat sink

with voltage regulator 7805(IC2) to avoid any damage to the circuit. Check continuity

between respective connections using a multimeter. checkInitially, byvarying present VR1,

set the contrast level for proper wrok line flowing robot. for looser connections or dry

soldering joining.

17

3.2 Programming

Using Keil's "C51" C Compiler (µVision IDE)

These simple instructions will walk you through the process of configuring Keil's µVision

IDE and C51 C Compiler with settings that produce code that can be download and run on

the 8051 development board .PJRC does not provide technical support for use of Keil's

software. We can--not provide any assistance should these instructions not apply to your

project's code or your µVision installation. However, these instructions were tested and

confirmed to work using "Hello World" example provided with Keil's C51 evaluation

software, version 7.06a.For further assistance with Keil's software, please refer to the manual

Keil’sprovides, or contact Keil for technical support.

Step 1: Copy Startup Code To Your Project

Copy the file "startup.a51" from "c:\keil\c51\lib" to "c:\keil\c51\examples\hello", or the

equivilant pair of directories if you installed µVision in a different directory/drive

location.Add this new copy of "startup.a51" to your project.

Right click "source group 1"

Choose "Add Files to Group 'Source Group 1'

Set "Files of type" to "All files (*.*)"

and select "Startup.a51"

When "startup.a51" has been added to your project, the left side tree representing your project

will be updated, similar to Figure 1.

Step 2: Edit Startup and Other Code

Edit "startup.a51" file. Locate the line "CSEG AT 0" and change it to "CSEG AT 0x2000".

Remember that this will only change the "startup.a51" that you copied to this project. The

global copy in "c:\keil\c51\lib" will remain unchanged.Edit "hello.c", and change the line that

sets TH1. For 115200 baud, you should set this to 255.

Figure 1 shows both of these files opened in µVision, edited with these changes.

18

Figure 3.2.1: Editing Source Code

(Optional): Define a New Target Name For This Board

In this example, the target named "Simulator" was modified to produce output compatible

with this board, which is the fastest and easiest approach.Perhaps a better approach would be

to create a new target, with a name such as "PJRC 8051 Development Board, Rev 5" and

apply these changes to that target rather than the "Simulator" target.

Step 3: Configure Build Target

Click on the "Project" menu, and select "Options for Target 'Simulator'". This will bring up

the Options for Target dialog box, where you must make several changes to configure Keil's

compiler to produce code that will work properly.

First, select the "Target" tab:

Enter 22.1184 in the "Xtal (Mhz)" field.

Uncheck "Use On-chip ROM".

Define "Off-chip Code memory" from 0x2000 to 0x3FFF.

Define "Off-chip Xdata memory" from 0x4000 to 0x7FFF.

19

For larger projects, you may need to change these settings to allocate the memory usage

according to your project's requirements. Such memory allocation planning is beyond the

scope of this simple example.

Fig 3.2.2:put the xtal range

Finally, select the "C51" tab. Check "Interrupt vectors at address:" and set the corresponding

value to 0x2000.

20

Figure 3.2.3: Options for Target Dialog, C51 Tab

Once all these changes have been made in all three tabs, click "OK" to commit your changes

to the build target.

Step 4: Compile and Download Intel-Hex Output

To compile the code, click on the "Project" menu and select "Build target". If there are n

errors, the compiler will finish and produce an intel-hex output file, which in this example is

"hello hex".Download the intel-hex file as described in the Using the 8051 Development

BoardFor the First Time page. To run your program using the "J" (Jump) command, and

enter 2000 (which should be the default).To quit, press the board's RESET button to return to

the monitor. You may need to press the ENTER key to allow PAULMON2 to re-detect your

baud rate, if your program overwrites the 4 bytes that are used to store the previously

detected baud rate.

Optional) Reconfigure For Flash ROM

Alternately, you could define the off-chip code memory from 8000 to F7FF and off-chip

Xdata memory from 2100 to 0x7FFF, set CSEG to 0x8000 in startup.a51, and set the

interrupt vectors at address 0x8000. This would configure the compiled code to run from the

Flash ROM, and you can use the autostart utility (on the LED blink example page) to make it

run automatically when the board boots.

21

Proteus:-

Proteus 8 is a best simulation software for various designs with microcontroller. It is mainly

popular because of availability of almost all microcontrollers in it. So it is a handy tool to test

programs and embedded designs for electronics hobbyist. You can simulate your

programming of microcontroller in Proteus 8 Simulation Software.After Simulating your

circuit in Proteus 8 Software you can directly make PCB design with it so it could be a all in

one package for students and hobbyists. So I think now you have a little bit idea about what is

proteussoftware.If you have clear idea about what is proteus 8 simulation software then you

can start proteus 8 simulations at this point of time. I am sure that you have your proteus 8. If

you don’t have then download from above link. To learn Proteus 8 You can start with a series

of video tutorials or you can download a Proteus 8 Software Tutorial PDF. But main and

most important thing with this software is hands on experiments. the more you work the

better you become There is no shortcut.After making your Schematic you have to do PCB

designing so here is the video tutorial which describes Single layer auto routing. According to

me this much information is enough for what is proteus software. If you want to get more

information on what is proteus software then feel free to comment below with your

difficulties about what is proteus software. We will try our best to solve your difficulties

related to what is proteussoftware.We have a separate section on Proteus 8 Simulation

Software which covers all simulations and tutorials have a look at there.To know more and

get latest updates on Proteus 8 Software Subscribe to mail and we would be sending you all

the updates related to Proteus 8 software

Fig no 3.2.4:open the proteus

And after some time you will go to a upper part of aro. This arocolour is white .this aero will

go to isis.

22

Then proteus window is open

Fig no 3.2.5:open the proteus window

And after some time you will go to the library .and select the component . there are many

component Are available.and all are simulate the circuit.we are show this diagmram

Fig no 3.2.6: choose the components

23

Then after simulate the circuit burn the program in the micro controller we are show the this

circuit diagram

Fig no 3.2.7:burn the program in proteus

When the program is burn in circuit then you will chek .this ckt is doing proper wrok or

not.We show this diagram

Fig no 3.2.8: proteus is ckt is wroking

24

CHAPTER 4:

TESTING AND VALIDATION OF RESULT

First of all I want to check the power supply when power supply is awrok properly.

Fig no 4.1:testing power supply

When the power supply connect the pic microcontroller and chek the out put it is

wrokproperlly or not

Fig no 4.2:testing microcontroller

25

CHAPTER 5:

FUTURE SCOPE

Ina future we can modify sound activated massage display as sound operated massage display

a what we are saying that all are display on the lcd screen by advancing and connecting it

sound module and memory in the present circuit of project.This can be help in to produce

smart notice board at school, collage, railway station, hospital etc. whare the immediate

announcement are required after very small interval of time. By this if there is any

announcement than we display on the screen by asking againsd the condenser microphone

sensor which sense the voice signal and sound module converted that signal after different

procces it will display in the screen of lcd.

26

CHAPTER 6:

CONCLUSION

This is an interesting idea in which a message is displayed on an LCD screen whenever a

sound is produced. The message remains on LCD for a short duration of time and then

disappears. This topic demonstrates the interfacing of a sound operated circuit and LCD

display with the pic microcontroller (16f73). The circuit can be used to display welcome

message at entrance; or warning messages at public places. It can also be used to aid

communication for deaf and dumb people.

27

APPENDIX

PROGRAMING:

#include<pic.h>

#define port P1

#define dataport P2 //Data port for LCD

#define sec 1000

//CONTROL PINS

sbit rs = port^0;

sbit rw = port^1;

sbit e = port^2;

sbit sensor_input=P0^0;

void delay(unsigned int sec) //Time delay function

{

int i,j ;

for(i=0;i<msec;i++)

for(j=0;j<1275;j++);

}

void lcd_cmd(unsigned char item) //Function to send command to LCD

{

dataport = item;

rs= 0;

rw=0;

e=1;

delay(1);

e=0;

return;

}

void lcd_data(unsigned char item) // Function to send data to LCD

{

dataport = item;

rs= 1;

rw=0;

e=1;

delay(1);

e=0;

return;

}

void lcd_data_string(unsigned char *str) //Function to send string to LCD

{

int i=0;

while(str[i]!='\0')

{

lcd_data(str[i]);

28

i++;

delay(10);

}

return;

}

void main()

{

unsigned char str1[] ="MAHARISHI MARKENDESHWAR ";

unsigned char str2[] ="UNIVERSITY";

sensor_input=1;

sensor_input=0;

lcd_cmd(0x38);

lcd_cmd(0x0e);

lcd_cmd(0x01);

while(1)

{

if(sensor_input==1)

{

lcd_cmd(0x82);

lcd_data_string(str1);

lcd_cmd(0xc6);

lcd_data_string(str2);

delay(sec);

lcd_cmd(0x01);

delay(100);

}

}

}

29

REFERENCES

[1]: http://en.wikipedia.org/wiki/

[2]: http://www.instructables.com/tag/type-id/category-technology/

[3]: http://electronics.howstuffworks.com/tech

[4]: https://www.youtube.com/results?search_query=push+button+telephone

[5]:https://www.askanswer.co.in/