KITTIWAKE SAL EXPORT SYSTEM - gov.uk...The Kittiwake SAL Export System comprised a Single Anchor...

Transcript of KITTIWAKE SAL EXPORT SYSTEM - gov.uk...The Kittiwake SAL Export System comprised a Single Anchor...

REVISION NO: C2 KITTIWAKE SAL EXPORT SYSTEM DECOMMISSIONING PROGRAMME

DATE : 06/07/2012 DOCUMENT NO: CEU-PRJ-GKA0028-REP-0003

PAGE: 2 OF 13

AMENDMENT RECORD All amendments to this document shall be recorded on the Amendment Record sheet below. No changes to this document are to be made without approval from the document Approver. Date Incorporated by Revision Section Description

06/07/12

Stewart Ford C2 1.,4.,5.,6. & 7.

Text amended in response to DECC comments. Ref email 25/05/12.

06/07/12

Stewart Ford C2 8., 9. & 10. Added in response to DECC comments. Ref email 25/05/12.

REVISION NO: C2 KITTIWAKE SAL EXPORT SYSTEM DECOMMISSIONING PROGRAMME

DATE : 06/07/2012 DOCUMENT NO: CEU-PRJ-GKA0028-REP-0003

PAGE: 3 OF 13

DISTRIBUTION RECORD Copy No.

Recipient Department/Location

01 02 03 04 05 06 07

Information Management Alex Mateo Marian Bruce David Wilson Alan Walker Alan McLachlan Bob Nye

DCC Aberdeen DECC ([email protected]) DECC ([email protected]) NCNS Regional Manager, CEU Dana ([email protected]) Shell ([email protected]) Subsea Infrastructure Manager, CEU

REVISION NO: C2 KITTIWAKE SAL EXPORT SYSTEM DECOMMISSIONING PROGRAMME

DATE : 06/07/2012 DOCUMENT NO: CEU-PRJ-GKA0028-REP-0003

PAGE: 4 OF 13

TABLE OF CONTENTS 1 INTRODUCTION .............................................................................................................. 5

1.1 Background ........................................................................................................... 5

1.2 Field Information ................................................................................................... 5

1.4 Related Documents .............................................................................................. 7

2 SUMMARY ....................................................................................................................... 7

3 OPERATIONS .................................................................................................................. 7

3.1 Pipeline PL2205 Recovery .................................................................................... 7

3.2 SAL Structure Recovery ....................................................................................... 8

3.3 Debris Clearance ................................................................................................ 10

3.4 Debris Trawl ........................................................................................................ 10

4 VARIANCES FROM THE PROGRAMME ...................................................................... 11

5 ENVIRONMENTAL SURVEY ......................................................................................... 11

6 INSPECTION AND MONITORING ................................................................................. 11

7 PROJECT COSTS ......................................................................................................... 11

8 MILESTONES ................................................................................................................ 11

9 NOTIFICATIONS ............................................................................................................ 12

10 SEABED CLEARANCE CERTIFICATE ........................................................................ 12

REVISION NO: C2 KITTIWAKE SAL EXPORT SYSTEM DECOMMISSIONING PROGRAMME

DATE : 06/07/2012 DOCUMENT NO: CEU-PRJ-GKA0028-REP-0003

PAGE: 5 OF 13

1 INTRODUCTION

1.1 Background

This close-out report summarise the outcome of the Kittiwake SAL Export System Decommissioning Programme dated 24th June 2009. It is intended that this report is read in conjunction with the decommissioning programme and therefore concentrates on how the work was completed and any deviations from the programme.

The Kittiwake SAL Export System Decommissioning Programme incorporates decommissioning programmes for Pipeline PL2205 and the Kittiwake SAL Structure.

The parties responsible for each decommissioning programme are as follows:

SAL Assembly: Dana Petroleum (E&P) Limited, Dana Petroleum Public Limited Company, Nordic Troll and Trym LLC, Venture North Sea Oil Limited and Venture Production PLC

Pipeline PL2205: Dana Petroleum (E&P) Limited, and Venture North Sea Oil Limited

The Kittiwake SAL Export System comprised a Single Anchor Loading (SAL) structure anchored to the seabed by four integral suction anchors and a 3km flexible pipeline. Both of these components were leased items and were therefore returned to the owner for potential rehire.

The Kittiwake SAL Export System replaced the Kittiwake Loading Buoy (KLB) as the export route for crude oil from Kittiwake. The KLB has since been decommissioned. The SAL system was replaced by an export pipeline in 2007. The SAL pipeline and the pipework within the SAL structure were thoroughly flushed, disconnected, sealed with blind flanges and left filled with treated seawater. As the lease for the system terminated in 2010, final decommissioning of the system was planned on the basis of returning the equipment within this timescale.

1.2 Field Information

Kittiwake is located in Block 21/18 of the UKCS (Central North Sea), licence number P.0351. Kittiwake is approximately 135km East of Peterhead at 6 369 780N 530 721E. The Kittiwake SAL assembly is located approximately 2.9km North East of Kittiwake Platform at 6 372 079N 532 535E. The water depth at SAL is 85m.

1.3 Scope of Decommissioning

The scope of decommissioning encompasses the complete removal of the Kittiwake SAL Export System and returning the seabed to a safe condition for fishing and other uses of the sea.

The export riser and tie-in spool which also form part of PL2205 have been retained for potential reuse. These items, which are both within the Kittiwake 500m safety zone, are presently filled with treated seawater.

Redundant mattresses, grout bags and other recovered waste materials will be sent for disposal by a UK based licensed disposal contractor.

REVISION NO: C2 KITTIWAKE SAL EXPORT SYSTEM DECOMMISSIONING PROGRAMME

DATE : 06/07/2012 DOCUMENT NO: CEU-PRJ-GKA0028-REP-0003

PAGE: 6 OF 13

A survey of the area around the SAL and the pipeline was undertaken. Man-made debris considered to be significant was identified and subsequently recovered and sent for disposal by a UK based licensed disposal contractor.

Once the removal scope was completed, a debris trawl, covering the SAL 500m safety zone and a 200m corridor centred along the pipeline route, was carried out to confirm that the seabed is clear of significant debris and safe for the resumption of fishing activities. The pipeline survey started at the perimeter of the Kittiwake safety zone. This work was organised by the Scottish Fishermen’s Federation and verified by an independent third party.

Seabed samples were taken and tested for the presence of hydrocarbons and other pollutants. These, together with samples taken in earlier environmental surveys undertaken in the area, will be used as a basis for discussing and agreeing requirements for further environmental monitoring with DECC.

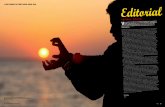

Schematic of a SAL in Operation

REVISION NO: C2 KITTIWAKE SAL EXPORT SYSTEM DECOMMISSIONING PROGRAMME

DATE : 06/07/2012 DOCUMENT NO: CEU-PRJ-GKA0028-REP-0003

PAGE: 7 OF 13

1.4 Related Documents

1. Kittiwake SAL Export System Decommissioning Programme.

2. Kittiwake SAL Debris Survey Subsea7 Report No ET0650-KSS-R-001

3. Post SAL2 Debris Recovery GL Noble Denton Report No A7350

4. Kittiwake SAL Decommissioning Environmental Survey: Environmental Study and Habitat Assessment August 2010 Guardline Report Ref 8469.

5. Trawl Sweep Certificate Scottish Fishermen’s Federation

2 SUMMARY

Pipeline PL2205 was successfully recovered during summer 2009 and offloaded at Peterhead. It was transferred to reels and stored until formally handed over to the owner at the end of the contractual hire period in 2010.

The first attempt to recover the SAL structure took place in July 2010. This attempt was unsuccessful and a second, successful campaign was undertaken in April 2011. The SAL was towed to Mekjarvik in Norway where it was placed on the quayside and handed over to the owner.

An environmental survey was carried out during 2010.

The bulk of seabed debris clearance was completed in July 2010 and completed in July 2011.

A debris trawl was conducted by the Scottish Fishermen’s Federation in September 2011. The material that was recovered. was disposed of using the facilities provided by Kummunenes Internasjonale Miløorganisation (KIMO) for the safe disposal of debris caught in fishing nets.

3 OPERATIONS

3.1 Pipeline PL2205 Recovery

The pipeline was recovered using the reel ship Seven Navica. This was essentially a reverse lay process and was completed without incident.

REVISION NO: C2 KITTIWAKE SAL EXPORT SYSTEM DECOMMISSIONING PROGRAMME

DATE : 06/07/2012 DOCUMENT NO: CEU-PRJ-GKA0028-REP-0003

PAGE: 8 OF 13

Seven Navica Recovering the SAL Flowline at Kiitiwake.

The pipeline was offloaded onto two Aquatic reels in Peterhead harbour. Unfortunately an extreme storm passed through at the time of the transfer to shore and the onshore mobile crane could not operate. As a result a significant period of “waiting on weather” resulted whilst Seven Navica was docked.

The pipeline was eventually transferred to shore and put in store pending formal transfer to the owner at the end of the contract hire period in 2010.

3.2 SAL Structure Recovery

The first attempt to recover the SAL structure took place in July 2010. The plan was to recover the SAL and tow it to shore using a procedure that was essentially a reverse of installation. The SAL was designed to be buoyant during tow to site and subsequent to to shore at the end of use. The proposal was therefore in line with the original design intent.

The SAL structure is anchored to the seabed by four integral cylindrical suction anchors. These cylinders are in contact with each other so that there are a total of five chambers, the fifth camber being formed by the central space between the four main chambers.

Unfortunately a significant quantity of clay remained adhered to the cylinders after the anchors were extracted from the seabed and there was insufficient buoyancy to refloat the SAL structure. It was also thought possible that clay was present in the central chamber. Much of the clay on the external surfaces was removed but the weather had changed and, as a suitable weather window was not forecast for the foreseeable future, the decision was taken to ensure that that the SAL structure was stable on the seabed, and recovery operations were suspended.

REVISION NO: C2 KITTIWAKE SAL EXPORT SYSTEM DECOMMISSIONING PROGRAMME

DATE : 06/07/2012 DOCUMENT NO: CEU-PRJ-GKA0028-REP-0003

PAGE: 9 OF 13

The Pencil Buoy Concept

Although it was considered likely that the SAL structure could be refloated, a different recovery method was adopted to eliminate uncertainty. The alternative method involved suspending the structure from a buoy during the tow. This method required the structure to be negatively buoyant and was therefore not sensitive to the weight variations caused by adhered clay. It is also less weather critical than the conventional tow envisaged by the SAL designers. However this method requires a deep harbour and a suitable “hard” bottom on which to park the structure before it is lifted inshore by a shear leg crane vessel.

The alternative operation was successfully completed in April 2011 and the SAL formally handed over to its owners.

REVISION NO: C2 KITTIWAKE SAL EXPORT SYSTEM DECOMMISSIONING PROGRAMME

DATE : 06/07/2012 DOCUMENT NO: CEU-PRJ-GKA0028-REP-0003

PAGE: 10 OF 13

Kittiwake SAL coming ashore at Mekjarvik

3.3 Debris Clearance

The bulk of the debris clearance was undertaken during the first attempt to recover the SAL. It was not possible to recover all the material at this point and the remainder was dealt with after the SAL was off site in 2011.

All waste material was returned to Peterhead harbour and sent for disposal by a licenced contractor.

No hazardous material was present.

3.4 Debris Trawl

A debris trawl was undertaken by the Scottish Fishermen’s Federation (SFF) later in the year to confirm that the seabed had been adequately cleared and that it would be safe to resume fishing activities and other uses of the sea.

The target area covered the 500m safety zone around the SAL and a 200m corridor centred on the pipeline route. Inevitably the area trawled is much larger than the target to permit safe vessel manoeuvers. Some small metal items were recovered but the only sizable items were a vacuum cleaner and portable hi-fi (ghetto blaster). Neither were found in the target area.

The certificate issued by SFF confirming that the seabed is clear is attached in Section 10.

REVISION NO: C2 KITTIWAKE SAL EXPORT SYSTEM DECOMMISSIONING PROGRAMME

DATE : 06/07/2012 DOCUMENT NO: CEU-PRJ-GKA0028-REP-0003

PAGE: 11 OF 13

4 VARIANCES FROM THE PROGRAMME

The abandonment of the first attempt to recover the SAL made it necessary to apply for an extension to the programme schedule. An extension to July 2012 was granted.

Environmental samples were taken before the SAL structure was finally removed from site. This took advantage of an opportunity to make use of a survey vessel on hire for other projects.

5 ENVIRONMENTAL SURVEY

An environmental survey was undertaken in August 2010 and the results referenced to recent environmental surveys in the same area. The results will be discussed with DECC with a view to agreeing any further sampling requirements.

6 INSPECTION AND MONITORING

The scope of any on-going requirements for inspection and monitoring will be discussed and agreed with DECC.

7 PROJECT COSTS

Programme

Estimate £m Final £m

Pipeline PL2205

2.3 2.8

SAL Anchor Structure

3.5 5.7

Project Total

5.8 8.5

Pipeline PL2205 was recovered a year early and was stored pending formal hand-over at the end of the hire period. The overspend relates entirely to the cost of preservation and onshore storage made necessary by early recovery (£0.4m) and the weather delay during load in (£0.3m).

The overspend in recovering the SAL Anchor Structure resulted entirely from the aborted first recovery attempt. Costs for the first attempt were £2.9m whilst costs to complete in 2011 were £2.8m.

8 MILESTONES

Milestone Planned Earliest

Planned Latest

Programme Variance

Actual

PL2205 Removed Aug 2009 Sept 2010 - Aug 2009

SAL Anchor Structure Removed Aug 2009 Sept 2010 Sept 2011 April 2011

Offshore Work Completed Dec 2009 Feb 2011 July 2012 Oct 2011

REVISION NO: C2 KITTIWAKE SAL EXPORT SYSTEM DECOMMISSIONING PROGRAMME

DATE : 06/07/2012 DOCUMENT NO: CEU-PRJ-GKA0028-REP-0003

PAGE: 12 OF 13

9 NOTIFICATIONS

The following have been advised that the works have been completed and that the seabed is clear:

United Kingdom Hydro-graphic Office (UKHGO)

Health and Safety Executive

Kingfisher service

UKGO are in receipt of the seabed clearance certificate attached in Section 10.

10 SEABED CLEARANCE CERTIFICATE

The seabed clearance certificate issued by the Scottish Fishermen’s Federation is attached below.

REVISION NO: C2 KITTIWAKE SAL EXPORT SYSTEM DECOMMISSIONING PROGRAMME

DATE : 06/07/2012 DOCUMENT NO: CEU-PRJ-GKA0028-REP-0003

PAGE: 13 OF 13