Lab3 Roundness Composite Lab 2 Ahmedawad

-

Upload

ahmed-awad -

Category

Documents

-

view

28 -

download

3

description

Transcript of Lab3 Roundness Composite Lab 2 Ahmedawad

Firing Order

The firing order is the sequence of power delivery of each cylinder in a multi-cylinder reciprocating engine.

This is achieved by sparking of the spark plugs in a gasoline engine in the correct order, or by the sequence of fuel injection in a Diesel engine. When designing an engine, choosing an appropriate firing order is critical to minimizing vibration, to improve engine balance and achieving smooth running, for long engine fatigue life and user comfort, and heavily influences crankshaft design.

A camshaft is a shaft to which a cam is fastened or of which a cam forms an integral part. This allows the camshaft to be in direct contact with the valve, thus aiding in the efficiency and overall power output of the engine itself and eliminating the need for push rods.

Objectives: To find the arrangement and firing order of a camshaft

Materials: Camshaft, measuring device Experimental work:

Hold and center the camshaft by using the tailstock

Rotate the carriage hand wheel until the plunger touch the cam

Rotate the shaft until the contact touch the highest point

Take the reading

Go for the next cam and take the reading (angle) of highest point and so on

Reading:

cam no. 1 2 3 4 5 6 7 8

Angle (degree) 220 330 245 125 307 60 150 37

Cam Profile

A cam is a rotating or sliding piece in a mechanical linkage used especially in

transforming rotary motion into linear motion or vice-versa.

The cam can be seen as a device that rotates from circular to reciprocating (or sometimes oscillating) motion. A common example is the camshaft of an automobile, which takes the rotary motion of the engine and translates it into the reciprocating motion necessary to operate the intake and exhaust valves of the cylinders.

Cam profile terms

RAMPS: The parts of a camshaft lobe that actually initiate the lifting and descending movement of the lifter are called "ramps". Ramps include the lash ramp, the opening ramp, and the closing ramp. Camshaft lobe ramps are ground to have different rates of lifter movement in terms of velocity and degrees of duration, as measured in degrees of crankshaft rotation. The "lash ramp" of a camshaft lobe is a mid-point location between the opening ramp and closing ramp. The "opening ramp" of a camshaft lobe is the point where the lifter just begins to lift until the point that it reaches the nose of the lobe. The "closing ramp" is the point of the camshaft lobe from the nose back down to the lash ramp. NOSE The "nose" of a camshaft lobe is the top or the highest maximum lift point for the valve. It is where valves are kept open for as long as possible before making the transition to the closing ramp. BASE CIRCLE The "base circle", also known as the "heel", is the lowest point of the camshaft lobe and is the place where the valve is in the closed position. The "base circle" is the point where all valve lash settings are made.

Objectives: Drawing and identifying the cam profile terms

Materials: Camshaft, measuring device

Experimental work:

Hold and center the camshaft by using the tailstock

Rotate the carriage hand wheel until the plunger touch the cam

Rotate the shaft

Take the reading

Reading:

angle 0 10 20 30 40 50 60 70 80 90 reading 17.146 17.393 17.885 18.727 19.898 20.604 20.759 20.231 19.228 18.227

angle 100 110 120 130 140 150 160 170 180 190

reading 18.227 17.453 17.059 16.937 16.976 16.892 16.722 16.687 16.777 16.768

angle 200 210 220 230 240 250 260 270 280 290

reading 16.781 16.722 16.743 16.777 16.804 16.838 16.876 16.922 16.914 16.945

angle 300 310 320 330 340 350

reading 16.957 16.998 17.001 17.001 17.029 17.085

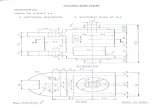

Apparatus:

Roundness Test

Error of circularity (out of roundness) is the radial distance between the minimum circumscribing circle and the maximum inscribing circle which contain the profile of the surface

Objectives: To find the get the maximum out of roundness of a shaft

Materials: Camshaft, measuring device Experimental work:

Hold and center the camshaft by using the tailstock

Rotate the carriage hand wheel until the plunger touch the cam

Rotate the shaft through a predefined angle

Take the reading

Reading:

angle 0 10 20 30 40 50 60 70 80 90

reading 16.105 16.19 16.06 16.03 15.987 15.948 15.95 15.865 15.819 15.887

angle 100 110 120 130 140 150 160 170 180 190

reading 15.755 15.725 15.69 15.667 15.65 15.64 15.635 15.648 15.658 15.675

angle 200 210 220 230 240 250 260 270 280 290

reading 15.702 15.742 15.785 15.832 15.87 15.903 15.958 16.005 16.04 16.069

angle 300 310 320 330 340 350

reading 16.095 16.145 16.158 16.175 16.174 16.165

Apparatus:

Calculation:

1st: using analytical solution

Roles used:

𝑥𝑖 = 𝑟𝑖 cos(𝜃𝑖)

𝑦𝑖 = 𝑟𝑖 sin(𝜃𝑖)

𝑎 =2 ∑ 𝑥

𝑛

𝑏 =2 ∑ 𝑦

𝑛

𝑅 =∑ 𝑟

𝑛

𝑥𝑖′ = 𝑥𝑖 − 𝑎

𝑦𝑖′ = 𝑦𝑖 − 𝑏

𝛿𝑖 =𝑥𝑖

2 + 𝑦𝑖2 − 𝑅2

2𝑅

𝜃

𝑟𝑖

𝑥𝑖 𝑟𝑖 cos(𝜃𝑖)

𝑦𝑖 𝑟𝑖 sin(𝜃𝑖)

𝑥′ 𝑥𝑖 − 𝑎

𝑦′ 𝑦𝑖 − 𝑏

𝛿

0 0 16.105 16.105 0 15.86516 0.046429

10 10 16.19 15.94404 2.811364 15.70419 2.857793

20 20 16.06 15.09146 5.492844 14.85162 5.539273

30 30 16.03 13.88239 8.015 13.64254 8.061429

40 40 15.987 12.24675 10.27625 12.00691 10.32267

50 50 15.948 10.25118 12.21688 10.01133 12.26331

60 60 15.95 7.975 13.81311 7.735156 13.85953

70 70 15.865 5.42615 14.90822 5.186306 14.95465

80 80 15.819 2.746941 15.57867 2.507097 15.6251

90 90 15.887 -3.3E-09 15.887 -0.23984 15.93343

100 100 15.755 -2.73583 15.51565 -2.97567 15.56208

110 110 15.725 -5.37827 14.77667 -5.61811 14.8231

120 120 15.69 -7.845 13.58794 -8.08484 13.63437

130 130 15.667 -10.0706 12.00162 -10.3104 12.04805

140 140 15.65 -11.9886 10.05963 -12.2284 10.10606

150 150 15.64 -13.5446 7.82 -13.7845 7.866429

160 160 15.635 -14.6921 5.347485 -14.9319 5.393914

170 170 15.648 -15.4103 2.717247 -15.6501 2.763676

180 180 15.658 -15.658 -6.4E-09 -15.8978 0.046429

190 190 15.675 -15.4369 -2.72194 -15.6767 -2.67551

200 200 15.702 -14.7551 -5.3704 -14.9949 -5.32397

210 210 15.742 -13.633 -7.871 -13.8728 -7.82457

220 220 15.785 -12.092 -10.1464 -12.3319 -10.1

230 230 15.832 -10.1766 -12.128 -10.4165 -12.0816

240 240 15.87 -7.935 -13.7438 -8.17484 -13.6974

250 250 15.903 -5.43915 -14.9439 -5.67899 -14.8975

260 260 15.958 -2.77108 -15.7156 -3.01092 -15.6691

270 270 16.005 9.85E-09 -16.005 -0.23984 -15.9586

280 280 16.04 2.785317 -15.7963 2.545473 -15.7499

290 290 16.069 5.495922 -15.0999 5.256078 -15.0535

300 300 16.095 8.0475 -13.9387 7.807657 -13.8922

310 310 16.145 10.37781 -12.3678 10.13796 -12.3214

320 320 16.158 12.37775 -10.3862 12.1379 -10.3397

330 330 16.175 14.00796 -8.0875 13.76812 -8.04107

340 340 16.174 15.19859 -5.53183 14.95874 -5.4854

350 350 16.165 15.91942 -2.80702 15.67957 -2.76059

∑ 4.317183 -1.83573

average 15.90006

Cartesian coordinate

Polar coordinate:

15.5

15.6

15.7

15.8

15.9

16

16.1

16.2

16.3

16.4

0 50 100 150 200 250 300 350 400

15.1

15.3

15.5

15.7

15.9

16.1

16.3

16.5

𝑎 = 0.239844

𝑏 = −0.10199

𝑅 = 15.90006 𝑚𝑚

𝑒 = 0.260626 𝑚𝑚

𝛼 = −23.0369°

𝑚𝑎𝑥𝑖𝑚𝑢𝑚 𝑜𝑢𝑡 𝑜𝑓 𝑟𝑜𝑢𝑛𝑑𝑛𝑒𝑠𝑠 = |0.062163| + |−0.07492| = 0.137083

15.6

15.7

15.8

15.9

16

16.1

16.2

16.3

0 50 100 150 200 250 300 350 400

0.137

2nd method:

Get a, b from ∑ 𝑥 , ∑ 𝑦 then calculate 𝛼 𝑎𝑛𝑑 𝑒

𝑟𝑖 = 𝑅 + 𝛿𝑖 + 𝑒 sin( 90 − 𝛼 + 𝜃𝑖)

𝑟𝑖 = 𝑅 + 𝛿𝑖 + 𝑒 sin( 90 + [𝜃𝑖 − 𝛼])

𝑟𝑖 = 𝑅 + 𝛿𝑖 + 𝑒 cos(𝜃𝑖 − 𝛼)

𝛿𝑖 = 𝑟𝑖 − 𝑅 − 𝑒 cos(𝜃𝑖 − 𝛼)

𝑎 =2 ∑ 𝑥

𝑛

𝑎 = 0.239844

𝑏 =2 ∑ 𝑦

𝑛

𝑏 = −0.10199

𝑅 =∑ 𝑟

𝑛

𝑅 = 15.90006 𝑚𝑚

𝑒 = √𝑎2 + 𝑏2

𝑒 = 0.260626 𝑚𝑚

𝛼 = 𝑡𝑎𝑛−1 (𝑏

𝑎)

𝛼 = −23.0369°

𝑚𝑎𝑥𝑖𝑚𝑢𝑚 𝑜𝑢𝑡 𝑜𝑓 𝑟𝑜𝑢𝑛𝑑𝑛𝑒𝑠𝑠 = |0.088929| + |−0.0349| = 0.123192

0.123

𝜃

𝑟𝑖

𝑥𝑖 𝑟𝑖 cos(𝜃𝑖)

𝑦𝑖 𝑟𝑖 sin(𝜃𝑖)

𝛿

0 16.105 16.105 0 -0.0349

10 16.19 15.94404 2.811364 0.071452

20 16.06 15.09146 5.492844 -0.03056

30 16.03 13.88239 8.015 -0.02677

40 15.987 12.24675 10.27625 -0.03123

50 15.948 10.25118 12.21688 -0.0281

60 15.95 7.975 13.81311 0.018344

70 15.865 5.42615 14.90822 -0.02125

80 15.819 2.746941 15.57867 -0.02227

90 15.887 -3.3E-09 15.887 0.088929

100 15.755 -2.73583 15.51565 -0.00297

110 15.725 -5.37827 14.77667 0.002809

120 15.69 -7.845 13.58794 -0.00181

130 15.667 -10.0706 12.00162 -0.00076

140 15.65 -11.9886 10.05963 -0.00077

150 15.64 -13.5446 7.82 -0.00136

160 15.635 -14.6921 5.347485 -0.0048

170 15.648 -15.4103 2.717247 0.001848

180 15.658 -15.658 -6.4E-09 -0.00222

190 15.675 -15.4369 -2.72194 -0.00657

200 15.702 -14.7551 -5.3704 -0.00756

210 15.742 -13.633 -7.871 -0.00135

220 15.785 -12.092 -10.1464 0.003112

230 15.832 -10.1766 -12.128 0.007979

240 15.87 -7.935 -13.7438 0.001536

250 15.903 -5.43915 -14.9439 -0.01087

260 15.958 -2.77108 -15.7156 -0.00085

270 16.005 9.85E-09 -16.005 0.002951

280 16.04 2.785317 -15.7963 -0.00215

290 16.069 5.495922 -15.0999 -0.00893

300 16.095 8.0475 -13.9387 -0.01331

310 16.145 10.37781 -12.3678 0.012644

320 16.158 12.37775 -10.3862 0.008653

330 16.175 14.00796 -8.0875 0.016236

340 16.174 15.19859 -5.53183 0.01368

350 16.165 15.91942 -2.80702 0.011032

Sum 4.317183 -1.83573

Average 15.90006 0.119922 -0.05099

Semi analytical method:

𝑒 =𝑟𝑚𝑎𝑥 − 𝑟𝑚𝑖𝑛

2

𝑒 =16.19 − 15.635

2= 0.2775 𝑚𝑚

𝛼 = 𝜃𝑖 𝑎𝑡 𝑟𝑖 = 𝑟𝑚𝑎𝑥 𝛼 = 10°

15.1

15.3

15.5

15.7

15.9

16.1

16.3

16.5

0.2775

Graphical Method:

𝛼 = 10°

𝑒 =16.19 − 15.675

2= 0.2575 𝑚𝑚

15.1

15.3

15.5

15.7

15.9

16.1

16.3

16.5

0.2575

Concentricity

Concentric objects share the same center, axis or origin. Circles, tubes, cylindrical

shafts, disks, and spheres may be concentric to one another. Notice that two

objects can have equal radii and be concentric and different.

Objectives: To find the concentricity between stepped shaft

Materials: Stepped shaft, measuring device

Experimental work:

Hold and center the shaft by using the tailstock

Rotate the carriage hand wheel until the plunger touch the shaft

Rotate the shaft by predefined angle

Take the reading

Readings:

1st steeped (a):

angle 0 10 20 30 40 50 60 70 80 90 reading 27.905 27.911 27.985 27.847 27.813 27.888 27.86 27.837 27.721 27.708

angle 100 110 120 130 140 150 160 170 180 190

reading 27.786 27.776 27.702 27.702 27.7 27.775 27.756 27.645 27.638 27.635

angle 200 210 220 230 240 250 260 270 280 290

reading 27.63 27.64 27.652 27.658 27.671 27.798 27.706 27.733 27.755 27.884

angle 300 310 320 330 340 350

reading 27.816 27.837 27.86 27.881 27.99 27.903

2st steeped (b):

angle 0 10 20 30 40 50 60 70 80 90

reading 31.187 31.189 31.184 31.151 31.14 31.14 31.127 31.11 31.108 31.094

angle 100 110 120 130 140 150 160 170 180 190

reading 31.085 31.076 31.065 31.051 31.045 31.04 31.035 31.031 31.033 31.035

angle 200 210 220 230 240 250 260 270 280 290

reading 31.054 31.061 31.074 31.088 31.102 31.116 31.129 31.14 31.15 31.164

angle 300 310 320 330 340 350

reading 31.18 31.187 31.192 31.197 31.199 31.195

3rd stepped (C):

angle 13 33 53 73 93 113 133 153 173 13

reading 70.612 70.361 70.381 70.173 70.083 70.05 70.078 70.16 70.247 70.612

angle 193 213 232 254 274 294 313 333 353 193

reading 70.286 70.405 70.566 70.634 70.762 70.935 70.912 70.86 70.678 70.286

Analysis and cartesian representation of the shaft:

a:

Eccentricity = 0.128 mm

𝛼 = 4.7°

27.5

27.6

27.7

27.8

27.9

28

28.1

0 50 100 150 200 250 300 350 400

Rea

din

(mm

)

angle (degree)

b:

Eccentricity = 0.079mm

𝛼 = −18.8°

C:

Eccentricity = 0.56mm

𝛼 = −23.9°

31

31.05

31.1

31.15

31.2

0 50 100 150 200 250 300 350 400

Re

adin

g (m

m)

angle ( degree)

69.8

70

70.2

70.4

70.6

70.8

71

71.2

0 50 100 150 200 250 300 350 400

Rea

din

g (m

m)

angle (degree)

Analysis:

By using cosine rule: 𝑐2 = 𝑏2 + 𝑎2 − 2𝑏𝑎 cos𝐶

Eccentricity between the 1st step and the 2nd step

𝐶2 = 𝑒12 + 𝑒2

2 − 2𝑒1𝑒2 cos(𝛼1 + 𝛼2)

= 0.1282 + 0.0792 − 2 × 0.128 × 0.079 cos(4.7 + 18.8)

= 0.0040783377

𝐶 = 0.063862 𝑚𝑚

0.064

Eccentricity between the 1st step and the 3rd step

𝐶2 = 𝑒12 + 𝑒3

2 − 2𝑒1𝑒3 cos(𝛼1 + 𝛼3)

= 0.1282 + 0.562 − 2 × 0.128 × 0.56 cos(4.7 + 23.9)

= 0.20411636

𝐶 = 0.451792 𝑚𝑚

0.452

-0.25

-0.2

-0.15

-0.1

-0.05

0

0.05

0 0.1 0.2 0.3 0.4 0.5 0.6

1

2

3

Eccentricity between the 2nd step and the 3rd step

𝐶2 = 𝑒22 + 𝑒3

2 − 2𝑒2𝑒3 cos(𝛼3 − 𝛼2)

= 0.0792 + 0.562 − 2 × 0.079 × 0.56 cos(23.9 − 18.8)

= 0.2317112

𝐶 = 0.481363 𝑚𝑚

0.4813

Apparatus: