Laboratory Manual - AGH University of Science and Technologyhome.agh.edu.pl/~zsliwa/cw/ex_1.pdf ·...

-

Upload

truongliem -

Category

Documents

-

view

225 -

download

1

Transcript of Laboratory Manual - AGH University of Science and Technologyhome.agh.edu.pl/~zsliwa/cw/ex_1.pdf ·...

Laboratory Manual

CAM 3 – Core & Cavity Design – Injection molds

Faculty of Mechanical Engineering and RoboticsDepartment of Robotics and MechatronicsDr. Eng. Zbigniew Śliwa

2

Objective

To create surface elements of the injection mold on the basis of the given solid model geometry.

3

Prerequisites

The basic knowledge of CATIA v5 in the scope of files management, 3D model manipulation and the proper use of specification tree.

NOTICE !

To complete the task you need to have the model named: CCDmodel.CATPart.You should download or receive by e-mail the file CCDmodel.stp . Open it in Part Design module. System will transform the file to the CATPart format. Save the transformed file.

4

Preparatory activities

1. Open new folder named Core & Cavity Design and save CCDmodel CATIA Part in it.

2. Open the new file of type Product and save it in the just created folder with the name Product1

3. Click Product1 in the specification tree and choose module Core & Cavity Design

4. Find Import Model (on the right side) and apply to the file CCD.CATPart

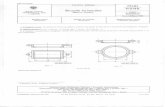

The model and the tree should look exactly like in the figure Check carefully !

The imported model is presented in the tree with the name: MoldedPart.

5

Main Pulling Direction

1. Choose Pulling Direction (menu on right)2. Click the model3. In the opened window don't change

settings and click OK.

New elements: Core, Cavity, Other, NoDraft appeared in the tree.Their colors are respectively: red, green, blue and pink. Two last elements need further actions

6

Direction in Slider Area

1. Choose icon Slider Lifter Direction2. Drag the compass to the center of the hole to define the pulling

direction in the area.3. When value -1 appears in the field DX, click Locked4. In the bottom of the window click Local transfer (or Target in CATIA

v5r20) and choose Point continuity5. Click the flat pink face and (focused) blue face of hole. Click OK. Both

chosen faces should become yellow defining a Slider Area.

The tree shows replacement of two faces: Other and NoDraft, with the one: Slider/Lifter.

7

Explode View

1. Switch on the icon Explode View2. Change Explode value into 100.3. You can choose one or two of pulling

directions listed in the window Pulling direction

Explode View helps to evaluate surfaces and pulling directions

8

The Cavity – preparatory activities

1. From main menu choose: Insert Geometrical Set→ . Enter name PS Cav Temp (Parting Surface Cavity Temporary). The name matters !!! Be exact.

2. Hide in the tree: Core and Slider/Lifter3. Delete empty branches Other i NoDraft4. Draw the sketch on plane xy: a square 300x300 mm

with the center point (0, 0)

9

Parting Surfaces (1)

1. Choose Parting Surface from the workbench2. Click the model in 3D space3. Click two white points on the edge.

12

After the second pointthe green line appears

Choose Mark

Click the opposite

line

10

Parting Surfaces (2)

In the same way make surfaces adjacent to the straight segments of the edge of the model's base

11

Parting Surfaces (3)

In the same way make surfaces by the three remaining arcs of the model's edge.

Change operation

Choose two points of the arc and twoedges marked as

Section1 and Section2

12

Parting Surfaces (4)

Click two white points ofthe vertical profile

and the opposite line

1

2

3

Back toExtrude

13

Parting Surfaces (5)

There are still twogaps to be filled in

with surface elements.

14

Parting Surfaces (6)

ClickSweep

ThenProfile and

Guide curvethen OK

Do the same on the other sideof the „tunel”

15

Conjoining the surfaces

1. Find and click Join.2. Click each formed surface, excluding the

green one of the model belonging to the Cavity in the specification tree. Then OK.

PSCavity contains all newly created surface elements (except the green model). The last Join element contains all surfaces joined together.

16

Checking the surface

Click Join in the specification tree. All borders of faces are marked with orange color

Notice that all original component surfaces forming the Join surface have been automatically hidden.

17

Cutting the surface (1)

Find and click3D Curve Offset

Fill in the data into Curve Offset Definition widow by clicking proper elements (rectangular sketch, xy plane)

and setting the Offset value: -35 mm. Then OK.

18

Cutting the surface (2)

ChooseExtrude

Build a surface withdata given below

19

Cutting the surface (3)

Use Split with data shown in the figure. If needed, click Other side to remove the outer part of the surface. Then OK.

Hide a cutting surface.

20

Moving the surface to the Cavity.1 (1)

ClickTransfer an element

Choose Propagation type and Destination like the figure shows.Click white surface somewhere by the model. The surface will change color into green.

ClickOK

ChooseCopy

21

Moving the surface to the Cavity.1 (2)

In the Cavity.1 branch of the tree the new element TrfSurface appeared which is a copy of elements forming the parting surface.

When clicking each element of the Cavity branch, the respective geometry area should be marked.

22

Aggregating the element Cavity.1 (1)

In the definition window choose Cavity.1 and mark Create datum Join. The list of elements should be automatically filled in.

Click OK.

ChooseAggregate Mold Area

23

Aggregating the element Cavity.1 (2)

In the Cavity branch the new elementSurface.7 appeared. It represents the whole surface of the mold's cavity.

Surface.2 has beenautomatically moved to the newbranch CCV_NoShow.1in the end of the tree.Split.2 must be hidden manually.

24

Modeling the Core

1. Hide the surface in Cavity.12. Show the surface in Core.13. Insert the new Geometrical Set and name it PS Cor Temp4. Perform subsequent steps as described from point 4 on page 8.

25

The surface of Core.1

The second part of the mold is ready made.

26

Modeling the Slider/Lifter (1)

1. Hide the surface in the Core.1 branch2. Show the surface in the Slider/Lifter.1 branch3. Create the new Geometrical Set (Insert-> Geometrical

Set) and name it PS Slid Temp.4. Create or copy the sketch with rectangle 300x300 mm

and the center point (0, 0).

27

Modeling the Slider/Lifter (2)

ChooseParting Surface

Click the model surface.White points appear

Take two points and opposite line of the sketch to create surfaces in the way applied before. The result should be as visible on the next slide.

28

Modeling the Slider/Lifter (3)

Press OK.The system will automatically merge created elements into one Join and will hide original elements.

29

Modeling the Slider/Lifter (4)

According to the method applied to the two previous surfaces, make Split,Transfer an element and Aggregate Mold Area.

The final result is shown in the figure.

30

The final result of the task completion

1. Show surfaces in Cavity.1 and Core.1, as well as Solid.1 in the branch Result of PartBody.

2. Apply Explode View.

The task is completed. Compare results.

31

Summary.

Created surfaces can be used to design the injection or casting mold.

32

Good Luck !