LABYRINTH SEAL PUMPS - Home - ACD · LABYRINTH SEAL PUMPS • ACD’s Labyrinth seal design is...

-

Upload

truongphuc -

Category

Documents

-

view

297 -

download

6

Transcript of LABYRINTH SEAL PUMPS - Home - ACD · LABYRINTH SEAL PUMPS • ACD’s Labyrinth seal design is...

LABYRINTH SEAL PUMPS

• ACD’s Labyrinth seal design is reliable and provides trouble free centrifugal pump operation eliminating the need for a traditional mechanical seal.

•Incorporatesagastypesealthateffectivelyseals around the shaft to protect against static and dynamic liquid leakage.

• The insulating closure plate along with the staggered stainless steel distance piece provides an interrupted cold-transference path to prevent “ice bridging.”

• Optimized tolerance and design result in highefficiencyandverylowsealinggasconsumption.

• Designed as an exchangeable cartridge foraddedflexibility.

• The non-contacting seal design makes the sealing life virtually unlimited.

• Speeds up to 8000 RPM.• Discharge pressures to 800 PSI (55 bar).

• Single gas (w/ mixture out)• Dual Gas• Reverse Bias

• Seal gas panel

• Process applications where continuous operation is required.

• Pumping applications where contami-nation must be kept to a minimum or when safety does not allow process gas to be vented to the atmosphere.

• High suction pressure applications that exceed mechanical seal capability

•ACDoffersthereversebiassealconfigurationforhighpurity(Argon)applications.

Features & BeneFits

availaBle laByrinth seal conFigurations:

options

applications

• Labyrinth seal cartridge with replaceable sleeves

• High performance seal gas regulators• “Double” – staggered web stainless steel

intermediate• Insulating closure-plate• Labyrinth seal interconnecting piping• Babbitt labyrinth seal liner for Oxygen,

Nitrogen, Argon and Methane service.

• LIN• LOX • LAR• Methane (LNG)• Consult with ACD for other liquids

liquids pumped

typical scope oF supply

Manufacturing

2321 S. Pullman Street Santa Ana, CA 92705 USATel 800.525.4216 (USA only)Tel +1.949.261.7533 • Fax [email protected] • www.acdcom.com

Bulletin No. ACD Laby-R1.15© 2015 ACD LLC, Printed in USASpeciFicaTionS SubjecT To change wiThouT noTice

global service

north america

atlantaatlanta, georgia, uSa+1 404.696.8113 • Fax +1 [email protected] • cryoindservice.com

california (acd service) Santa Ana, California, USA+1.714.568.0201 • Fax [email protected] • acdcom.com

houstonhouston, Texas, uSa+1 281.590.4800 • Fax +1 [email protected] • cryoindservice.com

pittsburghimperial, pennsylvania, uSa+1 724.695.1910 • Fax +1 [email protected] • cryoindservice.com

red deerRed Deer, Alberta, Canada+1.403.352.4436 • Fax [email protected] • cryoindservice.com

torontoToronto, ontario, canada+1 416.502.1950 • Fax +1 [email protected] • cryoindservice.com

international

australiaDandenong, Victoria, australia+61.3.9791.7888 • Fax [email protected] • cryoquip.com

BrasilSão paulo - Sp, brasilTel/Fax +55.11.2015.4288/4289 [email protected] • cryoindservice.com

chinahangzhou, china+86.571.8619.4799 • Fax [email protected] • cryoindservice.com

europe (acd cryo)ch-4142 Muenchenstein Switzerland+41.61.413.0230 • Fax: [email protected] • acdcryo.com

D-79415 bad bellingen germany+49.7635.8105.0 • Fax: [email protected] • acdcryo.com

united arab emiratesjebel ali Free Zone, Dubai, uaeTel: [email protected] • acdcom.com

indiaa Division of Rhine engineering pvt. Ltd.Vadodara, gujarat, india+91.265.283 0113 • Fax +91.265.283 [email protected] • acdcom.comKolkatta, west bengal, india+91.973.216 [email protected] • acdcom.com

KoreaYongin-si, gyeonggi-do, Korea+82.31.286.6114 • Fax [email protected] • cryoindservice.com

malaysiaShah alam, Selangor D.ehsan, Malaysia+60 (3) 5740.4800 • Fax +60 (3) [email protected] • cryoindservice.com

LABYRINTH SEAL PUMPS

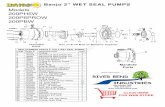

Pressure Regulator2 Places

Electric MotorTEFC

Motor Mounting Holes Electrical

Conduit Port

Seal Gas Mixture Out3/8" Tube

Discharge:Mates withFlat Face Flange

Suction:Mates withFlat Face Flange

Closure/InsulatingPlate, 0.25" Thick

Nitrogen SealGas in, 1/4" NPTFFar Side

Primary SealGas in, 1/4" NPTFFar Side

(Closure/Insulating Plate Removed for clarity)

1st Stage Seal

ExhaustMixture

Out

Primary SealGas Source

Regulator Regulator

Reference Pressure

From Pump Discharge

REVERSE BIAS GAS SEAL

1st Stage Seal

ExhaustMixture

Out

Primary SealGas Source

Regulator

Reference Pressure

SINGLE GAS SEAL W/ MIXTURE OUT

From Pump Discharge

Regulator

GN

1st Stage Seal

2nd StageSeal

ReferencePressure

ExhaustMixtureOut

Primary SealGas Source

Regulator

Reference Pressure

2 Gas

From Pump Discharge

reverse Bias gas seal single gas seal with mixture out

dual gas seal Flow

typical dual gas laByrinth seal pump

The Labyrinth Seal Component system is completely plumbed, assembled and factory tested. Only three fieldconnectionsarerequiredforeaseofinstallation.Performaceandinstallationdatashouldbeusedforreferenceonly.PleasecontactACDifcertifiedinformationisrequired.

For Pumping applications where product contamination must be kept to a minimum, or safety does not allow the process gas to be freely vented to atmosphere, a dual gas seal isamust.Thisdesignbuffersthefirststage of the labyrinth with product gas and the second stage with an external GN2 gas supply.