L 700 XL USA INT - istcgroup.com ring vacuum pumps and... · a vacuum pump, compressor or vacuum...

Transcript of L 700 XL USA INT - istcgroup.com ring vacuum pumps and... · a vacuum pump, compressor or vacuum...

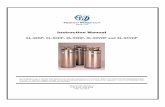

L_700 Vectra XLLiquid Ring Vacuum Pumps and Compressors

L_Series

2 nash_elmo Industries L_700 Vectra XL

L_700 Vectra XL – World class design & performance

The liquid ring pumps produced by Nash and Siemens (elmo) have been known

for nearly 100 years as powerhouses, designed to stand up to the rigorous, non-

stop demands of the harshest industrial environments. With the formation of

nash_elmo in 2002, we have combined our product lines to enable us to offer the

highest performance, reliability and efficiency in every product class. The L_700

Vectra XL meets that standard.

The L_700 Vectra XL vacuum pumps and compressors are created specifically for the

chemical processing industry. They combine the highest standard of reliability

with a new level of ingenuity. nash_elmo employs advanced design technologies

to achieve optimum performance and unprecedented production efficiencies.

Production efficiencies ultimately passed on to our customers in the form of

unique value and unequaled performance.

The L_700 Vectra XL pumps have been designed from the ground up, based on cus-

tomer defined market requirements. The multidisciplinary design process relied on

input from R&D, manufacturing, marketing and most importantly our customers –

the chemical process engineers. The result: a revolutionary line of pumps tough

enough to be branded nash_elmo.

Durability is only one important aspect. All L_700 Vectra XL models incorporate a

simple modular concept with interchangeable parts that result in a high level of

adaptability. These pumps also include technological advancements such as a

patented new cone design and a new rotor configuration. The machines can be

used in applications discharging against positive back pressure.

nash_elmo L_700 Vectra XL pumps meet high combustible range standards and

are ATEX certified. These vacuum pumps and compressors are in accordance with

guideline 94/9/EG, category 1 and 2. Further on the L_700 Vectra XL was designed

with API 681 specifications in mind.

Overall, the L_700 Vectra XL models are the result of painstaking engineering

and the use of finite element analysis, which determines the most efficient

means to achieve the highest level of performance and the greatest

possible value. A world class design.

Operating level of the L_700 Vectra XL as

a vacuum pump, compressor or vacuum

pump against positive back pressure.

Compressor

0 PSIGbar abs.

453

Cap

acity

151

Atmospheric

VACUUM PUMP

0 133

in HgAmbar abs.

301000

Cap

acity

Vacuum pump

0

VACUUM PUMP

0 XXX

XXXXXX

XXXXXX

Qua

lity?

??

Vacuum pump against positiveback pressure

45 PSIG

Cap

acity

03 bar abs.33 mbar abs.

Atmospheric

XL

302

1 in HgA

3D CAD and finite element analysis

enabled nash_elmo engineering to

optimize the L_700 Vectra design.

nash_elmo Industries L_700 XL 3

XL 35

XL 45

XL 60

XL 80

XL 100

XL 130

XL 150

XL 250

XL 350

XL 500

0 500 1000 1500 2000 2500 3000cfm

L_700 Vectra XL pumps are ideally suited to handle a wide variety

of chemical processing applications, including:

� Reactor vacuum

� Vacuum distiller

� Evaporator vacuum

� VCM recovery

� Vacuum filtration

� Explosive & corrosive gas compression

� Solvent recovery

� Drying

� Extrusion

� Methane extraction & boosting

... and many others

L_700 Vectra XL Capacity range

The L_700 Vectra XL is a pump designed to stand up to the harsh

environments found in the chemical processing industries.

The L_700 Vectra XL is constructed of ductile iron and stainless steel.

It can accommodate a variety of mechanical seals and achieves higher

differential and hydrotest pressure ratings than our general industrial

models – the L_700 Vectra GL. While the L_700 Vectra XL incorporates

several unique parts for the chemical processing industry, the entire

Vectra line shares many common parts to provide maximum efficiency

and optimum value. Key elements of the design are the improved

cone angles, which decrease the size of the pump and nash_elmo's

patented Gas Scavenging Technology, which dramatically improves

pump performance at high vacuum levels.

We design and develop solutions engineered to your

individual needs. Contact us for further details.

4 nash_elmo Industries L_700 Vectra XL

ConeRotor

Universal

stuffing box

External

bearing

housing

L_700 Vectra XL – Vacuum technology for chemical processing

Inlet

Mechanical

seal

Vacuum range 0-29 in Hg vac. / to 33 mbar abs.

Mechanical seals* Single, double and cartridge

Differential pressure capability 30 psi / 2 bar

Compressor pressure 30 psig / 3 bar abs.

Hydrotest pressure 150 psig / 11 bar abs. standard

(225 psig / 16 bar abs. optional)

Construction material Ductile iron, stainless steel

Basic specifications

* Mechanical seals are standard on stainless steel XL 35 - XL 150 models.

Optional on others.

Suction

Discharge

nash_elmo Industries L_700 Vectra XL 5

Flange dimensions are to ANSI and ISO standards, respectively.

All dimensions are approximate.

Discharge

External

bearing

housing

L_700 Vectra XL Dimensions

Model Binches

Cinches

Dinches

Einches

Suction & dischargeflange connection

Ainches

XL 35 30XL 45 32

13 14 6 2 3-IN. FLG. 2-IN. FLG.

XL 60 36XL 80 39

17 16 7 2 3-IN. FLG.

XL 100 424-IN. FLG.

XL 130 4619 20 8 2 4-IN. FLG.

XL 150 47 22 22 9 2 6-IN. FLG. 4-IN. FLG.XL 250 55 24 27 12 3 6-IN. FLG. 6-IN. FLG.XL 350 64 29 31 14 3 8-IN. FLG. 6-IN. FLG.XL 500 72 35 37 16 4 10-IN. FLG. 8-IN. FLG.

Features Benefits

Compact design Less floor space required

External mechanical seals Flexibility & ease of maintenance

Direct drive speeds for For worldwide use

50/60 Hz motors

Extended pressure ratings Ability to handle tough applications

where backpressure is required

Conical design Better ability to handle water / particulate

slugs / residual gas compression

One moving part Long term reliability

Variable port design High efficiency

Patented gas scavenging Increased performance at high vacuum levels

Improved cone angle Reduced pump length

Optimized design using Extended scope of application

finite element analysis

Factory performance tested Trouble free start-up and operation

Backed by 2 year warranty Peace of mind

and over 100 years of vacuum

and compressed gas experience

Packaged systems – L_700 VectraPaks

Optional components:

� Inlet check valve

� Inlet isolation valve

� Vacuum relief valve

� Seal line isolation valve

� Shock arrestor pads

� Vacuum gauge

� Flow switch

� Vacuum receiver tank

� Adjustable frequency drives

Duplex combinations are avail-

able and packages may be

designed to meet other specific

requirements of your application.

If your requirements call for a packaged system, nash_elmo VectraPaks are preengineered, assembled

and piped – and they provide you with all the associated components for your application. Once-through,

partially recirculated and fully recirculated systems are available direct connected or v-belt-driven.

Generally, VetraPaks through size 250 are direct coupled and those in the larger sizes can be v-belt-driven.

Partially recirculated

system

Use

Where minimal contamination

problems exist and seal liquid

is plentiful.

Benefits

� Simplicity

� Low initial cost

� Lower seal liquid

consumption

Standard components

� Pump

� Base

� Motor / drive

� Seal water accessories

� Water trap silencer

Fully recirculated

system

Use

Where liquids and gases are

hazardous or toxic and where

contamination is a concern.

Benefits

� Low water consumption

(with air cooled heat

exchanger)

� Process gases

may be recovered

� Seal liquid contained and

isolated from non-

hazardous coolant systems

Standard components

� Pump

� Base

� Motor / drive

� Seal water accessories

� Separator

� Heat exchanger and

make up valve

6 nash_elmo Industries L_700 Vectra XL

Use

Where contamination is not a

problem and the supply of seal

liquid is plentiful.

Benefits

� Simplicity

� Lowest initial cost

Standard components

� Pump

� Base

� Motor / drive

� Seal water accessories

� Water trap silencer

Once-through system

Model Binches

Ainches

Cinches

XL 35 51 34 37XL 45 51 36 37XL 60 62 39 46XL 80 62 41 46XL 100 80 46 53XL 130 80 50 53XL 150 88 52 53XL 250 106 60 76XL 350 105 67 77XL 500 123 78 95

Model Binches

Ainches

Cinches

XL 35 56 30 46XL 45 56 30 46XL 60 69 35 53XL 80 69 35 53XL 100 67 41 60XL 130 74 41 60XL 150 82 43 54XL 250 95 53 76XL 350 N/A N/A N/AXL 500 N/A N/A N/A

L_700 Vectra XL direct-driven package dimensions L_700 Vectra XL belt-driven package dimensions

All dimensions are approximate.

nash_elmo Industries L_700 Vectra XL 7

For 100 years, we have been assisting our customers in making the right vacuum pump

or compressor choice. As your engineering partners, we will provide you with a

nash_elmo performance analysis which includes a review of your particular process

requirements, and provides you with alternative means for meeting your process needs.

We will supply engineering data and application information, along with short- and

long-term cost comparisons.

Beginning today and throughout the life of every nash_elmo system, our engineers are

ready to support you to meet your vacuum and compressor process tasks.

Factory tested

Before any nash_elmo vacuum pump or compressor is shipped out of our factory, it is

performance tested to meet the highest standards. We stand behind our products: every

nash_elmo L_700 Vectra XL comes with a TWO-YEAR WARRANTY. Our new test bay gives

us the capability to simulate nearly all real operating conditions for liquid ring pumps.

A global service network with local support

nash_elmo maintains service centers strategically located throughout the United States,

Europe and Asia. Each center is staffed by specialists with considerable application

know-how. They have original factory replacement parts in stock and are equipped

with the tools, fixtures and special machinery necessary for pump and compressor

repair. The nash_elmo commitment to service extends to its regional distribution cen-

ters and retailers. Stocked with inventories of factory parts and purchased components,

our distribution centers can deliver pumps and parts anywhere, any time. We are also

able to service vacuum pumps and compressors of other makes and models.

A new company, a unified vision

nash_elmo is more than a new company. It is the fusion of global leaders in the

development, design and application of vacuum and compressor system technology.

Our combined resources give us the ability to provide the best solution to any industrial

need virtually anywhere in the world. We are a company with an extensive range of

products and services and an unmatched reputation for reliability. Because nash_elmo

is a company with the resources to turn the most ambitious vision into reality and to

put that vision to work for you.

Commitment, reliability and worldwide support

HEN

NIG

· N

bg

All

ill

ust

rati

on

s are

non

-b

ind

ing ·

All

dim

en

sion

s are

ap

pro

xim

ate

. Su

bje

ct

to t

ech

nic

al

mod

ific

ati

on

s

European Headquarters

Nuremberg, Germany

Katzwanger Straße 150

D-90461 Nürnberg

Tel.: +49 911 1454 0

Order-No: VNE:B-PB015-A1-AM

Printed in Germany

2238/019 10.0 / 04-2004

© 2004 All rights reserved

nash_elmo Industries

www.nash-elmo.com

Corporate Headquarters

Trumbull, CT USA

9 Trefoil Drive

Trumbull, CT 06611-1330

Tel.: +1 800 553 6274

Other nash_elmo product lines

L_Series: Liquid Ring Pumps

D_Series: Dry Pumps

Robust technology for the highest demands and varied applications

Machines in the L_Series distinguish themselves through low opera-

ting temperatures and are suitable for handling splash water, steam

and condensates. They were developed for the toughest applications

and can safely and reliably extract or compress even explosive gas/

steam mixtures (ATEX-certified). Selection of a suitable operating

liquid enables the L_Series vacuum pumps and compressors to be

optimally integrated into processes. Thanks to their low operating

costs and extensive performance range up to 37,000 m3/h

(22,000 cfm), they excel in any application.

Proven, reliable and extremely quiet

Whether vacuum pumps, compressors or systems for conveying air,

gases or air/gas mixtures, the extensive range of products in the

G_Series meets the widest range of requirements. Thanks to their

variable voltage motors, many are usable anywhere in the world

without the need for conversion. In addition to their compact con-

struction, full UL/CSA certification and innovative design, G_Series

pumps and compressors offer a comprehensive power range up to

2,500 m3/h (1,470 cfm), maximum power density and a wide selec-

tion of accessories, including frequency converters.

Simple design for varied applications

The vane pumps in our V_Series are known for their robust design,

easy handling and long service life. Furnished with an extremely

sturdy metal coating as well as installation- and service-friendly

plug & play functionality, these high performance machines are

extremely quiet in operation, and can meet even the most chal-

lenging industrial demands while covering an impressive perfor-

mance range up to 4,000m3/h (2,350 cfm) and 10 bar g (145 psig).

High reliability with low operating costs

The dry-running vacuum pumps in our D_Series are explosion-proof

and were specially developed for production processes involving

sensitive materials. Throughout the entire process, they operate

condensation-free – and therefore corrosion-free – because there

are no operating fluids to mix with the process gases. As a result,

discharge gases can simply be collected and/or returned to the process.

There are no waste products. In addition, all pumps in the D_Series

are highly efficient and provide a constant suction capacity over an

extremely wide range of pressures with a performance range up to

to 2,200 m3/h (1,300 cfm).

V_Series: Vane Pumps

G_Series: Gas Ring Blowers