KD 225-315-350-400-440

-

Upload

giusy-e-gerry -

Category

Documents

-

view

48 -

download

1

Transcript of KD 225-315-350-400-440

KD 225_315_350_400_440

PREFACE

- Every attempt has been made to present within this service manual, accurate and up to date technicalinformation.

However,developmentontheKOHLERseriesiscontinuous. Therefore,theinformationwithinthismanualissubjecttochangewithoutnoticeandwithoutobligation.

- TheinformationcontainedwithinthisservicemanualisthesolepropertyofKOHLER. As such, no reproduction or replication in whole or part is allowed without the express written permission of

KOHLER.

Informationpresentedwithinthismanualassumesthefollowing:

1- ThepersonorpeopleperformingserviceworkonKOHLERseriesenginesisproperlytrainedandequippedtosafelyandprofessionallyperformthesubjectoperation;

2- The person or people performing service work onKOHLER series engines possesses adequate hand andKOHLERspecialtoolstosafelyandprofessionallyperformthesubjectserviceoperation;

3- ThepersonorpeopleperformingserviceworkonKOHLERseriesengineshasreadthepertinentinformationregardingthesubjectserviceoperationsandfullyunderstandstheoperationathand.

- This manual was written by the manufacturer to provide technical and operating information to authorisedKOHLERafter-salesservicecentrestocarryoutassembly,disassembly,overhauling,replacementandtuningoperations.

- Aswellasemployinggoodoperatingtechniquesandobservingtherighttimingforoperations,operatorsmustreadtheinformationverycarefullyandcomplywithitscrupulously.

- Timespentreadingthisinformationwillhelptopreventhealthandsafetyrisksandfinancialdamage. Writteninformationisaccompaniedbyillustrationsinordertofacilitateyourunderstandingofeverystepofthe

operatingphases.

- 3 -

WARRANTY CERTIFICATE

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENTYOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board andKohlerCo.arepleasedtoexplaintheemission control system warrantyonyour2012engine.InCalifornia,newheavy-dutyoff-roadenginesmustbedesigned,builtandequippedtomeettheState’sstringentanti-smogstandards.KohlerCo.mustwarranttheemissioncontrolsystemonyourengineforthetimeperiodlistedbelowprovidedtherehasbeennoabuse,neglectorimpropermaintenanceofyourengine.Youremissioncontrolsystemmay includepartssuchasthefuel-injectionsystemandtheair inductionsystem.Also includedmaybehoses,connectorsandotheremissionrelatedassemblies.Whereawarrantableconditionexists,KohlerCo.willrepairyourheavy-dutyoff-roadengineatnocosttoyouincludingdiagnosis,partsandlabor.

MANUFACTURER’S WARRANTY COVERAGE:

Youroff-road,dieselengineemissioncontrolsystemiscoveredunderwarrantyforaperiodoffive(5)yearsor3,000hours,whicheveroccursfirst,beginningonthedatetheengineorequipmentisdeliveredtoanultimatepurchaserforallconstantspeedengineswithmaximumpower19≤kW<37andratedspeedlessthan3,000rpm,allvariablespeedengineswithmaximumpower19≤kW<37,andallvariableorconstantspeedengineswithmaximumpowergreaterthan37kW.Youroff-road,dieselengineemissioncontrolsystemonvariableorconstant-speedengineswithmaximumpowerlessthan19kW,andforconstantspeedengineswithmaximumpower19≤kW<37andratedspeedequaltoorgreaterthan3,000rpmiscoveredunderwarrantyforaperiodoftwo(2)yearsor1,500hours,whicheveroccursfirst.Ifanyemissionrelatedpartonyourengineisdefective,thepartwillberepairedorreplacedbyKohlerCo.

OWNER’S WARRANTY RESPONSIBILITIES:

As theheavy-dutyoff-roadengineowner,youare responsible for theperformanceof the required maintenance listed in your Kohler Co. owner’s manual.KohlerCo.recommendsthatyouretainallreceiptscoveringmaintenanceonyourheavy-dutyoff-roadengine,butKohlerCo.cannotdenywarrantysolelyforthelackofreceiptsorforyourfailuretoensuretheperformanceofallrecommendedscheduledmaintenance.Astheheavy-dutyoff-roadengineowner,youshouldhoweverbeawarethatKohlerCo.maydenyyouwarrantycoverageifyourheavy-dutyoff-roadengineoremissioncontrolrelatedcomponenthasfailedduetoabuse,neglect,impropermaintenanceorunapprovedmodifications.Yourengineisdesignedtooperateoncommercialdieselfuel(No.1orNo.2lowsulfurorultralowsulfurdieselfuel)only.UseofanyotherfuelmayresultinyourenginenolongeroperatingincompliancewithCalifornia’semissionsrequirements.Youareresponsibleforinitiatingthewarrantyprocess.TheAirResourcesBoardsuggeststhatyoupresentyourheavy-dutyoff-roadenginetoaKohlerCo.dealerassoonasaproblemexists.Thewarrantyrepairsshouldbecompletedbythedealerasexpeditiouslyaspossible.Pleasereviewthedocumenttitled,“KohlerCo.FederalandCaliforniaEmissionControlSystemsLimitedWarrantyOff-RoadDieselEngines”,forcompletedetailsofyourheavy-dutyoff-roadenginewarranty.IfyouhaveanyquestionsregardingyourwarrantyrightsandresponsibilitiesorthelocationofthenearestKohlerCo.authorizedservicelocation,youshouldcontactKohlerCo.at1-800-544-2444oraccessourwebsiteatwww.kohlerengines.com.

LIMITED 3 YEAR KOHLER® DIESEL ENGINE WARRANTY

KohlerCo.warrantstotheoriginalretailconsumerthateachnewKOHLERDieselenginesoldbyKohlerCo.willbefreefrommanufacturingdefects inmaterialsorworkmanship innormal service for aperiodof three (3) yearsor2000hourswhicheveroccurs first from thedateofpurchase,provideditisoperatedandmaintainedinaccordancewithKohlerCo.’sinstructionsandmanuals.Ifnohourmeterisinstalledasoriginalequipmentthen8hoursofuseperdayand5daysperweekwillbeusedtocalculatehoursused.

Ourobligationunderthiswarrantyisexpresslylimited,atouroption,tothereplacementorrepairatKohlerCo.,Kohler,Wisconsin53044,orataservicefacilitydesignatedbyusofsuchpartsasinspectionshalldisclosetohavebeendefective.

Thiswarrantydoesnotapplytodefectscausedbyunreasonableuse,includingfaultyrepairsbyothersandfailuretoprovidereasonableandnecessarymaintenance.

Thefollowingitemsarenotcoveredbythiswarranty:Engineaccessoriessuchasfueltanks,clutches,transmissions,power-driveassembliesandbatteries,unlesssuppliedorinstalledbyKohlerCo.Thesearesubjecttothewarranties,ifany,oftheirmanufacturers.

KOHLERCO.AND/ORTHESELLERSHALLNOTBELIABLEFORSPECIAL,INDIRECT,INCIDENTIALORCONSEQUENTIALDAMAGESOFANYKIND,includingbutnotlimitedtolaborcostsortransportationchargesinconnectionwiththerepairorreplacementofdefectiveparts.

IMPLIEDORSTATUTORYWARRANTIES,INCLUDINGWARRANTIESOFMERCHANTABILITYORFITNESSFORAPARTICULARPURPOSE,AREEXPRESSLYLIMITEDTOTHEDURATIONOFTHISWRITTENWARRANTY.Wemakenootherexpresswarranty,norisanyoneauthorizedtomakeanyonourbehalf.

Somestatesdonotallowlimitationsonhowlonganimpliedwarrantylasts,ortheexclusionorlimitationofincidentalorconsequentialdamages,sotheabovelimitationorexclusionmaynotapplytoyou.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrights,whichvaryfromstatetostate.

Toobtainwarrantyservice

PurchasermustbringtheenginetoanauthorizedKohlerservicefacility.Tolocatethenearestfacility,visitourwebsite,www.kohlerengines.com,andusethelocatorfunction,consultyourYellowPagesortelephone1-800-544-2444.

ENGINEDIVISION,KOHLERCO.,KOHLER,WISCONSIN53044

- 4 -

INDEX

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

ThismanualcontainspertinentinformationregardingtherepairofKOHLERwater-cooled,indi-rectinjectionDieselenginestypeKD 225_315_350_400_440:updatedJune20,2012.INDEX

PREFACE .................................................................................................................................................................. 2

WARRANTY CERTIFICATE ..................................................................................................................................... 3Limited3yearkohler®dieselenginewarranty.................................................................................................................. 3Californiaemissioncontrolwarrantystatement................................................................................................................. 3Yourwarrantyrightsandobligations.................................................................................................................................. 3

1 - TROUBLE SHOOTING ........................................................................................................................................ 7Possiblecausesandtroubleshooting................................................................................................................................ 7

2 - GENERAL REMARKS AND SAFETY INFORMATION ...................................................................................... 8Safetyregulations............................................................................................................................................................... 8Generalsafetyduringoperatingphases............................................................................................................................ 9Safetyandenvironmentalimpact...................................................................................................................................... 9

3 - MODEL NUMBER AND IDENTIFICATION ....................................................................................................... 11Manufacturerandmotoridentificationdata.......................................................................................................................11Approvaldata.....................................................................................................................................................................11

4 - TECHNICAL DATA ............................................................................................................................................ 12Characteristicskd225_315_350.......................................................................................................................................12Characteristicskd400_440...............................................................................................................................................13

5 - CHARACTERISTICS ......................................................................................................................................... 14Characteristicspower,torqueandspecificfuelconsumptioncurves...............................................................................14

6 - OVERALL DIMENSIONS ................................................................................................................................... 16

7 - MAINTENANCE - RECOMMENDED OIL TYPE - REFILLING ........................................................................ 18Maintenance......................................................................................................................................................................18Fuel....................................................................................................................................................................................18Recommendedoil..............................................................................................................................................................19Aceasequences................................................................................................................................................................19

8 - DISASSEMBLY/REASSEMBLY ........................................................................................................................ 20Disassemblyandreassembly........................................................................................................................................... 20Dryaircleanerforkd315andkd350............................................................................................................................... 20Dryaircleanerforkd225................................................................................................................................................. 20Dryaircleanerforkd400-440..........................................................................................................................................21Prefilterfordryairfilter......................................................................................................................................................21Oil-bathaircleaner(optional)........................................................................................................................................... 22Muffler............................................................................................................................................................................... 22Rockerarmcoverbreathersystem................................................................................................................................... 22Rockerarmcover-breatherricirculation......................................................................................................................... 23Valve/rockerarmclearance(KD225-315-350)................................................................................................................ 23TheenginesKD400and440havehydraulictappets,thereforenoadjustmentisrequired........................................... 23Donotstarttheengineforapproximately4hourstoallowthehydraulictappetstosettlecompletely........................... 23HydraulictappetsKD400-440........................................................................................................................................ 24Tank.................................................................................................................................................................................. 25FuelfilterKD225-400-440(versionwithinternalfilter)................................................................................................... 25FuelfilterforKD225-315-350-400-440(versionwithexternalfilter)........................................................................ 25Re-coilstarting.................................................................................................................................................................. 26Shroud.............................................................................................................................................................................. 26Flywheel............................................................................................................................................................................ 26

- 5 -

INDEX

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Cylinderhead.................................................................................................................................................................... 27Injectorprojection............................................................................................................................................................. 27Valves-Disassembly........................................................................................................................................................ 28Valves-Oilsealinvalveguide......................................................................................................................................... 28Valve,springs.................................................................................................................................................................... 28Valves,characteristics...................................................................................................................................................... 29Valves,guidesandhousings............................................................................................................................................ 29Valves,guideinsertion...................................................................................................................................................... 29Dimensionsandclearancebetweenguidesandvalvestems(mm)................................................................................ 30Valvesseatsandvalveseatbores................................................................................................................................... 30Valveseatlapping............................................................................................................................................................. 30Cylinder..............................................................................................................................................................................31Cylinderroughness............................................................................................................................................................31Piston.................................................................................................................................................................................31Dimensionsofpistonsandcylinders,Logo.......................................................................................................................31Pistonrings,distancebetweenthetips(mm)................................................................................................................... 33Pistonrings,playbetweentheslots(mm)........................................................................................................................ 34Pistonrings,assemblyorder............................................................................................................................................ 34Piston-Refitting............................................................................................................................................................... 34Clearance.......................................................................................................................................................................... 34Pistonprotrusioncheck.................................................................................................................................................... 35Connectingrod................................................................................................................................................................. 36Connectingrod,pistonpin................................................................................................................................................ 36Connectingrodalignement............................................................................................................................................... 36Crankshaftendplay.......................................................................................................................................................... 36Driveshaftoilseals........................................................................................................................................................... 37Driveshaft,lubricationducts,borethreadonflywheelsideandp.t.o.............................................................................. 37Driveshaft,connectionradius.......................................................................................................................................... 37Driveshaft,mainjournal/crankpindiameter,gearcoverbearinginsidediameterontimingside.................................... 37Crankshaft-journaldiameter(mm).................................................................................................................................. 38Availabilityofbearings...................................................................................................................................................... 38Camshaft........................................................................................................................................................................... 39Camshaftjournalsandbore............................................................................................................................................. 39Dimensionsofcamshaftjournalsandbore(mm)............................................................................................................. 39Camheight(mm)............................................................................................................................................................... 39Camshafttiming................................................................................................................................................................ 40Camshaft–AntireversesystemKD400-440................................................................................................................... 40Automaticdecompression.................................................................................................................................................41Camshaftendplay.............................................................................................................................................................41Dynamicbalancer(onrequest)..........................................................................................................................................41Dinamicbalancertiming................................................................................................................................................... 43Valvetimingcheck............................................................................................................................................................ 43Timinganglesforoperation(0.15valveplay)................................................................................................................... 44Timinganglesforinspection(0.65-0.70valveplay)......................................................................................................... 44Speedgovernor................................................................................................................................................................ 45Speedgovernorremoval.................................................................................................................................................. 45Refittinggearcoverontimingside................................................................................................................................... 45

9 - LUBRICATION SYSTEM .................................................................................................................................... 46KD225-315-350lubricationsystemandbreatherrecirculationsystem...................................................................... 46KD400-440lubricationsystemandbreatherrecirculationsystem..................................................................................47Oilpump............................................................................................................................................................................ 48Oilpump-clearancebetweenrotors............................................................................................................................... 48Oilpressureregulationvalve............................................................................................................................................ 48Internalstrainer................................................................................................................................................................. 48Oilfilter.............................................................................................................................................................................. 49Oilpressurecheck............................................................................................................................................................ 49Calibratedpipeforlubricationofhydraulictappets.......................................................................................................... 49Oilpressurecurveatidlespeed....................................................................................................................................... 50Oilpressurecurveatfullspeed........................................................................................................................................ 50Fuelling/injectioncircuitforKD315-350-400-440............................................................................................................51Fuelling/injectioncircuitforKD225...................................................................................................................................51

- 6 -

INDEX

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

10 - FUEL SYSTEM ................................................................................................................................................. 52FuelfilterKD225-315-350-400-440................................................................................................................................ 52FuelfilterKD225(versionwithinternalfilterintank)....................................................................................................... 52Feedpump(optional)........................................................................................................................................................ 52Fuelpump,driverodprotrusion........................................................................................................................................ 53Injectionpump.................................................................................................................................................................. 53Injectionpumpfittinginthecrankcase............................................................................................................................. 53Injectionpumpcomponentsanddisassembly................................................................................................................. 54Injectionpump,body,plungeranddeliveryvalve............................................................................................................. 54Injectionpumprefitting..................................................................................................................................................... 54Injectionpumpnon-returnvalve....................................................................................................................................... 55Outletfittingcomponentsfor315-350EPAE400-440engines...................................................................................... 55Injectionpump,Rilsantuberemoval................................................................................................................................ 55Injectionpump,Rilsantuberefitting................................................................................................................................. 55Injectionpumpdeliverycheckontestbench................................................................................................................... 56Staticinjectiontiming........................................................................................................................................................ 56Staticinjectionleadtestonflywheel................................................................................................................................. 57Injectionadvanceadjustment........................................................................................................................................... 58Injector.............................................................................................................................................................................. 58Leakagetime(waste)........................................................................................................................................................ 59Nozzles............................................................................................................................................................................. 59Injectorcalibration............................................................................................................................................................. 59

11 - ELECTRICAL SYSTEM .................................................................................................................................... 6212V,12Aelectricignitiondiagram.....................................................................................................................................61Alternator...........................................................................................................................................................................61Alternatorbatterychargergraph(12V,12A)......................................................................................................................6124V,9Aalternatorbatteryrechargingcurve..................................................................................................................... 6212V,30Aalternatorbatteryrechargingcurve................................................................................................................... 62Voltageregulator............................................................................................................................................................... 6212Velectricstarterdiagramwithvoltageregulatorbuiltintotheignitionpanel............................................................... 6312Velectricignitionlayoutwithmotorprotection(optional)............................................................................................. 63Diagramofelectricstartermotorprotectionwithsoleself-windingstarter-withoutbattery-(optional)......................... 64Testingvoltageregulatorforproperoperation................................................................................................................. 65Startingmotor................................................................................................................................................................... 65CharacteristiccurvesforstartingmotortypeDW(L)12V,1.1KW.................................................................................. 65CharacteristiccurvesofBoschstartermotortypeDW(L)12V,0.9kW........................................................................... 66CharacteristiccurvesofBoschstartermotortypeDW(L)24V,1.6kW........................................................................... 66Ignitionswitchpositions.................................................................................................................................................... 66Adjustments-KD315-350................................................................................................................................................ 67Idlingspeedsettinginno-loadconditions(standard)....................................................................................................... 67Idlespeedadjustment,forsmallcarversions.................................................................................................................. 67Fullspeedsettinginno-loadconditions(standard).......................................................................................................... 67

12 - SETTINGS / ADJUSTMENTS .......................................................................................................................... 68Adjustments-KD225-400-440....................................................................................................................................... 68No-loadidlingadjustment(standard)................................................................................................................................ 68No-loadtoprateadjustment(standard)............................................................................................................................ 68InjectionpumpflowrateadjustmentForKD225-315-350-400-440............................................................................... 68Injectionpumpdeliverylimitingandtorqueadapter(standard)....................................................................................... 68Injectionpumpdeliverysetting........................................................................................................................................ 69Requiredsettings(themostcommonones)..................................................................................................................... 69

14 - STORAGE ........................................................................................................................................................ 70Storage............................................................................................................................................................................. 70Internalengineprotection:................................................................................................................................................ 70Injectionsystemsprotection:............................................................................................................................................ 70Externalengineprotection:............................................................................................................................................... 70Procedurestobecarriedoutbeforestarttheengine........................................................................................................71

15 - TORQUE SPECIFICATIONS ........................................................................................................................... 72Maintorquespecifications................................................................................................................................................ 72Useofsealant................................................................................................................................................................... 72Tableoftighteningtorquesforstandardscrews(coarsethread)..................................................................................... 73Tableoftighteningtorquesforstandardscrews(finethread).......................................................................................... 73

1

- 7 -

POSSIBLE CAUSES AND TROUBLE SHOOTING

CloggedpipesCloggedfuelfilterAirinsidefuelcircuitCloggedtankbreatherholeFaultyfuelpumpInjectorjammedJammedinjectionpumpdeliveryvalveWronginjectorsettingExcessiveplungerblow-byJammedinjectionpumpdeliverycontrolWronginjectionpumpsettingOilleveltoohighJammedpressurereliefvalveWornoilpumpAirinsideoilsuctionpipeFaultypressuregaugeorswitchCloggedoilsuctionpipeBatterydischargedWrongorinefficientcableconnectionDefectiveignitionswitchDefectivestartermotorCloggedairfilterExcessiveidleoperationIncompleterunning-inEngineoverloadedAdvancedinjectionDelayedinjectionIncorrectgovernorlinkageadjustmentBrokenorloosegovernorspringIdlespeedtoolowWornorjammedpistonringsWornorscoredcylindersWornvalveguidesJammedvalvesWornbearingsGovernorlinkagenotfreetoslideDriveshaftnotfreetoslideDamagedcylinderheadgasket

TROUBLE

LUBR

ICAT

ION

POSSIBLE CAUSE

FUEL

CIR

CU

ITEL

ECTR

ICSY

STEM

MA

INTE

-N

AN

CE

SETT

ING

S/R

EPA

IRS

Enginedoesnot

start

Noacceleration

Blacksmoke

Excessiveoil

consum

ption

Too

low

oil

pressure

Enginestartsbut

stops

Non-uniformspeed

Whitesmoke

oilandfu

eldripping

fromexhaust

Increaseoillevel

THE ENGINE MUST BE STOPPED IMMEDIATELY WHEN:

1) -Theenginerpmssuddenlyincreaseanddecrease 2) -Asuddenandunusualnoiseisheard 3) -Thecolouroftheexhaustfumessuddenlydarkens 4) -Theoilpressureindicatorlightturnsonwhilerunning.

TABLE OF LIKELY ANOMALIES AND THEIR SYMPTOMS

Thefollowingtablecontainsthepossiblecausesofsomefailureswhichmayoccurduringoperation.Alwaysperformthesesimplechecksbeforeremovingorreplacinganypart.

TROUBLE SHOOTING

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

2

- 8 -

SAFETY REGULATIONS

GENERAL REMARKS AND SAFETY INFORMATION

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

GENERAL NOTES

. Kohler engines are built to provide safe and longlastingperformances, but in order to obtain these results it isessential that the maintenance requirements described inthe manual are observed along with the following safetyrecommendations.

. The engine has been built to the specifications of amachinemanufacturer,anditishisresponsibilitytoensurethat all necessary action is taken to meet the essentialand legally prescribed health and safety requirements.Any use of themachine other than that described cannotbe considered as complying with its intended purposeas specified by Kohler, which therefore declines allresponsibilityforaccidentscausedbysuchoperations.

. The following instructions are intended for the user of themachine in order to reduce or eliminate risks, especiallythoseconcerning theoperationandstandardmaintenanceoftheengine.

. The user should read these instructions carefully and gettoknowtheoperationsdescribed.Bynotdoingsohemayplaceatriskhisownhealthandsafetyandthatofanyoneelseinthevicinityofthemachine.

. The enginemay be used ormounted on amachine onlybypersonnelsuitably trained in itsoperationandawareofthedangers involved.This is particularly true for standardand, above all, special maintenance work. For specialmaintenance contact personnel trained specifically byKohler.Thisworkshouldbecarriedoutinaccordancewithexistingliterature.

. Kohlerdeclinesallresponsibilityforaccidentsorforfailuretocomplywiththerequirementsoflawifchangesaremadetotheengine’sfunctionalparametersortothefuelflowrateadjustments and speed of rotation, if seals are removed,or ifpartsnotdescribed in theoperatingandmaintenancemanual are removed and reassembled by unauthorizedpersonnel.

WARNING

. Inaddition toall othermachinespecifications,ensure thattheengine is inanearhorizontalpositionwhenstarting. lfstarting manually, ensure that the necessary operationscanbeperformedwithoutanyriskofstrikingagainstwallsordangerousobjects.Ropestarting(exceptforrecoilropestarting)isnotpermittedeveninemergencies.

. Checkthatthemachineisstablesothatthereisnoriskofitoverturning.

. Get to know the engine speed adjustment and machinestopoperations.

. Do not start the machine in closed or poorly ventilatedenvironments.The internal combustion process generatescarbon monoxide, an odourless and highly toxic gas, sospending too long a time in an environment where theengine discharges its exhaust products freely can lead tolossofconsciousnessandevendeath.

. The engine may not be used in environments containingflammable materials, explosive atmospheres or easilycombustible powders, unless adequate and specificprecautions have been taken and are clearly stated andcertifiedforthemachine.

. Topreventtheriskoffire,keepthemachineatadistanceofatleastonemetrefrombuildingsorothermachines.

. Children and animals must be kept at a sufficient distancefrom the machine to prevent any danger resulting from itsoperation.

. Fuel is flammable, so the tankmust be filled only when theengine is turned off. Dry carefully any fuel that may havespilled, remove the fuel container and any cloths soakedin fuel or oil, check that any sound-absorbing panels madeofporousmaterial arenot soakedwith fueloroil, andmakesurethatthegroundonwhichthemachineislocatedhasnotabsorbedfueloroil.

. Before starting, remove any tools that have been used forcarrying out maintenance work to the engine and/or themachine and check that any guards removed have beenreplaced. Incoldclimates it ispossible tomixkerosenewiththediesel fuel tomaketheengineeasier tostart.Theliquidsmust be mixed in the tank by pouring in first the keroseneand then the diesel fuel. ConsultKohler technical office formixture proportions. Petrolmay not be used because of theriskofitformingflammablevapours.

. During operation the surface of the engine reachestemperatures thatmaybe dangerous. Avoid in particular allcontactwiththeexhaustsystem.

. The liquid cooling circuit is underpressure.Donot carryoutany checks before the engine has cooled down, and eventhenopen the radiator capor theexpansion tank cautiously.Wear protective clothing and glasses. lf there is an electricfan,donotapproachtheenginewhile it isstillhotasthefanmaycomeonevenwhentheengineisnotrunning.Cleanthecoolingsystemwiththeengineturnedoff.

. While cleaning the oil bath air filter, check that the oil isdisposed of in such a way as not to harm the environment.Any filtering sponges in the oil bath air filter should not besoakedwithoil. Thecyclonepre-filtercupmustnotbefilledwithoil.

. Sincetheoilmustbeemptiedoutwhiletheengineisstillhot(approx. 80°C), particular care should be taken in order toavoid burns. In any casemake sure that oil does not comeinto contact with your skin because of the health hazardsinvolved.

. Fuelvapoursarehighlytoxic,sofilluponlyintheopenairorinwellventilatedenvironments.

. During operations which involve access to moving parts ofthe engine and/or removal of the rotary guards, disconnectandinsulatethepositivecableofthebatterysoastopreventaccidentalshortcircuitsandactivationofthestartermotor.

. Checkthebelttensiononlywhentheengineisturnedoff.

IMPORTANT

. To start the engine follow the specific instructions providedin the engine and/or machine operating manual. Do notuse auxiliary starting devices not originally installed on themachine(e.g.Startpilotsystemswhichutiliseetheretc.)

. Before carrying out any work on the engine, turn it off andallowittocooldown.Donotperformanyoperationwhiletheengineisrunning.

. Check that the discharged oil, the oil filter and the oilcontainedintheoilfilteraredisposedofinsuchawayasnottoharmtheenvironment.

. Close the fuel tank filler cap carefully after each fíllingoperation. Do not fill the tank right up to the top, but leavesufficientspacetoallowforanyexpansionofthefuel.

. Donotsmokeorusenakedflameswhilefilling.

2

- 9 -

GENERAL SAFETY DURING OPERATING PHASES

– Theprocedurescontainedinthismanualhavebeentestedandselectedbythemanufacturer’stechnicalexperts,andhencearetoberecognisedasauthorisedoperatingmethods.

– Anumberof proceduresmustbe carriedoutwith theaidof equipmentand tools that simplify and improve the timingofoperations.

– Alltoolsmustbeingoodworkingconditionsothatenginecomponentsarenotdamagedandthatoperationsarecarriedoutproperlyandsafely.

Itisimportanttowearthepersonalsafetydevicesprescribedbyworksafetylawsandalsobythestandardsofthismanual.– Holes must be lined up methodically and with the aid of suitable equipment. Do not use your fingers to carry out this

operationtoavoidtheriskofamputation.– Somephasesmayrequiretheassistanceofmorethanoneoperator.Ifso,itisimportanttoinformandtrainthemregarding

thetypeofactivitytheywillbeperforminginordertopreventriskstothehealthandsafetyofallpersonsinvolved.– Donotuseflammableliquids(petrol,diesel,etc.)todegreaseorwashcomponents.Usespecialproducts.– Usetheoilsandgreasesrecommendedbythemanufacturer. Donotmixdifferentbrandsorcombineoilswithdifferentcharacteristics.– Discontinueuseoftheengineifanyirregularitiesarise,particularlyinthecaseofunusualvibrations.– Donottamperwithanydevicestoalterthelevelofperformanceguaranteedbythemanufacturer.

SAFETY AND ENVIRONMENTAL IMPACT

Every organisation has a duty to implement procedures toidentify,assessandmonitor the influenceof itsownactivities(products,services,etc.)ontheenvironment.Proceduresforidentifyingtheextentoftheimpactontheenvi-ronmentmustconsiderthefollowingfactors:

- Liquidwaste - Wastemanagement - Soilcontamination - Atmosphericemissions - Useofrawmaterialsandnaturalresources - Regulationsanddirectivesregardingenvironmentalimpact

Inordertominimisetheimpactontheenvironment,themanu-

facturer nowprovidesanumber of indications to be followedbyallpersonshandling theengine, forany reason,during itsexpectedlifetime.

- All packaging componentsmust be disposed of in accor-dancewiththelawsofthecountry inwhichdisposal ista-kingplace.

- Keepthefuelandenginecontrolsystemsandtheexhaustpipes in efficientworking order to limit environmental andnoisepollution.

- When discontinuing use of the engine, select all compo-nentsaccordingtotheirchemicalcharacteristicsanddispo-seofthemseparately.

GENERAL REMARKS AND SAFETY INFORMATION

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

. Takecarewhenremovingtheoilfilterasitmaybehot.

. The operations of checking, filling up and replacing thecoolingliquidmustbecarriedoutwiththeengineturnedoffandcold. Takeparticular care if liquids containingnitritesare mixed with others not containing these compoundsas this may give rise to the formation of nitrosamineswhichareahealthhazard. Thecooling liquid ispolluting,so dispose of in a manner that does not damage theenvironment.

. In order to move the engine simultaneously use theeyebolts fitted for this purpose by Kohler. These liftingpointsarehowevernotsuitable for theentiremachine,sointhiscaseusetheeyeboltsfittedbythemanufacturer.

3

- 11 -

F EC

A DB

s/n

MADE IN ITALY

rpmXX XX XXXX

XX XX XXXX

XXXX

XXXXXXe9 • 97/68/CE • 00/000xx • xxxx •xx

Xx 0.00 xxx xxx xx

Model

Spec.

6

1

USE IN CONSTANT-SPEED APPLICATIONS ONLY

3 10

5

78

9

2 4

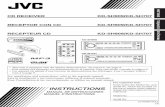

MODEL NUMBER AND IDENTIFICATION

Theidentificationplateshowninthefigurecanbefounddirectlyontheengine.Itcontainsthefollowinginformation:

A)Manufacturer’sidentityB)EnginetypeC)EngineserialnumberD) MaximumoperatingspeedE) Numberofthecustomerversion(formK)F)Approvaldata

Approval data

TheapprovalreferencedirectivesECareontheengineplate.

MANUFACTURER AND MOTOR IDENTIFICATION DATA

1)Modelyear.2)Enginedisplacement.3)Powercategory,kW.4)Particulateemissionlimit(g/kWh).5)EnginefamilyID.6)Kindofapplicationi.e.7)Injectiontiming(BTDC).8)Injectoropeningpressure(bar).9)Productiondate(example2012_Jan).10) EmissionControlSystem=ECS.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

4

1786631520,3:13600

5,0(6,8)4,6(6,2)4,1(5,6)15@2400

2620,00351,212/4433480500020025°35°***

1826634920,3:13600

5,5(7,5)5,1(7,0)4,7(6,4)

16,6@2400260

0,00381,212/4433540500020025°35°***

N.mmmmCm3

Nmg/kW.h

l/hlt

V/Ahkg

l./minl./minkg.

1696022421:13600

3,5(4,8)3,3(4,5)3,1(4,2)

10,4@2400267

0,00210,912/3628350380015025°35°***

315 350225

- 12 -

KD 315

KD 350

KD 225

TECHNICAL DATA

* ReferredtoNpower** ReferredtoNBpower*** Dependingontheapplication

ENGINETYPENumberofcylindersBoreStrokeSweptvolumeCompressionratioR.P.M. N80/1269/EEC-ISO1585PowerkW(HP) NBISO3046-1IFN NAISO3046-1ICXNMax.torque*Fuelconsumption**OilconsumptionCapacityofstandardoilsumpRecommendedbatteryDryweightCombustionairvolumeat3600r.p.m.Coolingairvolumeat3600r.p.m.Max.permissibledrivingshaftaxialloadinbothdirections continuousserviceforupto30min.Max.inclination discontinuousserviceforabout1min. permanentservice

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

CHARACTERISTICS KD 225_315_350

4

1827640120,3:13600

7,0(9,5)6,4(8,7)5,8(7,9)

21,3@24002620,0051,512/4445580550020025°35°***

1867644220,3:13600

7,7(10,5)7,0(9,6)6,4(8,7)

23,5@2400260

0,00551,512/4445635550020025°35°***

N.mmmmCm3

Nmg/kW.h

l/hlt

V/Ahkg

l./minl./minkg.

400 440

- 13 -

KD 400

KD 440

TECHNICAL DATA

* ReferredtoNpower** ReferredtoNBpower*** Dependingontheapplication

ENGINETYPENumberofcylindersBoreStrokeSweptvolumeCompressionratioR.P.M. N80/1269/EEC-ISO1585PowerkW(HP) NBISO3046-1IFN NAISO3046-1ICXNMax.torque*Fuelconsumption**OilconsumptionCapacityofstandardoilsumpRecommendedbatteryDryweightCombustionairvolumeat3600r.p.m.Coolingairvolumeat3600r.p.m.Max.permissibledrivingshaftaxialloadinbothdirections continuousserviceforupto30min.Max.inclination discontinuousserviceforabout1min. permanentservice

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

CHARACTERISTICS KD 400_440

5

- 14 -

KD 225

KD 315 KD 350

CHARACTERISTICS

CHARACTERISTICS POWER, TORQUE AND SPECIFIC FUEL CONSUMPTION CURVES

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

N (80/1269/EEC - ISO 1585) AUTOMOTIVE RATING :Intermittentoperationwithvariablespeedandvariableload.NB (ISO 3046 - 1 IFN) RATING WITH NO OWERLOAD CAPABILITY:continuosligthdutyoperationwithconstantspeedandvariableload.NA (ISO 3046 - 1 ICXN) CONTINUOS RATING WITH OVERLOAD CAPABILITY:continuosheavydutywithconstantspeedandconstantload.MN TorqueatNpower.CSpecificfuelconsumptionatNB power.Theabovepowervalues refer toanenginefittedwithair cleanerandstandardmuffler,after testingandat theenvironmental conditionsof20°Cand1bar.Max.powertoleranceis5%.Powerdecreasesbyapproximately1%every100mdialtitudeandby2%every5°Cabove25°C.

Note:ConsultKOHLERforpower,torquecurvesandspecificconsumptionsatratesdifferingfromthosegivenabove.

5

- 15 -

KD 400 KD 440

CHARACTERISTICS

CHARACTERISTICS POWER, TORQUE AND SPECIFIC FUEL CONSUMPTION CURVES

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

N (80/1269/EEC - ISO 1585) AUTOMOTIVE RATING :Intermittentoperationwithvariablespeedandvariableload.NB (ISO 3046 - 1 IFN) RATING WITH NO OWERLOAD CAPABILITY:continuosligthdutyoperationwithconstantspeedandvariableload.NA (ISO 3046 - 1 ICXN) CONTINUOS RATING WITH OVERLOAD CAPABILITY:continuosheavydutywithconstantspeedandconstantload.MN TorqueatNpower.CSpecificfuelconsumptionatNB power.Theabovepowervalues refer toanenginefittedwithair cleanerandstandardmuffler,after testingandat theenvironmental conditionsof20°Cand1bar.Max.powertoleranceis5%.Powerdecreasesbyapproximately1%every100mdialtitudeandby2%every5°Cabove25°C.

Note:ConsultKOHLERforpower,torquecurvesandspecificconsumptionsatratesdifferingfromthosegivenabove.

6

Note :Dimensionsshowninmm

- 16 -

KD 225

KD 315

KD 350

OVERALL DIMENSIONS

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

6

Note:Dimensionsshowninmm.

- 17 -

KD 400

KD 440

OVERALL DIMENSIONS

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

7

10 50 250 500(*)(*)

(**)

(**)(***)

(°)

- 18 -

MAINTENANCE - RECOMMENDED OIL TYPE - REFILLING

Failure to carry out the operations described in the table may lead to technical damage to the machine and/or system

MAINTENANCE INTERVAL (HOURS) OPERATION COMPONENT OIL-BATHAIRCLEANER HEADANDCYLINDERFINSCLEANING INJECTOR AIRCLEANEROIL LEVEL OILSUMPCHECK VALVE/ROCKERARMCLEARANCE INJECTORSETTING AIRCLEANER SUMP REPLACEMENT OILFILTERCARTRIDGE FUELFILTERCARTRIDGE DRYAIRCLEANERCARTRIDGE

(*) Undersevereworkingconditions,cleandaily.(**) Underextremelydustyconditions,changeevery4-5hours.(***) Seerecommendedoiltype.(°)Afterthepolyurethaneprefilterhasbeenserviced6-10times(seefig.2for315-350engines),whentheclogging

indicator(ifinstalled)signalsthatthepartmustbereplaced,orifitisirreparablyclogged.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Toavoidexplosionsorfireoutbreaks,donotsmokeorusenakedflamesduringtheoperations.Fuelvapoursarehighlytoxic.Onlycarryouttheoperationsoutdoorsorinawellventilatedplace.Keepyourfacewellawayfromtheplugtopreventharmfulvapoursfrombeinginhaled.Disposeoffuelinthecorrectwayanddonotlitterasitishighlypolluting.

FUEL

Whenrefuelling,itisadvisabletouseafunneltopreventfuelfromspillingout.Thefuelshouldalsobefilteredtopreventdustordirtfromenteringthetank.Usethesametypeofdieselfuelasusedincars.Useofothertypesoffuelcoulddamagetheengine.Thecetaneratingofthefuelmustbehigherthan45topreventdifficultstarting.Donotusedirtydieselfuelormixturesofdieselfuelandwatersincethiswouldcauseseriousenginefaults.

Thecapacityofthestandardtankis:

KD225 = l.3.0KD315 = l.4.3KD350 = l.4.3KD400 = l.5.0KD440 = l.5.0

7

-30

-25

-20

-15

-10

-5 0

+5

+10

+15

+20

+25

+30

+35

+40

+45

SAE 20WSAE 10W

+50

SAE 30SAE 40

SAE 10W-30SAE 10W-40

SAE 10W-60SAE 15W-40 base minerale

SAE 15W-40 base semi-sintetica

SAE 20W-60 base semi-sintetica

SAE 5W-30 base sintetica

SAE 0W-30 base sintetica

SAE 5W-40 base sintetica

-35

-40

CCMC G- 2

CF CE CD CC CB CA SA SB SC SD SE SF SG

DIESEL BENZINA - ESSENCE - PETROL BENZIN - GASOLINA

CCMC G- 3 G- 5CCMC PD - 1 / PD - 2

CCMC D- 2D- 4CCMC D- 3D- 5

MIL - L - 2104 DMIL - L - 2104 E

MIL - L -46152 CMIL - L- 46152 D/E

MB 226.1 MB 226.5MB 227.1 MB 227.5

228.3 MB 228.1

VW 501.01VW 500.00

SHAPIG- 4

SJ

VOLVO VDSMAN QC 13-017

VW 505.00

- 19 -

MAINTENANCE - RECOMMENDED OIL TYPE - REFILLING

Theenginecouldbedamagedifallowedtooperatewithinsufficientoil.Itisalsodangeroustoaddtoomuchoilasitscom-bustioncouldsharplyincreasetherotationspeed.Useasuitableoilinordertoprotecttheengine.Thelubricationoilinfluencestheperformancesandlifeoftheengineinanincredibleway.Theriskofpistonseizure,jammedpistonringsandrapidwearofthecylinderliner,thebearingsandallmovingpartsin-creasesifoilwhosecharacteristicsdifferfromtherecommendedtypeisused,oriftheoilisnotregularlychanged.Allthisnotablyreducesenginelife.Oilviscositymustsuittheambienttemperatureinwhichtheengineoperates.

Oldoilcancauseskincancerifrepeatedlyleftincontactwiththeskinandforlongperiodsoftime.Ifcontactwiththeoilisinevitable,youareadvisedtothoroughlywashyourhandswithsoapandwaterassoonaspossible.Appropriateprotectiveglovesetcshouldbeworeduringthisoperation.Oldoilishighlypollutingandmustbedisposedofinthecorrectway.Donotlitter.

GRADE

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

RECOMMENDED OIL

AGIPSUPERDIESELMULTIGRADE15W40specificationsAPICF-4/SG ACEA E2,B2 MIL-L-46152 D/E. ESSO SPECIAL PKW-UNI-FLODIESEL15W40 specificationsAPICF-4/SGACEAE2,B2MIL-L-46152D/E. In the countrieswhereAGIPandESSOproducts arenotavailable,useoilAPISJ/CFforDieselenginesoroilcorrespon-dingtothemilitaryspecificationMIL-L-46152D/E.

OIL SUPPLY ( liters ) KD 225Standard oil sump

filter included 0.9

OIL SUPPLY ( liters ) KD 315Standard oil sump

filter included 1.2

OIL SUPPLY ( liters ) KD 350Standard oil sump

filter included 1.2

OIL SUPPLY ( liters ) KD 400 - 440Standard oil sump

filter included 1.5

ACEA SEQUENCES

A=Gasoline(Petrol)B=LightDieselfuelsE=HeavyDieselfuels

Requiredlevels:

A1-96 A2-96 A3-96

B1-96 B2-96 B3-96

E1-96 E2-96 E3-96

1 2

3

8

- 20 -

DISASSEMBLY/REASSEMBLY

WARNINGS!During repair operations, whenusing compressed air, wear eyeprotection.

DISASSEMBLY AND REASSEMBLY

Besides disassembly and reassembly operations this chapter alsoincludescheckingandsettingspecifications,dimensions, repairandoperating instructions.Always use original KOHLER spare parts forrepairoperations.

Clean the filtering element with air blast.Air must be blownfrominsidetooutsidethecartridgeatadistanceofatleast15cmfromthepaper.Lightly and repeatedly tap the element on a hard surface toeliminateallexcessdirt.

Cartridgecomponents: 1Seal 2 Metallicbody 3 Polyurethaneprefilter4 outermesh 5Filtermedia6 Blade7 Insideenvelope8 Metallicbody9Innerseal

Cartridge characteristics:mediaporosity7µm,usefulfilteringarea1960cm2.Polyurethane pre-filter characteristic:porosity60p.p.i.,frontarea207cm2.

Note: Pre-filter3canundergomaintenanceoperations;ifdirty,washwithsoapandwateranddry(maximum10cleanings).Seepage18forcartridgereplacement.

Clean the filtering element with air blast.Air must be blownfrominsidetooutsidethecartridgeatadistanceofatleast15cmfromthepaper.Lightly and repeatedly tap the element on a hard surface toeliminateallexcessdirt.Replaceifirreparablyclogged.

Cartridgecomponents:

1 Completecover2Filteringmaterial3Support

Characteristicsofthefilteringmaterial:paperporosity:3µmfilteringarea:4400cm²outerringinopen-cellpolyurethane

Seepage18for thefrequencywithwhichthefilteringmaterialmustbechanged.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Dry air cleaner for KD 315 and KD 350

Dry air cleaner for KD 225

8

4 4a

5 5a

6

7

- 21 -

DISASSEMBLY/REASSEMBLY

Clean the filtering element with air blast.Air must be blownfrominsidetooutsidethecartridgeatadistanceofatleast15cmfromthepaper.Lightly and repeatedly tap the element on a hard surface toeliminateallexcessdirt.

Openaircleaner(fig.4).Unscrewthewingnut1(fig.4a)andremovethefilterelement(fig.5).ChecktherubbersealisundamagedA(fig.5a)Cleanthefilteringelementwithairblast.Ifthefilteringelementhasbeenalreadycleanedothertimes,orifitisirreparablyclogged,throwitawayandreplace.RefittheairfilterandmakesurethesealAisproperlyinserted,thentightenthewingnut1.

Makesure that thefilter ismounted in thecorrectwayother-wise dust and other impurities could ilfiltrate into the intakeducts.

Prefilter for dry air filter

Removeandcleanthepre-filterifclogged.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Dry air cleaner for KD 400-440

8

11

9 10A

8

- 22 -

DISASSEMBLY/REASSEMBLY

Never clean the filtering element6 using solventswith a lowflashpoint.Thiscouldcauseanexplosion!

Makesurethattheretentionrings4 - 5 areinagoodconditionandreplacethemiftheyaredamaged.

Oil-bath air cleaner (optional)

Components:1 Uppershell1AUpperunitwithseparatorpre-filter2 Secondaryfilterelement3Primarypolyurethane4Internalsealring5Externalrubbergasket6 Lowermetalfilterelement7 Lowercup8Oillevelgauge

Characteristics of filter element 2:madeofViledonsyntheticfabric,porosity120gr/m2,resin-covered.

Characteristics of filter element 3:open-celledpolyurethanefoam;porosity45P.P.I..Bothfilterelementscanbewashedwithsoapandwaterforamaxi-mumof10times.Washthemetalfilter6 withDieselfuelBlowoutexcessfuelwithcom-pressed air. See pages 14 and 15 for periodic maintenance detailsandoilreplacement.

Allowtheexhaustmanifoldtocoolbeforedemountingitinordertopreventscorchingandburns.

Muffler

Whenreassemblingreplacetheexhaustmanifoldgaskets.Tightennutsto25Nm.Themufflerdesignincludesinternalsoundabsorbingpanels.TightenthebearingnutsandscrewAtoa25Nmtorquevalue.

Rocker arm cover breather system

Thecrankcasebreathersystemislocatedinsidetherockerarmcover.Checkthatdiaphragm 2isintact;washwithDieseloilandblowthrou-ghthesmallmeshelement 4withcompressedair.Whenreassemblingfixbox3withLoctite"Form-a-gasketNo.6"andscrewplate5.Alsoseebelow.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

13

12

13a

13b

8

- 23 -

DISASSEMBLY/REASSEMBLY

Alwayscheckthethespringandvalvetomakesuretheyareinagoodconditions.

Rocker arm cover - Breather ricirculation

Crankcasevaporrecirculationoccursthroughduct4.Iftheairfilterclogs,theincreasedintakevacuumcouldsuckoilthrou-ghduct4intothecombustionchamber,causingtheenginetooperateatarunawayrate.Thisispreventedbyvalcuumvalve2which,whenthe vacuum increases, overcomes the resistance of spring 3 andshutstheduct4.Makesurethatoilplug5iscorrectlyclosed.Refitcover1andtightenrockerarmcoverto10Nm.

Setvalve/rockerarmclearancewhentheengine iscold:bringpistonto top dead center on the compression stroke and set clearance at0.10-0.15mmusingathicknessgauge.Tightenlocknut.

N.B.: Since an automatic decompression device is available on theexhaustlobe,manualyrotatetheengineuntilthetappetsareatlowestpoint.

When replacing the rocket arms, position the piston at the bottomdead centre and tighten the fixing screw gradually to adjust thehydraulictappets.Whiletightening,makesurethatA fitscorrectlyintoB(fig.13a).Theadjustingscrewpinshouldbetightenedto20Nm.

Do not start the engine for approximately 4 hours to allow the hydraulic tappets to settle completely.

Oncethetappetshavesettled,tightentheboltto10Nm.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Valve/rocker arm clearance ( KD 225-315-350 )

The engines KD 400 and 440 have hydraulic tappets, therefore no adjustment is required.

8

- 24 -

DISASSEMBLY/REASSEMBLY

Caption

1-Lockring2-Uppercollar3-Oilinletholes4-Low-pressurechamber5-Piston6-Play-recoveryspring7-Case8-Areatobelubricated9-High-pressurechamber10-Checkvalve11-Identificationmarks

Fillthelow-pressurechamberthroughtheoilinletholes.If clearanceoccurswhile running, as the tappet returns to thebaseof the camshaft, theplay-recovery spring stretchesout,keepingalltimingsystempartsclosetogether.While the play-recovery spring is stretching, the check valve lets oil into the high-pressure chamber from the low-pressurechamber,torecovertheincreaseinvolumeinthehigh-pressurechamber,causedbythestretchingspring.Inthisway,sinceoilispracticallyuncontrollable,whenthevalveisnextopened,playwillbecompletelyrecovered.Duringeachcycleasmallamountofoilisdrawnfromthehigh-pressurechamberintothepistoncouplingwallwiththecaseandthen,passingthroughtheinternalinlethole,flowsintothelow-pressurechamber.Thetappetisshortenedbylessthan0.1mmeachcycle.Thisallowsthetappettomakeupthereductioninplaywhiletheengineisrunning.Itisnotnecessaryfortheoiltoreachthetappetonthedownwardstroke:lightpressureisenoughtoensurethatairbubblesdonotform.Thetappetmaybesuppliedwiththehigh-pressurechamberfullorempty.Thelow-pressurechamberisalwaysempty.Thetappetshouldalwaysbehandledinanuprightpositiontopreventthehigh-pressurechamberfromemptying.Thesurface thatcomes intocontactwith thecamshouldbe lubricatedgenerouslyduringassemblyusingASCOMPUND40typeMOLYSLIP(seefigure).Thisoperationisimportanttoensurecorrectlubricationrightfromthestart.Thedistributionsystemisassembledasfollows:

a)MakesurethatthepistonisbetweentheBottomDeadCentreandthehalfwaypointb)Inserttherodsintopositiononthetappetsc)Mounttherockerarmandthejointblock,thentightenthefixingnuttothespecifiedtorqued)DONOTSTARTTHEENGINEFORATLEAST4HOURSAFTERTIGHTENINGTHEROCKERARMSbecausethevalve-pistoncontactmaybeputatrisk.

Thetappetisunloadedwhenitispossibletoshifttheinternalpartby3.5÷4mmusingaforceof30Nm.Ifthetappetsareloaded(forexampleiftheyhavebeenleftinahorizontalposition)theenginewillbenoisyduringthefirstfewminutesafterswitchingon,untiltheairhasbeencompletelydrainedoutoftheinsideofthetappetsthemselves.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Hydraulic tappets KD 400-440

Distributionuseshydraulictappetsforautomaticadjustmentofvalveclearance.ThefigureshowsthetappetusedinKD400engines.

14

16 17

15

8

- 25 -

DISASSEMBLY/REASSEMBLY

Toavoidexplosionsorfireoutbreaks,donotsmokeorusena-kedflamesduringtheoperations.Fuelvapoursarehighlytoxic.Onlycarryouttheoperationsout-doorsorinawellventilatedplace.Keepyour facewellawayfromtheplug topreventharmfulva-poursfrombeinginhaled.Disposeoffuelinthecorrectwayanddonotlitterasitishighlypolluting.

Tank

Unscrewtheupperand lowerstudsandremove thewashers,whichotherwisemightmake removal of the tank difficult. Next disconnectthefuelandairbleedingtubes.Completelyemptythetanktomakesurethatnoimpuritiesremain.Whenreassemblingtightentheuppernutsto15Nm.

1Fuelfilter2Fueltank3Filtersleeve4Filtercartridge5Flushring6Nut7Unionseal8Dieselfueloutletunion9Flatwasher

Seepage18forthefrequencywithwhichthefuelfiltermustberepla-ced.Seefig.99forthedimensions.

Loosentheclampsanddisconnectthehoses.

Characteristics

Filteringarea≥390cm2

Paperporosity≤7µm.Seepage18forreplacementSeefig.98fordimensions.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Fuel filter for KD 225 - 315 - 350 - 400 - 440 (version with external filter)

Fuel filter KD 225-400-440 (version with internal filter)

18

19

20

8

- 26 -

DISASSEMBLY/REASSEMBLY

Re-coil starting

Operation:Whenpullinghandle10,thankstotheactionoffrictionspring12,te-eth 4protrude fromcap3.Afterstarting these teethgoback to theinitial position because the cap rotates.Rope9 is re-woundaroundpulley6bymeansofspring7.

Components:1 Retainer 7Spring2 Washer 8Guard3Cap 9 Rope4Flyweights 10Handle5 Spring 11 Ropeguide6Pulley 12 Spring

Note: thereare twokindsofguards8,one forengineswithan rpmabove 2000 and onewith fewer cooling channels for engineswithalowerrpm

Onreassembly,tightenthescrewsto10Nm.

Shroud

Theshroudandthemetalsheetingoutsidethecylinderaremadeofspecialmaterial(ANTIPHON)whichabsorbsnoise,thusreducingto-talenginesoundpressurelevels.Whenrefittingtightenshroudscrewsto10Nm.

Duringthedemountingphases,payparticularattentiontopre-vent the flywheel from dropping as this could seriously injuretheoperator.Wearprotectivegoggleswhenremovingtheflywheelring.

Flywheel

Unscrewbolt1inaclockwisedirection.Removetheflywheelwithapuller.Makesurethat thetaperedsurfacethatcouplestothedriveshaft isnotdamaged.To remove the starter rim, it is advisable to cut it into several partswithahacksawandto thenuseachisel.Toreplace,slowlyheat for15-20minutestoatemperatureof300°Cmax.Fit the rim into the flywheel housing.make sure that it rests evenlyagainstthesupportofthehousingitself.Allowittoslowlycool.Whenrefittingtightenbolt1to150Nm.Seepages34and35forinjectiontimingreferencemarks.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

21

22

8

- 27 -

DISASSEMBLY/REASSEMBLY

Donotdemountwhenhotorthepartcouldbecomedeformed.

Cylinder head

If thesurfaceof thecylinderheadisdeformed,flatten itbyremoving0.2mmofmaterialatmost.Alwaysreplacetheseal.Seefigs46-47-48-49-50whenselectingthethickness.Theboltsmustbetightenedindifferentphasesfortheva-riousengines,incompliancewiththeordershowninthefigure:

Firsttightenthe4screwsM10,thenthe2sidescrewsM6.Lubricatetheshanksofthebolts,undertheirheadsandthewasherswithengineoil.Donotusetoomuchoil.Oilthatdepositsinthethre-adedholeonthecylinderblockcouldbecomepressurizedduringthetighteningphase,sensiblydiminishingthedrivingforce.Alwaysmakesurethattheholesonthecylinderblockaredryandclean.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Injector projection

TheendofnozzleAshouldproject2,5mmforKD225-315-350and3,0÷3,5mmforKD400-440fromthecylinderheadplane.AdjustwithcoppergasketsBwiththicknessof0.5,1and1.5mm

Engine KD 350

1stphase: tightenall thebolts toa30Nm torquevalue inacrossed fashion.

2ndphase:unscrewalltheboltsby180°.3rdphase: tightenall thebolts toa20Nm torquevalue ina

crossedfashion.4th phase: make a 60° turn in the same order as the 3rd

phase.5thphase:tightenthe2sidebolts(5)toa10Nmtorquevalue

For KD 400 and 400 engines

1stphase:tightenallscrewscrosswiseto20Nm.2ndphase:tightenthescrewsinthesameorderto40Nm.3rdphase:tightenallscrewsinthesameorderto50Nm.4thphase:followingthesameorderasinphase3,rotate60°.5thphase:followingthesameorderasinphase4,rotate60°.6thphase:tightenthe2sidescrews(5)to10Nm

Engine KD 225

1stphase: tightenall thebolts toa30Nmtorquevalue inacrossedfashion.

2ndphase:unscrewalltheboltsby180°.3rdphase: tightenall thebolts toa20Nmtorquevalue ina

crossedfashion.4th phase: make a 52° turn in the same order as the 3rd

phase.5thphase:tightenthe2sidebolts(5)toa10Nmtorquevalue.

Engine KD 315

1stphase: tightenall thebolts toa30Nmtorquevalue inacrossedfashion.

2ndphase:unscrewalltheboltsby180°.3rdphase: tightenall thebolts toa20Nmtorquevalue ina

crossedfashion.4th phase: make a 72° turn in the same order as the 3rd

phase.5thphase:tightenthe2sidebolts(5)toa10Nmtorquevalue.

25 26

27

23 24

8

- 28 -

DISASSEMBLY/REASSEMBLY

Valves - Disassembly

Components:1Valvestem2 Oilseal3Springwasher/set4 Spring5Cap6 Halfcollets

Note: To remove half collets place a suitable plate under the valveheadandpressdownfirmlyasindicatedinthefigure.

Valves - Oil seal in valve guide

To prevent seal 2 from being deformed when the valve guide ismounted,fititintotool1serialN°7107-1460-047afterhavingthorou-ghlylubricatedit,thenproceedasindicatedinthefigure.

Valve, springs

Measurethefreelengthwithacaliper.

FreelengthA =33.72

FreelengthA =34,88

Note:ReplacethespringifthefreelengthA is1mmlessthanspeci-fied.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Engine KD 225-315-350

Engine KD 400-440

29

30

28

8

- 29 -

2993inu8iSrC54X

1

D 6,13÷4,13 0,63÷8,53 8,73÷6,73

L 8,18 19 4,29÷0,29

aaaaa '5654÷'53°54

2

3

4 2993INU8iSrC54X>--

5 2993INU6.12NiNnMrC07X>--

aaaaa '5654÷'53°54

225 - 315 - 350 - 400 - 440

315 - 350 400 - 440 225

DISASSEMBLY/REASSEMBLY

Valves, characteristics

IntakevalveA

ExhaustvalveB-Stemandheadareoftwodifferentmaterials

Valves, guides and housings

1 Intakeguide2 Exhaustguide

A=40B=31C=11.000-11.018D =11.040-11.055

A=35B=30C=10.000-10.020D =10.040-10.055

Note: Valve guides with outer diameters increased by 0.5 mm arealsoavailableasspares. In thiscase,housingCmustbe in-creasedby0.5mmforassemblypurposes.

Valves, guide insertion

Heattheblocktoatemperatureof160°-180°Forcetheguides,consideringdistance Aand Binrelationtotheblocksurface.

A=25.8-26.2B=34.8-35.2

A=23.8-24.2B=28.8-29.2

WeldJoint

ChromePlated

ChromePlated

BaseMaterial

BaseMaterial

BaseMaterial

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Dimensions (mm) for KD 315-350-400-440

Dimensions (mm) for KD 225

Dimensions (mm) for KD 315-350-400-440

Dimensions (mm) for KD 225

31

32

33 34

8

A 530,6÷020,6 040,7÷520,7

B 000,6÷589,5 000,7÷589,6 000,7÷589,6

)B-A( 050,0÷020,0 550,0÷520,0

)B-A( 41,0

400-440225 315-350

Clearance

Limit

- 30 -

A 15,23÷05,23 10,73÷00,73 10,93÷00,93

B 26,23÷06,23 21,73÷01,73 21,93÷01,93

C 15,82÷05,82 10,33÷00,33 10,53÷00,53

D 26,82÷06,82 21,33÷01,33 21,53÷01,53

225 315-350 400-440

DISASSEMBLY/REASSEMBLY

Dimensions and clearance between guides and valve stems (mm)

Valves seats and valve seat bores

Dimensions (mm)

Note : Since the seats are supplied pre-finished, theymust not bemachinedafterhavingbeeninserted.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Valve seat lapping

Aftercuttingvalveseats,lapvalveseatswithfinelappingcompound.Thesealingsurface Sshouldnotexceed2mm.LoweringvalveforKD225-315-350(D=0.55÷0.85mm).LoweringvalveforKD400-440(D=0.35÷0.65mm).Wearlimit1.5mm.

37

35 36

38 39

40 41

8

510,96÷00.96 079,86÷559,86 60.0÷30.0

51.87÷00.87 079.77÷559.77 60.0÷30.0

510.28÷00.28 079.18÷559.18 60.0÷30.0

510,28÷00,28 079,18÷559,18 60.0÷30.0

510,28÷00,28 049,18÷529,18 90.0÷60.0

510,68÷00,68 079,58÷559,58 60.0÷30.0

225

315

350 - 350EPA

400

400EPA

440 - 440EPA

ClearanceØ PistonØ Cilinders

- 31 -

DISASSEMBLY/REASSEMBLY

Cylinder

Setaboregaugetozerowithacalibratedring.Checkdiameterat1, 2and3;repeattheoperationatthesamepointsafterturningtheboregauge90°.Ifwearexceedsthemax.givenvalueby0.05,borethecylinderandfitoversizepistonandrings.Seefig.40and41forcylinderdiametervalues.

Do notmanually hone the cylinder bore surfaceswith emeryclothorothermeans.

Cylinder roughness

Thecross-hatchpatternshouldbeatanangleof45°-55°;linesshouldbeuniformandclearinbothdirections.Averageroughnessmustrangebetween0.5mm1µm.Thecylindersurfacewhichcomesintocontactwithpistonringsshouldbemachinedwiththeplateaumethod.

Piston

Being of low expansion type, the piston allows small clearancesbetweenpistonandcylinderand,thus,oilconsumptionisreduced.Removecirclipsandpistonpin.Removepistonringsandcleangrooves.MeasurediameterQat theAdistancefromtheskirtbottom(A=12mm).Replace the piston and piston rings if wear on the diameter is 0.05mmmorethantheminimumvaluegiven(seetableinfig.40-41).

Note:Oversizepistonsof0.50and1.00mmareavailable.

Dimensions of pistons and cylinders, Logo

Logo can be found inside the piston

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

8

- 32 -

DISASSEMBLY/REASSEMBLY

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

42

8

04.0÷02.0

05.1÷00.1 05.0÷03.0

05.0÷52.0

05.0÷03.0

05.0÷03.0

05.0÷52.0

53.0÷02.0

05.1÷00.1 05,0÷03,0

05.0÷52.0

53.0÷02.0

05.1÷00.1 05.0÷03.0

05.0÷52.0

53.0÷02.0

05.0÷03.0

04.0÷02.0

- 33 -

DISASSEMBLY/REASSEMBLY

Piston rings, distance between the tips (mm)

Fit the piston ring into the top part of the cylinder andmeasure thedistancebetweenthetips.

225

315

350

400

440

1stpistonring(nitrided)

2ndpistonring*

3rdpistonring,oilscraper(nitred)

1stpistonring(chromated)

2ndpistonring(torsional)

3rdpistonring,oilscraper

1stpistonring(nitrided)

2ndpistonring*

3rdpistonring,oilscraper(nitred)

1stpistonring(nitrided)

2ndpistonring*

3rdpistonring,oilscraper(nitred)

1stpistonring(chromated)

2ndpistonring(torsional)

3rdpistonring,oilscraper

Piston ringsEngine

Value

stamped - GOE stamped - ko stamped - N

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Wearlimit1mm-forthe2ndpistonringofkD225andKD350engines,thewearlimitis2.0mm.

43 44

45

46

47

8

A 511.0÷70.0 01.0÷70.0 11.0÷530.0 11,0÷70,0

B 80.0÷40.0 80.0÷50.0 90.0÷050.0 90,0÷50,0

C 70.0÷30.0 570.0÷40.0 780.0÷030.0 70,0÷30,0

225 315 350-400 440

- 34 -

DISASSEMBLY/REASSEMBLY

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Piston rings, play between the slots (mm)

Replacethepistonorpistonringsifthevalueexceedsthemaximumlimit.

Piston rings, assembly order

A =1stChromiumplatedpistonring(nitridedfor225-350-400)B =2ndpistonring(torsional)C =3rdpistonring(oilscraper)(nitridedfor225-350-400)D =Chromiumplatedzone

Note: Ifaword(top,orsomeotherword)iswrittenonthesurfaceofapistonring,mountthatsurfaceupwards.

Beforeinsertingthepistonintothecylinder,oilandturnthepi-stonringssothatthecutsarestaggered120°toeachother.

InKD350andKD225engines,thesecondpistonringisnottorsional,whilethefirstandthirdpistonringsdonothavechro-miumplatedzonesbutarenitrided.

Lubricate the followingpartswithoil beforemounting: thepi-stonpin,thepiston,thecylinderandthebig-endbearing

Piston - Refitting

Connectpiston toconnecting rod, lubricatepistonpinand introduceit into thepiston/connecting rodassemblybyexertingpressurewithyourthumb.Fitbothpistonpincirclipsandcheckthattheyarewellseated.When introducing both the connecting rod and the piston into thecylindermakesurethatthelargercrownsurfaceA (ifcomparedtothecombustionchamber)isonthesamesideasthepushrodopeningB.

Clearance

A =ClearanceC =HeadgasketThethicknessofgasket Cdeterminestheclearance A,whichmustbe0.45-0.55mmforKD315withinjectionpumpserialN°6590-259;itis0.50-0.60mmwithinjectionpumpserialN°6590-281.Theclearanceis0.45-0.55mmforKD225inallcases.Theclearanceis0.50-0.60mmforKD350-400-440inallcases.ForthecorrectthicknessofgasketCseetableinfig.49÷50.There are gaskets with inner diameters oversized by 1mm for KD315andKD350,requiredifthecylindersareground.

49 50

48

8

054,0÷153,0 9,0 005,0÷563,0 1

055,0÷054,0 1 006,0÷005,0 1,1

056,0÷055,0 1,1 007,0÷006,0 2,1

057,0÷056,0 2,1

054,0÷563,0 9,0 005,0÷014,0 1

055,0÷054,0 1 006,0÷015,0 1,1

056,0÷055,0 1,1 007,0÷016,0 2,1

057,0÷056,0 2,1

004,0÷563,0 9,0 005,0÷014,0 1

005,0÷004,0 1 006,0÷015,0 1,1

006,0÷005,0 1,1 007,0÷016,0 2,1

007,0÷006,0 2,1

- 35 -

DISASSEMBLY/REASSEMBLY

Piston protrusion check

Tocalculatetherightthicknessforthegasket,theprotrusionbetweenthepistonandthecylinderheadsurfacemustbemeasured.Useadialindicatorwithbaseplate.Resettozerowhilerestingonasurfaceplate, thenpositionagainst thecylinderheadbaseplaneasshowninthediagram,sothatthedial indicatorrodrestsagainstthepiston.Nowtakethereading.Repeattheoperationintheotherthreepoints(goingcrosswise)andtakethereadings.Calculate the average of these four readings to get the precisemeasurement of the protrusion between the piston and the cylinderheadbaseplane.Choosetheappropriategasketaccordingtothefollowingtable.

Onlyremovetheheadgasketfromitsprotectivewrappingjustbeforeassembly.

See page 26 when tightening the cylinder head

Havingchosentherequiredthickness,mountthegasketasshowninthefigure(seeletterA).FindthenumberofnotchesinzoneBtofindthethicknessofthega-sketwhenthecylinderheadismounted.Thegasket thicknessgiven in the table is theoneobtainedwith thegasketmountedandtheheadtorqued.

Head gasket (mm)

0

1notch

2notches

3notches

0

1notch

2notches

Pistonprotusion

GasketThickness

Numberofnotches

Numberofnotches

GasketThickness

Pistonprotusion

Pistonprotusion

GasketThickness

Numberofnotches

Numberofnotches

GasketThickness

Pistonprotusion

0

1notch

2notches

3notches

0

1notch

2notches

0

1notch

2notches

3notches

0

1notch

2notches

Numberofnotches

GasketThickness

Pistonprotusion

Numberofnotches

GasketThickness

Pistonprotusion