KNOWN: FIND: SCHEMATIC AND GIVEN DATA: Steam p = 80 bar … · 2017-10-23 · 2 (b) The exit flow...

Transcript of KNOWN: FIND: SCHEMATIC AND GIVEN DATA: Steam p = 80 bar … · 2017-10-23 · 2 (b) The exit flow...

1

4.3 Steam enters a 1.6-cm-diameter pipe at 80 bar and 600oC with a velocity of 150 m/s.

Determine the mass flow rate, in kg/s.

KNOWN: Pressure, temperature, and velocity of steam entering a 1.6-cm-diameter pipe.

FIND: Mass flow rate, in kg/s.

SCHEMATIC AND GIVEN DATA:

ENGINEERING MODEL:

1. Flow is one-dimensional.

ANALYSIS:

The governing equation for one-dimensional flow in terms of specific volume is

v

AVm

At p = 80 bar and T = 600oC, the steam is superheated vapor. Obtaining specific volume of the

steam from Table A-4: v = 0.04845 m3/kg.

Cross-sectional area of the flow based on pipe diameter is

2

2

222 m 00020.0

cm 10000

m 1)cm 6.1(

44A

D

Solving for the mass flow rate yields

/kgm 0.04845

m/s) )(150m (0.00020

3

2

m = 0.62 kg/s

D = 1.6 cm

Steam

p = 80 bar

T = 600oC

V = 150 m/s

1

4.16 Air enters a one-inlet, one-exit control volume at 6 bar, 500 K, and 30 m/s through a flow

area of 28 cm2. At the exit, the pressure is 3 bar, the temperature is 456.5 K, and the velocity is

300 m/s. The air behaves as an ideal gas. For steady-state operation, determine

(a) the mass flow rate, in kg/s.

(b) the exit flow area, in cm2.

KNOWN: Air flows through a one-inlet, one-exit control volume with known pressure,

temperature, and velocity at the inlet and exit.

FIND: Determine the mass flow rate and exit flow area.

SCHEMATIC AND GIVEN DATA:

ENGINEERING MODEL:

1. The control volume shown on the accompanying figure is at steady state.

2. The ideal gas model applies for the air.

ANALYSIS:

(a) The mass rate balance for one-inlet, one-exit, steady flow is

1m = mm 2

For the inlet, state 1, the mass flow rate can be determined from given data and the ideal gas

equation of state.

1m = 1

111

1

11

/

VV

TMR

pA

v

A

Substituting values yields

1m =

24

22

52

cm 10

m

bar

m

N10

K 500

kmol

kg97.28

Kkmol

mN8314

bar 6s

m30cm 28

= 0.351 kg/s

p1 = 6 bar

T1 = 500 K

V1 = 30 m/s

Air

21

p2 = 3 bar

T2 = 456.5 K

V2 = 300 m/s

p1 = 6 bar

T1 = 500 K

V1 = 30 m/s

Air

21

p2 = 3 bar

T2 = 456.5 K

V2 = 300 m/s

2

(b) The exit flow area can be determined from given data and the ideal gas equation of state.

2m = 2

222

2

22

/

VV

TMR

pA

v

A

Solving for area

A2 =

22

22

V

/

p

TMRm=

2

24

2

5 m

cm 10

m

N10

bar

bar 3s

m300

K 5.456

kmol

kg97.28

Kkmol

mN8314

s

kg351.0

= 5.1 cm2

1

4.36 Nitrogen, modeled as an ideal gas, flows at a rate of 3 kg/s through a well-insulated

horizontal nozzle operating at steady state. The nitrogen enters the nozzle with a velocity of 20

m/s at 340 K, 400 kPa and exits the nozzle at 100 kPa. To achieve an exit velocity of 478.8 m/s,

determine

(a) the exit temperature, in K.

(b) the exit area, in m2.

KNOWN: Nitrogen flows through a nozzle.

FIND: (a) the exit temperature, in K, and (b) the exit area, in m2.

SCHEMATIC AND GIVEN DATA:

ENGINEERING MODEL:

1. The control volume shown with the schematic is at steady state.

2. For the control volume, ,0cv W ,0cv Q and pe = 0.

3. Model nitrogen as an ideal gas.

ANALYSIS:

(a) The energy rate balance

0 = mWQ cvcv [(h1 – h2) + ½ (V12 – V2

2) + g(z1 – z2)]

simplifies to

0 = [(h2 – h1) + ½ (V22 – V1

2)]

Since enthalpy values for nitrogen are provided on a molar basis in Table A-23, the energy rate

balance is expressed in terms of molar enthalpy

M

hh )([0 1 2 + ½ (V2

2 – V1

2)]

Solving for exit molar enthalpy, which is a function of only temperature, gives

)VV(2

21

221 2

Mhh

From Table A-23, kJ/kmol 98881 h

From Table A-1 (nitrogen): M = 28.01 kJ/kmol

Nitrogen

T1 = 340 K

p1 = 400 kPa

V1 = 20 m/s

Nozzle

kg/s 31 m

p2 = 100 kPa

V2 = 478.8 m/s

1 2

2

Substituting values and solving for exit molar enthalpy give

2

22

2

s

mkg1

N 1

mN 1000

kJ 1

s

m20

s

m8.478

2

kmol

kg01.28

kmol

kJ9888h

2h = 6683 kJ/kmol

From Table A-23, the temperature that corresponds to the exit molar enthalpy is T2 = 230 K.

(b) From the mass rate balance

2

2212

VA

v mm

Substituting 2

22

p

RTv from the ideal gas equation of state and solving for the area give

22

212

VA

p

RTm

2

2

m

N 1000

kPa 1

kJ 1

mN 1000

kPa) )(100s

m (478.8

K) (230

kmol

kg01.28

Kkmol

kJ 8.314

kg/s) (3

A

A2 = 0.004278 m2

1

4.100 Separate streams of air and water flow through the compressor and heat exchanger

arrangement shown in Fig. P4.100. Steady-state operating data are provided on the figure. Heat

transfer with the surroundings can be neglected, as can all kinetic and potential energy effects.

The air is modeled as an ideal gas. Determine

(a) the total power required by both compressors, in kW.

(b) the mass flow rate of the water, in kg/s.

KNOWN: Separate streams of air and water flow through a compressor and heat exchanger

arrangement.

FIND: (a) The total power required by both compressors, in kW, and (b) the mass flow rate of

the water, in kg/s.

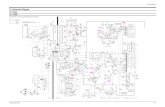

SCHEMATIC AND GIVEN DATA:

ENGINEERING MODEL:

1. Control volumes at steady state enclose the compressors and heat exchanger.

2. For each control volume, heat transfer with the surroundings is negligible and kinetic and

potential effects can be ignored.

3. The air is modeled as an ideal gas.

ANALYSIS:

1

2

Heat exchanger

3

Air

p1 = 1 bar

T1 = 300 K

kg/s 6.01 m

p2 = 3 bar

T2 = 600 K

p3 = p2

T3 = 450 K

T6 = 30oC

p6 = p5

6 5

Water

T5 = 20oC

p5 = 1 bar

Compressor A Compressor B

p4 = 9 bar

T4 = 800 K4

cvAW cvBW

2

(a) A mass balance for the air flowing through compressor A, the heat exchanger, and

compressor B gives

4321 mmmm = 0.6 kg/s

The energy rate balance for compressor A

0 = mWQ cvAcvA [(h1 – h2) + ½ (V12 – V2

2) + g(z1 – z2)]

simplifies to

)( 21cvA hhmW

The specific enthalpies for air at state 1 and state 2 are obtained from Table A-22: h1 = 300.19

kJ/kg and h2 = 607.02 kJ/kg. Substituting values and solving yield

s

kJ 1

kW 1

kg

kJ 02.607

kg

kJ 19.300

s

kg6.0cvA

W = −184.1 kW

Similarly for compressor B,

)( 43cvB hhmW

The specific enthalpies for air at state 3 and state 4 are obtained from Table A-22: h3 = 451.80

kJ/kg and h4 = 821.95 kJ/kg. Substituting values and solving yield

s

kJ 1

kW 1

kg

kJ 95.821

kg

kJ 51.804

s

kg6.0cvB

W = −222.1 kW

The total power required by both compressors is

cvBcvAtotal WWW = (−184.1 kW) + (−222.1 kW) = −406.2 kW

The negative sign indicates power is to the compressors.

(b) Since the air and water do not mix in the heat exchanger, the steady state mass balance

reduces to

32 mm = 0.6 kg/s

65 mm

The steady state form of the energy rate balance

3

e

ee

ee

i

ii

ii gzV

hmgzV

hmWQ22

022

cvcv

simplifies to

663355220 hmhmhmhm

or substituting results from the mass balance

)()(0 655322 hhmhhm

Solving for the mass flow rate of water gives

56

3225

)(

hh

hhmm

The specific enthalpies of water at state 5 and state 6 are obtained from Table A-2:

h5 ≈ hf5 = 83.96 kJ/kg and h6 ≈ hf6 = 125.79 kJ/kg. Substituting values and solving yield

kg

kJ 96.83

kg

kJ 25.791

kg

kJ 51.804

kg

kJ 07.026

s

kg6.0

5

m

5m = 2.23 kg/s

1

4.11 An 8-ft3 tank contains air at an initial temperature of 80

oF and initial pressure of 100

lbf/in.2 The tank develops a small hole, and air leaks from the tank at a constant rate of 0.03 lb/s

for 90 s until the pressure of the air remaining in the tank is 30 lbf/in.2 Employing the ideal gas

model, determine the final temperature, in oF, of the air remaining in the tank.

KNOWN: Air at specified initial temperature and pressure leaks from rigid tank until a final

specified pressure is attained by the air remaining in the tank.

FIND: Final temperature of air remaining in tank, in oF.

SCHEMATIC AND GIVEN DATA:

ENGINEERING MODEL:

1. The control volume is defined by the dashed line on the accompanying diagram.

2. Air can be modeled as an ideal gas.

ANALYSIS:

The ideal gas model can be applied to the final state, state 2, to determine the temperature of the

air remaining in the tank.

p2V2 = m2RT2

Solving for temperature yields

T2 = Rm

Vp

2

22

Pressure and volume are known at state 2. The mass in the tank at state 2, m2, equals the initial

mass in the tank, m1, less the mass that leaks from the tank. Since the mass flow rate, em , is

constant, the amount of mass that leaks from the tank is

em t = (0.03 lb/s)(90 s) = 2.7 lb

The initial mass, m1, is obtained using the ideal gas equation of state

t = 90 s

Process 1 → 2Initial State – State 1 Final State – State 2

V1 = 8 ft3

T1 = 80oF

p1 = 100 lbf/in.2

Air Air

V2 = V1 = 8 ft3

p2 = 30 lbf/in.2

em = 0.03 lb/s

t = 90 s

Process 1 → 2Initial State – State 1 Final State – State 2

V1 = 8 ft3

T1 = 80oF

p1 = 100 lbf/in.2

Air Air

V2 = V1 = 8 ft3

p2 = 30 lbf/in.2

em = 0.03 lb/s

2

m1 = 1

11

RT

Vp

The gas constant, R, is the universal gas constant divided by the molecular weight of air.

Temperature must be expressed on an absolute scale, T1 = 80 oF = 540

oR. Substituting values

and applying the appropriate conversion factor yield

m1 =

2

23

2

ft 1

in. 144

R540

lbmol

lb97.28

Rlbmol

lbfft1545

ft 8in.

lbf100

= 4.0 lb

Collecting results

m2 = 4.0 lb – 2.7 lb = 1.3 lb

Substituting m2 to solve for T2 yields

T2 =

2

23

2

ft 1

in. 144

lbmol

lb97.28

Rlbmol

lbfft1545

lb 3.1

ft 8in.

lbf30

= 498.5oR = 38.5

oF

Note the need to convert the final temperature from oR to

oF to provide the answer in the

requested units.