Lathe- EXERCISE.docx

description

Transcript of Lathe- EXERCISE.docx

TURNING EXERCIES – IP710 – Dr.V.RAMESH

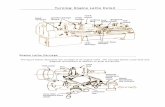

1. Write an ISO program for step turning operation of the component shown in figure using canned cycles. The diameter of the work piece = 30mm

N0 G90 F0.5 S1200 T0101 M03N10 G00 X30 Z2N11 G71 U0.5 R0.5N12 G71 P30 Q80 U0.05 W0.05N30 G01 X20 Z0N40 G01 X20 Z-20N50 G01 X25 Z-20N60 G01 X25 Z-40N70 G01 X30 Z-40N80 G01 X30 Z-60N100 G28 U0 W0

N110 M05 M30

2. Write the part program for the CNC lathe using canned cycles for the component shown in figure. Assume suitable cutting conditions and cutting tools. The diameter of the work piece = 40mm.

3. Write the CNC lathe programming for a FANUC controlled machine using canned cycles. Take the diameter of the work piece = 30mm, depth of cut = 0.5mm, speed = 1200rpm. Assume feed and other data suitably.

N0 G90 F0.5 S1200 T0101 M03N10 G00 X35 Z2N30 G71 U0.5 R1N35 G71 P36 Q90 U0.05 W0.05N36 G01 X20 Z0N50 G01 X20 Z-15N60 G02 X25 Z-25 R15N70 G01 X25 Z-40N80 G03 X30 Z-50 R15N90 G01 X30 Z-70N100 G28 U0 W0N110 M05 M30

4. Write a part program for a FANUC controlled CNC Lathe for the given component using canned cycle. Take the depth of cut 0.5mm & speed 1200rpm. Assume suitable cutting conditions and cutting tools.

5. Write a part program for a FANUC controlled CNC Lathe for the given component using canned cycle. Take the depth of cut 0.5mm & speed 1200rpm. Assume suitable cutting conditions and cutting tools.

To determine U= (Max. Dia of wp- min dia of profile)/2 = (35-25)/2 = 5N0 G90 F0.2 S1200 T0101 M04N10 G00 X38 Z2N30 G73 U5 R10 N40 G73 P50 Q120 U0.05 W0.05N50 G01 X25 Z0N60 G01 X25 Z-30N70 G01 X35 Z-30N80 G01 X35 Z-40N90 G01 X25 Z-55N100 G02 X25 Z-65 R10

N110 G01 X35 Z-80N120 G01 X35 Z-90N130 G01 X38 Z2N140 G28 U0 W0

N150 S400 T0202 M06N160 G00 X26 Z0N170 G76 P010160 Q5 N180 G76 X22.6 Z-30 P1200 Q200 F2N190 G28 U0 W0N200 M05 M30

6. Write an ISO program for the component shown in figure using canned cycles. The diameter of the work piece = 30mm. Take the depth of cut 0.5mm & speed 1200rpm. Assume suitable cutting conditions and cutting tools.

7. Write the CNC lathe program for a FANUC controlled machine using subroutine codes. Take the diameter of the work piece = 40mm, depth of cut = 0.5mm, speed = 1200rpm. Assume feed and other data suitably.

N0 G90 F0.2 S1200 T0101 M04N10 G00 X42 Z2N30 M98 P1 2000N130 G28 U0 W0N140 M05 M30

O2000;N30 G73 U12 R24N40 G73 P50 Q120 U0.05 W0.05N50 G01 X16 Z0N60 G01 X16 Z-20N70 G03 X30 Z-28 R8N71 G01 X30 Z-45N80 G01 X40 Z-60N90 G01 X40 Z-68N100 G02 X40 Z-78 R8N110 G01 X40 Z-88N120 G01 X50 Z2N121 M99

8. Write the CNC lathe programming for a FANUC controlled machine using canned cycle. Take the diameter of the work piece = 40mm, depth of cut = 0.5mm, speed = 1200rpm. Assume feed and other data suitably.

9. Prepare part program for the CNC lathe using subroutines for the component shown below. Assume suitable cutting conditions and cutting tools. Doc=1 MM

N0 G90 F0.2 S1200 T0101 M04N10 G00 X42 Z2N21 G71 U1 R0.5N22 G71 P50 Q90 U0.05 W0.05N50 G03 X20 Z-10 R10N60 G01 X24 Z-20N70 G02 X35 Z-30 R10N71 G01 X35 Z-40N80 G03 X40 Z-52 R10N90 G01 X40 Z-117N111 G00 X45 Z2N112 G28 U0 W0

N180 T0202 M06N190 G00 X45 Z-65N191 G00 X40 Z-65N200 G75 R1N210 G75 X20 Z-77 P1000 Q1999 (If width of parting tool is 2 mm)N220 G00 X45 Z-65N230 G28 U0 W0

N300 T0303 M06N310 G01 X45 Z-115N320 G01 X40 Z-115N330 G76 P010100 Q10N340 G76 X38 Z-77 P1000 Q100 F2N350 M05 M30

10. Write an ISO part programming for the FANUC controlled CNC Lathe using canned cycle. Work piece diameter = 30mm, Work piece material = Mild Steel, Feed = 0.2mm/rev, Speed for turning = 1200rpm, Depth of cut = 0.5mm.

N0 G90 F0.5 S1200 T0101 M04N20 G00 X30 Z2N40 G71 G71 U0.5 R0.5 – Roughing CycleN50 G71 P60 Q120 U0.05 W0.05N60 G01 X15 Z0N70 G01 X15 Z-10N80 G01 X18 Z-10N90 G01 X18 Z-45N100 G01 X18 Z-55N110 G02 X28 Z-70 R20N120 G01 X28 Z-80N130 G01 X30 Z2N135 G70 P60 Q120 – Finishing cycleN136 G00 X30 Z2N140 G28 U0 W0

N150 S400 T0202 M06N160 G01 X20 Z-45N170 G01 X18 Z-45N180 G76 P010160 Q20 N190 G76 X15.6 Z35 P1200 Q200 F2N200 G01 X30 Z2N210 G28 U0 W0

N220 S1200 T0303 M06N230 G01 X30 Z-45N240 G01 X18 Z-47N250 G75 R1N255 G75 X10 U1 Z-53 P1000 Q1000 N260 G28 U0 W0N300 M05 M30

11. Write the CNC lathe programming for a FANUC controlled machine. Take the diameter of the work piece = 30mm, depth of cut = 0.5mm, speed = 1200rpm. Assume feed and other data suitably.

N0 G90 F0.2 S1200 T0101 M04N10 G00 X30 Z2N20 G00 X0 Z0 - Facing operationN21 G00 X30 Z2 N30 G73 U7 R14 – Pattern Repeating Canned CycleN40 G73 P50 Q130 U0.05 W0.05N50 G01 X15 Z0N60 G03 X18 Z-10 R12N70 G01 X18 Z-28N80 G01 X29 Z-38N90 G01 X18 Z-48N100 G01 X18 Z-66N110 G02 X28 Z-81 R20N120 G01 X28 Z-91N130 G01 X32 Z2N140 G28 U0 W0

N150 S400 T0202 M06 – Threading ToolN160 G00 X22 Z0N161 G01 X18 Z-10N170 G76 P010100 Q10N180 G76 X16 Z-30 P1000 Q100 F2N190 G28 U0 W0N200 M05 M30

12. Write an ISO part programming for the FANUC controlled CNC Lathe using canned cycles. Work piece diameter = 30mm, Work piece material = Mild Steel, Feed = 0.2mm/rev, Speed for turning = 1200rpm, Depth of cut = 0.5mm.

13. Prepare part program for the CNC lathe using subroutines for the component shown below. Assume suitable cutting conditions and cutting tools.

N0 G90 F0.2 S1200 T0101 M04N10 G00 X40 Z0N20 M98 P3 7000N30 M05 M30

O7000;

G01 U0 W-30G02 U0 W-10 R5N60 M99

14. Prepare part program for the CNC lathe using subroutines for the component shown below. Assume suitable cutting conditions and cutting tools

N01 G90 F0.2 S1200 T0101 M04 N10 G00 X30 Z5N20 G00 X30 Z0 N30 G76 P010160 Q10N40 G76 X27.6 Z-40 P1200 Q100 F2 - RH THREAD FROM Z0 TO Z-40N50 G01 X30 Z-90N60 G76 P010160 Q0.5 N70 G76 X27.6 Z-50 P1200 Q100 F2 - LH THREAD FROM Z-90 TO Z-50

N80 G01 X30 Z-42 N90 G75 R1N100 G75 X20 Z-50 P1000 Q1000 - PARTING OPERATIONN110 G28 U0 W0N120 M05 M30