KINETIX INTEGRATED MOTION - Klinkmannmedia.klinkmann.fi/catalogue/en/Rockwell/Rockwell_Power... ·...

Transcript of KINETIX INTEGRATED MOTION - Klinkmannmedia.klinkmann.fi/catalogue/en/Rockwell/Rockwell_Power... ·...

KINETIX INTEGRATED MOTION

REALIZE THE POWER OF THE INTEGRATED ARCHITECTURE

www.klinkmann.com6 / 2011

RSLogix 5000

RSView HMI Internet

EtherNet/IP

SERCOS Interface™ SERCOS Interface™

WebBrowser

ControlLogixCompactLogix 1768-L43

Kinetix 6000Multi-Axis System

Kinetix 6000Multi-Axis System

Ultra3000Servo Drive

Kinetix 7000High PowerServo Drive

wwwwww

MP-SeriesIntegrated Gear Motor

MP-SeriesLow Inertia

Motor

MP-SeriesStainless Steel

Motors

MP-SeriesFood Grade

Motors

TL-Series NEMA Motor/MP-Series Integrated Linear Actuator

KINETIXINTEGRATED MOTION – REALIZE THE POWER OF TRUE INTEGRATION

It’s a breakthrough in motion control. It’s a breakthrough in sequential control. It’s Kinetix IntegratedMotion, a revolutionary concept fromRockwell Automation.

Fierce. That's the only way to describe today’s competitive businessclimate. Time, money and productivity are more important than ever,and survival depends on staying one step ahead of the competition.Fortunately, you’re not facing those sizeable challenges alone.There’s been a true breakthrough in motion control, bringingunmatched flexibility to your machine design and unprecedentedefficiency to your manufacturing floor. It’s Kinetix® Integrated Motion.And it’s only available through the Rockwell Automation Integrated Architecture.

With Kinetix, you’ll benefit from:• A machine control architecture that integrates sequential, motion,

power and mechanics in a single platform• Allen-Bradley world-class motion control products• Motion application expertise

Kinetix® brings you a complete motion solution – seamless integrationof the Allen-Bradley ControlLogix®, CompactLogix™ or SoftLogix™

controllers, SERCOS interface™ Digital Motion Modules, Allen-Bradley®

servo drives, motors and actuators, and extensive applicationknowledge, – to make integrated motion the new standard for machine control.

2

Kinetix provides true integration of logic

and motion control, with just one controller and

one software package that integrate control,

power and mechanics. As a result of this

true integration, you'll enjoy:

• Seamless transfer of information throughout

the machine and enterprise

• Increased speed and precision for greater

productivity and improved process quality

• Shorter time to market through faster

application development

• Increased uptime and lower maintenance costs

• Lower system costs

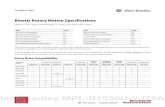

Kinetix Architecture

EASIER AND FASTERFROM DESIGN TO MAINTENANCE

3

EASY TO DESIGN – SAVE APPLICATIONDEVELOPMENT TIME• One software; one intuitive programming

environment for sequential, motion andprocess. Applications can be reduced to small,easily understood parts.

• Concurrent electrical design and programming reduces the time it takes to get product to customers

• Create tags once and use enterprise-wide through visualization tools such as RSView®

• Choice of three IEC-61131-3 languages within RSLogix 5000:– Ladder Logic– Sequential Function Chart– Structured Text

• Quickly add and configure motion axes using wizard-based configuration tools - just point and click

• Graphical motion profile and CAM configurationtools provide easy-to-use visual information

• Write and re-use modular code• Flexible and scalable control solution for handling

a wide range of applications

EASY TO INSTALL – SAVE TIME AND REDUCESPACE CONSUMPTION• Minimize your wiring with Kinetix:

– Plug and play drives and motors speed up commissioning

– One SERCOS fiber optic linkreplaces up to 18 discrete wiresper drive

•

Components are eliminated:– One integrated sequential

and motion controller– One software package– Smaller enclosure

panel requirements

Motion instructions are integrated into RSLogix 5000™

software for fast, convenient programming.

Single software packageto program motioncontrol, sequential

control and servo drives.

Easily collect and viewproduction data fromone central location.

An information-enabled architecture - Detailed motiondrive and motor information where you need it, when youneed it, providing early detection of problems and reducingthe risk of damage to motors and other plant equipment.

EASY TO MAINTAIN – REDUCE DOWNTIME• One investment in training, licensing and spare parts• Field upgradable features shared across all Logix platforms• Routine condition monitoring and process reporting methods• Quick and easy system re-start with absolute feedback• Advanced diagnostics via RSLogix 5000• True integration simplifies data collection. With excellent information

available, fault tracing and correction are easier. Lost production is minimized

• Quick and easy firmware revision management for all Kinetix servo drives via RSLogix 5000

EASY TO OPERATE –OPTIMIZE MACHINE PERFORMANCE• Train once, gain from

your investment across future applications

• Improve machine availability and reliability

• Integrate plant floor and business systems

• High performance machine control solution

• RSLogix 5000 extends configuration and monitoring support to the servo drive

Digital Motion interfaceKinetix drives are optimized for the ControlLogix, CompactLogix or SoftLogix SERCOS interface Digital Motion Modules.SERCOS (SErial Real-time COmmunications System) is a controller/drive interface using noise-immune, fiber optic cables.The result is state-of-the-art motion control with these important benefits:

• Kinetix provides advanced diagnostics and process reporting via the SERCOS interface.• A single fiber optic ring serves as the sole interface between control and drive. It replaces

costly command and feedback wiring, reducing both installation time and wiring costs.• Wide variety of motion module options for ControlLogix, CompactLogix and SoftLogix.• Up to 16 axes of motion can be controlled from one motion module.• System is fully expandable, with up to 32 axes supported per controller.

Multiple controllers can be used if additional axes are needed.

All five links of the Kinetix chain work together to provide unprecedented efficiency, productivity and ease of use.

Logix PlatformsLogix combines motion, sequential, process and drive control into one multi-tasking control platform, resulting in lower system costs, easier maintenance and simplifiedsystem installation.

ControlLogix, CompactLogix and SoftLogix using RSLogix 5000 softwareKinetix uses the Logix control platform to provide a highly scalable control solution.ControlLogix is capable of handling the most intensive applications; CompactLogixprovides cost-effective control for smaller applications, and SoftLogix provides Logix capabilities in a personal computer package. All three are high performance,easy-to-use controllers which use RSLogix 5000 software to configure, program and monitor a system. Motion control functions are embedded in the RSLogix5000 programming software and in the controller. As a result, motion and sequential commands are executed together for complete synchronization ofsequential and motion control.

LanguagesExtensive set of motioncommands is available in three IEC-61131-3languages: Ladder Logic,Structured Text andSequential Function Chart.Multiple languages can beused for the same project.Choose the language that is best for the function being performed.

4

Graphical Motion Profile Editor• Quickly create complex motion profiles

and CAMs with the graphical motionprofile editor built into RSLogix 5000.

• Monitor profiles created dynamically during runtime.

Structured Text

Sequential Function Chart

LadderLogic

Programming and Commissioning• Choice of multiple programming

languages offers flexibility.• Programming and

commissioning are simplified with “plug and play” drive connectivity.

•Wizard-based configuration tools make it easy to add and configure motion axes and drives.

• Graphical editor simplifies creation of complex motion profiles.

Diagnostics and Maintenance• RSLogix 5000 drive hookup diagnostics and auto-tuning

save commissioning time and improve machine performance.• With remote diagnostics, detailed drive and motor status

information is available anywhere in the Logix system,allowing you to remotely manage applications where needed.

• System level software and firmware revision management feature provides time-saving tools for user-directed updates.

WORLD-CLASS PRODUCTSWORKING TOGETHER TO PROVIDE A SUPERIOR SOLUTION

Kinetix MotorsAllen-Bradley servo motors are designed to provide the ideal combination of performance andcost-effectiveness for your application. A variety of motor families are available to meet yourrequirements, including stainless steel motors for hygienic environments, high power motorsand compact high performance motors with NEMA frame sizes. Kinetix motor familiestypically use Smart Motor Technology to provide automatic identification of a specific motorconnected to the drive, reducing commissioning time. Accuracy and velocity stability areincreased with more than 2,000,000 position counts per motor revolution. Motors offercontinuous torque from less than one Nm up to 700 Nm.

Kinetix ActuatorsMachine builders and end users seeking a compact, efficient and cost-effective alternative topneumatic, hydraulic actuation, or component-based servo actuator solutions can benefitfrom the new Allen-Bradley MP-Series Integrated Linear Actuators. These rod-style electro-mechanical actuators combine the motor, long life ballscrew actuator, and a high-resolutionabsolute feedback device into a single unit, reducing mechanical complexity and assembly requirements. When youneed a rotary actuator, look to the MP-Series Integrated Gear Motor for a high torque, direct drive servo solution.This carefully designed package offers optimized performance, size and connectivity.

Kinetix DrivesThe Kinetix 6000, Kinetix 7000 and Ultra3000 are all part of the drives link of the Kinetix Integrated Motion solution, allowing you to match the drive to the specific needs of your application. They are seamlessly integrated into the Logix platforms and communicate to the controller through the SERCOS fiber optic link. As part of the Kinetix Solution, these drives offer: plug and play configurability, fast integration and start up, superior diagnosticcapabilities, and reduced wiring and installation costs. All Kinetix drives are matched to Kinetix servo motors such as the MP family, featuring highresolution feedback encoders for improved system performance and have built-in support for multi-turn absolute encoders to maintain position duringpower loss. The Kinetix 6000 and Kinetix 7000 feature GuardMotion, an embedded technology that provides safety as part of Kinetix Integrated Motion.With GuardMotion, you can take advantage of high performance servo drives that not only provide safety for personnel but also enable machineproductivity enhancements.

5

With Kinetix, you can easily add and configuredrives using familiar RSLogix 5000 wizard-based configuration tools.

Kinetix 6000 – The Kinetix 6000 multi-axis servo drive combines advanced control capability with innovative modular design features tosignificantly improve system performance while saving time and money. This new generation of servo drive offers compact size,

simplified wiring and easy-to-use components. The Kinetix 6000 is available in global voltages for use with motors offeringcontinuous torque from less than one Nm to 700 Nm. For applications with power requirements from 1.2 kW to 22 kW.

Kinetix 7000 – The Kinetix 7000 servo drive extends the benefits of Kinetix® Integrated Motion to high powerapplications, delivering ease of use as well as outstanding performance based on established, successful

product designs. Use with both permanent magnet (synchronous) and induction (asynchronous)motors. For applications with power requirements up to 150 kW.

Ultra3000 – The Ultra3000 is a high performance digital servo drive that provides flexibilityin single or multi-axis applications. The Ultra3000 is compatible with a large variety of

Allen-Bradley motors offering continuous torque from less than one Nm to 700 Nm. Forapplications with power requirements from .5 kW - 22 kW.

Kinetix 6000

Ultra3000

Kinetix 7000

S

Integrated Linear Actuators available in mid-2006.

At the development stage . . .Kinetix allows the machine designer to maximize efficiency for virtually everymanufacturing application. Kinetix uses fewer components to provide seamlessintegration of control, communication and visualization, while reducing time,cost and complexity from concept to commissioning.

COST REDUCTIONSFROM MACHINE DEVELOPMENT TO THE FACTORY FLOOR

For machine builders, Kinetix saves time and money every step of the way

DESIGN• Greatly reduce engineering time and costs by re-using engineering practices• Fewer components minimize initial hardware purchases• Only one software package to purchase, install and keep up to date• Less training required with just one comprehensive software package• Eliminate communication code between components

INSTALLATION• Fewer connections significantly reduce labor required for wiring• Fewer total components are faster and less expensive to install

COMMISSIONING• Increased system reliability makes start-up faster and easier• Engineers can commission an entire system from a single point

PRODUCTION• Troubleshooting is easier, with detailed drive and motor status information

available in RSLogix 5000 and the ControlLogix or SoftLogix control program• Greater reliability results in fewer follow-up calls after machinery is installed• Increase sales by providing customers with machines that improve productivity

Traditional motion controltypically involves programmingfor the PLC plus separateprogramming for motion controland drives. Each requiresspecific programming expertiseas well as communication andsynchronization code. Kinetixgreatly simplifies the process,resulting in a significant savings of time and money.

“Similar servo motion programs, such as theblank feed and the partition feed, took significantly less time to program using theControlLogix motion programming software.Programming time was cut by 50%. We simplycut, pasted, and renamed.Programming took an hour, instead of several hours.”

— Manager of Electrical

Engineering at a major

packaging machinery OEM

6

Without Kinetix . . .

Simplify Your Solution

Kinetix Integrated Motion

1 Controller

1 Software Package

1 Programming Language

Traditional Motion Control

2Controllers

2 SoftwarePackage

2Programming

Languages

ExtraCommunication

Logic

ExtraCoordination

Logic

Your choice of• Ladder• Sequential

Function Chart• Structured Text

Your choice of• ControlLogix• CompactLogix• SoftLogix

On the Plant Floor...

Kinetix is an effective solution for basic motion control as well as high performance

applications requiring high speeds, high accuracy, system configuration flexibility and precise

control of many axes. Kinetix effectively handles packaging, material handling, converting,

assembly and other industries with applications that require superior performance and

dependability without sacrificing accuracy. Kinetix can meet these complex production

requirements because it provides true integration between motion and sequential control.

Kinetix-enabled machinery brings the flexibility to keep up with frequent line changes

and the scalability to easily handle the introduction of new products. Integrated motion

increases total throughput and uptime, maximizing equipment utilization while making

maintenance much easier and more efficient.

...Responding to changing needs is everything.

• You’ll find Kinetix systems are easy to understand and simple to expand and optimize

• There’s no complex interface code to troubleshoot

7

Motion Analyzer provides the tools to do it right the first timeMotion Analyzer is a powerful software tool used for developingmotion control solutions. Motion Analyzer assists you inselecting the correct motor, servo drive, and gearbox if required.Motion Analyzer containssophisticated optimizationtools to help you maximizeperformance, inertia ratio,and mechanical alternativesfor motion controlapplications. Motion Analyzer:

• allows you to fully optimizeyour servo solution

• provides highly advanced optimization utilities

• provides system performance information

• performs tolerance analysis • provides a multi-segment

cycle profile • provides unlimited

profile steps • allows you to

import/export profiles• provides for a variety

of actuator configurations• allows you to export the

application selectionsand details to Microsoft® Word

Motion application expertise with worldwide supportIn addition to world-class products, Rockwell Automation offers the industry’s broadest range of support services to help youimplement your motion control solution – no matter where youare. Our specialists in motion control and servo drive technologyhave the expertise to evaluate your application requirements andhelp you achieve the optimum solution. In addition, we offer awide range of application experience to assist you with yoursolution, providing productivity improvements while helping toreduce commissioning time. Our broad range of applicationexpertise will guide you to a complete Rockwell Automationsolution that meets your needs today and in the future.

Rockwell Automation Engineering Solutions leverages RockwellAutomation’s decades of know-how to provide world-classtechnical support through:

• Real-time Phone Support - Call centers directly route you to the product specialist who can answer your question immediately.

• Web Services – Site hosts a variety of technical support tools including: manuals, product updates and online support requests.

• Support Products – Support tools have been designed to prevent the problems you face on a daily basis. These products help reduce the time it takes to troubleshoot problems or configure equipment for control applications.

• On-site Services – On-site technical assistance is only a call away. The Rockwell Automation Engineering Solutions team from across the world provides the expertise customers need for new project start-ups, projects that need supplemental resources and efficient problem solving.

WORLD-CLASSSUPPORT SERVICES AND TOOLS

For additional product information, refer to the Allen-Bradley Kinetix Motion Control Selection Guide: Publication # GMC-SG001x.For more information on Kinetix Integrated Motion or any of our support services, contact your nearest Rockwell Automation sales office or motion control distributor, or refer to our Web site: www.ab.com/motion

All trademarks, company names and product names referred to throughout this publication are for identification only and remain the property of their respective companies.Publication MOTION-BR001E-EN-P – February 2006 — Supersedes Publication MOTION-BR001D-EN-P – May 2005 Copyright ©2006 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Create, import, and export complexmulti-segment cam profiles.

Comprehensive analysis ofperformance results

Define motion profilerelationships in multi-axissystems to optimize powersupply (IAM) selection

Rockwell_Power_Motion_Kinetix_Integrated_Motion_Brochure_en_0611.pdf

Samaratel. +7 846 273 95 [email protected]

Yekaterinburgtel. +7 343 376 [email protected]

St. Petersburgtel. +7 812 327 [email protected]

Moscowtel. +7 495 641 [email protected]

Helsinkitel. +358 9 540 [email protected]

Vilniustel. +370 5 215 [email protected]

Rigatel. +371 6738 [email protected]

Мinsktel. +375 17 200 [email protected]

Tallinntel. +372 668 [email protected]

Кievtel. +38 044 495 33 [email protected]

www.klinkmann.com