K-FLEX NBR/PVC Elastomeric Foam Page...

Transcript of K-FLEX NBR/PVC Elastomeric Foam Page...

K-FLEX NBR/PVC Elastomeric Foam Page 1 of 4 29-Jan-15 SDS01-0115

100 Nomaco Drive 800-765-6475 Youngsville, NC 27596 Fax: 800-765-6471

www.kflexusa.com

SAFETY DATA SHEET

Manufacturer’s name and address: Supplier’s name and address:

Refer to Manufacturer

K-FLEX USA 100 Nomaco Dr Youngsville, NC 27596 USA Telephone No. : (800) 765-6475 Website Address : www.kflexusa.com Product Identifier : K-FLEX Elastomeric Foam; K-FLEX INSUL-TUBE, K-FLEX INSUL-

SHEET, K-FLEX INSUL-LOCK, K-FLEX INSUL-LOCK SEAM SEAL K- FLEX ECO, K-FLEX DUCT LINER GRAY, K-FIT, K-TEK K 41-E, ELASTOMERIC TAPE

Chemical Name : NBR/PVC Elastomeric Foam Recommended Use : This product is classified as an “article” according to Title 29 of

the Code of Federal Regulations, OSHA Part 1910.1200C.

Hazardous Ingredient : None

Description : Elastomeric closed-cell foam comprised of nitrile butadiene rubber/polyvinyl chloride (NBR/PVC). Available in rolls and sheets of various dimensions.

Inhalation : Unlikely route of exposure. No measures established. Skin Contact : If rash or irritation develops, wash with soap and water. If rash

or irritation persists, consult a physician. Eye Contact : Small particles may cause irritation. Flush with water. If

irritation persists, consult a physician. Ingestion : Unlikely route of exposure. No adverse effects anticipated.

SECTION 1 - IDENTIFICATION

SECTION 2 – HAZARD(S) IDENTIFICATION

SECTION 3 – COMPOSITION/INFORMATION OF INGREDIENTS

SECTION 4 – FIRST-AID MEASURES

K-FLEX NBR/PVC Elastomeric Foam Page 2 of 4 29-Jan-15 SDS01-0115

100 Nomaco Drive 800-765-6475 Youngsville, NC 27596 Fax: 800-765-6471

www.kflexusa.com

Extinguishing Media : Water, CO2, Dry Chemical, Foam Special Firefighting Procedures : Recommend NIOSH/MSHA approved self-contained breathing

apparatus and full protective clothing be worn. Decomposition Products : Upon combustion, HCI, HCN, and other hazardous gases may

be evolved.

Personal Precautions : Recommend light to medium duty cloth or leather gloves and approved safety glasses.

Emergency Procedures : None.

Hints for Safe Handling : None. Hints for Fire and Explosion Protection : None. Hints for Separation of Incompatible Materials : None. Storage Recommendations : Avoid storage in confined areas where temperatures may

exceed 51°C (125°F).

Medical Conditions Aggravated by Exposure : Not established. Codes Used : N/A General Health Measures : N/A Engineering Controls : Local exhaust ventilation is recommended for control of

airborne dust, fumes, and vapors in confined areas.

Appearance : Sheets, rolls, and tubes; some with self-adhesive Color : Black, white, or gray. Odor : Negligible to no odor. Melting Point : N/A Boiling Point : N/A Lower Explosion Limit : N/A Upper Explosion Limit : N/A Vapor Pressure @ 20°C : 0.1

SECTION 5 – FIRE-FIGHTING MEASURES

SECTION 6 – ACCIDENTAL RELEASE MEASURES

SECTION 7 – HANDLING AND STORAGE

SECTION 8 – EXPOSURE CONTROLS/PERSONAL PROTECTION

SECTION 9 – PHYSICAL AND CHEMICAL PROPERTIES

K-FLEX NBR/PVC Elastomeric Foam Page 3 of 4 29-Jan-15 SDS01-0115

100 Nomaco Drive 800-765-6475 Youngsville, NC 27596 Fax: 800-765-6471

www.kflexusa.com

Vapor Density (Air = 1) : N/A Solubility : Insoluble Specific Gravity (H2O = 1) : N/A Flash Point : N/A

Stability : Stable. Incompatibility : N/A Decomposition Products : Upon combustion, HCI, HCN, and other hazardous gases may

be evolved.

Effects on short- and long-term Exposure : When used and handled according to specification, the

product does not have any harmful effect to the best of our knowledge.

Classified as non-hazardous to waters.

Disposal : Not a RCRA hazardous waste. Dispose of in accordance with local, state, and federal regulations.

No hazardous materials.

N/A

SECTION 10 – STABILITY AND REACTIVITY

SECTION 11 – TOXICOLOGICAL INFORMATION

SECTION 12 – ECOLOGICAL INFORMATION

SECTION 13 – DISPOSAL CONSIDERATIONS

SECTION 14 – TRANSPORT INFORMATION

SECTION 15 – REGULATORY INFORMATION

K-FLEX NBR/PVC Elastomeric Foam Page 4 of 4 29-Jan-15 SDS01-0115

100 Nomaco Drive 800-765-6475 Youngsville, NC 27596 Fax: 800-765-6471

www.kflexusa.com

Revised January, 2015. The information and recommendations contained herein are based upon data that is accurate and reliable, to the best of K-FLEX USA, LLC knowledge and belief. With respect to information and recommendations, K-FLEX USA, LLC makes no representations or warranties of any kind or nature, expressed or implied.

SECTION 16 – OTHER INFORMATION

Page 1Water Based Liner Adhesive

S A F E T Y D A T A S H E E T

SECTION I - PRODUCT AND COMPANY IDENTIFICATION

SECTION II - HAZARDOUS INGREDIENTS / SARA III INFORMATION

SECTION V - FIRE-FIGHTING MEASURES

SECTION III – COMPOSITION/INFORMATION ON INGREDIENTS

SECTION IV – FIRST AID MEASURES

SECTION VI – ACCIDENTAL RELEASE MEASURES

PRODUCT NAME: MANUFACTURERS’ADDRESS: EMERGENCY PHONE: BUSINESS HOURS: REVISION DATE: INFORMATION PHONE: REVISION #: PREPARED BY: DOT HAZARD CLASS:

Water Based Liner AdhesiveElgen Manufacturing Company INC.10 Railroad Ave, Closter NJ 07624INFOTRAC: (800) 535-5053 6AM - 6PM 04/01/2016 (800)503-9805 3-15 IT Department. Supersedes all previous Not Hazardous - UN Number: N/A

REPORTABLE COMPONENTS CAS NUMBER Weight %

None

PROPRIETARY COMPONENT CAS NUMBER CONCENTRATION

Trade Secret Proprietary Blend

INHALATION: Remove to fresh air. If breathing is difficult, administer oxygen. If breathing has stopped, administer artificial respiration. Contact physician or emergency medical facility immediately.

SKIN: Remove contaminated clothing and shoes. Wash exposed area thoroughly with soap and water for at least 15 minutes. Do not rub affected area. If irritation persists, get medical attention. Skin reaction may take 24 to 48 hours to develop. Wash contaminated clothing before reuse.

EYES: Immediately flush eyes with large amounts of water for at least 15 minutes while frequently lifting the upper and lower eyelids. If irritation persists, call a physician.

INGESTION: Do not induce vomiting. Contact physician or emergency medical facility immediately. Never give anything by mouth to an unconscious person.

FLASH POINT None

FIRE AND EXPLOSION HAZARD Closed containers exposed to extreme heat may rupture due to pres-sure build up

EXTINGUISHING MEDIA The product will only burn after the water it contains is driven off. For dried film use water, foam, carbon dioxide or dry chemical.

FIRE FIGHTING INSTRUCTIONS Water may be used to cool exposed containers.

SPILL CLEANUP: Dike, contain, or absorb with inert absorbent material. Collect spilled material in a salvage container. Prevent spill from entering sewers, drains, streams, waterways, or other bodies of water.

ACCIDENTAL RELEASE MEASURES: Dispose of in accordance with all local, state and federal regulations.

SECTION VII – HANDLING AND STORAGEHANDLING: DO NOT ALLOW TO FREEZE. Store in a cool dry location away from heat. Keep containers tightly closed

and store with adequate ventilation.

STORAGE: Keep in a dry, cool place, protect material from freezing.

OTHER PRECAUTIONS: DO NOT TAKE INTERNALLY. Avoid inhalation of excess vapors, ingestion, and unnecessary, pro-longed, or repeated contact with this and any other chemical. Change soiled work clothes fre-quently. Clean hands after handling. KEEP OUT OF REACH OF CHILDREN.

HMIS Ratings: Health: 1 Flammability: 0 Reactivity: 0 Personal Protective Equipment: B

Page 2Water Based Liner Adhesive

S A F E T Y D A T A S H E E T S A F E T Y D A T A S H E E T

SECTION XIII – DISPOSAL CONSIDERATIONS

SECTION XII – ECOLOGICAL INFORMATION

SECTION XI – TOXICOLOGICAL INFORMATION

SECTION X – STABILITY AND REACTIVITY DATA

SECTION IX - PHYSICAL / CHEMICAL PROPERTIES

SECTION VIII – EXPOSURE CONTROLS/PERSONAL PROTECTIONENGINEERING CONTROLS : Use only in area provided with appropriate exhaust ventilation.

EYE PROTECTION : Use chemical splash goggles or OSHA permitted safety glasses.

SKIN PROTECTION : Protection gloves

RESPIRATORY PROTECTION : Not required under normal conditions. Provide sufficient ventilation to maintain constant fresh air in workspace. If TLV is exceeded, use NIOSH/MSHA approved organic vapor and mist, supplied air, or self-contained breathing apparatus. Avoid breathing sanding dust.

FORM Mobile Liquid SPECIFIC GRAVITY (H20=1) 1.1-1.2

COLOR White or Black BOILING POINT 212°F

ODOR Mild, Sweet PH 8.0-9.5

SOLUBILITY IN WATER Miscible PERCENT VOLATILE BY WEIGHT 55-65%

COATING V.O.C. 22 g/l VISCOSITY (CPS) approx. 2,000-3,500

WATER SOLUBILITY Soluble FREEZING POINT 32°F(0°C)

CONDITIONS TO AVOID : Coagulation may occur after freezing, thawing, or boiling.

INCOMPATIBILITY : Metal salts, mineral acids (i.e. sulfuric, phosphoric, etc.) Strong oxidizing agents. Strong reducing agents.

DECOMPOSITION : May form toxic materials on thermal decomposition including Carbon monoxide (CO), Carbon dioxide (CO2), and various hydrocarbons. Under fire conditions, this product will release hydrogen chloride gas.

POLYMERIZATION : Polymerization will not occur.Stable at ambient temperatures.

SKIN : Prolonged and repeated contact with product may cause skin irritation.

EYES : Direct contact, may cause irritation.

INHALATION : Adverse health effects from vapors or spray mists in poorly ventilated areas may include irritation of the mucous membranes of the nose, throat, and respiratory tract and symp-toms of headache and nausea.

ECOTOXICITY: No ecotoxicity data was found for the product

ENVIRONMENTAL FATE: No environmental information found for this product

Consult with the US EPA Guidelines listed in 40 CFR Part 261.3 for the classifications of hazardous waste prior to disposal. Further-more, consult with your state and local waste requirements or guidelines, if applicable, to ensure compliance. Arrange disposal in accordance to the EPA and/or state and local guidelines.

STABILITY :

S A F E T Y D A T A S H E E TPage 3Water Based Liner Adhesive

S A F E T Y D A T A S H E E T

SECTION XV –REGULATORY INFORMATION

SECTION XIV – TRANSPORT INFORMATION

SECTION XVI –OTHER INFORMATION

DOT HAZARD CLASS Not Hazardous

UN NUMBER N/A

PACKING GROUP N/A

SHIPPING NAME N/A

This product is considered non-hazardous under the OSHA Hazard Communication Standard 29 CFR 1910.1200.EMERGENCY PLANNING AND COMMUNITY RIGHT-TO-KNOW (SARA TITLE III):Section 311/312 Categorizations (40 CFR 370): Immediate (Acute) Health Hazard.Section 313 Information (40 CFR 372) – Toxic Chemicals List: This product contains the following substances subject to the reporting requirements of Section 313 of Title III of the Superfund Amendments and Reauthorization Act of 1986 and 40 CFR 372:Component: none. Toxic Substances Control Act (TSCA): All components of this product are on the TSCA Inventory or are exempt from TSCA Inventory requirements.CALIFORNIA PROPOSITION 65 (Safe Drinking Water and Toxic Enforcement Act of 1986): None listed.

CREATION DATE 06/10/2009

REVISION DATE 06/01/2016

REVISION NOTE SDS - 16 Section

AUTHOR IT Department

All the information above is believed to be accurate and represents the best information currently available to us. However, we make no warranty of merchantability or any other warranty, express or implied, with respect to such information, and we assume no liability resulting from its use. Users should make their own investigations to determine the suitability of the information for their particular purposes. In no event shall Elgen Manufacturing be liable for any claims, losses, or damages of any third party or for lost profits or any special, indirect, incidental, consequential or exemplary damages, howsoever arising, even if Elgen Manufacturing has been advised of the possibility of such damages.

Product Data Sheet

WATER-BASED LINER ADHESIVE

Description

Standard Construction

5 Gallon Pails52 Gallon Drums

FeaturesThis adhesive can be sprayed, brushed, or rolled and is designed for both manual and automatic applications. It provides excellent results with easy cleanup. Our duct liner adhesive contains antimicro-bial agents that remain effective after the adhesive has cured.

Non-flammable, no unpleasant odors or hazardous fumes. Safe to use in enclosed areas.

Easy clean up with warm water

Good wet-tack

Fast drying with high tack.

Excellent coverage.

Contains zero VOC (volatile organic compounds).

Meet Requirements For Iowa Precision Coil Lines.

LEED Compliant

ALL STATED SPECIFICATION ARE SUBJECT TO CHANGE WITHOUT NOTICE OR OBLIGATION

Elgen’s Water - Based Liner Adhesive is an economical, water-based product for bonding insulation to metal surfaces. A non-oxidizing vinyl copolymer adhesive with excellent tem-perature and moisture resistance after curing, it forms a durable bond that will not become brittle with age.

Packaging

Guarantee

All Elgen products are guaranteed by Elgen Manufacturing against defective material.

Elgen Manufacturing10 Railroad Ave, Closter NJ 07624 Tel: 800.503.9805 :: Fax: 201.964.9030 [email protected] :: www.elgenmfg.com

Properties Value

Composition A high solids, water base adhesive that is non-flammable when wet.

Color White/Black

Viscosity 2000 to 3000 cps

Solids Content 37% ± 2%

Weight per Gallon 10.0 ± 0.1 #/gallon

Drying time

Tack-free: 3 to 4 hours (depending on humidity and temperature)Complete drying: 2 to 3 days at room temperature

Application and storage

KEEP FROM FREEzING50°F TO 100°F

Store and ship at temperatures above 32°F.

Use within 6 months after receipt.

Service temperature 0°F to 180°F

Flammability Wet - Non-flammable. Dry - Slow burning.

Clean-upThin with water. Clean up when wet with warm water. Dry clean up with aromatic or chlorinated solvents.

Meets requirements of NFPA 90A & 90BMeets requirements of ASTM C-916

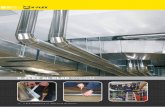

K-FLEX DUCT® LINER GRAY

Flexible, Closed Cell Elastomeric Foam InsulationResponsive to Market

Industry & Product Expertise 3rd Party Certif ied Products 25/50-rated up to 2” thick

Systems ApproachFactory-applied Options

14 Production Facil it ies Worldwide

TECHNICAL PROPERTIES

A key design objective of modern residential, commercial and industrial facilities is to incorporate a concern for energy consumption, as well as occupant comfort and safety. A healthier, more productive and more attractive environment depends in large part on well-designed and properly-insulated HVAC duct systems, which carry air to conditioned spaces inhabited by people,

C O M PA R I S O N B E T W E E N M AT E R I A L S

K-FLEX Duct® Liner Gray

Closed Cell Elatomeric

Fibrous Semi-Closed Cell

Elastomeric

Closed Cell Structure Yes No No

Flexible Yes Yes Yes

Thermal k (75°F mean) 0.25 0.23 0.25

water vapor transmission (wvt) without jacketing (perm-in)

<0.06 25.00 Info not available

25/50 flammability rating Yes (2”) Yes Yes (1”)

Service Temperature (°F) -297°F to +220°F 0°F to +250°F -297°F to + 180°F

Density (pcf) 3 - 4 1.5 - 3 3 - 6

Available with PSA Yes No No

Fiber-free Yes No Yes

Non-porous Yes No No

Resists Dirt Accumulation Yes No Yes

NRC Value (1”) 0.50 0.75 0.60

sensitive equipment, or a combination of both.

The advent of enhanced Indoor Air Quality (IAQ) has influenced engineers to 1) keep interior ducts free of foreign materials that bring fibers into the air stream, absorb moisture, or support mold growth, and 2) address sound reduction mechanically through deflection and

other methods. However, not using interior insulation results in increased transferred noise, energy loss, and higher cost solutions. Using a fiber-free, closed cell elastomeric liner provides a solution for all of these issues.

1.Noise Reduction

2.Energy Conservation

3.IAQ Control

DUCT LINER BENEFITS

2

0

0.2

0.4

0.6

0.8

1

1.2

125 250 500 1000 2000 4000

NOISE REDUCTIONEffective noise reduction in ducts requires an integrated strategy of good mechanical layout, vibration isolation and insulation with noise absorbing properties. Acoustic performance can be categorized into two functions: noise reduction (absorption) and sound barrier. For duct lining applications, the primary acoustical goal of the insulation is to achieve noise reduction through the absorption of sound waves and the subsequent conversion of sound energy into heat. The insulation absorbs noise from the air handler (fan) and room, and prevents it from traveling down the duct and exiting at the vent openings.

Noise reduction, quantified by the Noise Reduction Coefficient (NRC), measures the percentage of sound absorption in a reverberation room by

Sound Performance Comparison

K-FLEX DUCT® LINER GRAY

Fiberglass

Semi-Closed Cell Elastomeric

Sound Absorption 125 Hz 250 Hz 500 Hz 1000 Hz 2000 Hz 4000 Hz NRC

1” K-FLEX Duct® Liner Gray 0.12 0.25 0.97 0.32 0.52 0.52 0.50

1” Fibrous* 0.04 0.24 0.69 0.96 1.05 1.01 0.75

1” Semi-Closed Cell Elastomeric* 0.08 0.22 1.03 0.37 0.68 0.50 0.60

Hz

Soun

d Ab

sorp

tion

%

Equipment Rumble(present in all units)

High Pitched Whistle(uncommon: indicates mechanical problem)

*Taken from manufacturer’s published data.**Tested as insulation only. Testing conducted with insulation attached to metal would lead to high STC rating around 25.

determining noise decay rate. K-FLEX Duct® Liner Gray outperforms fibrous, and is comparable to semi-closed cell elastomeric, in absorbing noise at low frequencies associated with equipment rumble (125 - 500 Hz), which is the #1 target for acoustical treatment. Noise from higher frequencies, i.e. high pitched screeching, is the result of a mechanical problem downstream and is not usually a consideration.

Sound barriers, quantified by the Sound Transmission Loss (STL), reduce the amount of noise that pass through an area being by reflecting the sound waves back to its source. STL values are defined as the difference in decibels (dB) between the average sound pressure levels in the source and receiving rooms before and after acoustic treatment

which are then used to determine the Sound Transmission Class (STC) of the product. Sound barrier properties are generally related to the mass of the material in that the higher the mass, the higher (better) the STC value. In the case of metal air ducts, the metal duct itself is a good barrier material and the insulation is not a major contributor as a sound barrier. When STC values are given for duct lining materials, they are often tested as a composite (insulation and metal together) as this provides a more accurate measure of the STL of the application and if the insulation were tested by itself, it would not provide a very high value. It should be noted however, that insulation, when adhered to the duct will reduce noise created by vibration from the duct.

Sound Barrier** 125 Hz 250 Hz 500 Hz 1000 Hz 2000 Hz 4000 Hz STC

1.5” K-FLEX Duct® Liner Gray 12 10 13 14 22 31 16

3

0

1

2

3

4

5

0 2 4 6 8 10

0.01

0.1

1

0.2

0.4

0.6

0.8

1

0 2 4 6 8 10

0.01

0.1

1

ENERGY CONSERVATIONThermal insulation is commonly used to reduce energy consumption of HVAC systems and equipment. If improper insulation is used, potential threats include heat loss through duct walls and moisture intrusion into the interior structure of the insulation. Since water is a very good conductor, the capability of an insulation material to slow water vapor from penetrating into its interior

Thermal k performance over time with moisture gain (10 years)

R value performance over time with moisture gain (10 years)

wvt (perm-in) .01 .10 1.00

k-value (start) .250 .250 .250

k-value (10 years) .255 .310 1.88

k-value (75°F mean)

wvt (perm-in) unjacketed

Closed Cell Elastomeric

0.25 0.05

Fibrous 0.23 25.00

Semi-Closed Cell Elastomeric

0.25 not published

An R-value of 4.2 is required by IECC, ASHRAE and nearly every state building code.

R-va

lue

Year

Year

wvt

wvt

Ther

mal

k

wvt (perm-in) .01 .10 1.00

R-value (start) 4.2 4.2 4.2

R-value (10 years) 4.12 3.15 0.55

structure is fundamental for the long-term efficiency of the application.

SMACNA allows 5% moisture intrusion for fiberglass liner, BUT: For every 1% moisture gain, the insulation effectiveness drops 7.5%. As indicated below, if the wvt of the insulation is less than 0.10 perm-in, there will be minimal long-term effects on the k-value.

4

IAQ CONTROL MOLD RESISTANCE / LOW VOC / NON-FIBROUSFor an insulation material to defend against indoor air quality (IAQ) problems, it must resist condensation and moisture intrusion that can lead to mold, and ensure that the air passing over it does not contain fibers or dust. In ductwork that functions using conditioned air, the formation of condensation on the surface of the insulating material, within it, or on the outside of the metal is a negative factor.

Condensation forms as a result of the direct contact of warm humid air with a cold surface if the temperature of the surface is lower than the Dew Point of the humid air. The surface temperature of a duct and of the insulation depends on the application conditions and the R-value of the insulation material. If the insulation material is vapor permeable, moisture can move inside the insulation to reach areas where the temperature is

Winter: Cold air outside duct, warm air inside duct

K-FLEX Closed Cell Inherent Vapor Retarder:Distributed Resistance

Condensation Formation Open Cell with concentrated vapor retarder: puncture or improper installation = moisture intrusion

Summer: Warm air outside duct, cold air inside duct

Result w/ Fibrous: Mold growth on insulation Result w/ Fibrous: Mold growth on ceiling from water drip (corrosion on duct also possible)

Cold Air

Vapor Drive

Vapor Drive

K-FLEX Closed Cell Inherent Vapor Retarder: Distributed Resistance

Condensation FormationOpen Cell with concentrated vapor retarder: puncture or improper installation = moisture intrusion

Warm Air

Cold Air

Vapor Drive

Vapor Drive

low enough to have condensation, even if the surface temperature of the insulation is high enough to prevent surface condensation. An insulation material with low wvt would prevent this situation from occuring.

K-FLEX Duct® Liner Gray has tested as being mold resistant to ASTM G 21 standards. This is a result of a closed cell structure that inherently resists moisture and wicking, an added anti-microbial agent, a smooth surface skin that resists dirt accumulation, and a fiber-free composition that makes it non-particulating and non-eroding. K-FLEX Duct® Liner Gray is GREENGUARD® certified as a low VOC material, meeting the requirements for the “Children & Schools” and “Indoor Air Quality” classifications.

In contrast, fibrous or open cell materials rely on a concentrated moisture vapor barrier (foil jacket or surface-applied coating). If the barrier is damaged (even a pinhole) or the edges are not properly sealed, they are susceptible to moisture intrusion and subsequent mold growth. Once moisture penetrates, it can wick and involve large areas in the mold growth process. The EPA & NAIMA recommend the immediate removal of wet fiberglass to prevent mold, which means additional costs.

A study published in the April 2004 issue of ASHRAE Journal showed that an inspection of 150 office buildings with fiberglass duct liner revealed that 92% of them had fungal growth. Semi-closed cell elastomeric insulation would also be susceptible to moisture intrusion. Often times, the insulation can have moisture issues before the building is enclosed or commissioned.

Warm Air

Duct

Insulation InsulationDuct

5

PERFORMANCE • Reliable: Excellent thermal k after 10 years• Temperature Range: -297°F to +220°F• Low perm (<0.06 perm-in) without jacketing = No vapor barrier facing / edge treatment needed• Available with or without factory-applied PSA• Inherently high mold & mildew resistance• Fiber-free & Low VOC = IAQ• GREENGUARD® Certified - Children & Schools™ Classification for low VOC & Microbial Resistance Listing• Contains an EPA-registered antimicrobial agent for added protection• No erosion, cracking or delamination at high velocity air flow rates• Low pressure loss (values comparable to fiberglass)**• Sustainable: Lasts the life of the system

PROPERTY RATING CRITERIANRC 1” 0.50 ASTM C 423STC 1.5” (insulation only)

16 ASTM E 90

wvp <0.06 perm-in ASTM E 96Water Absorption <.2% ASTM C 209Thermal k 0.25 (Btu-in/h-ft2-°F) ASTM C 177 & C 518R-value 1” = 4.2, 2” = 8Fire Rating 25/50 up to 2” thick

PassASTM E 84NFPA 90 A / 90 B

Air Erosion Pass up to 10,000 fpm UL 181Mold Pass ASTM G 21Energy Rating Complies ASHRAE 90.1Elastomeric Duct Lining Requirements

Pass ASTM C 1534

SPECIFICATION COMPLIANCE • ASTM C534 Type 2 (Sheet), Grade 1• ASTM C1534• ASTM D1056-00-2C1• ASTM C423/E795 NRC=0.50 at 1” thickness • New York City MEA 186-86-M Vol. V • USDA & RoHS Compliant• UL 94-5V Flammability Classification (Recognition No. E300774) • ASTM E84: 25/50 at 2” and below• Meets requirements of NFPA 90A Sect. 2.3.3 for Supplementary Materials for Air Distribution Systems up to 2” thickness• Meets requirements of UL 181 Sections 11.0 and 16.0 (Mold Growth/Air Erosion)• Meets requirements of ASTM C411 (Test Method for Hot Surface Performance of High Temperature Thermal Insulation)• GREENGUARD certified under the “Children & Schools” and “Indoor Air Quality” classifications

**PRESSURE LOSS (H2O/100 ft): K-FLEX DUCT® LINER GRAY vs. Fiberglass

Velocity(ft/m) 10” x 10” 16” x 16” 24” x 24”

1000 .311 / .207 .102 / .114 .052 / .068

2000 1.007 / .806 .377 / .443 .207 / .266

3000 2.021 / 1.797 .799 / .988 .473 / .594

4000 3.467 / 3.179 1.386 / 1.748 .849 / 1.050

0

0.5

1

1.5

2

1000 2000 3000 4000

Pres

sure

Los

s

Velocity

16” x 16” Duct

6

TOTA

L CO

ST

INSTALLATION & MAINTENANCE• No Double Wall required to prevent air erosion or airborne fibers On average, double wall is 60% more expensive than single wall No need to wrap in mylar No need to finish (seal) exposed edges• Easy to fabricate & install (use SMACNA guidelines) No issues using weld pins or impact-applied fasteners (K-FLEX recommends pins & adhesives to fasten liner to metal) Easy to cut manually or with an automated machine Works well with automated, semi-automated, and handheld equipment• Flexible: non-rigid, non-breakable• No protective clothing required during installation• Safe: Non-dusting, Non-wicking, Non-abrasive, Non-itching• Low Maintenance• Easy to Clean – Smooth and Durable Surface, Resists Tearing• Available with factory-applied pressure sensitive adhesive (PSA)

• Bellefonte High School, Pennsylvania• City Of Doral Courthouse, Florida• Washington State University Veterinary Science Building, Washington• Finn Hill School, Washington• Allegheny College, Pennsylvania• Pine Richland High School, Pennsylvania• Taunton Courthouse, Massachusetts• University of Massachusetts, Massachusetts• Massachusetts Department of Transportation, Massachusetts• Kelowna General Hospital, British Columbia, Canada• Bloomsburg University, Pennsylvania• Woodward Elementary School, British Columbia

PROJECT REFERENCE LIST

7

HEADLINE Subheadline

www.kflexusa.comtel. 800-765-6475 - fax: 800-765-6471

100 Nomaco DriveYoungsville, NC 27596

KFAP-0001-0911