Process Design of Heat Exchanger: Types of Heat exchanger ...

KELVION THERMAL SOLUTIONS A Rebrand for the Heat Exchanger ... · PDF fileHeat Exchanger...

Transcript of KELVION THERMAL SOLUTIONS A Rebrand for the Heat Exchanger ... · PDF fileHeat Exchanger...

CKELVION THERMAL SOLUTIONS

Catering for companies across Southern Africa and far beyond, Kelvion Thermal Solutions manufactures air cooled heat exchangers, shell and tube heat exchangers, pressure vessels and cooling towers for the petrochemical, power and mining industries.

PRODUCTION: Karl Pietersen

A Rebrand for the Heat Exchanger Specialists

//Kelvion Thermal Solutions was better known for many years as GEA Aircooled Systems,

whose South African operations began in 1975. The parent company was founded by Otto Happel senior in Bochum, Germany in the 1920s, and was initially a company specialising in the manufacture of dust removal systems. Its name - Gesellschaft fur Entstaubungs-Anlagen - translates to ‘company for dust-removal-plants’ - and lent it the more commonly seen abbreviation GEA.

Over its distinguished lifetime the company’s activities diversified into various related fields, encompassing thermal and energy technologies, food and process engineering, air-treatment,

refrigeration and environmental technology.

GEA began its South African operations in 1971. At the outset, this arm of the business served primarily as an engineering and sales office for the group’s products and services, which at the time were essentially imported from the German parent company. GEA Aircooled Systems was then founded in 1975, winning some notable contracts catering for the power industry in the early 1970s, which were then followed by further contracts for the petrochemical industry. These rapid successes combined to result in an aggressive expansion of the South African operation.

The acquisition and subsequent

extension of local manufacturing facilities followed out of necessity, in order to keep pace with the growing demand for its relatively new services. GEA Aircooled Systems became largely independent after a total technology transfer from the parent company, giving it full control over the day-to-day running of the company.

When GEA sold GEA Heat Exchangers Group to an investor, Triton, in 2014, the group was subsequently split into three distinct divisions: Kelvion, which specialises in industrial heat exchangers; Enexio, whose forte is cooling systems for the power industry; and DencoHappel, which offers heating, ventilation and air conditioning.

Enexio is a pioneer in the field of

40 / www.enterprise-africa.net

We are proud supporters of

Kelvion Thermal

• ASME SA 516 Gr 60-65-70N Inc HIC Resistant Qualities• EN 10028 P265GH / P355 NL2/ P460NL2• ASME SA 387 Gr 11 / 22 / 5 / 91• Stainless Steels & Heat Resistant Alloys• A240 Type 304/316/321/904• Duplex (31803/2205) Super Duplex (32750/32760)• Constructional Steels: S355J2+N / S460 N / S690 QL• Wear Resistant Steel: 400/450/500 Brinell• Weathering Steels: S355J2W+N / Corten A&B• Armour Plate: Protection 400 & 500 - Accredited to Military

Grades• Clad Plates• Dished Heads Up to 7000mm Dia• Additional Services: Plasma Cutting / Water Jet Cutting / Laser

Cutting / Tubes / Sections / Forgings

South AfricaCarlos De OliveiraTel: +27 31 708 1365Mobile: +27 82 [email protected]

United KingdomSimon Ollerenshaw+44 1675 [email protected]

Contact:

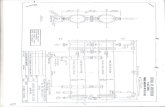

operates from a large-scale, 21,500 m2 manufacturing facility in Roodekop, Germiston, while its product offering includes air-cooled heat exchangers, shell and tube heat exchangers, pressure vessels and columns, plate heat exchangers, cooling towers and air-cooled condensers.

In addition to the products that the company manufactures in South Africa itself, it also markets the full range of Kelvion products which covers transformer cooling systems, transformer oil pumps, machine cooling systems and plate heat exchangers, alongside others smaller, yet no less critical.

The company is currently completing work on an air-cooled condenser at Eskom’s Medupi power station, which is scheduled for completion in 2017. This air-cooled condenser will be one of the largest in the world, with a plot area of about 72,000 m2. The Medupi plant is located at Lephalale in Limpopo Province, in the northern part of South Africa. Once complete, this

baseload facility is expected to provide around 12% of the nation’s total power generation capacity.

One of Eskom’s flagship power plants, Medupi is something of a technological showcase. With drought currently plaguing much of South Africa it is one of few countries in the world facing extreme water stress, a principal reason why the country’s state-owned electricity provider Eskom is well on the way to building the world’s largest air-cooled coal plant to solve its ongoing electricity shortage, and electing not to build a water-cooled plant.

The 4790 MW plant will be the biggest dry-cooled power station in the world. It is composed of six Alstom STF100 steam turbines, each capable of producing 794 MW. Kelvion comes into the equation in providing the air-cooled condensers (ACCs), while Hitachi is suppling its supercritical boilers whose capacity for steam is 2288 t/h per boiler.

A vital cog in an enormously complex process, firstly a series of low-NOx burners with staged combustion are used to burn the coal. After using all the useful energy from the steam, it is sent horizontally to the air-cooled condensers, where a massive steel and concrete structure supports the ACC modules which use GEA’s A-tube arrangement in order to maximize the volume of galvanized tubing subjected to cooling. Huge fans continually blow air across these tubes to cool the steam down to the desired temperature to bring about condensation.

Capturing and reusing waste heat in biomass plants is central to efficient, effective operations, and heat exchangers play a vital role at every processing facility in which heat is essential, whether it is an oil refinery or a biomass power plant. As energy efficiency importance grows, the role of heat exchangers will become even greater, and their technologies more advanced. Heat is

generated for and in various industrial processes, and were it not for heat exchangers, massive amounts of thermal energy would be wasted.

Kevin McGinnis, Sales Director for heavy industries and mining at Kelvion, points to several common sources of waste heat in industry: turbines, dryers, kilns, incinerators, boilers and flue gas from heaters or burners, to name but a few. “In general, waste heat can be captured with various types of heat exchangers and used for various applications,” he says, “including combustion air preheating; heating a facility, plant, building or home; boiler feedwater preheating; heating a process fluid for another application.”

What sets Kelvion apart from the many other heat exchanger companies is its ability to offer its customers one of the world’s largest product portfolios

in the field, according to McGinnis. “It includes individual solutions for practically all conceivable applications and complex environmental conditions, including plate, shell-and-tube, finned-tube and refrigeration heat exchangers, and modular cooling tower systems.” Such diversity of product and innovative ethos will allow Kelvion Thermal Solutions to continue to thrive as the country embraces increasingly ambitious solutions to power generation.

KELVION THERMAL SOLUTIONSINDUSTRY FOCUS: ENGINEERING

42 / www.enterprise-africa.net www.enterprise-africa.net / 43

policy of constant innovation, a tag that Kelvion works to uphold. It is arguably most well-known for the development and pioneering of the direct air-cooled steam condensation system, becoming the world leader in this field, as well as in the design and manufacture of finned tube heat transfer equipment.

In keeping with this, at this year’s Power-Gen Europe & Renewable Energy World Europe Kelvion will present its heat exchangers for energy supply in solar thermal power plants. It will exhibit performance-enhancing solutions for steam power plants, such as feed-water preheaters and condensing systems, surface condensers and air-cooled condensers designed to remove non-condensable gases present in the steam cycle. All the solutions on show will seek to achieve optimal energy yield and maximum efficiency.

Kelvion Thermal Solutions has, it goes without saying, substantial thermodynamic and mechanical design expertise, as well as engineering, manufacturing and contract management capabilities. It

power cooling and water treatment, and has established itself over past four decades. It boasts experience in and a pioneering approach to engineering, manufacturing and service, delivering state of the art solutions for power plants, water and wastewater applications. DencoHappel, meanwhile, is among the leading technology innovators in the field of air treatment, air conditioning and filter technology, as well as cooling process air. It has employed the cutting-edge innovative concepts it has built up over more than 100 years of operations, to set new technological standards in fulfilling its customers’ requirements.

Since GEA Heat Exchangers became Kelvion, GEA Aircooled Systems has become an integral part of the group, thanks to its noteworthy thermodynamic and mechanical design expertise, as well as engineering, manufacturing and contract management capabilities. GEA Aircooled Systems became Kelvion Thermal Solutions (Pty) Ltd in 2016.

GEA was a name associated with a

KELVION THERMAL SOLUTIONS

+27 11 861 1500 [email protected]

za.kelvion.com