Journal of Engineered Fibers and Fabric - Defect Detection on...

Transcript of Journal of Engineered Fibers and Fabric - Defect Detection on...

Journal of Engineered Fibers and Fabrics 85 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

Defect Detection on Patterned Fabrics Using Distance Matching Function and Regular Band

Junfeng Jing Panpan Yang Pengfei Li

Xian Polytechnic University Xian Shaanxi CHINA

Correspondence to

Panpan Yang email 1051209316qqcom

ABSTRACT In this paper regular band is presented to detect defects on patterned fabrics Patterned fabrics are firstly disposed by fabric average to form object images mixed with positive and negative pixels in this proposed method Distance matching function is computed to determine the periodic distance of patterned fabrics The obtained periodic distance would be the length and width of regular band on row and column Two features are calculated with regular band The threshold of defect segmentation is extracted from the training step Two features of regular band negotiating the threshold are considered as a fabric defect Regular band method in this paper can avoid patterned interference and obtain perfect results in defect detection of patterned fabrics Various defects on patterned fabrics can be inspected and speedy defect detection could prove the performance ability in practice Keywords Patterned Fabrics Regular Band patterned unit FeaturesDistance matching function INTRODUCTION Quality of textile fabric plays an important role in the textile industry and fabric defects immensely decrease the worth of textile fabrics Price reduction ranges from 45 to 65 [1] compared to the original price of a product Patterned fabric is a high additional fabric on the basis of gray fabric so patterned fabric defect can cause larger loss than the gray ones The success rate and speed of artificial detection on patterned fabric are lower than gray fabrics which own success rate of 60-70 [2] and speed of 15-20mmin [3] Automated inspection realization on patterned fabrics could produce a large number of advantages and profits

Textured fabrics are generally divided into uniform [4] random [5] and patterned textures [6] Uniform textures are presented with identical texture in human visual system Most detection algorithms [7] are appropriate for detecting defects on uniform textures Such as wavelet transform Gabor filters and other approaches [8-12] are applied to detect defects and perfect results in defect detection are obtained Inspection of uniform textured material was analyzed with sundry methods in the research of Ajay Kumar [13] Random textures are regarded as the irregular textures Brazakoville et al [14] proposed a model-based approach for inspecting random textured materials Evaluation consistency of printed fabrics is the main problem in printed textures including printed fabrics wood texture and wall paper in the experiment of Brazakovic et al A number of regular designs on fabrics constitute patterned fabrics A proposed transformation scheme for textured pattern was inspired by the ring-projection algorithm [15] in YH Zhangrsquos research [16] and a non-defect pattern sliding over the whole visual image from pixel to pixel was used for determining the degree of regularity in target image Ngan and Pang [17-18] applied a method in defect detection of patterned fabrics and an applied golden image was acted as a convolution filter on the testing image The resultant matrix showed periodic waveforms and fabric defect brought a subtle change in resultant matrix so that fabric defect could be segmented Henry YT Ngan [19] applied a wave let based method in defect detection of patterned fabrics LBP operator of window and corresponding feature vector are used to detect defects of patterned fabrics in reference [20]Both algorithms can mark the position of a fabric defect but are low in accuracy

Journal of Engineered Fibers and Fabrics 86 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

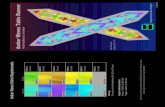

On the basis of the statistical principle of moving average and standard deviation Ngan and Pang also proposed regular band method possessing robust performance in patterned design Selecting period length is used for optimizing the optimal defect detection results and appropriate period length could lead to perfect detection results This paper proposes a method based on defect the detection approach [21] of Ngan and Pang to contra pose patterned fabrics shown in Figure 1 Equalization preprocessing is performed firstly to reduce noise and regulate pixels of fabrics Regular band on row and column can act as the statistical principle of moving window Average in moving window of defect-free fabrics would shift all experimental fabrics n and m respectively represent the length of regular band on row and column which are determined by the size of patterned unit Feature two and feature one are selected as the object of regular band statistic Feature two is in this paper by

way of combining the average of defect-free fabrics and sample fabric pixels Feature one is mended with high index coefficient on shifting fabrics to enlarge the distance between defect and fabrics The goal of this paper is to finish defect detection of patterned fabrics which owns various interferences to recognize fabric defect for people Speedy on-line defect detection of patterned fabrics and matching the speed of detection system can realize real-time detection in the textile industry The paper is organized with four sections The first section is an introduction including previous research on patterned fabrics and proposed method The second section narrates the foundation of proposed algorithm and the core algorithm based on the statistics way of regular band The third section offers defect segmentation step The final section provides experimental results in defect detection on fabrics and analysis of corresponding detection results

Training step Detection step

Input five non-defective patterned fabric imagesCalculate size of fabrics periodic unit (mn) via

distance match function

Input a defective patterned fabric image

Equalization operationEqualization operation

Calculate average value M0

Feature one calculation separately in row regular band with n-length and column regular band with m-length of training fabric images

Feature two calculation separately in row regular band with n-length and column regular band with m-length of training fabric images

Merger detection results as final defect detection result

Average maximum and minimum respectively act as four pairs of threshold

Feature one

calculation in row regular band with

n-length and column regular band with m-

length of fabric sample image

Feature two calculation in row regular band with n-length and column regular band with m-length of fabric sample image

Based on four pairs of threshold four results of defect segmentation are obtained

Non-defective fabric images are shifted by M0 Defective fabric image is shifted by M0

FIGURE 1 The whole process of proposed algorithm in patterned fabric defect detection

Journal of Engineered Fibers and Fabrics 87 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

REGULAR BAND ALGORITHM Way of Regular Band To realize regular band algorithm [22] statistical pixels of patterned fabrics have to be computed with a certain length to express the features Figure 2 shows the way of statistical pixels of patterned fabrics in regular band In Figure 2 M and N represent the size of patterned fabrics m and n mean the length of regular band on column and row of patterned fabrics and number 1234 and 5 are the obtained results of regular band on patterned fabrics and the size of regular band resultant image is (45)

2

3

2

1 43 5

4

m

nN

M

FIGURE 2 Way of statistical pixels of patterned fabrics in regular band

If M=N and m is greater than n M-m+1 would be smaller than N-n+1 M-m+1 and N-n+1 of regular band act as the size of resultant image One-Dimensional Distance Matching Function The distance matching function proposed by Oh et al [23] is defined to calculate the periodic distance of periodic function Because neighbor patterned units of fabrics have similarity the periodic distance is selected via choosing the smallest difference of adjacent results from one-dimensional function The periodic distance can be calculated with distance matching function as Eq (1)

2

1( ) [ ( ) ( )]

N p

ip g i g i pλ

minus

=

= minus +sum (1)

Parameter p represents periodic distance of one-dimensional function g (i)The results of distance matching function of one row and one column of fabrics are exhibited as Figure 3

(a) (b)

FIGURE 3Distance matching function of one-dimensional signal from fabric row (a) and column (b)

Distance Matching Function for Fabrics Fabrics can be considered as a two-dimensional function where f(xy) means the gray value of fabrics The row or column of fabrics would be identified the one-dimensional function the sum of

one--dimensional row or column would be the results of distance matching function as Eq (2) and Eq (3) The results of distance matching function can be depicted in Figure 4

Journal of Engineered Fibers and Fabrics 88 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

(a) (b)

FIGURE 4 Results of distance matching function on fabric rows (a) and columns (b)

1 1

2

( ) [ ( )

( )]

N pM

xx y

sum p f x y

f x y p

λ

minus

= =

=

minus +

sum sum (2)

1 1

2

( ) [ ( )

( )]

M pN

yy x

sum p f x y

f x p y

λ

minus

= =

=

minus +

sum sum (3)

Second Forward Difference The resultant difference between variable and forward variable of distance matching function is identified as first forward difference The difference of distance matching function with variable p+1 and variable p is named as ( )1D p first forward differences of distance matching function are listed as Eq (4)-(7) ( )1D p and ( )2D p are respectively the first difference of fabric row and fabric column

(4)

(5)

(6)

(7)

Second forward difference ( )max1D pD is the

difference of first forward differences with variable p+1 and variable p Eq (8) and Eq (9) are the ways to calculate second forward difference

( )max1D pD and ( )

max2D pD are the second forward

difference from fabric row and fabric column

( ) ( )max1 1 1( 1)D p D p D pD = minus minus (8)

( ) ( )

max2 2 2 ( 1)D p D p D pD = minus minus (9) The maximum of second forward difference is extracted to attain the corresponding periodic distance The periodic distance of fabrics is equal to obtained periodic distance p

Journal of Engineered Fibers and Fabrics 89 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

(a) (b)

FIGURE 5 Second forward difference of distance matching function on fabric rows (a) and columns (b)

Parameters m and n can be obtained by calculating the size of patterned unit Parameter m is equal to the periodic distance of patterned row Parameter n means the period of patterned column Parameters m and n computed by distance matching function would be applied in regular band Figure 5 shows the results of second forward difference The process of distance match function can be concluded as following Step 1 Input Figure 5(c) Step 2 Choose a reasonable scope of parameter variable p (pltM and pltN) Calculate distance matching function in equation (2) and (3) with variable p as Figure 4 Step 3 Count second forward difference of distance matching function with variable p as Figure 5 Step 4 Extract the maximum of second forward difference the parameter p would be determined Preprocessing on Patterned Fabrics Before the operation of proposed method on patterned fabrics equalization operation [24] should be done to get rid of noise of patterned fabrics and the pixels of patterned fabrics could be regulated properly Equalization processing changes the grayscale histogram concentrated of original image into a uniform distribution within the scope of all gray and make the number of pixel gray level consistent The whole process is shown as Figure 6

FIGURE 6The whole procedure of equalization operation Calculate Average for Shifting Fabrics After the preprocessing of patterned fabrics patterned fabric images should be dealt with average value of non-defective fabrics and this operation builds the foundation for later steps In this step n is the statistics number of regular band on row and m is the statistics number of regular band on column Regular band algorithm on column could be performed as long as row is changed into column

1

1 1

11

01 1

( ( (( ( )) ) 1)) r nM N n

x r y rM IM x y n N n M

+ minusminus +

= = =

= minus +sum sum sum (10)

Journal of Engineered Fibers and Fabrics 90 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

The mean of existed n-length pixels in row of all training fabrics is computed as Eq (10) IM(xy) is input image Parameter 1r is the starting position of regular band on patterned fabrics and n is the length of regular band(MN) is the size of IM(xy)Parameters x and y represent the position of gray value The obtained average value 0M should be subtracted by all pixels of patterned fabrics which can make pixels of patterned fabrics closer to zeros than original fabrics The relationship of Figure 7(b0) and Figure 7(b1) is the same as 7(a0) and Figure 7(a1) Figure 7(a1) and Figure 7(b1) establish foundation for effectiveness of proposed algorithm

(a) (b) Thick Bar patterned fabrics Defect-free patterned fabrics

(a0) (b0) Gray value distribution of (a) Gray value distribution of (b)

(a1) (b1) Gray value distribution result Gray value distribution result

of (b0) subtracted by 0M of (b0) subtracted by 0M

FIGURE 7 Whole process of shift operation with 0M

Kernel of Regular Band Feature one [25] and feature two are computed to distinguish the normal and defective part utilizing regular band on patterned fabrics Feature one and feature two is useful in detection of patterned fabrics as Eq (12) and Eq (13) IM(xy) is defined as the consequence of equalization operation S(xy) is the disposed fruit of IM(xy) via 0M shown in Eq (11) Patterned fabrics are altered in Eq (11) being an important role in regular band which offers a platform to pledge the availability of regular band algorithm N and M are the size of input fabrics Parameters n and m are captured from the size of patterned unit via distance matching function Feature one and Feature two are calculated within the moving window of (m1) or (1n)(m1) is the size of moving window on fabric row(n1) acts as the size of moving window on fabric column

1r is the first position of moving window 1M is used for computing the average value of moving window from S(xy)

0( ) ( )S x y F x y M= minus (11)

1

1

13

1 1( ) [1 1]r n

x rf S x y r N nσ

+ minus

=

= minus isin minus +sum (12)

1

1

1

1

2 1

( ( ) ) [1 1]

r n

x rS x y M

f r N nn

+ minus

=

minus= isin minus +sum

(13)

1

1 1

11

11 1

( ( (( ( )) ) 1)) r nM N n

x r y rM S x y n N n M

+ minusminus +

= = =

= minus +sum sum sum (14)

The mean of existed n-length pixels in row of S(xy) is computed as Eq (14) Feature one in Eq (12) is structured to elongate the gap between defect pixels and normal pixels thus fabric defect can be abstracted from patterned fabrics Feature two in Eq (13) is entrusted with difference between S(xy) and average of corresponding S(xy) of non-defective fabrics Compared with normal part of fabrics defective part has larger gap than the average of S(xy) All the mentioned equations are applied in

Journal of Engineered Fibers and Fabrics 91 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

regular band on rows In the same way Eq (11) Eq (12) and Eq (13) could also be applied in regular band of column as long as variable quantities are transformed into homologous variable quantities in regular band of column DEFECT SEGMENTATION Threshold Calculation The thresholds are obtained via calculating feature one and feature two Five non-defective fabrics are applied in training step and the maximum and minimum of feature one and feature two are extracted in regular band on rows and columns of every fabric image The threshold set is the average value of saved maximum and minimum on rows and columns of five fabric images and the calculated equations are shown in Eq (15)

]min[max

11

1

rowsfrowsf

rowsf

imumimum

Threshold = (15)

Where

))))(max(((

max

1

1

1

5

1 15

1

g

nN

ig nNnumnum

rowsf

ifmeanmean

imum

sumsum+minus

== +minus==

=

))))(max(((

min

1

1

1

5

1 15

1

g

nN

jg nNnumnum

rowsf

jfmeanmean

imum

sumsum+minus

== +minus==

=

Eq (15) represents the segmentation thresholds which are made of average maximum and minimum on rows of feature one The threshold of feature two can be obtained as long as replacing feature one with feature two in Eq (15) Function lsquomeanrsquo is the identity of average function Regular band threshold on column could also be calculated with Eq (15) via changing regular band on row into regular band on column of feature one and feature two Eq (16) introduces the row threshold including calculated thresholds of feature one and feature two Eq (17) combines row threshold and column threshold as the final thresholds The definitions of Eq (16) and Eq (17) are exhibited as following

rowsfrowsf

rows

ThresholdThresholdThreshold

21

= (16)

columnsrows ThresholdThresholdThreshold

= (17)

Binarization Based on the computed threshold Feature one and feature two obtained in sample fabrics are compared with threshold from training fabrics If the feature one and feature two of sample fabrics are included in the extent of threshold 0 would be endowed in corresponding position in )( yxD or the position would be given to 255 )( yxD is defined as Eq (18)

(18)

In experiment 30 training samples and 85 testing samples are applied in experiments Every texture possesses 5 training samples with same texture 6 classes of texture are utilized to prove effectiveness of proposed method Experimental fabrics are patterned fabrics including 20 defects from 6 textures to validate the availability of proposed method The experimental fabrics are derived from the TILDA database [26] and Henry YT Ngan from Industrial Automation Research Laboratory Dept of Electrical and Electronic Engineering The University of Hong Kong The processor of applying computer is intel(R) core(TM) i5-2400CPU 310GHZand RAM of computer is 400GB A 32-bit operating system of computer is owned Matlab software of computer is used to implement the proposed algorithm RESULTS Parameters m and n from distance matching function The size of patterned unit (mn) can be determined with distance matching function and the results of determining patterned unit from fabrics are shown in Figure 8 The parameters m and n are listed in

Journal of Engineered Fibers and Fabrics 92 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

Table Iwhich includes all the fabric size of patterned unit in Figure 8 The size of patterned unit (mn) would be applied in regular band to detect patterned defects Besides training time and detection time are listed in Table I Total run time equals to the sum of detection time and training

time Training time occupies the majority of total run time Fast detection time promises the possibility of operation in real situations The complexity of proposed method is O (MN) which is related to the size of fabrics

FIGURE 8 Results of determining patterned unit of fabrics

TABLE I Size of patterned unit and running time of proposed method on various fabrics

Images of Figure 8 (a) (b) (c) (d) (e) (f)

Parameter n 23 27 27 28 10 19

Parameter m 17 37 23 79 9 16

Training time

of regular band

2316981

seconds

3229209

seconds

2402773

seconds

2865476

seconds

1924046

seconds

2182325

seconds

Detection time of

regular band

0204037

seconds

0242415

seconds

0223430

seconds

0285310

seconds

0157748

second

0188936

seconds

Feasibility of Regular Band To prove the effectiveness of regular band the disposed results of sample fabrics are revealed in 2-D and 3-D Feature one and feature two are calculated in regular band to partition fabric defects Feature one and feature two calculated via regular band on row and column are exhibited in Figure 9 In Figure 9 it can

be concluded that fabric defects own higher results of feature one and feature two compared with non-defective areas thus a threshold is existed to separate defect of patterned fabrics The segmentation results in a(1) b(1) c(1) and d(1) are combined as the final defect detection results

Journal of Engineered Fibers and Fabrics 93 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

(I) Thick Bar sample fabric

FIGURE 9 (I) is sample fabrics (a1) and (a2) feature one resultant distribution in 2-D and 3-D via regular band of row (b1) and (b2) feature two resultant distribution in 2-D and 3-D via regular band of row (c1) and (c2) feature one resultant distribution in 2-D and 3-D via regular band of column (d1) and (d2) feature two resultant distribution in 2-D and 3-D via regular band of column

Journal of Engineered Fibers and Fabrics 94 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

The Statistics of Detection Results Defect detection results could be classified into four kinds Overall Detection (OD) True Detection (TD) False Alarm (FA) and Misdetection (MD) True Detection (TD) can be explained that white area of binary image equals to the corresponding defect on fabrics False Alarm (FA) indicates that the white area

includes the corresponding defect region and other white regions of the fabrics Overall Detection (OD) acts as the combination of TD and FA Misdetection (MD) shows no white areas in resultant images The statistical results of fabric detection are concluded in Table II

TABLE II The statistical results of fabric detection types in the output binary images

Detection

results

Broken End Thin Bar Thick Bar Netting

Multiple

Hole Knots

Fabrics from

TILDA

database

Overall

Detection

(OD)

100

(1515)

100

(1515)

100

(1515)

93

(1515)

100

(1515)

100

(55)

100

(55)

True Detection

(TD)

93

(1415)

100

(1315)

100

(1515)

93

(1415)

93

(1415)

100

(55)

93

(45)

False Alarm

(FA)

7

(115)

0

(215)

0

(015)

0

(015)

7

(115)

0(05) 7

(15)

Misdetection

(MD)

0(015) 0(015) 0(015) 7

(115)

0(015) 0(05) 0(05)

Various Defects Detection Results of Patterned Fabrics In the experiments patterned fabrics including Broken End Hole Thin Bar Thick Bar and Netting Multiple are detected on box-patterned and star-patterned fabric backgrounds shown in Figure 10 Patterned fabrics in TILDAT database are also inspected in this paper which are observed with perfect detection results Dot-patterned fabrics results are included in Figure 10 Proposed method based on the analysis of patterned fabrics extracts the period features and defect on fabrics would break the regular rule of fabrics

Periodic features are constructed by feature two and feature one in this paper Distance matching function is used for extracting the size of moving window on row and column Regular band is relative to regular band of Henry YT Ngan Regular band applied the same way of extracting features as Henry YT Ngan but regular band extracting two features forms two complementary and independent factors to segment defect of fabrics accurately However Henry YT Ngan utilized the relationship between mean and variance to recognize defects on patterned fabrics

Journal of Engineered Fibers and Fabrics 95 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

FIGURE10 Defects on patterned fabrics detected with proposed method

DISCUSSION Double weft broken weft or warp are considered as defects which are caused by horizontal and vertical damage of fabrics When these defects occur to patterned fabric moving window is selected to extract feature of fabric unit and defects can destroy the regularity of fabrics So defects destroying the regularity of fabrics can be inspected with proposed method CONCLUSION The supervised defect detection method including training step and detection step is introduced in this paper Equalization pretreatment is done on both

non-defective fabrics and sample fabrics to reduce fabric noise and build a foundation for proposed algorithm Patterned fabrics are dealt with gray pixels via row statistics and column statistics with certain length and parameters m and n acted as the length are assigned to the size of patterned unit which is calculated via distance matching function The way of statistics fabric pixels is named as regular band Feature one and feature two is computed on basis of regular band In training step feature one and feature two in regular band are calculated to receive the maximum and minimum The gained extents of feature one and feature two in regular band are defined as threshold limits In detection step feature one and

Journal of Engineered Fibers and Fabrics 96 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

feature two of fabric defects would not be included in threshold limits thus achieving defect detection on patterned fabrics Fleet defect detection can furnish the possibility of implementation in practice Defect detection on patterned fabrics can avoid interference of pattern and the threshold of defect detection can be extracted in training period thus achieving speedy on-line defect detection of patterned fabrics and matching the speed of detection system in the textile industry REFERENCES [1] KL Mak amp P Peng Detecting defects in textile

fabrics with optimal Gabor filters [J] International Journal of Computer Science 20061(4)274-282

[2] Junfeng Jing Huanhuan Zhang Pengfei Li amp Jinyuan Jia Fabric defect detection using Gabor filters and defect classification based on LBP and Tamura method[J] The Journal of The Textile Institute 2013 104(1)18-27

[3] Junjie Chen amp Chunping Xie Automatic cloth inspection system [J] Textile Science and Technology Progress 2004(5)56-57

[4] Arkady Cherkassky amp Amotz Weinberg Objective evaluation of textile fabric appearance part 1 basic principles protrusion detection and Parameterization [J] Textile Research Journal 20103(80)226-235

[5] Xianghua Xie amp Mirmehdi M Texems texture exemplars for defect detection on random textured surfaces [J] Pattern Analysis and Machine Intelligence 2007 29 (8)1454 ndash 1464

[6] D Chetverikov Pattern regularity as a visual key [J] Image and Vision Computing 2000 18(12)975-985

[7] Henry YT Ngan Grantham KH Pang amp Nelson HC Yung Automated fabric defect detectionmdashA review [J] Image and Vision Computing 2011 29(7)442ndash458

[8] Rimac-Drlje S Keller A amp Nyarko K E Self-Learning system for surface failure detection[C] EURASIP 13th European Signal Processing Conference EUSIPCO 2005

[9] A Ahmadyfard et al A novel approach for detecting defects of random textured tiles using Gabor wavelet[J] World Applied Sciences Journal 2009 7 (9) 1114-1119

[10] A Khodaparast amp A Mostafa On line quality control of tiles using wavelet and statistical properties[C] In Proceedings of the 2nd Iranian Conference on Machine Vision and

Image Processing 2003 153ndash159 [11] Junfeng JingHang Li amp Pengfei Li Combined

fabric defects detection approach and quadtree decomposition [J] Journal of Industrial Textiles 2012 41 (4)331-344

[12] Mostafavi M S A new method in detection of ceramic tiles color defects using genetic C-means algorithm [J] Proceeding of World Academy of Science Engineering and Technology 2006 168-171

[13] Ajay Kumar Computer vision-based fabric defect detection A survey [J] IEEE Transactions on Industrial Electronics 200855(1)348 - 363

[14] Chin R T Automated visual inspection 1981 to 1987[J] Computer Vision Graphics and Image Processing 1988 41(3) 346-381

[15] Du-Ming Tsai amp Ya-Hui TsaiRotation-invariant pattern matching with color ring-projection [J] Pattern Recognition 2002 35(1)131-141

[16] YH Zhang CWM Yuen WK Wong amp Chi-wai Kan An intelligent model for detecting and classifying color-textured fabric defects using genetic algorithms and the Elman neural network[J] Textile Research Journal 201181(17) 1772ndash1787

[17] Ngan H Y T Pang G K H amp Yung S P et al Defect detection on patterned jacquard fabric[C] Applied Imagery Pattern Recognition Workshop Proceedings 32nd IEEE 2003 163-168

[18] HYT Ngan amp GKH Pang Novel method for patterned fabric inspection using Bollinger bands [J] Optical Engineering 2006 45 (8) 1-13

[19] Ngan H Y T Pang G K H Yung S P et al Defect detection on patterned jacquard fabric[C]Applied Imagery Pattern Recognition Workshop 2003 Proceedings 32nd IEEE 2003 163-168

[20] Tajeripour F Kabir E Sheikhi A Defect detection in patterned fabrics using modified local binary patterns[C]Conference on Computational Intelligence and Multimedia Applications 2007 International Conference on IEEE 2007 2 261-267

[21] HYT Ngan amp GKH Pang Regularity analysis for patterned texture inspection [J] Automation Science and Engineering 20096 (1)131-143

Journal of Engineered Fibers and Fabrics 97 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

[22] Reddy R O K Reddy B E amp Reddy E K Texture analysis and defect classification for fabric images using regular bands and quadratic programming[C] Proceedings of International Conference on Advances in Computing Springer India 2012 927-934

[23] Oh G Lee S amp Yong Shin S Fast determination of textural periodicity using distance matching function [J] Pattern Recognition Letters 1999 20(2) 191-197

[24] Pisek E amp Wang Y Equalization techniques using viterbi algorithms in software-defined radio systems US Patent 8069401[P] 2011-11-29

[25] Zeeshan Khatri Muhammad Hanif Memon Awais Khatri amp Anwaruddin Tanwari Cold Pad-Batch dyeing method for cotton fabric dyeing with reactive dyes using ultrasonic Feature one [J] Ultrasonics Sonochemistry 2011 18(6)1301-1307

[26] Work group on texture analysis of DFG TILDA textile texture database August 1996 (httplmbinformatikuni-freiburgderesearchdfg-texturetilda)

AUTHORSrsquo ADDRESSES Junfeng Jing Panpan Yang Pengfei Li Xian Polytechnic University 19 of the South Jinhua Road Xian Shaanxi 710048 CHINA

- REFERENCES

-

Journal of Engineered Fibers and Fabrics 86 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

On the basis of the statistical principle of moving average and standard deviation Ngan and Pang also proposed regular band method possessing robust performance in patterned design Selecting period length is used for optimizing the optimal defect detection results and appropriate period length could lead to perfect detection results This paper proposes a method based on defect the detection approach [21] of Ngan and Pang to contra pose patterned fabrics shown in Figure 1 Equalization preprocessing is performed firstly to reduce noise and regulate pixels of fabrics Regular band on row and column can act as the statistical principle of moving window Average in moving window of defect-free fabrics would shift all experimental fabrics n and m respectively represent the length of regular band on row and column which are determined by the size of patterned unit Feature two and feature one are selected as the object of regular band statistic Feature two is in this paper by

way of combining the average of defect-free fabrics and sample fabric pixels Feature one is mended with high index coefficient on shifting fabrics to enlarge the distance between defect and fabrics The goal of this paper is to finish defect detection of patterned fabrics which owns various interferences to recognize fabric defect for people Speedy on-line defect detection of patterned fabrics and matching the speed of detection system can realize real-time detection in the textile industry The paper is organized with four sections The first section is an introduction including previous research on patterned fabrics and proposed method The second section narrates the foundation of proposed algorithm and the core algorithm based on the statistics way of regular band The third section offers defect segmentation step The final section provides experimental results in defect detection on fabrics and analysis of corresponding detection results

Training step Detection step

Input five non-defective patterned fabric imagesCalculate size of fabrics periodic unit (mn) via

distance match function

Input a defective patterned fabric image

Equalization operationEqualization operation

Calculate average value M0

Feature one calculation separately in row regular band with n-length and column regular band with m-length of training fabric images

Feature two calculation separately in row regular band with n-length and column regular band with m-length of training fabric images

Merger detection results as final defect detection result

Average maximum and minimum respectively act as four pairs of threshold

Feature one

calculation in row regular band with

n-length and column regular band with m-

length of fabric sample image

Feature two calculation in row regular band with n-length and column regular band with m-length of fabric sample image

Based on four pairs of threshold four results of defect segmentation are obtained

Non-defective fabric images are shifted by M0 Defective fabric image is shifted by M0

FIGURE 1 The whole process of proposed algorithm in patterned fabric defect detection

Journal of Engineered Fibers and Fabrics 87 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

REGULAR BAND ALGORITHM Way of Regular Band To realize regular band algorithm [22] statistical pixels of patterned fabrics have to be computed with a certain length to express the features Figure 2 shows the way of statistical pixels of patterned fabrics in regular band In Figure 2 M and N represent the size of patterned fabrics m and n mean the length of regular band on column and row of patterned fabrics and number 1234 and 5 are the obtained results of regular band on patterned fabrics and the size of regular band resultant image is (45)

2

3

2

1 43 5

4

m

nN

M

FIGURE 2 Way of statistical pixels of patterned fabrics in regular band

If M=N and m is greater than n M-m+1 would be smaller than N-n+1 M-m+1 and N-n+1 of regular band act as the size of resultant image One-Dimensional Distance Matching Function The distance matching function proposed by Oh et al [23] is defined to calculate the periodic distance of periodic function Because neighbor patterned units of fabrics have similarity the periodic distance is selected via choosing the smallest difference of adjacent results from one-dimensional function The periodic distance can be calculated with distance matching function as Eq (1)

2

1( ) [ ( ) ( )]

N p

ip g i g i pλ

minus

=

= minus +sum (1)

Parameter p represents periodic distance of one-dimensional function g (i)The results of distance matching function of one row and one column of fabrics are exhibited as Figure 3

(a) (b)

FIGURE 3Distance matching function of one-dimensional signal from fabric row (a) and column (b)

Distance Matching Function for Fabrics Fabrics can be considered as a two-dimensional function where f(xy) means the gray value of fabrics The row or column of fabrics would be identified the one-dimensional function the sum of

one--dimensional row or column would be the results of distance matching function as Eq (2) and Eq (3) The results of distance matching function can be depicted in Figure 4

Journal of Engineered Fibers and Fabrics 88 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

(a) (b)

FIGURE 4 Results of distance matching function on fabric rows (a) and columns (b)

1 1

2

( ) [ ( )

( )]

N pM

xx y

sum p f x y

f x y p

λ

minus

= =

=

minus +

sum sum (2)

1 1

2

( ) [ ( )

( )]

M pN

yy x

sum p f x y

f x p y

λ

minus

= =

=

minus +

sum sum (3)

Second Forward Difference The resultant difference between variable and forward variable of distance matching function is identified as first forward difference The difference of distance matching function with variable p+1 and variable p is named as ( )1D p first forward differences of distance matching function are listed as Eq (4)-(7) ( )1D p and ( )2D p are respectively the first difference of fabric row and fabric column

(4)

(5)

(6)

(7)

Second forward difference ( )max1D pD is the

difference of first forward differences with variable p+1 and variable p Eq (8) and Eq (9) are the ways to calculate second forward difference

( )max1D pD and ( )

max2D pD are the second forward

difference from fabric row and fabric column

( ) ( )max1 1 1( 1)D p D p D pD = minus minus (8)

( ) ( )

max2 2 2 ( 1)D p D p D pD = minus minus (9) The maximum of second forward difference is extracted to attain the corresponding periodic distance The periodic distance of fabrics is equal to obtained periodic distance p

Journal of Engineered Fibers and Fabrics 89 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

(a) (b)

FIGURE 5 Second forward difference of distance matching function on fabric rows (a) and columns (b)

Parameters m and n can be obtained by calculating the size of patterned unit Parameter m is equal to the periodic distance of patterned row Parameter n means the period of patterned column Parameters m and n computed by distance matching function would be applied in regular band Figure 5 shows the results of second forward difference The process of distance match function can be concluded as following Step 1 Input Figure 5(c) Step 2 Choose a reasonable scope of parameter variable p (pltM and pltN) Calculate distance matching function in equation (2) and (3) with variable p as Figure 4 Step 3 Count second forward difference of distance matching function with variable p as Figure 5 Step 4 Extract the maximum of second forward difference the parameter p would be determined Preprocessing on Patterned Fabrics Before the operation of proposed method on patterned fabrics equalization operation [24] should be done to get rid of noise of patterned fabrics and the pixels of patterned fabrics could be regulated properly Equalization processing changes the grayscale histogram concentrated of original image into a uniform distribution within the scope of all gray and make the number of pixel gray level consistent The whole process is shown as Figure 6

FIGURE 6The whole procedure of equalization operation Calculate Average for Shifting Fabrics After the preprocessing of patterned fabrics patterned fabric images should be dealt with average value of non-defective fabrics and this operation builds the foundation for later steps In this step n is the statistics number of regular band on row and m is the statistics number of regular band on column Regular band algorithm on column could be performed as long as row is changed into column

1

1 1

11

01 1

( ( (( ( )) ) 1)) r nM N n

x r y rM IM x y n N n M

+ minusminus +

= = =

= minus +sum sum sum (10)

Journal of Engineered Fibers and Fabrics 90 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

The mean of existed n-length pixels in row of all training fabrics is computed as Eq (10) IM(xy) is input image Parameter 1r is the starting position of regular band on patterned fabrics and n is the length of regular band(MN) is the size of IM(xy)Parameters x and y represent the position of gray value The obtained average value 0M should be subtracted by all pixels of patterned fabrics which can make pixels of patterned fabrics closer to zeros than original fabrics The relationship of Figure 7(b0) and Figure 7(b1) is the same as 7(a0) and Figure 7(a1) Figure 7(a1) and Figure 7(b1) establish foundation for effectiveness of proposed algorithm

(a) (b) Thick Bar patterned fabrics Defect-free patterned fabrics

(a0) (b0) Gray value distribution of (a) Gray value distribution of (b)

(a1) (b1) Gray value distribution result Gray value distribution result

of (b0) subtracted by 0M of (b0) subtracted by 0M

FIGURE 7 Whole process of shift operation with 0M

Kernel of Regular Band Feature one [25] and feature two are computed to distinguish the normal and defective part utilizing regular band on patterned fabrics Feature one and feature two is useful in detection of patterned fabrics as Eq (12) and Eq (13) IM(xy) is defined as the consequence of equalization operation S(xy) is the disposed fruit of IM(xy) via 0M shown in Eq (11) Patterned fabrics are altered in Eq (11) being an important role in regular band which offers a platform to pledge the availability of regular band algorithm N and M are the size of input fabrics Parameters n and m are captured from the size of patterned unit via distance matching function Feature one and Feature two are calculated within the moving window of (m1) or (1n)(m1) is the size of moving window on fabric row(n1) acts as the size of moving window on fabric column

1r is the first position of moving window 1M is used for computing the average value of moving window from S(xy)

0( ) ( )S x y F x y M= minus (11)

1

1

13

1 1( ) [1 1]r n

x rf S x y r N nσ

+ minus

=

= minus isin minus +sum (12)

1

1

1

1

2 1

( ( ) ) [1 1]

r n

x rS x y M

f r N nn

+ minus

=

minus= isin minus +sum

(13)

1

1 1

11

11 1

( ( (( ( )) ) 1)) r nM N n

x r y rM S x y n N n M

+ minusminus +

= = =

= minus +sum sum sum (14)

The mean of existed n-length pixels in row of S(xy) is computed as Eq (14) Feature one in Eq (12) is structured to elongate the gap between defect pixels and normal pixels thus fabric defect can be abstracted from patterned fabrics Feature two in Eq (13) is entrusted with difference between S(xy) and average of corresponding S(xy) of non-defective fabrics Compared with normal part of fabrics defective part has larger gap than the average of S(xy) All the mentioned equations are applied in

Journal of Engineered Fibers and Fabrics 91 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

regular band on rows In the same way Eq (11) Eq (12) and Eq (13) could also be applied in regular band of column as long as variable quantities are transformed into homologous variable quantities in regular band of column DEFECT SEGMENTATION Threshold Calculation The thresholds are obtained via calculating feature one and feature two Five non-defective fabrics are applied in training step and the maximum and minimum of feature one and feature two are extracted in regular band on rows and columns of every fabric image The threshold set is the average value of saved maximum and minimum on rows and columns of five fabric images and the calculated equations are shown in Eq (15)

]min[max

11

1

rowsfrowsf

rowsf

imumimum

Threshold = (15)

Where

))))(max(((

max

1

1

1

5

1 15

1

g

nN

ig nNnumnum

rowsf

ifmeanmean

imum

sumsum+minus

== +minus==

=

))))(max(((

min

1

1

1

5

1 15

1

g

nN

jg nNnumnum

rowsf

jfmeanmean

imum

sumsum+minus

== +minus==

=

Eq (15) represents the segmentation thresholds which are made of average maximum and minimum on rows of feature one The threshold of feature two can be obtained as long as replacing feature one with feature two in Eq (15) Function lsquomeanrsquo is the identity of average function Regular band threshold on column could also be calculated with Eq (15) via changing regular band on row into regular band on column of feature one and feature two Eq (16) introduces the row threshold including calculated thresholds of feature one and feature two Eq (17) combines row threshold and column threshold as the final thresholds The definitions of Eq (16) and Eq (17) are exhibited as following

rowsfrowsf

rows

ThresholdThresholdThreshold

21

= (16)

columnsrows ThresholdThresholdThreshold

= (17)

Binarization Based on the computed threshold Feature one and feature two obtained in sample fabrics are compared with threshold from training fabrics If the feature one and feature two of sample fabrics are included in the extent of threshold 0 would be endowed in corresponding position in )( yxD or the position would be given to 255 )( yxD is defined as Eq (18)

(18)

In experiment 30 training samples and 85 testing samples are applied in experiments Every texture possesses 5 training samples with same texture 6 classes of texture are utilized to prove effectiveness of proposed method Experimental fabrics are patterned fabrics including 20 defects from 6 textures to validate the availability of proposed method The experimental fabrics are derived from the TILDA database [26] and Henry YT Ngan from Industrial Automation Research Laboratory Dept of Electrical and Electronic Engineering The University of Hong Kong The processor of applying computer is intel(R) core(TM) i5-2400CPU 310GHZand RAM of computer is 400GB A 32-bit operating system of computer is owned Matlab software of computer is used to implement the proposed algorithm RESULTS Parameters m and n from distance matching function The size of patterned unit (mn) can be determined with distance matching function and the results of determining patterned unit from fabrics are shown in Figure 8 The parameters m and n are listed in

Journal of Engineered Fibers and Fabrics 92 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

Table Iwhich includes all the fabric size of patterned unit in Figure 8 The size of patterned unit (mn) would be applied in regular band to detect patterned defects Besides training time and detection time are listed in Table I Total run time equals to the sum of detection time and training

time Training time occupies the majority of total run time Fast detection time promises the possibility of operation in real situations The complexity of proposed method is O (MN) which is related to the size of fabrics

FIGURE 8 Results of determining patterned unit of fabrics

TABLE I Size of patterned unit and running time of proposed method on various fabrics

Images of Figure 8 (a) (b) (c) (d) (e) (f)

Parameter n 23 27 27 28 10 19

Parameter m 17 37 23 79 9 16

Training time

of regular band

2316981

seconds

3229209

seconds

2402773

seconds

2865476

seconds

1924046

seconds

2182325

seconds

Detection time of

regular band

0204037

seconds

0242415

seconds

0223430

seconds

0285310

seconds

0157748

second

0188936

seconds

Feasibility of Regular Band To prove the effectiveness of regular band the disposed results of sample fabrics are revealed in 2-D and 3-D Feature one and feature two are calculated in regular band to partition fabric defects Feature one and feature two calculated via regular band on row and column are exhibited in Figure 9 In Figure 9 it can

be concluded that fabric defects own higher results of feature one and feature two compared with non-defective areas thus a threshold is existed to separate defect of patterned fabrics The segmentation results in a(1) b(1) c(1) and d(1) are combined as the final defect detection results

Journal of Engineered Fibers and Fabrics 93 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

(I) Thick Bar sample fabric

FIGURE 9 (I) is sample fabrics (a1) and (a2) feature one resultant distribution in 2-D and 3-D via regular band of row (b1) and (b2) feature two resultant distribution in 2-D and 3-D via regular band of row (c1) and (c2) feature one resultant distribution in 2-D and 3-D via regular band of column (d1) and (d2) feature two resultant distribution in 2-D and 3-D via regular band of column

Journal of Engineered Fibers and Fabrics 94 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

The Statistics of Detection Results Defect detection results could be classified into four kinds Overall Detection (OD) True Detection (TD) False Alarm (FA) and Misdetection (MD) True Detection (TD) can be explained that white area of binary image equals to the corresponding defect on fabrics False Alarm (FA) indicates that the white area

includes the corresponding defect region and other white regions of the fabrics Overall Detection (OD) acts as the combination of TD and FA Misdetection (MD) shows no white areas in resultant images The statistical results of fabric detection are concluded in Table II

TABLE II The statistical results of fabric detection types in the output binary images

Detection

results

Broken End Thin Bar Thick Bar Netting

Multiple

Hole Knots

Fabrics from

TILDA

database

Overall

Detection

(OD)

100

(1515)

100

(1515)

100

(1515)

93

(1515)

100

(1515)

100

(55)

100

(55)

True Detection

(TD)

93

(1415)

100

(1315)

100

(1515)

93

(1415)

93

(1415)

100

(55)

93

(45)

False Alarm

(FA)

7

(115)

0

(215)

0

(015)

0

(015)

7

(115)

0(05) 7

(15)

Misdetection

(MD)

0(015) 0(015) 0(015) 7

(115)

0(015) 0(05) 0(05)

Various Defects Detection Results of Patterned Fabrics In the experiments patterned fabrics including Broken End Hole Thin Bar Thick Bar and Netting Multiple are detected on box-patterned and star-patterned fabric backgrounds shown in Figure 10 Patterned fabrics in TILDAT database are also inspected in this paper which are observed with perfect detection results Dot-patterned fabrics results are included in Figure 10 Proposed method based on the analysis of patterned fabrics extracts the period features and defect on fabrics would break the regular rule of fabrics

Periodic features are constructed by feature two and feature one in this paper Distance matching function is used for extracting the size of moving window on row and column Regular band is relative to regular band of Henry YT Ngan Regular band applied the same way of extracting features as Henry YT Ngan but regular band extracting two features forms two complementary and independent factors to segment defect of fabrics accurately However Henry YT Ngan utilized the relationship between mean and variance to recognize defects on patterned fabrics

Journal of Engineered Fibers and Fabrics 95 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

FIGURE10 Defects on patterned fabrics detected with proposed method

DISCUSSION Double weft broken weft or warp are considered as defects which are caused by horizontal and vertical damage of fabrics When these defects occur to patterned fabric moving window is selected to extract feature of fabric unit and defects can destroy the regularity of fabrics So defects destroying the regularity of fabrics can be inspected with proposed method CONCLUSION The supervised defect detection method including training step and detection step is introduced in this paper Equalization pretreatment is done on both

non-defective fabrics and sample fabrics to reduce fabric noise and build a foundation for proposed algorithm Patterned fabrics are dealt with gray pixels via row statistics and column statistics with certain length and parameters m and n acted as the length are assigned to the size of patterned unit which is calculated via distance matching function The way of statistics fabric pixels is named as regular band Feature one and feature two is computed on basis of regular band In training step feature one and feature two in regular band are calculated to receive the maximum and minimum The gained extents of feature one and feature two in regular band are defined as threshold limits In detection step feature one and

Journal of Engineered Fibers and Fabrics 96 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

feature two of fabric defects would not be included in threshold limits thus achieving defect detection on patterned fabrics Fleet defect detection can furnish the possibility of implementation in practice Defect detection on patterned fabrics can avoid interference of pattern and the threshold of defect detection can be extracted in training period thus achieving speedy on-line defect detection of patterned fabrics and matching the speed of detection system in the textile industry REFERENCES [1] KL Mak amp P Peng Detecting defects in textile

fabrics with optimal Gabor filters [J] International Journal of Computer Science 20061(4)274-282

[2] Junfeng Jing Huanhuan Zhang Pengfei Li amp Jinyuan Jia Fabric defect detection using Gabor filters and defect classification based on LBP and Tamura method[J] The Journal of The Textile Institute 2013 104(1)18-27

[3] Junjie Chen amp Chunping Xie Automatic cloth inspection system [J] Textile Science and Technology Progress 2004(5)56-57

[4] Arkady Cherkassky amp Amotz Weinberg Objective evaluation of textile fabric appearance part 1 basic principles protrusion detection and Parameterization [J] Textile Research Journal 20103(80)226-235

[5] Xianghua Xie amp Mirmehdi M Texems texture exemplars for defect detection on random textured surfaces [J] Pattern Analysis and Machine Intelligence 2007 29 (8)1454 ndash 1464

[6] D Chetverikov Pattern regularity as a visual key [J] Image and Vision Computing 2000 18(12)975-985

[7] Henry YT Ngan Grantham KH Pang amp Nelson HC Yung Automated fabric defect detectionmdashA review [J] Image and Vision Computing 2011 29(7)442ndash458

[8] Rimac-Drlje S Keller A amp Nyarko K E Self-Learning system for surface failure detection[C] EURASIP 13th European Signal Processing Conference EUSIPCO 2005

[9] A Ahmadyfard et al A novel approach for detecting defects of random textured tiles using Gabor wavelet[J] World Applied Sciences Journal 2009 7 (9) 1114-1119

[10] A Khodaparast amp A Mostafa On line quality control of tiles using wavelet and statistical properties[C] In Proceedings of the 2nd Iranian Conference on Machine Vision and

Image Processing 2003 153ndash159 [11] Junfeng JingHang Li amp Pengfei Li Combined

fabric defects detection approach and quadtree decomposition [J] Journal of Industrial Textiles 2012 41 (4)331-344

[12] Mostafavi M S A new method in detection of ceramic tiles color defects using genetic C-means algorithm [J] Proceeding of World Academy of Science Engineering and Technology 2006 168-171

[13] Ajay Kumar Computer vision-based fabric defect detection A survey [J] IEEE Transactions on Industrial Electronics 200855(1)348 - 363

[14] Chin R T Automated visual inspection 1981 to 1987[J] Computer Vision Graphics and Image Processing 1988 41(3) 346-381

[15] Du-Ming Tsai amp Ya-Hui TsaiRotation-invariant pattern matching with color ring-projection [J] Pattern Recognition 2002 35(1)131-141

[16] YH Zhang CWM Yuen WK Wong amp Chi-wai Kan An intelligent model for detecting and classifying color-textured fabric defects using genetic algorithms and the Elman neural network[J] Textile Research Journal 201181(17) 1772ndash1787

[17] Ngan H Y T Pang G K H amp Yung S P et al Defect detection on patterned jacquard fabric[C] Applied Imagery Pattern Recognition Workshop Proceedings 32nd IEEE 2003 163-168

[18] HYT Ngan amp GKH Pang Novel method for patterned fabric inspection using Bollinger bands [J] Optical Engineering 2006 45 (8) 1-13

[19] Ngan H Y T Pang G K H Yung S P et al Defect detection on patterned jacquard fabric[C]Applied Imagery Pattern Recognition Workshop 2003 Proceedings 32nd IEEE 2003 163-168

[20] Tajeripour F Kabir E Sheikhi A Defect detection in patterned fabrics using modified local binary patterns[C]Conference on Computational Intelligence and Multimedia Applications 2007 International Conference on IEEE 2007 2 261-267

[21] HYT Ngan amp GKH Pang Regularity analysis for patterned texture inspection [J] Automation Science and Engineering 20096 (1)131-143

Journal of Engineered Fibers and Fabrics 97 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

[22] Reddy R O K Reddy B E amp Reddy E K Texture analysis and defect classification for fabric images using regular bands and quadratic programming[C] Proceedings of International Conference on Advances in Computing Springer India 2012 927-934

[23] Oh G Lee S amp Yong Shin S Fast determination of textural periodicity using distance matching function [J] Pattern Recognition Letters 1999 20(2) 191-197

[24] Pisek E amp Wang Y Equalization techniques using viterbi algorithms in software-defined radio systems US Patent 8069401[P] 2011-11-29

[25] Zeeshan Khatri Muhammad Hanif Memon Awais Khatri amp Anwaruddin Tanwari Cold Pad-Batch dyeing method for cotton fabric dyeing with reactive dyes using ultrasonic Feature one [J] Ultrasonics Sonochemistry 2011 18(6)1301-1307

[26] Work group on texture analysis of DFG TILDA textile texture database August 1996 (httplmbinformatikuni-freiburgderesearchdfg-texturetilda)

AUTHORSrsquo ADDRESSES Junfeng Jing Panpan Yang Pengfei Li Xian Polytechnic University 19 of the South Jinhua Road Xian Shaanxi 710048 CHINA

- REFERENCES

-

Journal of Engineered Fibers and Fabrics 87 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

REGULAR BAND ALGORITHM Way of Regular Band To realize regular band algorithm [22] statistical pixels of patterned fabrics have to be computed with a certain length to express the features Figure 2 shows the way of statistical pixels of patterned fabrics in regular band In Figure 2 M and N represent the size of patterned fabrics m and n mean the length of regular band on column and row of patterned fabrics and number 1234 and 5 are the obtained results of regular band on patterned fabrics and the size of regular band resultant image is (45)

2

3

2

1 43 5

4

m

nN

M

FIGURE 2 Way of statistical pixels of patterned fabrics in regular band

If M=N and m is greater than n M-m+1 would be smaller than N-n+1 M-m+1 and N-n+1 of regular band act as the size of resultant image One-Dimensional Distance Matching Function The distance matching function proposed by Oh et al [23] is defined to calculate the periodic distance of periodic function Because neighbor patterned units of fabrics have similarity the periodic distance is selected via choosing the smallest difference of adjacent results from one-dimensional function The periodic distance can be calculated with distance matching function as Eq (1)

2

1( ) [ ( ) ( )]

N p

ip g i g i pλ

minus

=

= minus +sum (1)

Parameter p represents periodic distance of one-dimensional function g (i)The results of distance matching function of one row and one column of fabrics are exhibited as Figure 3

(a) (b)

FIGURE 3Distance matching function of one-dimensional signal from fabric row (a) and column (b)

Distance Matching Function for Fabrics Fabrics can be considered as a two-dimensional function where f(xy) means the gray value of fabrics The row or column of fabrics would be identified the one-dimensional function the sum of

one--dimensional row or column would be the results of distance matching function as Eq (2) and Eq (3) The results of distance matching function can be depicted in Figure 4

Journal of Engineered Fibers and Fabrics 88 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

(a) (b)

FIGURE 4 Results of distance matching function on fabric rows (a) and columns (b)

1 1

2

( ) [ ( )

( )]

N pM

xx y

sum p f x y

f x y p

λ

minus

= =

=

minus +

sum sum (2)

1 1

2

( ) [ ( )

( )]

M pN

yy x

sum p f x y

f x p y

λ

minus

= =

=

minus +

sum sum (3)

Second Forward Difference The resultant difference between variable and forward variable of distance matching function is identified as first forward difference The difference of distance matching function with variable p+1 and variable p is named as ( )1D p first forward differences of distance matching function are listed as Eq (4)-(7) ( )1D p and ( )2D p are respectively the first difference of fabric row and fabric column

(4)

(5)

(6)

(7)

Second forward difference ( )max1D pD is the

difference of first forward differences with variable p+1 and variable p Eq (8) and Eq (9) are the ways to calculate second forward difference

( )max1D pD and ( )

max2D pD are the second forward

difference from fabric row and fabric column

( ) ( )max1 1 1( 1)D p D p D pD = minus minus (8)

( ) ( )

max2 2 2 ( 1)D p D p D pD = minus minus (9) The maximum of second forward difference is extracted to attain the corresponding periodic distance The periodic distance of fabrics is equal to obtained periodic distance p

Journal of Engineered Fibers and Fabrics 89 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

(a) (b)

FIGURE 5 Second forward difference of distance matching function on fabric rows (a) and columns (b)

Parameters m and n can be obtained by calculating the size of patterned unit Parameter m is equal to the periodic distance of patterned row Parameter n means the period of patterned column Parameters m and n computed by distance matching function would be applied in regular band Figure 5 shows the results of second forward difference The process of distance match function can be concluded as following Step 1 Input Figure 5(c) Step 2 Choose a reasonable scope of parameter variable p (pltM and pltN) Calculate distance matching function in equation (2) and (3) with variable p as Figure 4 Step 3 Count second forward difference of distance matching function with variable p as Figure 5 Step 4 Extract the maximum of second forward difference the parameter p would be determined Preprocessing on Patterned Fabrics Before the operation of proposed method on patterned fabrics equalization operation [24] should be done to get rid of noise of patterned fabrics and the pixels of patterned fabrics could be regulated properly Equalization processing changes the grayscale histogram concentrated of original image into a uniform distribution within the scope of all gray and make the number of pixel gray level consistent The whole process is shown as Figure 6

FIGURE 6The whole procedure of equalization operation Calculate Average for Shifting Fabrics After the preprocessing of patterned fabrics patterned fabric images should be dealt with average value of non-defective fabrics and this operation builds the foundation for later steps In this step n is the statistics number of regular band on row and m is the statistics number of regular band on column Regular band algorithm on column could be performed as long as row is changed into column

1

1 1

11

01 1

( ( (( ( )) ) 1)) r nM N n

x r y rM IM x y n N n M

+ minusminus +

= = =

= minus +sum sum sum (10)

Journal of Engineered Fibers and Fabrics 90 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

The mean of existed n-length pixels in row of all training fabrics is computed as Eq (10) IM(xy) is input image Parameter 1r is the starting position of regular band on patterned fabrics and n is the length of regular band(MN) is the size of IM(xy)Parameters x and y represent the position of gray value The obtained average value 0M should be subtracted by all pixels of patterned fabrics which can make pixels of patterned fabrics closer to zeros than original fabrics The relationship of Figure 7(b0) and Figure 7(b1) is the same as 7(a0) and Figure 7(a1) Figure 7(a1) and Figure 7(b1) establish foundation for effectiveness of proposed algorithm

(a) (b) Thick Bar patterned fabrics Defect-free patterned fabrics

(a0) (b0) Gray value distribution of (a) Gray value distribution of (b)

(a1) (b1) Gray value distribution result Gray value distribution result

of (b0) subtracted by 0M of (b0) subtracted by 0M

FIGURE 7 Whole process of shift operation with 0M

Kernel of Regular Band Feature one [25] and feature two are computed to distinguish the normal and defective part utilizing regular band on patterned fabrics Feature one and feature two is useful in detection of patterned fabrics as Eq (12) and Eq (13) IM(xy) is defined as the consequence of equalization operation S(xy) is the disposed fruit of IM(xy) via 0M shown in Eq (11) Patterned fabrics are altered in Eq (11) being an important role in regular band which offers a platform to pledge the availability of regular band algorithm N and M are the size of input fabrics Parameters n and m are captured from the size of patterned unit via distance matching function Feature one and Feature two are calculated within the moving window of (m1) or (1n)(m1) is the size of moving window on fabric row(n1) acts as the size of moving window on fabric column

1r is the first position of moving window 1M is used for computing the average value of moving window from S(xy)

0( ) ( )S x y F x y M= minus (11)

1

1

13

1 1( ) [1 1]r n

x rf S x y r N nσ

+ minus

=

= minus isin minus +sum (12)

1

1

1

1

2 1

( ( ) ) [1 1]

r n

x rS x y M

f r N nn

+ minus

=

minus= isin minus +sum

(13)

1

1 1

11

11 1

( ( (( ( )) ) 1)) r nM N n

x r y rM S x y n N n M

+ minusminus +

= = =

= minus +sum sum sum (14)

The mean of existed n-length pixels in row of S(xy) is computed as Eq (14) Feature one in Eq (12) is structured to elongate the gap between defect pixels and normal pixels thus fabric defect can be abstracted from patterned fabrics Feature two in Eq (13) is entrusted with difference between S(xy) and average of corresponding S(xy) of non-defective fabrics Compared with normal part of fabrics defective part has larger gap than the average of S(xy) All the mentioned equations are applied in

Journal of Engineered Fibers and Fabrics 91 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

regular band on rows In the same way Eq (11) Eq (12) and Eq (13) could also be applied in regular band of column as long as variable quantities are transformed into homologous variable quantities in regular band of column DEFECT SEGMENTATION Threshold Calculation The thresholds are obtained via calculating feature one and feature two Five non-defective fabrics are applied in training step and the maximum and minimum of feature one and feature two are extracted in regular band on rows and columns of every fabric image The threshold set is the average value of saved maximum and minimum on rows and columns of five fabric images and the calculated equations are shown in Eq (15)

]min[max

11

1

rowsfrowsf

rowsf

imumimum

Threshold = (15)

Where

))))(max(((

max

1

1

1

5

1 15

1

g

nN

ig nNnumnum

rowsf

ifmeanmean

imum

sumsum+minus

== +minus==

=

))))(max(((

min

1

1

1

5

1 15

1

g

nN

jg nNnumnum

rowsf

jfmeanmean

imum

sumsum+minus

== +minus==

=

Eq (15) represents the segmentation thresholds which are made of average maximum and minimum on rows of feature one The threshold of feature two can be obtained as long as replacing feature one with feature two in Eq (15) Function lsquomeanrsquo is the identity of average function Regular band threshold on column could also be calculated with Eq (15) via changing regular band on row into regular band on column of feature one and feature two Eq (16) introduces the row threshold including calculated thresholds of feature one and feature two Eq (17) combines row threshold and column threshold as the final thresholds The definitions of Eq (16) and Eq (17) are exhibited as following

rowsfrowsf

rows

ThresholdThresholdThreshold

21

= (16)

columnsrows ThresholdThresholdThreshold

= (17)

Binarization Based on the computed threshold Feature one and feature two obtained in sample fabrics are compared with threshold from training fabrics If the feature one and feature two of sample fabrics are included in the extent of threshold 0 would be endowed in corresponding position in )( yxD or the position would be given to 255 )( yxD is defined as Eq (18)

(18)

In experiment 30 training samples and 85 testing samples are applied in experiments Every texture possesses 5 training samples with same texture 6 classes of texture are utilized to prove effectiveness of proposed method Experimental fabrics are patterned fabrics including 20 defects from 6 textures to validate the availability of proposed method The experimental fabrics are derived from the TILDA database [26] and Henry YT Ngan from Industrial Automation Research Laboratory Dept of Electrical and Electronic Engineering The University of Hong Kong The processor of applying computer is intel(R) core(TM) i5-2400CPU 310GHZand RAM of computer is 400GB A 32-bit operating system of computer is owned Matlab software of computer is used to implement the proposed algorithm RESULTS Parameters m and n from distance matching function The size of patterned unit (mn) can be determined with distance matching function and the results of determining patterned unit from fabrics are shown in Figure 8 The parameters m and n are listed in

Journal of Engineered Fibers and Fabrics 92 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

Table Iwhich includes all the fabric size of patterned unit in Figure 8 The size of patterned unit (mn) would be applied in regular band to detect patterned defects Besides training time and detection time are listed in Table I Total run time equals to the sum of detection time and training

time Training time occupies the majority of total run time Fast detection time promises the possibility of operation in real situations The complexity of proposed method is O (MN) which is related to the size of fabrics

FIGURE 8 Results of determining patterned unit of fabrics

TABLE I Size of patterned unit and running time of proposed method on various fabrics

Images of Figure 8 (a) (b) (c) (d) (e) (f)

Parameter n 23 27 27 28 10 19

Parameter m 17 37 23 79 9 16

Training time

of regular band

2316981

seconds

3229209

seconds

2402773

seconds

2865476

seconds

1924046

seconds

2182325

seconds

Detection time of

regular band

0204037

seconds

0242415

seconds

0223430

seconds

0285310

seconds

0157748

second

0188936

seconds

Feasibility of Regular Band To prove the effectiveness of regular band the disposed results of sample fabrics are revealed in 2-D and 3-D Feature one and feature two are calculated in regular band to partition fabric defects Feature one and feature two calculated via regular band on row and column are exhibited in Figure 9 In Figure 9 it can

be concluded that fabric defects own higher results of feature one and feature two compared with non-defective areas thus a threshold is existed to separate defect of patterned fabrics The segmentation results in a(1) b(1) c(1) and d(1) are combined as the final defect detection results

Journal of Engineered Fibers and Fabrics 93 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

(I) Thick Bar sample fabric

FIGURE 9 (I) is sample fabrics (a1) and (a2) feature one resultant distribution in 2-D and 3-D via regular band of row (b1) and (b2) feature two resultant distribution in 2-D and 3-D via regular band of row (c1) and (c2) feature one resultant distribution in 2-D and 3-D via regular band of column (d1) and (d2) feature two resultant distribution in 2-D and 3-D via regular band of column

Journal of Engineered Fibers and Fabrics 94 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

The Statistics of Detection Results Defect detection results could be classified into four kinds Overall Detection (OD) True Detection (TD) False Alarm (FA) and Misdetection (MD) True Detection (TD) can be explained that white area of binary image equals to the corresponding defect on fabrics False Alarm (FA) indicates that the white area

includes the corresponding defect region and other white regions of the fabrics Overall Detection (OD) acts as the combination of TD and FA Misdetection (MD) shows no white areas in resultant images The statistical results of fabric detection are concluded in Table II

TABLE II The statistical results of fabric detection types in the output binary images

Detection

results

Broken End Thin Bar Thick Bar Netting

Multiple

Hole Knots

Fabrics from

TILDA

database

Overall

Detection

(OD)

100

(1515)

100

(1515)

100

(1515)

93

(1515)

100

(1515)

100

(55)

100

(55)

True Detection

(TD)

93

(1415)

100

(1315)

100

(1515)

93

(1415)

93

(1415)

100

(55)

93

(45)

False Alarm

(FA)

7

(115)

0

(215)

0

(015)

0

(015)

7

(115)

0(05) 7

(15)

Misdetection

(MD)

0(015) 0(015) 0(015) 7

(115)

0(015) 0(05) 0(05)

Various Defects Detection Results of Patterned Fabrics In the experiments patterned fabrics including Broken End Hole Thin Bar Thick Bar and Netting Multiple are detected on box-patterned and star-patterned fabric backgrounds shown in Figure 10 Patterned fabrics in TILDAT database are also inspected in this paper which are observed with perfect detection results Dot-patterned fabrics results are included in Figure 10 Proposed method based on the analysis of patterned fabrics extracts the period features and defect on fabrics would break the regular rule of fabrics

Periodic features are constructed by feature two and feature one in this paper Distance matching function is used for extracting the size of moving window on row and column Regular band is relative to regular band of Henry YT Ngan Regular band applied the same way of extracting features as Henry YT Ngan but regular band extracting two features forms two complementary and independent factors to segment defect of fabrics accurately However Henry YT Ngan utilized the relationship between mean and variance to recognize defects on patterned fabrics

Journal of Engineered Fibers and Fabrics 95 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

FIGURE10 Defects on patterned fabrics detected with proposed method

DISCUSSION Double weft broken weft or warp are considered as defects which are caused by horizontal and vertical damage of fabrics When these defects occur to patterned fabric moving window is selected to extract feature of fabric unit and defects can destroy the regularity of fabrics So defects destroying the regularity of fabrics can be inspected with proposed method CONCLUSION The supervised defect detection method including training step and detection step is introduced in this paper Equalization pretreatment is done on both

non-defective fabrics and sample fabrics to reduce fabric noise and build a foundation for proposed algorithm Patterned fabrics are dealt with gray pixels via row statistics and column statistics with certain length and parameters m and n acted as the length are assigned to the size of patterned unit which is calculated via distance matching function The way of statistics fabric pixels is named as regular band Feature one and feature two is computed on basis of regular band In training step feature one and feature two in regular band are calculated to receive the maximum and minimum The gained extents of feature one and feature two in regular band are defined as threshold limits In detection step feature one and

Journal of Engineered Fibers and Fabrics 96 httpwwwjeffjournalorg Volume 10 Issue 2 ndash 2015

feature two of fabric defects would not be included in threshold limits thus achieving defect detection on patterned fabrics Fleet defect detection can furnish the possibility of implementation in practice Defect detection on patterned fabrics can avoid interference of pattern and the threshold of defect detection can be extracted in training period thus achieving speedy on-line defect detection of patterned fabrics and matching the speed of detection system in the textile industry REFERENCES [1] KL Mak amp P Peng Detecting defects in textile

fabrics with optimal Gabor filters [J] International Journal of Computer Science 20061(4)274-282