John Deere 440 Skidder Service Manual...John Deere MODEL: 440 Skidder THIS IS A MANUAL PRODUCED BY...

Transcript of John Deere 440 Skidder Service Manual...John Deere MODEL: 440 Skidder THIS IS A MANUAL PRODUCED BY...

John Deere

MODEL:

440 Skidder

THIS IS A MANUAL PRODUCED BY JENSALES INC. WITHOUT THE AUTHORIZATION OF JOHN DEERE OR IT'S SUCCESSORS. JOHN DEERE AND IT'S SUCCESSORS

ARE NOT RESPONSIBLE FOR THE QUALITY OR ACCURACY OF THIS MANUAL.

TRADE MARKS AND TRADE NAMES CONTAINED AND USED HEREIN ARE THOSE OF OTHERS, AND ARE USED HERE IN A DESCRIPTIVE SENSE TO REFER TO THE PRODUCTS OF OTHERS.

JD-S-TM1009

GDIn:ENTS

Section 10-GENERAL Group 5 Specifications Group 10 Tune-Up and Adjustment Chart Group 15 Lubrication Group 20 Separation

Section 20-ENGINE . Gtoup5J)lagnosis

Group Tp·: Basic·· E;ngine Group 15· Engine Luorication System Group 20 Governor and Speed Conh-ol Linkage

... GrOup 25C60ling System

Section 30-FUEL SYSTEM Group 5 System. Diagnosis Group 19 Tank, Transfer Pump; Filters, and Air Cleaner Group 15 Carburetor

.. Group 20 FueLlnjection Pumps Group 25 Fuel Injection Nozzles

Section 40-ELECTRICAL SYSTEM Group 5 Wiring Diagrams Group 10 Charging System Group 15 Ignition System Group 20 Starting Motor Group 25 Gauges

Section 50-POWER TRAIN Group 5 System Diagnosis Group 10 Clutches Group 15 Drive Shafts Group 20 Power Shift Transmission Group 25 Syncro-Range Transmission Group 30 Axle Assemblies Group 35 Differentials Group 40 Auxiliary Power System (Syncro-Range Transmission)

Section 6Q-STEERING AND BRAKES (See Section 70)

Section 70-HYDRAULIC SYSTEM Group 5 General Information, Testing, and Diagnosis Group 10 Hydraulic Pump Group 15 Filters, Valves, Oil Cooler, and Accumulators Group 20 Steering System Group 25 Brake System Group 30 Selective Control System

Section 80-MISCELLANEOUS COMPONENTS Group 5 Winch System Group 10 Frames

Litho in U.S.Ao

10/ !.

JD440 SKID,DIIIS TECHI>JICAL MANliAl

TM.HI09 (ifd~:

'Sectioa \,'8

GENERAL CONTENTS OF THIS SECTION

GROUP 5-SPECIFICATIONS Skidder Design .•.•.•••.••••••• Serial Numbers .•.•••.•.•.•.•. Model Numbers •.•.•••.•.•.•.• Engine . . . e ... • • • • • • • • • ... • • 4!' ". .. •

Electrical System. . • . • . • . • . • . •• Syncro-Range Transmission •.•••.• Power Shift Transmission .•.•.•.• Travel Speeds .•.•.•.•.•.•.•.• Drive AxleS .•.•.•.•.•.•••••.• Differentials ••.•. ~ .•.•.•.•.•. Hydraulic System. ~ • • • • • . • . • . • . Ste~ring ......... . ' .......... ' •. , ... Brakes ................................ .. Tire Options . • . • • • • • . • . • . • . • . Capacities •.•.•.•••.•.•••.•.• Winch." .' ................ • ' ............. .. Dimensions. • . • . . . • . . . • . • . • . •

GROUP lO-TUNE-UP AND ADJUSTMENT Preliminary Engine Testing .•.•.•. Engine Tune-Up ..•.•.•.•••.•.• Final Engine Testing .•.•.•.•.•.• Skidder Adjustments .•••.•.•.•.•

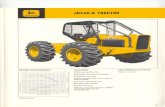

SKIDDER DESIGN

Fig. l-JD440 Series-A SkicJcJer

Litho in U.S.A.

Page

5-1 5-1 5-2 5-2 5-3 5-3 5-3 5-3 5-3 5-3 5-3 5-3 5-3 5-4 5-4 5-4 5-4

10-1 10-1 10-2 10-3

GROUP 15-LUBRICATION Lubrication Chart (capacities, lubri

cants, and intervals) •.•.•. <; •••

Engine Lubricating Oils •.•.•.•. , . Transmission-Hydraulic Oil •.•••.• Greases ............................. ..

GROUP 20-SEPARATION Separating Engine and Equipment

Frames ............. . ' ,e ."' ......... .. '.' ...

Removing Engine •••.•...•.•••. Removing Clutch Housing and Cowl

(Syncro-Range) •.•.•.•...•.•. Removing Upper Cowl. (Power SPift) •. Removing Syncro-Range Transmis-

sian, ................... 0 .......... ..

Removing Power Shift Transmission . Removing Axle Housings and Differ:-

Page

15-1 15-2 15-2 15-2

20-1 ,20-2

20-3 20..,.4

20-5 20-6

entials •.•.•. '.' •••. : o •••••••.• ., ·,.20-7 Adjusting Front Axle End Play. • • • • . 20-8 Specifications . • . • . • . • . • • • • • .• 20- 9 Tools e.," ............................. .. 20-9

Group 5 SPECIFICATIONS

The JD440 and JD440 Series-A Skidders are. of '> '¥ " " ,: ',::'.:' », i.~,

the articulated frame'-steered~e~ignforUsepri:' ! marily in Skidding tre~ 'lenkth logS front ii'fEllling 'i1!

area to. a central loading location. . .... . Main skidder parts are mounted in two frames,

the engine frame (front), and th~' eqtiipnl~nt frlime (rear). .

All references in this manual to front, rear, left, and rtght are in relation to tneposition' of the operator seated in the operator's st~tion.

SERIAL NUMBERS

The skidder (chassis) seri~l nqrnber is i9,~ated on, the clutch housing. NOTE:, Wilen orde~ing skidder and engine parts, record all the'dlgffs on this plate. ."

The engine serial number is located on the right si?e of the engine cylinder brocR~

Skidders :;,. JD440 TM-I009 (Jul-68)

ELECTRICAL SYSTEM ; Battery (dry) voltage (nominal).. 12 volts Battery specific gravity (cor-

rectedto 80°F.) (full charge) .. 1.260 Battery terminal grounded. • . •. Negative Alternator regulation • . • . • . •• Voltage

regulator

SYNCRO-RANGE TRANSMISSION Type - Constant mesh with 8 forward and 4

reverse speeds (3 reverse speeds on JD440 Skidders). Four shift stations. Synchronized shifting within stations except reverse.

Clutch - 12-inch, dry-type, feramic-faced, foot operated.

POWERSffiFT TRANSMISSION Type - Planetary, hydraulically actuated wet

disk clutches and brakes. 8 forward and 4 reverse speeds hydraulically shifted and controlled by a single lever.

Disconnect Clutch - 12-inch, dry-type clutch operated by a hand lever (as a starting aid).

TRAVEL SPEEDS (MPH) (with 16.9 x 30 Tires - no slippage)

1500 RPM 2500 RPM .,

Syncro- Power Syncro- Power Gear Range Shift Range Shift

1 1.3 0.9 2.0 1.5 2 2.1 1.3 3.1 2.2 3 2.7 2.0 4.0 3.4 4 3.5. 2.6 5.2 '.' 4.4 5 4.3 3.4 6.4 5.7 6 5.7 4.4 8.5 7.3 7 7.1 5.8 10.6 9.7 8 11.7 9.6 17.4 16.1

1st Reverse 1.3 1.1 2.0 1.8 2nd Reverse 2.1 1.5 3.1 2.5 3rd Reverse 3.5 2.3 5.2 3.9 4th Reverse 5.7 3.0 8.5 5.1

DRIVE AXLES Four wheel drive with inboard mounted plan

etary gears on all axles.

Oscillating front axle, fixed rear axle.

Litho in U.S.A.

General to Specifications 5-3

DIFFERENTIALS Front - full differential with hydraulic lock. Rear - Solid axle with no differential ac

tion - full differential without hydraulic

lock - full differential with hydraulic lock

(skidders with Power Shift)

HYDRA1:TLIC SYSTEM Type - Closed center, constant pressure sys

tem. Includes power steering, power brakes, differential lock(s), front blade, and remote functions.

Standby oil pressure - 2250 psi Hydraulic pump

output at 2000 psi - 23 gpm at 2500 engine rpm (early models)

STEERING

28 gpm at 2500 engine rpm (later models)

Full power steering controlled by steering wheel. Frame steered by two hydraulic cylinders. Turning clearance circle (with blade)

Skidders with Syncro-Range (16.9 x 30 tires) . • . •• • . • .• 35 ft. 6 in.

Skidders with Power Shift and Short Frame (16.9 x 30 tires) • 35 ft. 6 in.

Skidders with Power Shift and LongFrame (18.4 x 34 tires) .38 ft. 8 in.

Turning radius Skidders with Syncro-Range

(16.9 x 30 tires) • •• . • . • .• 16 ft. 8 in. Skidders with Power Shift and

Short Frame (16.9 x30 tires). 16 ft. 8 in. Skidders with Power Shift and

Long Frame (18.4 x 34 tires) • 19 ft. 2 in.

BRAKES Syncro-Range - Hydraulically operated disk

type on output shaft with single pedal control. Mechanical brake for parking and winching.

Power Shift - Axle-mounted single disk brakes, hydraulically operated with single pedal control. Mechanical brake for parking and winching.

Section 20

ENGINE CONTENTS OF THIS SECTION

GROUP 5-Diagnosis Diagnosing Engine Malfunctions . . •.

GROUP 10-BASIC ENGINE Diagnosing Basic Engine Malfunctions Head Assembly •.•.•.•.•.•.•.• Adjusting Valve Tappets .•.•.•.•. Block, Liners, Pistons, and Rods ..• Crankshaft, Main Bearings, and

Flywheel .•.•.•.•...•.•.•.. Camshaft .•.•.•.•••.•.•.•.•. Balancer Shafts •.•.•.•.•.•... Timing Gear Train •.•.•.•.•... Specifications . . ....•...•.•.•. Hardware Torques .••••.•.•.•. Engine Break-In ....•...•••... Tune-Up Data .••.•..•..••..•. Tools ..........•.•...•.•.•

Litho in U.S.A.

Page

5-2

10-1 10-1 10-3 10-4

10-8 10-10 10-11 10-12 10-15 10-17 10-17 10-18 10-18

GROUP 15'-ENGINE LUBRICATION Oil Pump and Filter •.•.•••.••• Tests and Diagnosis .•......... SpeCifications .............. . Thols . . • . . . • . • . • . • . • . • . • . .

Page

15-1 15-2 15-5 15-5

GROUP 20-GOVERNOR AND SPEED CONTROL LINKAGE

Diagnosing Malfunctions . . . . . • .• 20-1 Governor. • . • . • . • . • . • . . • • •• 20-1 Speed Control Linkage . • . • .• . • .• 20-4 Speed Control Adjustments . • . • .•. 20-4 Specifications • . • • • • • • • . • . • . .. 20- 8 Tools. . . . . . • . • . • . • . • . • . • .. 20-8

GROUP 25-ENGINE COOLING Diagnosing Malfunctions . . . . . . .• 25-1 Radiator . • . • . • . • . • . • . • . . . •. 25-1 Water Pump. . • . • . • . • • • . . . •. 25-1 Specifications • . • • • . . . • . • . . .• 25- 3 Tools. • . • . • . • . • . • . • . • . • . •. 25-3

Skidders - JD440 TM-1009 (Jul-58)

Do not nick or damage wear ring oil seal surface. Check crankshaft and wear ring surfaces for nicks and clean up if necessary.

Fig. 12-lnstalling Crankshaft Seal Wear Ring

12. Remove old oil seal from flywheel housing. Press new seal in rear of flywheel housing (lip inward) using a suitable driver, until seal case is flush with machined face of seal bore in housing. (JDE-2 Driver can be used if available.) Be sure· to support housing around bore while pressing in new seaL

INST ALLATION

1. Install inserts with thrust faces in rear main bearing bore. Install plain inserts in other main bearing bores. Make sure that tangs onaU inserts fit the locking grooves in the bores and that the oil holes in inserts line upwith oil passages in the block.

2. Make sure bearing caps are installed on the mains from which they were removed by referring to identification marks made at the time of removal. Loosely install cap screws in main bearing caps - until finger tight.

3. Align upper and lower thrust flanges on rear main bearing as follows: Tap the crankshaft to the rear to line up the front flanges. Then tap the crankshaft to the front to line up the rear flanges. Tighten main bearing cap screws to specified torque.

4. If crankshaft end play has not been checked with all repair parts installed, check it by method given in "Repair" in this group and compare measurement to "Specifications. II

Litho in U.S.A.

Engine Basic Engine

Fig. 13-lnstalling Main Bearing Caps

20 10_9

5. To facilitate installation of flywheel, screw two pilot studs into flywheel mounting screw holes in crankshaft. Tighten attaching cap screws to specified torque.

6. Place crankshaft oil slinger over front end of crankshaft with inside diameter of Slinger against front gear on crankshaft.

Fig. 14-/ostall;ng Flywheel Housing

Position JD251-4 Seal Protector over rear of crankshaft and coat protector and wear ring with engine oil. Install flywheel housing on rear of engine. Be careful not to invert oil seal lip in flywheel housing.

Install all other parts removed. Install engine (Group 20 of Section 10).

Secti • . 30

FUEL ·SYSTEM CONTENTS OF THIS SECTION

GROUP 5-SYSTEM DIAGNOSIS Page

Diagnosing Fuel System Malfunctions. 5-1

GROUP1Q-TANK, TRANSFER PUMP, FILTERS, AND CLEANER

Fuel Tank • . • . . .• • • . • . • . • . • •• 10-1 Fuel Transfer Pump. • • • .• . . .• .• 10-2 Fuel Filters. • . • . • • • . • . • . • . •. 10,..3 Air Cleaner • . • . • . • . • . • .• . • .. 10-4 Specifications . • . • . • .• .. • • • . • . •. 10-4

GROUP 15-CARBURETOR General Information . . • . • . • . • • •. 15-1 Diagnosing Malfunctions. • • . • . . .• 15-1 Repair .•.•..••.•••••.•.• '. •. 15-2 Preliminary Adjustments • . • . . . •. 15-4 Specifications . . • . • . • . • . • . • . •. 15 - 5 Tools. . • . • . •. • . • . • • • . • . • . •. 15-5

GROUP 20-FUEL INJECTION PUMPS Model "DB" Fuel Injection Pump

General Information • . • . . . • . •. 20-1 Diagnosing Malfunctions . . • . • .• 20-1

[)IAGNOSING DIESEL AND GASOLINE FUEL SYSTEM MALFUNCTIONS

The following is a guide for diagnosing fuel systems difficulties. For specific diagnosis of fuel system components, refer to the group which covers complete servicing.

FUEL NOT REACHING INJECTION PUMP OR CARBURETOR

Fuel too heavy at low temperatures (diesel). See Operator's Manual for correct fuel.

Filters clogged. Remove and clean or replace as necessary (Group 10). See Operator's Manual for correct fuel specifications.

Fuel lines clogged or restricted. Blowout all fuel lines with filtered air, or replace.

Litho in U.S.A.

RemOVal Repair . . ............................. . Installation and Timing . . • • • . • . Adjustment • . • . • . • . • '. • . • . • . Specifications . . • . • . • . • . • . • . Tools ..•.•••••.•.•.•.•.•.

Model "C" Fuel Injection Pump General Information •.•.•.•.•.• Diagnosing Malfunctions . • . • . • . • Removal ...... ., .......................... .. Repair .. ..' ............................ .. Installation and Timing. . • . • • • . Adjustment • . • . • . • . • . • . • ••. Specifications . . • . • . •. • . • . • . • Tools ...................................... ..

GROUP 25-FUEL INJECTION NOZZLES General Information .•.•.•.•.•.• Diagnosing Malfunctions . • . • . • . • . Removal ....•.•.•.•.•.•.•••. Installation . . • . • . • • . . • . • . • • • . Specifications • . • . •.•. • . • . • . • . . Tools ...•.• ; .............. .

Page

20-1 20-2 20-2 20-3 20-4 20-4

20-5 20-5 20-5 20-6 20-6 20-7 20-8 20-8

25-1 25-1 25-1 25-1 25-2 25-2

GroupS

SYSTEM DIAGNOSlS

ENGINE STARTS HARD

Air leak on suction side of system. Look for air leaks at all connections.

Fuel too heavy at low temperatures (diesel). See Operator's Manual.

Cranking speed too slow. Increase cranking speed.

Injection nozzle faulty (Group 25). Incorrect timing (Group 20-Diesel or Section 40-Gasoline). Filters clogged (Group 10).

Remove and clean or replace as necessary. Fuel lines clogged or restricted.

Blowout all fuel lines with filtered air. Water in fuel.

Drain and refill fuel tank. Prime and bleed diesel system.

Section 40

ELECTRICAL SYSTEM CONTENTS OF THIS SECTION

GROUP 5-WIRING DIAGRAMS Electrical System Schematics

JD440 ( -15142) .•.•••••.• JD440 (15143-49999) .•.•.•.•.• JD440 Series-A .•.•••••.•.•.

Wiring Components Charts JD440 ( -15142) •..••.•••• JD440 (15143-49999) •.•.•..... JD440 Series-A •.•.•.•.•.•..

Wiring Components Chart Keys JD440 ( -15142) ...•.•.•.. JD440 (15143-49999) .•.•.•.•.• JD440 Series-A .•.•.•.•.•.•.

GROUP 10-CHARGING SYSTEM

Page

5-3 5-6 5-9

5-4 5-7

5-10

5-5 5-8

5-11

OPen Alternator - Serial No. ( -15142)

Closed Alternator-Continued Brush Insulation and Continuity

Tests ..•.•••.•.•.•.•.•. Diode and Stator Tests •.•.•.•. Specifications ..•.•.•.•.•.•. Battery ..•.•.•.•.•.•.•...

GROUP 15-IGNITION SYSTEM Diagnosing Distributor Malfunc-

tions •.•.•.•••.•.•.•.•• Distributor Removal ....•.•••. Distributor Tests •.•.•.•.•.•• Distributor Repair •.•.•.•.•.• Distributor Installation .•...•.• Distributor Timing ...•.•.•.•• Coil Tests ..•.•.•.•.•..... Tools •...•.•...•.•.•.•.•. Specifications • . • . • . • . • . • . . .

Diagnosing Alternator Malfunc- GROUP 20-ST ARTING MOTORS tions .................. .

Alternator-Regulator Tests ..•.• Alternator Repair .•.•.•.•.•• Alternator Brushes and Slip Rings Diode and Stator Tests ....•..• Brush Insulation and Continuity

Tests ..•.•.•.•.•.•.•... Assembly •.•.•.•.•.•.•.•.. Pre-Installation Test ••.•.•.•• Specifications • . • . • . • . • . • . • .

10-1 10-2 10-3 10-4 10-4

10-4 10-7 10-8 10-8

Closed Alternator - Serial No. (15143-Up ) Diagnosing Alternator Malfunc-

tions ................. . Alternator-Regulator Tests •.••• Alternator Repair .•.•.•.•.•. Alternator Brushes and Slip Rings

Litho in U.S.A.

10-9 10-9

10-10 10-11

Tests and Diagnosis •.•.•.•... Repair •.•.•.•.•.•••.••••• Solenoid Switch Tests .•.•.•.•. Assembly •.•••.•.•.•.•.•.• Tools .•.•.•.•.•.•.•.•.•.• Specifications . • . • • • • . . • . . . •

GROUP 25-GAUGES Tests and Diagnosis .•.•••.•.• Specifications . • • • • • . . . • . • . • Assembly Notes .•.•.•.•...•.

Page

10-12 10-13 10-14 10-14

15-1 15-1 15-1 15-2 15-3 15-3 15-4 15-4 15-4

20-1 20-2 20-3 20-4 20-4 20-4

25-1 25-2 25-2

Section SO

POWER TR IN CONTENTS OF THIS SECTION

GROUP 5-SYSTEM DIAGNOSIS Syncro-Range Transmission . Power Shift Transmission ..•.•.•

GROUP 10-CLUTCHES CLUTCH ASSEMBLY (Syncro-Range Transmission) General Information .•.•.•...•. Diagnosing Malfunctions •.•.....• Removal .•.•.•.•.•.•.•.•.•. Repair •.•.•.•.•.•.•...•.•. Installation . . • . • . • . • . . . • . . . • Adjustment . • . • . • . • . • . • . • . • . Specifications . . •...•.•.•.•.• Tools .•.•.•.•...•.•••.•.•.

DISCONNECT CL UTCH ASSEMBLY (:Power Shift Transmission) General Information •.•.•••.•.• Diagnosing Malfunctions .•.•.... Removal .•.•.•.•.•.•.•••.•. Repair ..•.•.•.•.•.•.•••... Installation • . • . . . . . . . • . • . • . • Adjustment .•.•.•.•.•.•.•.•. Specifications . . •.•.•.•.•.•.• Tools .•.•.•.•.•.•.•.•.•.•.

GROUP 15-DRIVE SHAFTS General Information ..•.•••.•.. Diagnosing Malfunctions • • • . • . • . Winch Drive Line ..•.•.......• Transmission-to-Rear Differential . Transmission-to-Front Differential. Repair .•.•...•.•.•.•.•.•.. Specifications . • .•••.•.•.•.•.

Page

5-3 5-4

10-1 10-1 10-2 10-3 10-3 10-3 10-4 10-4

10-5 10-5 10-6 10-6 10-7 10-7 10-7 10-7

15-1 15-1 15-1 15-3 15-4 15-4 15-4

GROUP 20-POWER SHIFT TRANSMISSION General Information. . • . • . • . • .• 20-1 Diagnosing Malfunctions . • • • . • .• 20-12 Transmission Testing. . . • . • . • .• 20-13 Disassembly of Transmission Into Subassemblies .•.•••••.•.•

Winch Drive Gearing .•.•.•... Clutch Pack •.•.•.•.•.••••• Transfer Case .•...•.•.•.•.•

Litho in U.S.A.

20-15 20-15 20-15 20-15

GROUP 20-POWER SHIFT TRANSMISSION-Continued

Separation of Transfer Case from Transmission Case •.•.•.•...• Planetary Pack . • . • . • . . . • . • . Pedal Valve and Oil Pressure Regulating Valve •.•.•.•.•.•. Transmission Control Valve .....

Rebuild of Subassemblies .......• Clutch Pack .•.•.....•.•.•. Transmission Oil Pump ..•••.• Planetary Pack . • . • . • . • . • . • . Pedal Valve and Oil Pressure Regulating Valve •.•••.•..... Transmission Control Valve .. 0 •

Assembly of Transmission from Subassemblies ..•.•.•...•....

Transfer Case, Transmission Case, and Clutch Housing .•.•.• Planetary Pack .•.•...•.•.•. Clutch Pack ..•.•...•.•.•.• Winch Drive Gearing .•...•.•. Output Shaft ..•.•.•. 0 ••• 0 ••

Idler Shaft .•.•.•.•.•.•.•.• Reduction Shaft and Tow Discon-nect Lever .•.•.•.•.•.•.... Adjustment of Output Shaft Idler Shaft, and Reduction Shaft .•.•.. Transmission Park Lock .•.•...

Transmission Control Lever and Linkage ..•.•.•...•.•.•..... Transmission Adjustments ..•.•.• SpeCifications . . . •.•.•.•.•.... Tools .•.........•.•...•...

Page

20-18 20-18

20-18 20-18 20-19 20-19 20-19 20-21

20-24 20-27

20-28

20-28 20-29 20-29 20-29 20-30 20-31

20-31

20-31 20-32

20-33 20-34 20-36 20-39

GROUP 25-SYNCRO-RANGE TRANSMISSION General Information •.•...•.•. , 25-1 Diagnosing Malfunctions . . . • . • .• 25-3 Repairing Shifters and Shift Quadrant Controls

JD440 .•.•.•.•.•.•...•... JD440 Series-A ......•.•...

Transmission Shifters . . ..•.•..

("Contents"~Continued on Next Page.)

25-4 25-5 25-7

50 Power Train 5-2 System Diagnosis

Skidders - JD440 TM-1009 (Jul-68)

CONTENTS OF THIS SECTION-Continued

GROUP 25-SYNCRO-RANGE TRANSMISSION-Continued

Transmission Lubrication System .. Oil Pump •.•••.•.•.•.•.•.• Check Valve ...•••.•...•.•. Oil Filter Relief Valve •.•.•...

Transmission Shafts and Gears •••. Specifications ....•.•.•.•.•... Tools •...•.•.•.•.•.•.•.•••

GROUP 30-AXLE ASSEMBLIES

Page

25-9 25-10 25-10 25-11 25-12 25-18 25-20

General Information. • . • • • . • . •. 30-1 Diagnosing Malfunctions • . • . • . •. 30-1 Removal. . • . • . • . • . . . • . • . • .• 30-1 Repair . • . • . • . • . • . • . • . • . • .• 30-1 Installation . • . • • • . • • • . • . • . •. 30- 2 Specifications . . • . • .•. . . . . . . •. 30- 2

GROUP 35-DIFFERENTIALS Front Differential with Hydraulic Lock

General Information. . • . . .• . •. 35-1 Diagnosing Malfunctions . . • . • . •. 35-1

Litho in U.S.A.

GROUP 35-DIFFERENTIALS-Continued Removal •.•.•.•.•.•.•.•.•• Repair •••••••.•.•••.•••.• Adjustments . • . • . • .• . • . • . • . •

Rear Differentials Diagnosing Malfunctions .•••.•. Repair •••.•.•.•.•.•.•.•.•

Differential Lock Control Valve General Information .•.•.•••.• Diagnosing Malfunctions .•.•... Repair •••••.•.•.•.•.•.••• Pedal Adjustment . • . • .•. • . • . .

Specifications ............... .

GROUP 40-AUXILIARY POWER SYSTEM (Syncro-Range Transmission)

General Information .•.•.•••... Removal ....•.•.•.•••.•••.. Repair •.•••.•.•.•.•.•.•.•. Installation • . • . • . • • • . • . • . • . •

Page

35-1 35-2 35-4

35-5 35-5

35-7 35-7 35-7 35-8 35-9

40-1 40-1 40-2 40-2

Skidders - JD440 TM-1009 (Jul-6S)

TESTING TRANSMISSION

The transmission case acts as the hydraulic system oil sump. Oil levels must be checked to assure that the hydraulic system and differentials with locks are full before conducting any transmission testing. See Operator's Manual.

TRANSMISSION OIL FILTER

If transmission malfunction is detected or suspected, check the condition of the transmission oil filter. Unless the transmission control system is supplied with an adequate volume of clean oil, transmission tests will prove inaccurate.

PRESSURE TEST PROCEDURES

1. Disconnect driveline with towing disconnect lever.

2. Start engine and operate at 1900 rpm until an oil temperature of 140 0 to 1600 F. is attained (oil to full mark on dipstick).

3. Stop engine. Remove test plug at "CLUTCH" (Fig. 12) and install a 0 to 300 psi oil pressure gauge.

4. Start engine and measure transmission pump pressure at 1900 rpm engine speed. Pressure should be as shown in "Specifications." If necessary, adjust the oil pressure regulating valve to obtain correct pressure.

5. Depress pedal. With pedal depressed, pressure should drop below 5 psi within 1 second.

6. When pedal is released slowly, pressure should rise at a smooth, increasing rate until pedal is 1/2 to 1 inch from top. At this point, pressure should be approximately SO psi. Any further movement should cause pressure to jump to approximately pump pressure (Item 4).

7. Remove test plugs (Fig. 13) and install 0 to 300 psi oil pressure gauges at C1, C2, B1, B2, B3, B4, and C3. See "Tools."

Cl and C3 test plugs are located on the transmission control valve (see Fig. 29 for location) and may be reached from under the skidder or along the right hand steering cylinder with the skidder In a full left turn.

S. With the engine running at 1900 rpm, record pressure on the gauges at all speeds shown in Figure 14.

Litho in U.S.A.

Power Train Power Shift Transmission

50 20;..13

Fig. 12 - Transmission Clutch Pressure Test Points

-,

T 15442

Fig. 13 - Pump Pressure Test Points

9. If the pressure on engaged clutch and brake elements is more than 15 psi below pump pressure, excessive leakage is indicated.

If pressure is observed on any element, when that element should not be engaged, the trouble is probably a sticking valve or leakage within the control valve housing.

10. Remove test plug (83, Fig. 16) and install o to 100 psi pressure gauge to test transmission lubrication pressure (see Specifications).

Section 70

HYDRAULIC SYSTEM CONTENTS OF THIS SECTION

Group 5-GENERAL INFORMATION, TESTING, AND DIAGNOSIS Page

General Information. . • . • . • . . . . 5-1 System Testing. • . • . • . • . . . • . . . 5-6 Diagnosing Malfunctions. . • . • . . . • 5-10 Specifications. • . • . • . • . . . • . • .• 5-11 Tools . . . . . . . • . . . . . • . • . • . .. 5-11

Group 10-HYDRAULIC PUMP General Information ..•.•.•.•.• Diagnosing Pump Malfunctions . . . . Repair .•...•.•.•.•........ Specifications. • . • . • . • . • . . . . . . Tools .•.............•.....

10-1 10-2 10-2 10-6 10-6

Group 15-FILTERS, VALVES, OIL COOLER, AND ACCUMULATORS

Filters • . • . • . • . . . . . • . • . . . . . 15-1 Pressure Control Valve. . . . • . • .• 15-3 Oil Cooler Assembly. • . • . . . • . .. 15-5 Accumulators. . • . . . . . . . • . • . •. 15-6 Specifications. . . . . . • . . . • . . . • . 15-8

Group 20-STEERING SYSTEM General Information .•.•.•.•.•. Diagnosing Steering Malfunctions ..• Repair .........•.•.•...•..

Steering Valve .•.•.•.•.•.•.• Flow Control Valve .•.•.•.... Steering Cylinders .....•.•...

Specifications. . . . . . . . . . • . . . • .

Group 25-BRAKE SYSTEM General Information ........•.• Diagnosing Brake Malfunctions . • . . Repair ...•.......•.....•..

Brake Valve .....•......... Brake Pistons, Facings, and

Page

20-1 20-4 20-6 20-6

20-10 20-11 20-12

25-1 25-3 25-3 25-3

Disks. . • . . . . . • . • . • . .25-5, 25-8 Winching Brake. . . . . • . . .• 25-6, 25-8

Specifications. • . . . . . • . • . • . • .• 25 -10

Group 30-SELECTIVE CONTROL SYSTEM Selective Control Valve. . . . . . . .. 30-1

General Information. . . . . . . . .. 30-2 Diagnosing Valve Malfunctions. .. 30-3 Repair. . . . . • . . . . . . . . . . . •. 30-4 Adjustment. . . . . . . . • . . . • . .. 30-5

Breakaway Couplers. . • . . . . . • .. 30-7 Remote Cylinders. . . • . . . • . . . •. 30-9

Repair. . . . . . . . • . • . . . . . . .. 30-10 Blade Cylinders . . . . . . . • . • . . .. 30-11 Specifications. . . . . . . . . . . . . . .. 30-12

GroupS GENERAL INFORMATION, TESTING, AND DIAGNOSIS

GENERAL INFORMATION

The hydraulic system is of the closed-center, constant pressure type.

Main hydrauliC system cotnponents (Fig. 1) are: reservoir (transmiSSion case), charging circuit, main pump, power steering system, power brakes, and a selective control system to operate the front-mounted blade or remote cylinders. A hydraulic oil accumulato:r;' is also used when the unit is equ:ippedwithauXiliary hydraulic outlets, and a brake acCUtnulator is used on skidders with Power Shift Transmission.

Litho in U.S.A.

The CHARGING CIRCUIT consists of ageartype transmission pump which circulates oil: (1) to lubricate the transmission, (2) to lubricate and charge the main pump, and (3) to circulate oil through the oil cooler to cool transmission and hydraulic system components. This pump also provides pressure oil for clutch and brake operation on skidders with Power Shift.

All oil from the reservoir andreturnoiUrom hydraulic components passes through full flow filter(s) before entering the main hydraulic pump.

Section 80

ISCEL EOUS MP NE TS CONTENTS OF THIS SECTION

GROUP 5 - WINCH SYSTEM General Information ..•.•••.•... Testing and Diagnosis ••••.•.•.•• Repair

Control Valve • . . . .....•...• Pump .. " " .. " " ~ " 9 " e 0 III It .. " .. III 1:1 •

Winch Housing Assembly .•.•... Log Arch •.•.........•.••••

Specifications • • •.••••••••..•. Tools .. " .. e .. e .. e " • " e ,. ill e iii • iii " e " "

Page

5-1 5-3

5-5 5-6 5-8

5-14 5-15 5-16

GROUP 10 - FRAMES General Information .•••••.•••••. Repair " .. . . . e"" " • .. • 11 "8 " " .. " 0 III e 00

Specifications •••.•••••.•.•..•.

Page

10-1 10-2 10-2

Group 5

WINCH SYSTEM

GENERAL INFORMATION

The winch system consists of the winch assembly (control valve, hydraulic pump, and housing with gear train) and log arch.

The WINCH PUMP is of the positive-displacement gear-type and is located in the winch housing under the output shaft. The pump is driven by the pinion shaft drive gear and supplies pressure oil for clutching and releasing the winch brake.

During relief valve operation, pressure oil builds up in the pressure side of the pump and in the relief valve passage in the center of the pump. The relief valve opens, dumping oil into the pump cover bore connected by a passage to the suction side of the pump.

Litho in U.S.A.

The OIL FILTER is of the full-flow replaceable element-type. Oil flows through the filter when the control lever is in the Y 'HOLD" position.

The WINCH CLUTCH (disk type) is located inside the clutch and brake drum. A pressure plate and piston hydraulically engage the clutch. A release spring disengages the clutch pack after pressure oil is released.

The WINCH BRAKE is the contracting band type mounted around the winch drum and operated by a hydraulic piston and cylinder mechanism. The brake band is released by oil pressure and engaged by spring pressure.