IVIIIVIIIVIII - ajhamler.comajhamler.com/yahoo_site_admin/assets/docs/Field_Cot_from_CWW-II... ·...

Transcript of IVIIIVIIIVIII - ajhamler.comajhamler.com/yahoo_site_admin/assets/docs/Field_Cot_from_CWW-II... ·...

IV

II

IV

II

IV

II

ITHe PrAIrIe TrAVeLer, By CAPTAIN RANDolPH B. MARCy, APPleWooD BookS eDITIoN (2)

IV

II

IV

II

IV

II

ILI

BRA

RY O

F C

ON

GR

ESS

Randolph B. Marcy.

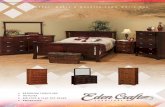

One of the most frequent requests I’ve received since the publication of Volume I has been for a period-correct cot, something that was relatively light, uncomplicated to assemble in the field, and easy to transport. In my research I really liked the simplicity of one described by Captain Randolph B. Marcy in his 1859 book, The Prairie Traveler, that’s perfect for both military and civilian use.

Marcy served extensively in the West prior to the Civil War, including an 1857 expedition with Brigadier General Albert Sidney Johnston to put down the Mormon uprising in Utah. Part of that journey included a forced march—in the dead of winter, no less—through the Rocky Mountains. Astoundingly, Marcy’s skills in the wilderness prevented the loss of a single man. This did not go unnoticed in Washington, and Marcy earned an appointment to the U.S. Department of State where he was requested to write a wilderness handbook for use during the country’s Western migration. The resulting book, The Prairie Traveler, quickly became a best seller, and remained so for the rest of the 19th century.

The book was a wonder (and quite readable—Marcy was an excellent writer), and contained virtually every conceivable tidbit of advice regarding living outdoors. Among the valuable info were sketches and descriptions of a variety of camp furniture, including the field cot presented in this chapter.

As you can see from the sketch and description shown at left, a lot of important details about the cot’s construction were left out—dimensions, joinery,

Chapter 13:� Field Cot

132 y Civil War Woodworking, Volume II

tI

Cut ListField CotOverall Dimensions: 33 1/4" x 80", standing 21" high (canvas height: 16")

Part Name Qty. Wood DimensionsA Headboard/Footboard 2 Poplar 13/16" x 1 5/8" x 33 1/4"B Legs 4 Poplar 13/16" x 12 1/8" x 2 1/4"C Rails 2 Maple 1 1/4" x 2 1/4" x 80"D Braces 4 Maple 1 1/4" x 1 1/4" x 4"E Locking Pegs 4 Oak Dowel 3/4" x 3 1/2"

Special Hardware1/4" x 2 1/2" Steel Round-head Rivets (4 needed)1/4" (hole) x 1/16" (thick) Steel Rivet Washers (8 needed)#10 x 5/8" Cut Copper Tacks (about 125 needed)#10 x 1 1/4" Steel Screws (4 needed)#10 x 2" Steel Screws (4 needed)

E

E

D

D

A

A

B

B

B

B

C

C

Chapter 13: Field Cot y 133

tI

materials and components of the wedge design are all absent. This presented a challenge when I sat down to draw up the plans, but at the same time it imparted a lot of freedom: As long as I followed the sketch and meager description, I could fill in the rest with typical construction of the period. I’m guessing travelers of the day did exactly the same thing.

Originally, these cots were probably on the small side, both length and width. But they weren’t production items, meaning they were most frequently built individually to order, so I did what they would have done—sized it to fit my own needs. I’m about 6' tall and have wide shoulders, so I made the sleeping surface 27" x 72" for personal comfort. (The dimensions of all the components listed in the Cut List on Page XX reflect

this.) I encourage you to do the same and tweak the dimensions to suit your needs.

Now, I did change one detail that was clear on Marcy’s sketch of the cot. The wedges used on the one in the book are triangular, and appear to fit into vertical mortises cut into the rail ends. This seemed unnecessarily complicated, so I opted to change those triangular wedges to simple dowels oriented horizontally instead of vertically. Not only are those easier, but because the dowel holes remove less material, they have the benefit of not weakening those rail ends at a key weight-stress point. As I’ve noted throughout the book, customizing construction details was very common back then, so making alterations—as long as they remain period-correct—is perfectly fine.

need these measurements

7 1/2"

33 1/4"

3 3/4"

Rivet hole 1/4"

Rivet hole 1/4"

2 1/4"1 1/4"

1 1/4"

1 3/8"

7/8"

3"

Reference marks on 6" centers

3 3/4"

Rivet hole 1/4"

2 1/4"1 1/4"

1 3/8"

7/8"

7/8"

3"

3 1/2" 2 1/2"

2"

19"

2 1/4"

134 y Civil War Woodworking, Volume II

tI

Because I have a large quantity of it in my lumber rack, I opted to use 7/8" poplar for the headboard/footboard and legs. For strength, I chose maple for the rails. We’ll take a look at other wood options in the “Variations” section at the end of the chapter.

Oh, one note: I refer to the end sets as “headboard” and “footboard” only for the convenience of distinguishing between the two in the project steps. In truth, they’re identical.

Prepare stock and workpiecesAs always, the first task is bringing all your stock to the desired thickness. Everything I needed for the headboard/footboard and legs was already at 7/8" so I was good to go there, but for the rails I brought some 2 1/4"-wide 6/4 maple (1 1/2" thick) down to the desired thickness of 1 1/4". (Fig. 1) When you’re cutting the stock for your rails, make each rail about a foot longer than needed and you’ll be able to get the stock for the rail braces—which need to be the same thickness—when you trim those rails to their 80" length. From the cutoffs you can cut the four 4" braces to length, then use a bandsaw, jigsaw or scrollsaw to cut them to shape per the Brace Pattern on Page XX. Set these aside for now.

You’ll still have a little bit of cutoff left, probably a small piece of scrap from each rail. Hang on to one of these, and you’ll be able to use it as a guide to fine tune the headboard/footboard and leg

mortises when we get to those. It’s a good idea to bevel all four corner edges of the rail, as in Fig. 2, for a couple of reasons. They’ll be easier to handle and easier to slip into the mortises when the bed is assembled, plus easing the top edges will cause less stress on the canvas once it’s mounted, helping to prevent wear and literal tear of the material with use. In Fig. 2, I’m using a small plane, but a sanding block works just as well.

Using the patterns on Page XX, trace the legs and headboard/footboard onto your stock. If you’ve cut and traced paper patterns, you may want to follow up with a rigid rule to darken and straighten out your leg cutlines, as in Fig. 3. Pencil in the locations of the mortises from the patterns onto the legs, as well as drilling locations for all rivets. Mark the drilling locations in the headboard/footboard workpieces as well, but not the mortises—you’ll use the completed leg mortises to mark those later.

As we’ve done a few times already, you’ll find it easier to cut out patterns in multiples—it saves time and ensures that parts come out identical. Double up the stock for the headboard/footboard, and create two pairs for the legs. Drive a screw through the center of the mortises, which will be cut out later, or into end waste areas to keep the workpieces together. Cut out the headboard/footboard and the legs on the bandsaw as in Fig. 4, or with a jigsaw.

While the workpieces are still paired, sand all curves smooth. A disc sander takes care of this task quickly but an orbital sander or sanding block works just as well. With all edges sanded smooth, check for machining marks and remove them by hand if necessary. The last thing to do before separating

Figure 2Figure 1

Chapter 13: Field Cot y 135

tI

the workpieces from their pairs is to drill all rivet locations.

If you haven’t done so already, once you’ve separated the components transfer the vertical and horizontal guidelines from the patterns onto each component; this will aid in assembly.

Making the mortisesTo cut out the mortises in the headboard/footboard and all four legs, you’ll find that a jigsaw will give you the straightest cuts, but you could also use a scrollsaw if you have one. Also, it helps to keep everything straight by doing each end of the cot separately as a complete set, beginning with leg mortises in each set. In the next several photos, I’ll be working on the footboard set first, but it doesn’t matter which one you start with.

Drill a starting hole for your saw into at least one corner of each marked mortise, being careful to drill only inside the marked lines. Clamp the workpiece to your workbench or other steady worksurface, then insert the jigsaw blade into the guide hole at the corner of the mortise. Carefully cut out each mortise, taking extra care to remain just inside the lines at all times. (Fig. 5) We’ll fine-tune the mortises in a moment, but as I’ve noted earlier it’s always better to leave too much wood than not enough.

With the mortises cut, use clamps or your workbench vise to hold each mortised leg upright for easier working. Now, take one of those small cutoff rail pieces from earlier and test-fit the mortise, as in Fig. 6. You want a fit that is smooth and easy for the rail to slip in, but firm enough that the rail won’t wiggle around too much. (However, the fit should not be snug; more on this later.) If you get that fit on the first try, you’re golden. More

Figure 5 Figure 6

Figure 4Figure 3

136 y Civil War Woodworking, Volume II

tI

likely, since we cut inside the lines you’ll probably need to tweak the fit to make them a bit larger. For this, some coarse or medium sandpaper wrapped around a piece of scrap to create a narrow sanding block works fine. (Fig. 7) Check the mortise frequently with the rail cutoff piece as you sand to avoid removing too much. Once you have the mortise adjusted for a good fit, smooth the inside a bit with medium-to-fine sandpaper. Repeat the entire procedure with the other leg from this end.

When you’re satisfied with the way the rails will fit through the mortises in each leg, slip a rivet through the legs and then into the footboard. Line up everything with the guidelines you copied earlier from the patterns onto the workpieces, and trace the mortise onto the footboard as in Fig. 8. Before removing the legs to cut the footboard mortises, at this point it’s a good idea to mark the footboard and each leg so the legs will go in the same places later in the assembly. The reason for this is that no matter how carefully you drill those rivet holes and cut the leg mortises, there could (probably will) be tiny unintentional variations between them—swap the legs from once side to the other and even the smallest difference could result in the mortises not quite lining up exactly, preventing the rails from sliding through. So mark the location of everything, and keep them ordered as you proceed. A good place to put your marks is inside the mortises to avoid unnecessarily marking up the wood just to have to remove it later. In fact, you can leave these markings there—no one will ever see them.

Cut the mortises in the footboard the same way you did for the legs, then fine-tune with the narrow

sanding block and your rail cutoff till the fit is right. Finally, put the legs back onto the footboard with the rivets, and slip the rail cutoff through the two back-to-back mortises on each side. If you fine-tuned everything OK, the cutoff should slip right through. If not, leave the leg on the footboard and tweak the combined mortises with the narrow sanding block.

Now just fold up the footboard set and put it aside, and repeat the entire above process to create the cot’s headboard set.

Assembly and locking it downWhen you’ve completed both end sets, move everything down to the floor or onto a large table and give it a test assembly as in Fig. 9. This is a “dry assembly” at this point, so those rivets aren’t cut to

Figure 9

Figure 8Figure 7

Chapter 13: Field Cot y 137

tI

Alternatives for rail bracing

Unfortunately, Captain Marcy didn’t give us any details on how the cot’s side rails lock against the headboard and footboard. They certainly had to lock in some manner, or the cot would have wobbled severely. Since the rails are wedged on the outside of the headboard/footboard, the most logical way to keep the cot steady is for the rails to press firmly against the inside. I accomplished this with a small brace underneath each rail end, but there are other options. This drawing compares three typical ways.

At the top is the attached-brace method featured in the project cot, which uses rails of consistent dimensions (2 1/4" high) along their entire length. This makes prepping those rails a bit easier, plus offers a means of removing and then repositioning the braces down the road if the cot begins to wobble with use.

In the example below that, the rail remains at 2 1/4" in the center, but is cut down by 1/2" on the underside the last 4" on each end to create a shoulder that takes the place of the braces, and makes the tenons 1 3/4" high. The mortises in the headboard/footboard and in each leg are also shortened to 1 3/4" to match. If the extra cutting doesn’t bother you, this method eliminates all four braces, meaning there are fewer components to make.

At the bottom is a variation on cutting down the tenon ends. The tenon is still cut to 1 3/4" high, but instead of taking 1/2" off just one side, 1/4" is removed from each to form a shoulder both top and bottom.

Of course, instead of making those tenon ends smaller, you can leave them at 2 1/4" and create shoulders by increasing the height of the rail between the end tenons instead. That option has the additional benefit of increasing rail strength.

Each of these methods has its own pros and cons, but the bottom line is that they’re equally effective for creating a sturdy cot. All are also completely period-correct, so choose whichever you prefer.

2 1/4" 2 1/4"

1 3/4"

1 3/4"

1/2"

1/4"

1/4"

2 1/4"

2 1/4"

138 y Civil War Woodworking, Volume II

tI

final length yet and aren’t peened over—for now, the loose fit is fine.

If you’ve done a good job with the mortises the cot should be pretty sturdy, but it probably has a bit of a wobble to it. We’ll take care of that wobble, plus ensure that everything stays together in use by wedging the rails from both sides of the headboard/footboard. On the outside a dowel peg will slip through the end of the rail, holding it tight; meanwhile, a brace on the inside presses against the wood from that side. Together, it makes for a solid structure in use.

Adjust the rails so they protrude 2" from the headboard/footboard. Then, taking care that the rails don’t move, mark around the rails on the outside and inside, as in Fig. 10. Disassemble the cot and move the rails to your bench or worktable.

Grab those four 4" braces you cut earlier and line them up on the rail so the high end is even with the inner marks, being sure you have the rails

oriented so you’re working on the underside. Drill countersunk pilot holes in the front and back of each brace, and then screw them into place as in Fig. 11. Don’t use glue for this—you may wish to remove and reposition the braces sometime down the road. I found that a 1 1/4" screw works well for the low end of the brace, while a 2" screw does the trick for the high end.

With all four braces mounted, move the rails over to your drill press. (You’ll want to rig up some type of support for the free ends of the rails as you drill so you can easily keep everything flat to the drill press table.) Center and drill a 3/4" hole through the end of each rail, locating the hole so it slightly overlaps that outer line as in Fig. 12. When assembled, those inner braces will stop the rail firmly against the headboard/footboard. On the outside, those holes will be just slightly below the level of the leg.

Figure 12 Figure 13

Figure 11Figure 10

Chapter 13: Field Cot y 139

tI

Cut a length of 3/4" dowel into four 3 1/2" pegs, one for each leg, and drill a 5/16"-diameter rope hole 3/4" from each end. At this point, you may be wondering how you’ll get those round dowels into the holes you drilled in the rails: Those holes are now slightly below the surface of the legs when viewed from the outside. Run each dowel over a piece of sandpaper (or against a belt sander), to create a slightly tapered flat a bit more than halfway up one side as in Fig. 13. Note in this photo that as I’m sanding that flat taper, I’ve oriented the rope hole so it is parallel with the sandpaper.

Reassemble the cot, then slip the dowel pegs into the hole so the flat area is against the leg, as in Fig 14. The taper allows the peg to slide in, but the further you insert it, the tighter it pulls everything together. With all four pegs inserted, the cot should be rock-solid.

At this point, the woodworking aspect of your field cot is complete. Before moving on to the canvas, disassemble everything and apply the finish of your choice to the wooden components. It’s perfectly all right to use no finish at all; remember, utility furniture like this was often left unfinished. However, I’d recommend at least one application of boiled linseed oil to impart a bit of moisture protection to the wood. BLO certainly won’t make your field cot waterproof (nothing will), but it will seal the wood and help it wear better in the field where things are guaranteed to be a bit damp at night. Flood on plenty of oil with a brush as in Fig. 15. Let the oil soak into the wood for about 15 minutes, and if most of the oil has absorbed into the

wood then slather some more on. Let everything sit for about a half hour more, and then wipe off any excess oil remaining on the wood surface with rags. (Be sure to dispose of oily rags properly.)

Allow everything to dry for at least 24-48 hours, and then test it by pressing a spot on the surface firmly with the pad of your thumb. If when you remove your thumb nothing happens, it’s good to go. However, if a slightly shiny wet spot appears where you pressed your thumb, then let things dry a bit longer. When the oil is fully dry, you can prepare to permanently mount the legs to each end set.

Taking care to follow your marks and assemble the legs in the same places they were before, slip rivets into the headboard/footboard from the inside of the cot, follow with a 1/16" washer on the outside, then slip the leg into place on the headboard/footboard. Slip a second rivet onto the tip of the rivet from the outside and mark it for cutting—as noted in Chapter 2, you want about half the rivet diameter to protrude for peening over. Since these are 1/4" rivets, mark them so 1/8" clears the washer, then remove the rivets and cut them to length on your marks.

Finally, reinsert the washers and rivets, and peen each of the rivets into place to permanently attach the legs. I’ve already discussed riveting in the tools and techniques section of Chapter 2, so I won’t repeat the procedure here.

Figure 14 Figure 15

140 y Civil War Woodworking, Volume II

tI

Canvas and final assemblyI’ve used strong cotton duck for the cot material, but any period-correct fabric such as drill or even carpet can be used.

To determine the necessary fabric size, measure the assembled cot’s width from about 1/4" from the bottom of the rail on one side across to the same place on the opposite rail. Add about 6" to each side for the hem. The reason for such a wide hem is to provide a double thickness of fabric where it wraps around and over the rails. This is where the most extensive wear will occur and a double layer will ensure a long-lasting cot. For length, measure the distance between the inside of the headboard and footboard, and add 1" on each end for a hem. For a field cot of the same dimensions that I’ve used, you’ll need a piece of fabric measuring 43" x 74".

Fold that extra 6" over on each side and iron flat. Fold over the last 1/2" of the fabric edge and run a row of stitching the length of the fabric to complete the side hems. Now, fold over the extra 1" on each end and iron flat as before. Fold over the last 1/2" of the fabric and run a row of stitching across the width to complete the hem at top and bottom.

Disassemble the cot and move the rails to your bench or worktable. To help line up the fabric, lightly pencil a continuous line on the outside of each rail 1/4" from the bottom. Attach the ends of

the fabric first, lining up the fabric with the front edge of the rail braces, and tack the ends into place with #10 x 5/8" cut copper tacks. Since these four corners will be the main anchors for the fabric, use several tacks to ensure that the material won’t pull loose.

Working from each end toward the middle, place pencil marks on the bottom edge of the fabric 1 1/2" apart for each tack location. Depending on how you’ve measured and possible fabric stretching, it’s fine if the last two marks in the middle turn out to be closer than 1 1/2". If they end up farther apart than 1 1/2", add another mark between those last two.

Start hammering in the tacks on every fifth mark. The idea here is to get the fabric seated and properly aligned with the line you drew along the rail, and evenly draw the fabric to that line along its length as you add more tacks. Once every fifth tack is hammered in, place tacks in the middle mark between the tacks already done. Now, pound in all the remaining tacks on their marks. (Fig. 16)

Lastly, thread a 54” length of 1/4" rope through pairs of the locking pegs, and tie off with a tight knot. You can see closer details of the finished tacks and roped pegs in Figs. 17 and 18.

When it’s time to break camp, pull out the locking pegs and disassemble the cot. Fold the legs in over the headboard and footboard and place the end sets onto the canvas and roll everything up. Use the roped pegs to tie off the bundle on each end as in Fig. 19.

Figure 16 Figure 17

Chapter 13: Field Cot y 141

tI

VariationsThe field cot in this project is eminently customizable. As with most of the projects in this book, the wood species I used was just what I preferred, so feel free to choose your favorite. Although some members of the SPF family can be quite strong, such as yellow pine, I’d limit their use to headboard, footboard and legs. For the rails, stick with hardwoods such as maple, oak, ash and the like.

Modify the dimensions to suit your needs—since these weren’t production items that’s exactly what they did when the size of the individual using them was known in advance. If you have a small frame, make your cot smaller—it’ll take up less room in a tent and be a lot lighter when transporting it.

Altering the cot width one way or the other doesn’t present any issues, but changing the rail length could. People were shorter back then, so most of these cots were probably shorter as well. As such, having only four legs was fine as far as load-bearing characteristics were concerned. The lengths of the rails in the project cot are probably at their limit in presenting a 72" sleeping surface; longer rails could be prone to sagging in the center (where you always find a third leg set in modern cots).

I’ve tested this cot in the field it and works fine for my 6', 190-pound frame. I don’t think I’d try jumping up and down on it, but it sleeps solidly with no worries. But if you’re taller and want longer rails, or if you weigh more than my 190 pounds, consider increasing the rail height from 2 1/4" to 2 1/2", or even 2 3/4".

Alternatively, you could add a pair of legs in the center. Accomplish this by riveting a leg made from 1x2 stock on the inside of the rails; these would flip down when you set the cot up, and fold up for transport when you roll everything up. Or, you could attach a block (similar to the rail braces) in the center of the underside of each rail. Drill the block for a 3/4" oak dowel that you could slip into the block when setting up the cot. That would be plenty strong to help distribute weight handling.

One last tip. I mentioned earlier that the rails should not fit snug into the mortises, and here’s why: Anytime you use this cot outdoors, the wood is going to swell a bit due to damp nighttime air (or getting rained on). If this happens before you set the cot up you may not be able to get those rails into the mortises, and if it happens after the cot is set up you may not be able to get it apart. The first time you use the cot you may want to toss a sanding block in the trunk of your car to ease the fit of those rail ends if you have trouble assembling it.

Figure 19Figure 18