Item : HP / IP / LP (3종 3기)

Transcript of Item : HP / IP / LP (3종 3기)

W.O : ULP-WO-20-047

Project : BARRY 8 PJT

Item : HP / IP / LP (3종 3기)

납기일 : 2021-10-02

배포일자 : 2021-09-01

배포수량 :

* 도면 외부 반출 금지 & 도면 좌대 정위치 정리

* 설계 담당자 : 이상운 차장 내선 : 9573

* 생산 담당자 : 김현진 차장 내선 : 9564

* 품질 담당자 : 박완희 과장 내선 : 9588

<일일 작업 서약>ULP 상무 하재호

1. 최신 도면 확인

2. 용접 절차서 (WPS) 확인

3. 재질 확인 (HEAT NO.)

4. 용접봉 전류,전압 준수

5. 예열,후열 조건확인

6. 취부, 용접부 건전성 확보 (청결,무결함)

7. 임시 부착물 표시

8. 용접부 비드 폭 확인

9. 용접부 표면결함 확인

10. 작업장내 금연 [훼손금지]

1 of 2

하기 list된 [ ● ]도면 (drawing) [ ] 서 류 (document) [ ] 자 료(data)를

[ ]참 조 (reference) [ ● ] 작 업 (working)

용으로 배포합니다.

No. 0 1 2 3 4 5

1 02/04

2 02/04

3 02/04

4 02/04

5 02/04

6 02/04

7 02/04

8 02/04 05/15 06/17

9 04/01

10 04/01 0901

11 04/01

12 04/01 0901

13 04/01

14 04/01

15 04/01

16 04/01

17 02/04 06/17

18 02/04 06/17

19 02/04

20 02/04

21 02/04

[ ● ] 이 하 여 백 [ ] 뒷 장 계 속 배포자 : (인)

ULP-STD-ENG-DOC-001

A3 - 1C A3 - 1C A3 - 1C -

이 상운

배

포

처

MFG. Dept.(생산부)

Q.C Dept.(품질관리부)

P.M(PM부)

Q.A Dept.(품.보/생.기)

PUR. Dept(구매부)

-

A2- 2CA3-1C

A3 - 1C

IP V17531-ISND-0004 INTERMEDIATE PRESSURE STEAM DRUM NOZZLE DETAIL

IP V17531-ISND-0007 18"x24" MANWAY ASSEMBLY FOR INTERMEDIATE PRESSURE STEAM DRUM

IP V17531-ISND-0002 INTERMEDIATE PRESSURE STEAM DRUM ASSEMBLY

IP V17531-ISND-0003 INTERMEDIATE PRESSURE STEAM DRUM WELDING DETAIL

HP V17531-HIND-0008 HP DRUM INTERNAL SUB ASSEMBLIES & DETAILS

IP V17531-ISND-0001 INTERMEDIATE PRESSURE STEAM DRUM HEAD & SHELL DETAILS

HP V17531-HIND-0006 HP DRUM INTERNAL SUB ASSEMBLIES & DETAILS

HP V17531-HIND-0007 HP DRUM INTERNAL SUB ASSEMBLIES & DETAILS

HP V17531-HIND-0004 HP DRUM INTERNAL SUB ASSEMBLIES & DETAILS

HP V17531-HIND-0005 HP DRUM INTERNAL DETAILS

HP V17531-HIND-0002 HP DRUM INTERNAL SECTION "B","C" & "D"

HP V17531-HIND-0003 HP DRUM INTERNAL SUB ASSEMBLIES & DETAILS

HP V17531-SDND-0010 HP STEAM DRUM NON-PRESSURE ATTACHMENT

HP V17531-HIND-0001 HP DRUM INTERNAL SECTION "A"

HP V17531-SDND-0008 EXTERNAL DAVIT FOR 18" x 24" MANWAY FOR HIGH PRESSURE

HP V17531-SDND-0009 INTERNAL DAVIT FOR 18" x 24" MANWAY FOR HIGH PRESSURE STEAM DRUM

HP V17531-SDND-0004 HIGH PRESSURE STEAM DRUM NOZZLE DETAIL

HP V17531-SDND-0007 18"x24" MANWAY ASSEMBLY FOR HIGH PRESSURE STEAM DRUM

HP V17531-SDND-0002 HIGH PRESSURE STEAM DRUM ASSEMBLY

HP V17531-SDND-0003 HIGH PRESSURE STEAM DRUM WELDING DETAIL

Rev. Number

Item No, Dwg. No./Doc. No. D E S C R I P T I O N

HP V17531-SDND-0001 HIGH PRESSURE STEAM DRUM HEAD & SHELL DETAILS

ULP-WO-20-047 BARRY 8 VOGT S.U. Lee J. Y. Jeon S.G.Sung

W/O No. Project Name CustomerPrep'd Chk'd Appr'd

(공 사 번 호) (공 사 명) (고 객)

DWG/DOC. DISTRIBUTION SHEETDoc. No. 20047-DS-05

Page

ULP CO., LTD. (도면/서류 배부 대장)Issue

01-Sep-21Data

2 of 2

No. 0 1 2 3 4 5

22 02/04

23 02/04 05/15

24 02/04 05/15 06/17

25 04/01

26 04/01

27 04/01

28 04/01

29 04/01

30 02/04 06/17

31 02/04 04/01 05/15

32 02/04 04/01 05/15

33 02/04 04/01 05/15 06/17

34 02/04

35 02/04

36 02/04 06/17

37 02/04

38 02/04

39 04/01

40 04/01

41 04/01

42 04/01

43 04/01

44 06/17

44 09/01ALL V17531-EBND-0251 STEAM DRUM MANWAY GASKET INSTALLATION

ALL V17531-SPND-0002 Shipping Clearance

- BLANK -

LP V17531-LIND-0004 LP DRUM INTERNAL DETAILS

LP V17531-LIND-0005 LP DRUM INTERNAL SUB-ASSEMBLIES & DETAILS

LP V17531-LIND-0002 LP INTERNAL SECTION "B" & C

LP V17531-LIND-0003 LP INTERNAL SUB-ASSEMBLIES & DETAILS

LP V17531-LSND-0011 LP STEAM DRUM NON-PRESSURE ATTACHMENT

LP V17531-LIND-0001 LP INTERNAL SECTION "A"

LP V17531-LSND-0009 INTERNAL DAVIT FOR 18" x 24" MANWAY FOR LOW PRESSURE STEAM DRUM

LP V17531-LSND-0010 LP STEAM DRUM NON-PRESSURE ATTACHMENT

LP V17531-LSND-0007 18"x24" MANWAY ASSEMBLY FOR LP STEAM DRUM

LP V17531-LSND-0008 EXTERNAL DAVIT FOR 18" x 24" MANWAY FOR LOW PRESSURE STEAM DRUM

LP V17531-LSND-0003 LOW PRESSURE STEAM DRUM WELDING DETAIL

LP V17531-LSND-0004 LOW PRESSURE STEAM DRUM NOZZLE DETAIL

LP V17531-LSND-0001 LOW PRESSURE STEAM DRUM HEAD & SHELL DETAILS

LP V17531-LSND-0002 LOW PRESSURE STEAM DRUM ASSEMBLY

IP V17531-IIND-0004 IP DRUM INTERNAL DETAILS

IP V17531-IIND-0005 IP DRUM INTERNAL DETAILS

IP V17531-IIND-0002 IP DRUM INTERNAL SECTION "B" & "C"

IP V17531-IIND-0003 IP DRUM INTERNAL DETAILS

IP V17531-ISND-0010 IP STEAM DRUM NON-PRESSURE ATTACHMENT

IP V17531-IIND-0001 IP DRUM INTERNAL SECTION "A"

IP V17531-ISND-0008 EXTERNAL DAVIT FOR 18" x 24" MANWAY FOR INTERMEDIATE PRESSURE

IP V17531-ISND-0009 INTERNAL DAVIT FOR 18" x 24" MANWAY FOR INTERMIDIATE PRESSURE STEAM DRUM

ULP CO., LTD. (도면/서류 배부 대장)Issue

01-Sep-21Data

Item No, Dwg. No./Doc. No. D E S C R I P T I O N

DWG/DOC. DISTRIBUTION SHEETDoc. No. 20047-DS-05

Page

W/O NO. : ULP-WO-20-047

Page : 1 of 1

Customer : VOGT Project name : BARRY 8 Delivery date : 2021. 10.02

생산 QC PM QA 구매

2C 1C 1C 1C 1C

1 2 O O O O O

2 2 O O O O O

3 3 O O O O O

4 0 O O O O O

5 1 O O O O O

6 1 O O O O O

설 계 변 경 통 보 서(Design changed Notice)ULP CO., LTD.

Issue For working 자재 재구매 No 제 작 완 료 No Cost impact No 개정 사유 고객 요청

S/No. Item No. DWG NO.Rev.

No.변 경 전 변 경 후

배부

첨부

HP V17531-HIND-0002 - Internal section 변경 (첨부 도면 참조) 도면 참조

HP V-17531-ISND-0002 -

IP V-17531-ISND-0010 - ANGLE HOLE SIZE 변경 (첨부 도면 참조) 도면 참조

IP V-17531-SDND-0010 - HP SUPPORT ANGLE 추가 표기. 도면 참조

LP V-17531-SPND-0002 - SHIPPING 도면 추가 도면 참조

HP V17531-HIND-0004 - Drawing No. 변경 도면 참조

ULP-STD-ENG-DOC-002

PRV INLET NOZZLE SIZE 변경 (첨부 도면 참조) 도면 참조

1~4 번사항 기존 반영 완료 되었으며, 5번 사항은 HP Internal section 업데이트 사항 임.

6번사항은 도면 numbering update 사항.

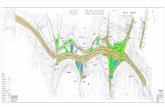

HP DRUM HEADSCALE: 1" = 1'-0"

HEAD TO SHELL DETAIL

13551 Triton Park Blvd

Suite 2000

Louisville, Ky. 40223 USA

WWW.VogtPower.com

RevisionsThis drawing contains Vogt Power International's confidential and proprietary information and cannot be used,

duplicated or disclosed in whole or in part, except with the express written permission of Vogt Power International.

EXCEPT AS EXPRESSLY STATED IN ANY WRITTEN CONTRACT - ALL WARRANTIES RELATING TO THIS DRAWING,

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS, ARE DISCLAIMED.

Vogt Power International, Inc. all rights reserved as an unpublished work.

Title

Internal Drawing Status Size Drawing No. Rev.

3RD ANGLE PROJECTION

Scale:

B V17531-SDND-0001

3/8" = 1"

FOR RECORD 02

HIGH PRESSURE STEAM DRUM HEAD& SHELL DETAILS

C

ALABAMA POWER COMPANYBARRY 8 COMBINED CYCLE PROJECT

BUCKS, ALHeat Recovery Steam Generator for

MHPSA

Project

06 05 04 03 02 METRIC THICKNESS DIMENSION 9-SEP-20 SD SEG DP01 GENERAL REVISION 17-AUG-20 SD SEG DP00 FIRST ISSUE 15-APR-20 SD SEG -- DP

Rev. Description Date Drawn Chkd.1 Chkd.2 Appr.

GENERAL NOTES:

1. HEADS TO COMPLY WITH THE REQUIREMENTS OF THE 2019 EDITION OF THE ASME BOILER CODE SECTIONS I, II, V & IX. 2. LENGTH, WIDTH, AND NUMBER OF COURSE SECTIONS TO BE CALCULATED BY THE DRUM FABRICATOR. ROLLING/FORMING TOLERANCES HAVE NOT BEEN ADDED TO THE THICKNESS SHOWN. 3. MATERIAL TO COMPLY WITH THE REQUIREMENTS IN DOCUMENT V17531-EMNC-0003 VPI PLATE MATERIAL SPECIFICATION. HEMISPHERICAL HEAD MATERIAL: SA-299 Gr. B DRUM SHELL MATERIAL: SA-299 Gr. B 4. FABRICATOR TO DESIGN WELD PREP TO MATCH FABRICATOR'S WELDING PROCESS AND SUBMIT FOR APPROVAL. 5. (1) DRUMS REQUIRED TOTAL, (2) HEADS PER DRUM (2) HEADS REQUIRED TOTAL.5'-11"

[1803]

10"

[253

]

2'-2

78"

[683

] 3"[7

6.2]

MACHINE FLAT, TO BEBEVELED TO MATCH

FAB. WELD DETAIL(SEE NOTE 4)

INSIDE DIA. ATHEAD CUTBACK

MIN

. TH

K.

534"

[146

]5'

-11"

[180

3]

WE

LD S

EA

M

n6'-134"

[n1873]

n6'-434"

[n1949]SEE NOTE 4

45'-0" SHELL LENGTH[13716] WELD SEAM TO WELD SEAM

TA

NG

EN

TLI

NE

10"[253]

INSIDE DIA.(HOLD)

MEAN DIA.(REF.)

MIN

. TH

K.

SH

ELL

INS

IDE

DIA

.

R3'-078"

[R937]

INSIDERADIUS

71516"

[201]

1

3

FRONT VIEW

REAR VIEW

LEFT DRUM HEAD RIGHT DRUM HEAD

CONTOUR DETAILSCALE: NONE

-THD3000#12"TEMP. ELEMENT CONN. FOR INNER-WALL (WG-TT-2051, 2052)2301

-THD3000#12"TEMP. ELEMENT CONN. FOR MID-WALL (WG-TT-2050, 2053)2300

2 1 8"BWSCH 1602 1 2"CONTINUOUS BLOWDOWN (WB-PP-2750)1090

1 1316"SWSCH 801"LOWER LG / LT CONN. (WG-PP-2558, 2560, 2562, 2564, 2566)5080

2'-2 1 4"BWSCH 14014"FEEDWATER INLET (WB-PP-2572)1060

1"SW3000#1"DRUM VENT (WB-VN-2556)11313

16"SW3000#34"PI, PT (WG-PP-2550, 2554)212

3 1 4"BW1.625" WALL3"PRV INLETS (WG-PP-2552, 2553)211

4 7 8"BWSCH XXS6"TCA COOLER RETURN (WB-PP-2607)110

1 1 16"SW3000#1"UPPER LG / LT CONN. (WG-PP-2557, 2559, 2561, 2563, 2565)507

5 3 16"BWSCH 1606"HPEV 1 RISER (WB-PP-2584)805

8 1 2"BWSCH 16010"STEAM OUTLET TO HPSH (WB-PP-2591)604

1'-5 3 4"BW1.75" WALL12"HPEV 5-7 RISER COLLECTION (WB-HDR-2555)203

1'-2 5 8"BW1.75" WALL10"HPEV 2-4 RISER COLLECTION (WB-HDR-2554)802

2'-4"BWSCH 14020"DOWNCOMER (WB-PP-2575)201ELLIPTICAL---3 1 2" WALL18" x 24"MANWAY ASSEMBLY2430

NOZZLE SCHEDULEREQUIRED HOLE SIZETYPEANSI RATING OR WALL THICKNESSNOMINAL PIPE SIZEDESCRIPTIONQTYPART/ ASSEMBLY NO.

BILL OF MATERIALSMAT'L SPEC.DESCRIPTIONQTY.PART NO.SA-299 Gr. BSHELL PLATE 5 3 4" THK. x 71" I.D. x 45'-0" LG.120

SA-299 Gr. BHEMISPHERICAL HEAD 3" THK. x 73 3 4" I.D.221

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

13551 Triton Park Blvd

Suite 2000

Louisville, Ky. 40223 USA

WWW.VogtPower.com

RevisionsThis drawing contains Vogt Power International's confidential and proprietary information and cannot be used,

duplicated or disclosed in whole or in part, except with the express written permission of Vogt Power International.

EXCEPT AS EXPRESSLY STATED IN ANY WRITTEN CONTRACT - ALL WARRANTIES RELATING TO THIS DRAWING,

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS, ARE DISCLAIMED.

Vogt Power International, Inc. all rights reserved as an unpublished work.

Title

Internal Drawing Status Size Drawing No. Rev.

3RD ANGLE PROJECTION

Scale:

REFERENCE DRAWINGS:

D V17531-SDND-0002

3/8" = 1'-0"

FOR RECORD 01

71" I.D. HIGH PRESSURE STEAMDRUM ASSEMBLY WG-DRM-2550

C

ALABAMA POWER COMPANYBARRY 8 COMBINED CYCLE PROJECT

BUCKS, ALHeat Recovery Steam Generator for

MHPSA

Project

06 05 04 03 02 01 GENERAL UPDATE 16-DEC-20 JP SD GLK MAS00 FIRST ISSUE 8-SEP-20 SL DLN -- MAS

Rev. Description Date Drawn Chkd.1 Chkd.2 Appr.

DRUM FABRICATOR TO:DETERMINE WELD PROCESS AND PROCEDURES FOR SHELL TO HEAD AND SHELL TO SHELL WELD SEAMS. DETERMINE SHELL SECTION LENGTHS. STAGGER LOCATION OF LONGITUDINAL WELD SEAMS.

PART NUMBERS ARE TO HAVE THE PREFIX OF "SD". FOR EXAMPLE, "20" (PART NUMBER) WOULD BE "SD20"

GENERAL NOTES:

1. DRUM MATERIAL & CONSTRUCTION TO BE IN ACCORDANCE WITH 2019 EDITION OF ASME BOILER CODE SECTIONS I, II, V & IX 2. ALL WELDED JOINTS SHALL RECEIVE PREHEAT IN ACCORDANCE WITH ASME SECTION 1 PARA. PW-38. POST WELD HEAT TREATMENT SHALL BE IN ACCORDANCE WITH PARA. PW-39. ANY WELDING AFTER PWHT SHALL CONSIDER THE REQUIREMENTS FOR PWHT EXEMPTION AND PREHEAT IN PW-39 AS WELL. 3. ALL LONGITUDINAL & CIRCUMFERENTIAL WELDED JOINTS REQUIRE VOLUMETRIC EXAMINATION PER PAR. PW-11. 4. ALL WELDS P1-P1 UNLESS NOTED OTHERWISE. 5. ALL NOZZLE TO SHELL, AND MANWAY TO HEAD WELDS REQUIRE NON DESTRUCTIVE EXAMINATIONS. 6. COMPLETED DRUM TO BE POST WELD HEAT TREATED PER PAR. PW-39. 7. BOTH HEADS TO HAVE 18" X 24" MANWAY ASSEMBLIES COMPLETE WITH COVERS, SHIPPING GASKETS, & HINGES/DAVITS (INTERNAL & EXTERNAL). 8. MANHOLE GASKET SURFACE TO BE REFINISHED AFTER POST WELD HEAT TREATMENT IF NECESSARY. 9. MANWAY ASSEMBLIES SUPPLIED BY DRUM FABRICATOR. INSTALL IN HEADS WITH INTERNAL PROJECTION PER PROJECT ASME CODE CALCULATIONS. 10. CODE STAMPING & DOCUMENTATION REQUIRED. 11. DRUM TO BE SHOP INSPECTED BY AUTHORIZED INSURANCE COMPANY. 12. ALL STUB PIPES & END CONNECTIONS ARE TO BE PLUGGED OR CAPPED BEFORE SHIPMENT. 13. DRUM IS TO BE WEIGHED PRIOR TO SHIPMENT, & WEIGHT PAINTED ON THE DRUM IN 3" HIGH NUMBERS. 14. QUANTITIES SHOWN FOR ONE (1) UNIT, ONE (1) UNIT REQUIRED TOTAL.

V17531-SDND-0001 - HIGH PRESSURE STEAM DRUM HEAD & SHELL DETAILSV17531-SDND-0003 - HIGH PRESSURE STEAM DRUM WELDING DETAILSV17531-SDND-0004 - HIGH PRESSURE STEAM DRUM NOZZLE DETAILSV17531-SDND-0007 - 14" x 18" MANWAY ASSEMBLY FOR HIGH PRESSURE STEAM DRUMV17531-SDND-0008 - EXTERNAL DAVIT FOR 14" x 18" MANWAY FOR HIGH PRESSURE STEAM DRUMV17531-SDND-0009 - INTERNAL DAVIT FOR 14" x 18" MANWAY FOR HIGH PRESSURE STEAM DRUMV17531-SDND-0010 - HP DRUM NON-PRESSURE ATTACHMENTS 510030-EBND-0101 - STANDARD FABRICATION TOLERANCES FOR HORIZONTAL VESSELS510030-EBND-0109 - STANDARD FABRICATION TOLERANCES FOR MACHINED FORGED NOZZLESV17531-SDNC-0001 - EQUIPMENT SPECIFICATION FOR SHOP FABRICATED STEAM DRUMS

51'-91116"

[15792] APPROX.

CL DRUMI

LEFT RIGHTFRONT

CL DRUMI

RIGHT LEFT

040004

45'-0"[13716]

SEAM TO SEAM

21

HIGH ALARM LEVEL +12.0"

HIGHEST LEVEL +14.0"

NORMAL LEVEL +7.0"

DRUM CENTER LINE 0"

LOW ALARM LEVEL +1.0"

STARTUP LEVEL -9.0"

LOWEST LEVEL -27.5"

DESIGN PRESSURE: DESIGN TEMP.: DRUM EFFICIENCY: LONG. 100%, CIR. 100%(WITHOUT INTERNALS OR NON-PRESSURE ATTACHMENTS)MINIMUM THICKNESS: SHELL - HEADS -

2,900 PSI (199.95 Bar)692°F (366.7°C)

5.75 IN. (146 mm)3 IN. (76.2 mm)

20

4'-818"

[1426]

7'-1118"

[2416]

11'-218"

[3407]

4'-818"

[1426]

7'-1118"

[2416]

11'-218"

[3407]

1'-10"[559]

5'-3"[1600]

10'-7"[3226]

14'-0"[4267]

1'-10"[559]

5'-3"[1600]

10'-7"[3226]

14'-0"[4267]

17'-6"[5334]

17'-6"[5334]

20'-218"

[6150]20'-21

8"[6150]

2'-0"[610]

2'-0"[610]

6'-0"[1829]

10'-0"[3048]

14'-0"[4267]

6'-0"[1829]

10'-0"[3048]

14'-0"[4267]

8'-0"[2438]

8'-0"[2438]

17'-6"[5334]

17'-6"[5334]

3'-518"

[1044]3'-51

8"[1044]

2'-5

12"

[749

]1'

-8"

[508

]

3'-5"[1041]

3'-5"[1041]

3'-5"[1041]

3'-5"[1041]

2'-5

12"

[ 749

]1'

-8"

[508

]

07

0004

10"[254]

100004

55°

15°

010004

020004

050004 01

000405

0004

05

0004

05

000405

0004

01

0004

02

0004

02

0004

02

000402

0004

03

0004

030004

040004

040004

040004

040004

0600003

03

0004

0600003

07

0004

080

0003

080

0003

080

0003

080

0003

07

000407

0004

CL DRUMI CL DRUMIFRONT

(x2)

(x2)

FRONT

080

0003

TYP. (x2)

07

0004TYP. (x2)

07

0004

080

0003

100004

CONTOUR OF "SD01"TO MATCH ID OF DRUM

120004

130004

110004

301

0003

300

0003

300

0003

301

0003

45°

45°

3000003

3010003

3000003

3010003

21

R1716"

[R37]

07

0004

080

0003

080

0003

07

0004

TBD.

116 "[2]

2'-0"[610]

430

0007

430

0007

EN

D O

F P

IPE

EN

D O

F P

IPE

EN

D O

F P

IPE

EN

D O

F P

IPE

11

0004

130003

120003

19'-0"[5791]

090

0003

45°

0900003

1'-0"[305]

3'-518"

[1044]3'-51

8"[1044]

17'-314"

[5264]2'-117

16"[900]

1'-234"

[375]6"

[152]

1'-2516"

[364]

11

0004

1'-0"[305]

MANWAY RING INSTALLATIONSCALE: 3/16" = 1"

HPEC OUTLET TO DRUMSCALE: 1 1/2" = 1'-0"

LOWER LEVEL GAUGE/TRANS. CONN.(5) REQUIRED

INNER-WALL TEMP. ELEMENTMID-WALL TEMP. ELEMENT

CONTINUOUS BLOWDOWN

BILL OF MATERIALSMAT'L. SPEC.BOM DESCRIPTIONQTYPART

SA-105SW-FLEXOLET, 3/4", 3000#212SA-105SW-FLEXOLET, 1", 3000#113

SA-106 Gr.CPIPE, 1" SCH 80 x 2'-3 1/2" (698mm) LG. (T.O.E.)515A-36PLATE, 1/4" THK. x 2 1/2" x 2 1/2"425

SA-105THREADED FLEXOLET, 1/2", 3000#430SA-105FITTING, 2 1/2", 6000#, THRD HALF COUPLING131SA-105FITTING, 1", 3000#, SW COUPLING532

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

FIGURE 1 FIGURE 2 FIGURE 3

13551 Triton Park Blvd

Suite 2000

Louisville, Ky. 40223 USA

WWW.VogtPower.com

RevisionsThis drawing contains Vogt Power International's confidential and proprietary information and cannot be used,

duplicated or disclosed in whole or in part, except with the express written permission of Vogt Power International.

EXCEPT AS EXPRESSLY STATED IN ANY WRITTEN CONTRACT - ALL WARRANTIES RELATING TO THIS DRAWING,

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS, ARE DISCLAIMED.

Vogt Power International, Inc. all rights reserved as an unpublished work.

Title

Internal Drawing Status Size Drawing No. Rev.

3RD ANGLE PROJECTION

Scale:

REFERENCE DRAWINGS:

D V17531-SDND-0003

1/8" = 1"

FOR RECORD 01

HIGH PRESSURE STEAM DRUMWELDING DETAILS

C

ALABAMA POWER COMPANYBARRY 8 COMBINED CYCLE PROJECT

BUCKS, ALHeat Recovery Steam Generator for

MHPSA

Project

NOTES:

1. SEE DRAWING V17531-SDND-0002 FOR GENERAL NOTES. 2. NOZZLE NOTE: ALL OLETS SHALL BE STRAIGHT I.D. BORE DESIGN (FLEXOLET OR EQUAL) 3. QUANTITIES SHOWN ARE FOR ONE (1) UNIT. ONE (1) UNIT TOTAL REQUIRED.

V17531-SDND-0002 - 71" I.D. HIGH PRESSURE STEAM DRUM ASSEMBLYV17531-SDND-0004 - HIGH PRESSURE STEAM DRUM NOZZLE DETAILSV17531-SDND-0007 - 18" x 24" MANWAY ASSEMBLY FOR HIGH PRESSURE STEAM DRUM

NOZZLE WELD SCHEDULEPART NO. "A" "B" "C" "D" "E" "F" FIGURE

NO. "P" NO. "R"

01 FULL PEN. 34" FULL PEN. - 1

8" 5'-5" (1651mm) 2 P1-P1 SEE DETAIL

02 FULL PEN. 12" FULL PEN. - 1

8" 4'-9" (1448mm) 2 P1-P1 SEE DETAIL

03 FULL PEN. 34" FULL PEN. - 1

8" 5'-1 1 2" (1562mm) 2 P1-P1 SEE DETAIL

04 FULL PEN. 38" - - 1

8" 5'-0" (1524mm) 3 P1-P1 1 7 16"

05 FULL PEN. 38" - - 1

8" 5'-1 1 4" (1556mm) 3 P1-P1 1 7 16"

06 FULL PEN. 38" FULL PEN. - 1

8" 4'-8" (1422mm) 2 P1-P1 SEE DETAIL

07 FULL PEN. 38" - - 1

8" 3'-5" (1041mm) 3 P1-P1 14"

08 FULL PEN. 38 - - 1

8" 3'-2 1 8" (968mm) 3 P1-P1 N/A

09 FULL PEN. 12" - - 1

8" 4'-3 3 8" (1305mm) 3 P1-P1 N/A

10 FULL PEN. 38" - - 1

8" 4'-5 3 8" (1356mm) 3 P5A-P1 1116"

11 FULL PEN. 38" - - 1

8" 4'-0" (1219mm) 3 P1-P1 38"

12 FULL PEN. 38" - - 1

8" - 3 P1-P1 14"

13 FULL PEN. 38" - - 1

8" - 3 P1-P1 14"

"F"

CL DRUMI

"A""E"

45~"B"

"P" NO.

GRIND ANY EXCESSWELD SMOOTH WITHI.D. OF NOZZLE

"R"

"F"

CL DRUMI

PART NO.

"C""E"45~

"A""E"

45~"B"

"P" NO.

PART NO.

"R" DRUM SHELLI.D.

DRUM SHELLI.D.

"F"

CL DRUMI

"A""E"

45~"D"

"A""E"

45~"B"

"P" NO.

DRUM SHELLI.D.

"R"

PART NO.

**

( = THERMAL SLEEVE ONLY)*

CL DRUMI HEAD

1'-3"[381]

REF.

3316"

[80] LOW POINT

(HOLD)

1'-6

"[4

57] R

EF

.

(FP)3/4

(FP)

3/4

430

0007

6"[152]

5'-2"[1575]

TO CL DRUMI

2'-1114"

[895] REF.

060

0002

06

0004

FP

3/8

17

0004

25(4) REQUIREDSPACED AT 90~APART

3/163/16

P1-P1TYP.

DO NOT WELD TO PIPE

DRUM SHELL

3"[76]

112"

[38]

080

0002

32

15

08

0004 DRUM SHELL

DRILL Ø1/4" [6] THRUHOLE AND DEBURR

THREAD THIS END

FP

1/845~

3/8

7/32

[

]

DO NOT DRILL THROUGH SHELL PLATE

R18"

[R3]

(FP)1/8

45~3/8

30

DRUM SHELL

(FP)1/8

45~3/8

30

DRUM SHELL

DO NOT DRILL THROUGH SHELL PLATE

[ ]

R18"

[R3]

.250

- 0.0

63+

in

6.4 - 0

1.6

+ m

m

[

]

300

0002

301

0002

PART NUMBERS ARE TO HAVE THE PREFIX OF "SD". FOR EXAMPLE, "12" (PART NUMBER) WOULD BE "SD12"

.260

- 0.0

15+

in

6.6 - 0

.4+ m

m

2 78 "[73]

.260-0.015

+

in

6.6-0.4

+ m

m

31

3/16

DRUM SHELL09

0004

090

0002

EN

D O

F P

IPE

712"

[190]

01 GENERAL UPDATE 16-DEC-20 JP SD GLK MAS00 FIRST ISSUE 8-SEP-20 SL DLN -- MAS

Rev. Description Date Drawn Chkd.1 Chkd.2 Appr.

FEEDWATER PIPE

DETAILSCALE: 3/8" = 1"

FEEDWATER THERMAL SLEEVE

DETAILSCALE: 3/8" = 1"

6" RISER NOZZLETCA COOLER RETURN NOZZLE

SCALE: 3/16" = 1"

DETAILSCALE: 3" = 1'-0"

1" UPPER LEVEL CONN. NOZZLESCALE: 3/16" = 1"

1" LOWER LEVEL CONN. THERMAL SLEEVE

DETAILSCALE: 3/8" = 1"

DOWNCOMER NOZZLE

10" RISER NOZZLE

12" RISER NOZZLE 6" STEAM OUTLET NOZZLE

SAFETY VALVE CONN. NOZZLESCALE: 3/16" = 1"

2 1/2" CONTINUOUS BLOWDOWN NOZZLESCALE: 3/16" = 1"

BILL OF MATERIALSMAT'L SPEC.DESCRIPTIONQTYPART

SA-105FORGED NOZZLE, 27.75" OD x 16.5" ID x 32.596" LG.201SA-105FORGED NOZZLE, 14.375" OD x 7.25" ID x 40.572 LG.802SA-105FORGED NOZZLE, 17.5" OD x 9.25" ID x 27.353" LG.203SA-105FORGED NOZZLE, 17.125" OD x 8.5" ID x 18.856" LG.604SA-105FORGED NOZZLE, 14" OD x 5.187" ID x 19.96" LG.805SA-105FORGING, 26" OD x 14.25" ID x 24" LG.106SA-105FORGED NOZZLE, 1.75" OD x 1.079" ID x 5.119" LG.507SA-105FORGED NOZZLE, 4.875" OD x 1.565" ID x 10.312" LG.508SA-105FORGED NOZZLE, 5.375" OD x 2.125" ID x 10.015" LG.209

SA-182 F22 CL.3FORGED NOZZLE, 10" OD x 4.897" ID x 12.076" LG.110SA-105FORGED NOZZLE, 6.5" OD x 3.25" ID x 6.657" LG.211

SA-106 Gr. C PIPE, 14" SCH 140 x 2'-11 1/4" LG.117

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

13551 Triton Park Blvd

Suite 2000

Louisville, Ky. 40223 USA

WWW.VogtPower.com

RevisionsThis drawing contains Vogt Power International's confidential and proprietary information and cannot be used,

duplicated or disclosed in whole or in part, except with the express written permission of Vogt Power International.

EXCEPT AS EXPRESSLY STATED IN ANY WRITTEN CONTRACT - ALL WARRANTIES RELATING TO THIS DRAWING,

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS, ARE DISCLAIMED.

Vogt Power International, Inc. all rights reserved as an unpublished work.

Title

Internal Drawing Status Size Drawing No. Rev.

3RD ANGLE PROJECTION

Scale:

REFERENCE DRAWINGS:

D V17531-SDND-0004

1 1/2" = 1'

FOR RECORD 01

HIGH PRESSURE STEAM DRUMNOZZLE DETAILS

C

ALABAMA POWER COMPANYBARRY 8 COMBINED CYCLE PROJECT

BUCKS, ALHeat Recovery Steam Generator for

MHPSA

Project

1. FOR GENERAL NOTES, SEE DRAWING V17531-SDND-0002 2. ALL OLETS SHALL BE STRAIGHT I.D. BORE DESIGN (FLEXOLET OR EQUAL).

V17531-SDND-0002 - 71" I.D. HIGH PRESSURE STEAM DRUM ASSEMBLYV17531-SDND-0003 - HIGH PRESSURE STEAM DRUM WELDING DETAILS510030-EBND-0109 - STD. FABRICATION TOLERANCES FOR MACHINED FORGED NOZZLES

NOTES:

01 GENERAL UPDATE 16-DEC-20 JP SD GLK MAS00 FIRST ISSUE 8-SEP-20 SL DLN -- MAS

Rev. Description Date Drawn Chkd.1 Chkd.2 Appr.

A----

2.688 in[68.3]

GROOVEDEPTH

24.0

00 in

[609

.6]

14.250 in[362.0]

26.000 in[660.4]

DRUM SHELL

R1716"

R37 mm

14.500 in368.3 mm

06

0003

2'-1

114"

[895

]

B---- 1.250 in

[31.8] REF.

14.000 in[355.6]

REF.

17

0003

C----

07

0002

08

0003

5.119 in[130.0]

.625 in[15.9]

1.07

9 in

[27.

4]

1.33

5 in

[33.

9]

1.75

0 in

[44.

5]

DRUM SHELL

E-----

C----

1.56

5 in

[39.

8]

1.81

5 in

[46.

1]

.313 in[7.9]

GROOVE

E-----

DRUM SHELL

1

2

5.187 in[131.7]

.719 in[18.3]

6.625 in[168.3]

14.000 in[355.6]

1.50

0 in

[38.

1]7.

375

in[1

87.3

]

19.8

75 in

[504

.8]

19.9

60 in

[507

.0]

R.125 in[R3.2]

05

0002

10

0002

1

3

.750

in[1

9.1]

.063 in[1.6]

LAND

.438 in[11.1]

A----

10°37.5°

.063 in[1.6]

LAND

.750 in[19.1]

B----

45°

.063

in[1

.6]

LA

ND

C----

37.5°

.063 in[1.6]

LAND

D----

SECTIONSCALE: NONE

E----

.063 in[1.6]

LAND

45°

PART NUMBERS ARE TO HAVE THE PREFIX OF "SD". FOR EXAMPLE, "01" (PART NUMBER) WOULD BE "SD01"

D----

R.125 in[R3.2]

37.5°

R.125 in[R3.2]

E----

1

2

32.5

96 in

[827

.9]

16.500 in[419.1]

1.750 in[44.5]

20.000 in[508.0]

27.750 in[704.9]

1.50

0 in

[38.

1]7.

749

in[1

96.8

]

1

2

DRUM SHELL

R.125 in[R3.2]

B----

SEE V17531-SDND-0002FOR NOZZLE FINISH

REQUIREMENTS01

0002

40.5

72 in

[103

0.5]

26.0

18 in

[660

.9]

7.250 in[184.2]

1.750 in[44.5]

10.750 in[273.1]

14.375 in[365.1]

1.50

0 in

[38.

1]3.

624

in[9

2.1]

02

0002

B----

DRUM SHELL

R.891[R22.6]

R35.250 in[R895.4]

1

2

R.125 in[R3.2]

9.250 in[235.0]

1.750 in[44.5]

12.750 in[323.9]

17.500 in[444.5]

1.50

0 in

[38.

1]4.

750

in[1

20.6

]

27.3

53 in

[694

.8]

R.125 in[R3.2]

1

2

DRUM SHELL

R1.031 in[R26.2]

03

0002

18.6

25 in

[473

.1]

18.8

56 in

[478

.9]

35° 45°

E----

8.500 in[215.9]

1.125 in[28.6]

10.750 in[273.1]

17.125 in[435.0]

R.125 in[R3.2]

1.50

0 in

[38.

1]6.

374

in[1

61.9

]

B----

B----

DRUM SHELL

04

0002

1

2

45°

45°37°

D----

DRUM SHELL

45°

69°

37° 45°

1

2

4.897 in[124.4]

6.625 in[168.3]

10.000 in[254.0]

.864 in[21.9]

3.37

6 in

[85.

7]1.

499

in[3

8.1]

12.0

00 in

[304

.8]

12.0

76 in

[306

.7]

E----

DRUM SHELL

R.125 in[R3.2]

11°

45°

23°

62°

52°10.312 in[261.9]

4.87

5 in

[123

.8]

3.250 in[82.6]

6.500 in[165.1]

1.625 in[41.3]

38° 45°

6.65

7 in

[169

.1]

6.62

5 in

[168

.3]

B----

8.155 in[207.1]

11

0002

E----

09

0003

.375 in[9.5]

2.125 in[54.0]

2.875 in[73.0]

5.375 in[136.5]

1.50

0 in

[38.

1]2.

500

in[6

3.5]10

.000

in[2

54.0

]

10.0

15 in

[254

.4]

45°39°

D----

E----

R.125 in[R3.2]

MANWAY ASSEMBLY (PLAN VIEW)

MANWAY ASSEMBLY (FRONT VIEW)

MANWAY RING

BOLTING PLATEMAT'L : SA-105 OR SA-516 GR 70

COVER PLATEMAT'L : SA-105 OR SA-516 GR 70BOLT DETAIL

DETAILSCALE: 1/2" = 1"

DETAIL SCALE: 1/2" = 1"

DETAIL MAT'L : SA-105 OR SA-516 GR 70

SCALE: 1/2" = 1"

BILL OF MATERIALSMAT'L SPEC.DESCRIPTIONQTY.PART

A-36ROUND BAR, 3/4" (20mm) DIA. x 11 7/8" (301mm) LG.141DETAILPLATE, 5 3/4" (146mm) THK. x 1'-9" (533mm) x 2'-3" (686mm)142SA-105MANWAY RING. SEE DETAIL143DETAILPLATE, 2 1/4" (57mm) THK. x 1'-1 3/8" (340mm) x 1'-9"

(533mm)144A

DETAILPLATE, 2 1/4" (57mm) THK. x 1'-1 3/8" (340mm) x 1'-9" (533mm)

144B

A193-B7SQUARE HEAD BOLT, 1 1/2" DIA. x 1'-7 1/2" (495mm) LG.645A194-2HHEAVY HEX NUT, 1 1/2"-8UN-2B646

F436HARDENED STEEL WASHER, 1 1/2" DIA.647-SHIPPING GASKET (NON-METALLIC)248

A-36PLATE, 1/2" (12mm) THK x 1" (25mm) x 1" (25mm) LG.149A-36PLATE, 3/4" (19mm) THK x 2" (51mm) x 2" (51mm) LG.250A307HEX TAP BOLT, 1/2"-13UNC-2A, 2 3/4" LG., (FULL THREAD)251

DETAILPLATE, 2" (51mm) THK x 3 3/8" (86mm) x 3 13/16" (97mm) 652

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

13551 Triton Park Blvd

Suite 2000

Louisville, Ky. 40223 USA

WWW.VogtPower.com

RevisionsThis drawing contains Vogt Power International's confidential and proprietary information and cannot be used,

duplicated or disclosed in whole or in part, except with the express written permission of Vogt Power International.

EXCEPT AS EXPRESSLY STATED IN ANY WRITTEN CONTRACT - ALL WARRANTIES RELATING TO THIS DRAWING,

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS, ARE DISCLAIMED.

Vogt Power International, Inc. all rights reserved as an unpublished work.

Title

Internal Drawing Status Size Drawing No. Rev.

3RD ANGLE PROJECTION

Scale:

REFERENCE DRAWINGS:

D V17531-SDND-0007

3/16" = 1"

FOR RECORD 01

18' x 24" MANWAY ASSEMBLYFOR HIGH PRESSURE STEAM

DRUM

C

ALABAMA POWER COMPANYBARRY 8 COMBINED CYCLE PROJECT

BUCKS, ALHeat Recovery Steam Generator for

MHPSA

Project

1. MANWAY RING, COVER & BOLT PLATE MAY BE MACHINED USING THE TWO RADII GEOMETRY AS SHOWN OR BY USING TRUE ELLIPTICAL GEOMETRY. EDGES TO BE PRECISELY MACHINED TO REQUIRED DIMENSIONED OVAL SHAPE. EDGE MUST BE SMOOTH AND CONTINUOUS ALL THE WAY AROUND WITH NO WAVINESS, INDENTATIONS, PROTRUSIONS OR VARIATIONS. 2. TOLERANCE OF + OR - 2mm (1/16") UNLESS OTHERWISE NOTED. 3. MACHINED SURFACE SHALL BE COATED WITH RUST INHIBITOR AND SEALING SURFACES TO BE PROTECTED DURING SHIPMENT. 4. INSTALL MANWAY COVER AND INTERNAL & EXTERNAL DAVIT ASSEMBLY AFTER DRUM HAS BEEN POSTWELD HEAT TREATED. 5. ALL WELDS P1-P1 UNLESS OTHERWISE NOTED. 6. QUANTITIES SHOWN ARE FOR (1) ONE MANWAY ASSEMBLY. (2) ASSEMBLIES REQUIRED PER HP DRUM. 7. SEE DRAWING V17531-SDND-0002 FOR ADDITIONAL GENERAL NOTES.

GENERAL NOTES:

V17531-SDND-0002 - 71" I.D. HP STEAM DRUM ASSEMBLYV17531-SDND-0008 - EXTERNAL DAVIT FOR 18" x 24" MANWAY FOR HIGH PRESSURE STEAM DRUMV17531-SDND-0009 - INTERNAL DAVIT FOR 18" x 24" MANWAY FOR HIGH PRESSURE STEAM DRUMV17531-EBND-0251 - MANWAY GASKET INSTALLATION AND BOLTING PROCEDURE

1/2" DIA. 13UNC-2BTHREADED HOLE

PART NUMBERS ARE TO HAVE THE PREFIX OF "SD". FOR EXAMPLE:"41" WOULD BE "SD41"

43----

50----

44----

45----

420----

INTERNAL DAVIT ASSEMBLY(SEE V17531-SDND-0009)

EXTERNAL DAVIT ASSEMBLY(SEE V17531-SDND-0008)

SPRING DISCSTO BE FIELDINSTALLED(SUPPLIED BY VPI)

A----

A----

3" [76]

RE

F.

250125 TO

INSIDE END

STAMP"INSIDE END"

ON O.D.

MACHINE INTERIOR FACE TO 125-250 RMS.NO RADIAL TOOL MARKS ALLOWED.FLAT WITHIN 0.005" TIR.

R18"

[R3]

420----

1'-3

"[3

81]

2'-0" - 132"

0'+

610 - 10+[ ]

438"

[111]

2'-834" - 0'

132"+

832 - 01+[ ]

438"

[111

]

1'-6

"-1

32"

0'+

457

- 10+

[]

2'-2

34"

- 0'

132

"+

679

- 01+

[]

5916

"[1

41] T

YP

434"

[121] TYP

51.5° TYP

R714"

[R184]TYP

R1158"

[R295] TYP

R1'-2916"

[R370] TYP

R1'-61516"

[R481] TYP

2'-3"[686]

533

[1'-9

"]

9716"

[240] TYP.

14"

[6] GAP

18"

[3]

4316"

[106] TYP.

534"

[146

] TY

P.

n8"[n203]

HOLE

n158"

[n41] HOLE TYP.

R834"

[R222]TYP.

R1'-4116"

[R408] TYP.

5916

"[1

41] T

YP

.

434"

[121] TYP.

44A

44B

51.5° TYP.

R834"

[R222] TYP.

R7316"

[R183] TYP.

9716"

[240] TYP.

R1'-4116"

[R408] TYP.

R1'-212"

[R368] TYP.

5916

"[1

41]T

YP

.

434"

[121] TYP.

1'-9

"[5

33]

1'-5

78"

-116

"0'

+

454

- 20+

[]

2'-3"[686]

1'-1178" - 1

16"0'+

606 - 20+[ ]

51.5° TYP.

46° TYP.

4"[1

02]T

YP

.

3 4"

[19]

40[19

16"]

5916

"-1

16"

0'+

141

- 20+

[]

534"

- 0'

116

"+

146

- 02+

[]

MACHINE SURFACETO 125-250 AA.NO RADIAL TOOLMARKS ALLOWEDFLAT WITHIN 0.005" TIR.

20° TYP.

20° TYP.

4316"

[106] TYP.

534"

[146

]TY

P.

6"[1

52]

3"[76]

41

3/16TYP.

51

42

49

48

312"

[89]

MIN

.

1'-7

12"

[495

]

n112"

[n38]

1 1/2-8 UN - 2A

CHAMFER BOLT HEADCORNER 1/8", TYP

3/163/16TYP.

114"

[32]

3/163/16

49

14"

[6]

1"[25]

38"

[10]

1" [25]

116

"-1

32"

0'+

2- 10+ [

]

42

R1"[R25]

2"[51]

2" [51]

1" [25]

34"

[19]

34"

[19]

2" [51]

18"

[3]

45°

18"

[3]

52----

34"

[19]25

16"[59]

1'-138"

[340]

44----

45----

43----

52----

50----

114"

[32]

5/80

45~5/16

(3) SIDES, TYP.

430

0002

250125 TO

31316

"[9

7]

12932

"[4

8]

338"

[86]

258"

[67]

11532"

[37] 118"

[29]

1916

"[4

0]

R2532"

[R20]

R14"

[R6]

01 UPDATED MANWAY ASSEMBLY 16-DEC-20 JP SD MAS00 FIRST ISSUE 8-SEP-20 SL DLN -- MAS

Rev. Description Date Drawn Chkd.1 Chkd.2 Appr.

STAMP TORQUINGSEQUENCE

EXTERNAL DAVIT ASSEMBLY(SEE V17351-SDND-0008)

'

'

'

'

'

'

'

'

DRUM HEAD

43----

MANWAY EXTERNAL DAVIT ASSEMBLY(PLAN VIEW)

MANWAY EXTERNAL DAVIT ASSEMBLY(FRONT VIEW)

BRACKETSCALE: 1/2" = 1"

LUG SCALE: 1/2" = 1"

EYE BOLTSCALE: 1/2" = 1"

DAVIT ARM ASSEMBLY

BILL OF MATERIALSMAT'L SPEC.DESCRIPTIONQTY.PART

A-36BAR, 1 1/2" DIA. x 2'-10 7/16" LG.261A-36PLATE, 1/2" THK. X 2 1/2") O.D. x 1 17/32" I.D. 262A-36PLATE, 1/2" THK. x 3" x 1'-4 7/8" LG.263A-36WELDED EYE BOLT, 3/8" DIA. x 6" LG.264A-36BAR, 3/8" DIA. x 4 5/8" LG.265F436WASHER, 3/8" DIA.266

A194-2HHEAVY HEX NUT, 3/8" DIA.467

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

13551 Triton Park Blvd

Suite 2000

Louisville, Ky. 40223 USA

WWW.VogtPower.com

RevisionsThis drawing contains Vogt Power International's confidential and proprietary information and cannot be used,

duplicated or disclosed in whole or in part, except with the express written permission of Vogt Power International.

EXCEPT AS EXPRESSLY STATED IN ANY WRITTEN CONTRACT - ALL WARRANTIES RELATING TO THIS DRAWING,

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS, ARE DISCLAIMED.

Vogt Power International, Inc. all rights reserved as an unpublished work.

Title

Internal Drawing Status Size Drawing No. Rev.

3RD ANGLE PROJECTION

Scale:

REFERENCE DRAWINGS:

D V17531-SDND-0008

1/4" = 1"

FOR RECORD 01

EXTERNAL DAVIT FOR 18" x 24"MANWAY FOR HIGH PRESSURE

STEAM DRUM

C

ALABAMA POWER COMPANYBARRY 8 COMBINED CYCLE PROJECT

BUCKS, ALHeat Recovery Steam Generator for

MHPSA

Project

1. QUANTITIES LISTED ARE FOR (1) ONE MANWAY ASSEMBLY. (2) TWO ASSEMBLIES REQUIRED PER DRUM. 2. ALL WELDS TO BE P1-P1 UNLESS NOTED OTHERWISE. 3. LOAD ON DAVIT ASSEMBLY NOT TO EXCEED 600 LBS. (272 KG)

V17531-SDND-0007 - 18" x 24" MANWAY ASSEMBLY FOR HIGH PRESSURE STEAM DRUMV17531-SDND-0009 - INTERNAL DAVIT FOR 18" x 24" MANWAY FOJR HIGH PRESSURE STEAM DRUMV17531-EBND-0251 - MANWAY GASKET INSTALLATION AND BOLTING PROCEDURE1

2" (13mm)x 3 3/8" (86mm) LG.SLOTTED HOLE

6

GENERAL NOTES:

64----

65----

610----

63----

14" x 45°

BEVEL TYP.

610----

278"

[73]

MANWAY RING

BOLTINGPLATE

1/41/4

045~

1/4

TYP.

14"

[6]

CL BOLTINGPLATE

I

6"[152]

n3

8"

[n10

]

4"[102] n1

2"[n13]

n114"

[n32]3/8-16 UNC - 2A

34"

[19]

12"

[13]

1316

"[3

0]

158"

[ 41]

n112"

[n38]

1'-478"

[429]

R6"[R152]

1'-6

"[4

57]

738"

[187

]

14"

[6]

7"[178]

62

61

2116"

[53]27

8"[73]

R14"

[R6]

5716"

[138]

534"

[146

]

R34"

[R19]

3" [76]

112"

[38]

3516"

[84] n11732"

[n39]TYP.

512"

[140]51

2"[140]

64----

65----

66

67

1/4TYP.

118"

[29]

63----

63----

PART NUMBERS ARE TO HAVE THE PREFIX OF "SD" FOR EXAMPLE:"61" WOULD BE "SD61"

278"

[73]

63----

65----

610----

64----

67

66

01 UPDATED EXTERNAL DAVIT 16-DEC-20 JP SD MAS00 FIRST ISSUE 8-SEP-20 SL DLN -- MAS

Rev. Description Date Drawn Chkd.1 Chkd.2 Appr.

63----

MANWAY INTERNAL DAVIT ASSEMBLY(PLAN VIEW)

HINGE ASSEMBLY

HINGE SUPPORT ASSEMBLY

MANWAY DOOR HARDWARE ASSEMBLY

DAVIT ARM ASSEMBLY

GUSSET

STIFFENER PLATE

BILL OF MATERIALSMAT'L SPEC.DESCRIPTIONQTY.PART

A-36ROUND BAR, 2 1/4" (57mm) DIA. x 4'-3 11/16" (1313mm) LG.170A-36PLATE, 1/2" (12mm) THK. x 4 3/4" (121mm) O.D. x 2 17/64"

(57.5mm) I.D.171

A-36PLATE, 1/2" (12mm) THK. x 2 3/4" (70mm) x 1'-4 3/4" (425mm) LG.

172

A-36PLATE, 1/2" (12mm) THK. x 4 1/2" (114mm) x 1'-11 1/2" (597mm) LG.

173

F436WASHER, 2 1/4"274A194-2HHEX NUT, 2 1/4"-4 1/2 UNC-2B575

A-36PLATE, 1" (25mm) THK, x 5 7/8" (149mm) x 6 5/16" (160mm) 176A-36PLATE, 1/2" (12mm) THK. x 3 9/16" (90mm) x 4 3/4" (121mm) 277A-36PLATE, 1" (25mm) THK. x 5 7/8" (149mm) x 9 1/4" (235mm)278A-36PLATE, 1/2" (12mm) THK. x 6" (152mm) x 7 1/4" (184mm)279A-36PLATE, 1" (25mm) THK, x 1 3/8" (35mm) x 5 5/8" (143mm) LG. 180A-36BAR, 4 1/2" (114mm) O.D. x 2 17/64" (57.5mm) I.D. x 5 5/8"

(143mm) LG.281

A1011-50SHIM, 1/4" (6mm) THK. x 2 3/8" (60mm) I.D. x 4 3/4" (121mm) O.D.

182

A193-B7HEX BOLT, 2 1/4" DIA x 11" (279mm) LG., 4 1/2 UNC-2A183A-36PLATE, 1" (25mm) THK, x 5 7/8" (149mm) x 6 5/16" (160mm) 184

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

13551 Triton Park Blvd

Suite 2000

Louisville, Ky. 40223 USA

WWW.VogtPower.com

RevisionsThis drawing contains Vogt Power International's confidential and proprietary information and cannot be used,

duplicated or disclosed in whole or in part, except with the express written permission of Vogt Power International.

EXCEPT AS EXPRESSLY STATED IN ANY WRITTEN CONTRACT - ALL WARRANTIES RELATING TO THIS DRAWING,

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS, ARE DISCLAIMED.

Vogt Power International, Inc. all rights reserved as an unpublished work.

Title

Internal Drawing Status Size Drawing No. Rev.

3RD ANGLE PROJECTION

Scale:

REFERENCE DRAWINGS:

D V17531-SDND-0009

3/16" = 1"

FOR RECORD 01

INTERNAL DAVIT FOR 18" x 24"MANWAY FOR HIGH PRESSURE

STEAM DRUM

C

ALABAMA POWER COMPANYBARRY 8 COMBINED CYCLE PROJECT

BUCKS, ALHeat Recovery Steam Generator for

MHPSA

Project

V17531-SDND-0007 - 18" x 24" MANWAY ASSEMBLY FOR HIGH PRESSURE STEAM DRUMV17531-SDND-0008 - EXTERNAL DAVIT FOR 18" x 24" MANWAY FOR HIGH PRESSURE STEAM DRUMV17531-EBND-0251 - MANWAY GASKET INSTALLATION AND BOLTING PROCEDURE

GENERAL NOTES:

1/2

30~3/16

1/2

30~3/16

714----

713----

3/845~

TYP.

712----

HOLE IN PART NO. 76

HOLE IN PART NO. 84

TOP

72----

3/83/8

2 1/4" - 4 1/2 UNC-2A

1/4

73----

711----

1. ALL WELDED JOINTS SHALL RECEIVE PREHEAT IN ACCORDANCE WITH ASME SECTION I PARA. PW-38. POST WELD HEAT TREATMENT SHALL BE IN ACCORDANCE WITH PARA. PW-39. ANY WELDING AFTER PWHT SHALL CONSIDER THE REQUIREMENTS FOR PWHT EXEMPTION AND PREHEAT IN PW-39 AS WELL. 2. QUANTITIES SHOWN ARE FOR (1) ONE MANWAY ASSEMBLY. (2) TWO ASSEMBLIES REQUIRED PER DRUM. 3. LOAD ON DAVIT ASSEMBLY NOT TO EXCEED 900 LBS. (408 KG) 6. ALL WELDS TO BE P1-P1 UNLESS NOTED OTHERWISE.

75

83

74

75

74

1/8 TACK

WELD NUT TO PLATEAFTER DOOR & DAVIT

ARE PLUMB & LEVEL, TYP.

713----

711----

712----

714----

SHOP NOTE:ASSEMBLE ENTIRE INTERNAL DAVIT BEFORE WELDINGHINGE TO DOOR OR DRUM HEAD TO ENSURE THAT DAVIT IS LEVEL AND PLUMB.VERIFY THAT INTERNAL DOOR IS SEATED CORRECTLY INTO MANWAY RING BEFORE WELDING HINGES.

658"

[168] REF.

1/4

CONTOUR ASSEMBLY TO MATCH HEAD ID

AT FIT-UP

578"

[149]

81

81

558"

[143

]

n21764"

[n57.5]

R2"[R51]

714"

[184]

578"

[149

]

21516

"[7

5]

n21764"

[Ø57.5]

6"[1

52]

1" [25]

1" [25]

914"

[235]61

2"[165]

78

79

78

79 79

n412"

[n114]80

3916"

[90]

578"

[149

]21516

"[7

5]

R12"

[R13]

n212"

[n64]

n21764"

[Ø57.5]

6516"

[160]39

16"[90]

434"

[121

]1" [25]

1" [25]

76

84

77

77 77

1045~

TYP.

1'-7"[483]

70

714"

[184

]

1'-5

12"

[445

]

1'-1

18"

[333

]

714"

[184

]

2 1/4" - 4 1/2 UNC-2A

R258"

[R67]

234"

[70]

1'-1112"

[597]

1'-7"[483]

214"

[57]

73----

82

72----

PART NUMBERS ARE TO HAVE THE PREFIX OF "SD" FOR EXAMPLE:"71" WOULD BE "SD71"

71----

n238"

[n60]TYP.

412"

[114

]

214"

[57]

(TOP PLATE)

(BOTTOM PLATE)

1/41/4

R14"

[R6]

338"

[86]

712"

[191

]

TACK WELDNUT TO BOLT

116

"[2

] GA

P

1'-434"

[425]

R112"

[R38]

314"

[83] 38"

[10]

75

R14"

[R6]

01 UPDATED INTERNAL DAVIT 16-DEC-20 JP SD MAS00 FIRST ISSUE 8-SEP-20 SL DLN --- MAS

Rev. Description Date Drawn Chkd.1 Chkd.2 Appr.

713----

714----

712----

711----73

SPRING DISCS TO BE FIELDINSTALLED (SUPPLIED BY VPI)

BOLTING PLATE

MANWAY RING

COVER PLATE

DRUM HEAD

1/4

MANWAY INTERNAL DAVIT ASSEMBLY(INSIDE VIEW)

CL MANWAY ASSEMBLYI

3'-41316"

[1036]3'-8"

[1118]4'-8"

[1422]4'-8"

[1422]4'-8"

[1422]

17'-314"

[5264]2'-117

16"[900]

14'-0"[4267]

14'-0"[4267]

15'-6916"

[4739]15'-69

16"[4739]

19'-334"

[5886]18'-93

4"[5734]

1'-8

" TYP

.[5

08]

1'-6

" TYP

.[4

57]

158" APPROX.

[41]

FRONT VIEW

PLAN VIEW

LEFT

5/16TYP.

SEE NOTE 1

15----

5/16TYP.

SEE NOTE 1

(2) PLACES

OU

TSID

E ED

GE

(REF

.)

SECTIONSCALE : 3/4" = 1'-0" ---

A

TO OF DRUMLC

OUTSIDE EDGE(REF.)

3"[76]

(4) SPACES @ 1'-5" = 5'-8"[1727]

6'-2"[1880]

02 0306

06 05 04 05

LC

3" [76]

6" [152

]

1112"

[292](3) SPACES @ 1'-5" = 4'-3"

[1295]

3 16" T

YP.

[5]

678"

[175

]

1'-1

34"

[349

]

134"

[44]

1516

"[2

4]

1316"

[21]

LC GAGEDRUM SADDLE ASSEMBLY

SCALE : 3/4" = 1'-0" ---100

A----

4'-1

11116

"[1

516]

13 4"

[44]

3'-1"[940]

60° 60°

R3'-514"

[1048]

1/41/4

TYP.

06

05

03

5/165/16

TYP.04

05

01

312" [89] RADIUS

ON CORNERS TYP.

TYP.

06

5/16

5/16

8" [203

]1'-2"[356]

2" TYP.[51]

GRAB BAR DETAILSCALE : 1" = 1'-0" ---

16

1'-2916"

[370]

1'-1116"

[331]

11 2"[3

8]

3" [76]

LADDER SUPPORT DETAILSCALE : 1 1/2" = 1'-0" ---

15

100----

OU

TSID

E ED

GE

(REF

.)

100----

07

LCD

RU

M

LC DRUMN.S. & F.S. 07N.S. & F.S.

102----

RIGHT

16----

15----

(2) PLACES

TYP.

5/16

TYP.SEE NOTE 1& 2

158" APPROX.

[41]

Ø1116"

[17]

102----

103----5/16

5/16

CJP P1-P1TYP.

18

45°

1845°

104----

105----

TYP.(8) PLACES

TYP.(5) PLACES

RIGHT

DETAILSCALE : 1 1/2" = 1'-0" ---

104

DETAILSCALE : 1 1/2" = 1'-0" ---

105

07

07

07

07

LCD

RU

M

LEFTLIFTING LUG DETAIL

SCALE : 1" = 1'-0" ---102

END VIEW

FRONT REAR

CL. PAD

LC DRUM

1'-812"

[521]1'-57

8"[454]

3'-1

01 4"[1

175]

1'-6" INSIDE PLATE[457]

9"[229]

103----

4'-3

"[1

295]

1'-2

"[3

56]

71 2"[1

91]

1'-3"[381]

712"

[191]

Ø378"

[98]

R612"

[165]

1516

"[2

4]

2"[51]

18"

[3]

45°

11

08

TYP.

09

91 16"

[230

]

38"

[10]

1/41/4

TYP.

1/4

71 2"[1

90] 33

4"[9

5]

21 4"[5

7]3" [76]

112"

[38]

3916"

[90]

R3'-514"

[1048]

81316

"[2

24]

91116

"[2

47]

4"[102]

2"[51]

11 2"[3

8]3" [76]

Ø1516" TYP.[24]

1/41/4

TYP.

1'-4

34"

[425

]

1'-1

"[3

30]

STANCHION PIPESCALE : 1" = 1'-0" ---

103

TYP.SEE NOTE 2 12

08

13

3/16

CTR'D ONPIPE

08

10

8 SLOTTED HOLES

GENERAL NOTES:1. P1-P1 ASME SECTION 1 TO NON-PRESSURE ATTACHMENT, 200° F MIN PREHEAT IS REQUIRED IF DRUM HAS BEEN POST WELD HEAT TREATED PRIOR TO WELDING.2. LEAVE A 1" (25mm) LG. GAP OF UNWELDED AREA AT BOTTOM CENTER OF ALL PADS AND STANCHIONS. AS A WEEP HOLE.3. ALL SADDLE COMPONENTS WELDING TO BE IN ACCORDANCE WITH LATEST STANDARDS OF AMERICAN WELDING SOCIETY STANDARD D1.1 USING FEXX=70KSI ELECTRODES.4. QUANTITIES SHOWN FOR ONE (1) UNIT. ONE (1) UNIT REQUIRED TOTAL.

FOR RECORD V17531-SDND-0010 03

HP STEAM DRUMNON-PRESSURE ATTACHMENT

38" = 1'-0"

FIRST ISSUE 11-NOV-20 TA SR MJW MAS

V17531-SDND-0002 - 71" I.D. HIGH PRESSURE STEAM DRUM ASSEMBLY WG-DRM-2550510030-EBND-0101 - STANDARD FAB. TOLERANCE FOR HORIZONTAL VESSELS.

14

45°

104----105

----

LC DRUM

R3'-514"

[1048]

4'-1

11116

"[1

516]

103----

3/16

SEE NOTE 1 & 2TYP. ALL PADS

TO DRUM

3/16

SEE NOTE 1 & 2TYP. ALL PADS

TO DRUM

BILL OF MATERIALPARTNO. QTY DESCRIPTION MAT'L SPEC.

01 2 PLATE, 134" (44mm) x 1'-13

4" x 7'-412"

ROLLED ON 3'-514" I.R. JIS G3101 SS400

02 2 PLATE, 134" (44mm) x 1'-13

4" x 6'-2" JIS G3101 SS400

03 2 PLATE, 5 8" (16mm) x 2'-714" x 5'-73

8" JIS G3101 SS400

04 4 PLATE, 5 8"(16mm) x 638" x 1'-3" JIS G3101 SS400

05 8 PLATE, 5 8" (16mm) x 638" x 1'-63

8" JIS G3101 SS400

06 4 PLATE, 5 8" (16mm) x 1'-1716" x 2'-71

4" JIS G3101 SS400

07 8 PLATE, 12"(12mm) x 1'-0" x 1'-0" LG.ROLLED ON 3'-51

4" I.R. JIS G3101 SS400

08 16 PLATE, 12"(12mm) x 1'-0" x 1'-0" LG.ROLLED ON 3'-51

4" I.R. JIS G3101 SS400

9 8 PLATE, 3 8"(10mm) x 3916" x 71

2" LG. JIS G3101 SS400

10 5 PLATE, 3 8"(10mm) x 4" x 1014" LG. JIS G3101 SS400

11 5 ANGLE, L90 x 90 x 10 x 718" LG. JIS G3101 SS400

12 2 PIPE, 4" SCH.80 x 1'-434" LG. SA-106 GR.B

13 2 PLATE, 3 8"(10mm) x 10" x 10" LG. JIS G3101 SS400

14 2 PLATE, 2" (51mm) x 1'-2" x 1'-3" LG. SA516 Gr.70

15 4 PLATE, 3 8"(10mm) x 3" x 1'-2916" LG. JIS G3101 SS400

16 4 RD. BAR, 3 4"(19mm) DIA. x 2'-414" LG. JIS G3101 SS400

17 1 PIPE, 4" SCH.80 x 1'-918" LG. SA-106 GR.B

18 1 PIPE, 4" SCH.80 x 41116" LG. SA-106 GR.B

19 1 PIPE, 4" SCH.80 x 1'-1118" LG. SA-106 GR.B

20 1 PIPE, 4" SCH.80 x 618" LG. SA-106 GR.B

21 4 PLATE, 3 8"(10mm) x 10" x 10" LG. JIS G3101 SS400

PART NUMBERS ARE TO HAVE THE PREFIX "SD90"FOR EXAMPLE, "01" (PART NUMBER) WOULD BE "SD9001"

02

A

B

C

D

8

Revisions

Vogt Power International, Inc. all rights reserved as an unpublished work.

Title

Internal Drawing Status Size Drawing No. Rev.

3rd ANGLEPROJECTION

Scale:

Appr.DrawnDateDescriptionRev.

D

Chkd.1

Chkd.2

13551 Triton Park BlvdSuite 2000Louisville, Ky. 40223 USAWWW.VogtPower.com

EXCEPT AS EXPRESSLY STATED IN ANY WRITTEN CONTRACT - ALL WARRANTIES RELATING TO THIS DRAWING,INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS, ARE DISCLAIMED.

This drawing contains Vogt Power International's confidential and proprietary information and cannot be used,duplicated or disclosed in whole or in part, except with the express written permission of Vogt Power International.

©

7 6 5 4 3 2 1

8 7 6 5 4 3 2 1

A

B

C

D

00

01

02

03

04

05

Project

REFERENCE DRAWINGS:

ALABAMA POWER COMPANYBARRY 8 COMBINED CYCLE PROJECT

BUCKS, ALHeat Recovery Steam Generator for

MHPSA

30°

30°

30°

30°

CL. PAD

CL. PAD

CL. PAD

GENERAL REVISION 18-MAY-21 TA SD MJW

106A----

3'-1

034"

[118

7]

2'-6"[762]

3'-1

034"

[118

7]

107A----

15'-634"

[4743]6'-47

16"[1942]

106----

106A----

107A----

107----

107A----

STANCHION PIPESCALE : 1" = 1'-0" ---

106

21CTR'D ON

PIPE

TYP.SEE NOTE 2 3/16

1'-2

3 16"

[360

]1'

-91 8"

[537

]

08

R3'-514"

[1048]

21CTR'D ONPIPE

08

STANCHION PIPESCALE : 1" = 1'-0" ---

107

TYP.SEE NOTE 2 3/16

41116

"[1

18]

41 2"[1

15]

17

18

COPE 12" [13]

1'-1

11 8"[5

87] 1'

-31 16

"[3

83]

21CTR'D ONPIPE

TYP.SEE NOTE 23/16

08

19

4916"

[116]713 16"

[199]

CONTOURPAD TODRUM SHELL

BENT PLATE

R3'-514"

[1048]

107----

61 8"[1

55]

41 2"[1

15]

08

20

21CTR'D ONPIPE

STANCHION PIPESCALE : 1" = 1'-0" ---

107A

TYP.SEE NOTE 23/16

STANCHION PIPESCALE : 1" = 1'-0" ---

106A

R3'-514"

[1048]

R3'-514"

[1048]

112"

[38]

PLATE DETAILSCALE : 1" = 1'-0" ---

21

10"[254]

10"

[254

]11 8"

TYP

.[2

9]

118" TYP.[29]

Ø1516" TYP.[24]

5" [127

]

CONTOURPAD TODRUM SHELL

18°

MAS

Ø1516" TYP.[24]

HOLE DIAMETER CHANGE 3-JUN-21 SD MJW MAS

44°

61°65°

33°

ADDED ANGULAR DIMENSIONS 14-JUN-21 SD MJW MAS

A

B

C

D

8

Revisions

Vogt Power International, Inc. all rights reserved as an unpublished work.

Title

Internal Drawing Status Size Drawing No. Rev.

3rd ANGLEPROJECTION

Scale:

Appr.DrawnDateDescriptionRev.

D

Chkd.1

Chkd.2

13551 Triton Park BlvdSuite 2000Louisville, Ky. 40223 USAWWW.VogtPower.com

EXCEPT AS EXPRESSLY STATED IN ANY WRITTEN CONTRACT - ALL WARRANTIES RELATING TO THIS DRAWING,INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS, ARE DISCLAIMED.

This drawing contains Vogt Power International's confidential and proprietary information and cannot be used,duplicated or disclosed in whole or in part, except with the express written permission of Vogt Power International.

©

7 6 5 4 3 2 1

8 7 6 5 4 3 2 1

A

B

C

D

00

01

02

03

04

05

Project

REFERENCE DRAWINGS:

ALABAMA POWER COMPANYBARRY 8 COMBINED CYCLE PROJECT

BUCKS, ALHeat Recovery Steam Generator for

MHPSA

71" I.D. HP DRUM INTERNALSECTION "A"

1" = 1'-0"

FOR RECORD V17531-HIND-0001 00

FIRST ISSUE 05-MAR-21 JP DLN DP MAS

V17531-HIND-0002 - 71" I.D. HP DRUM INTERNAL SECTIONS "B", "C" & "D"V17531-HIND-0003 & 0004 - 71" I.D. HP DRUM INTERNAL SUB-ASSEMBLIES & DETAILSV17531-HIND-0005 - 71" I.D. HP DRUM INTERNAL DETAILSV17531-ICND-0006 THRU 0008 - 71" I.D. HP DRUM INTERNAL SUB-ASSEMBLIES & DETAILS

1. FOR "BOM" SEE DWG V17531-HIND-0002.

2. PART NUMBERS IN ARE ITEM NUMBERS LISTED IN BILL OF MATERIALS.

3. PART NUMBERS IN ARE ASSEMBLIES OR ITEMS LOCATED ON DRAWINGS V17531-HIND-0003 THRU 0008 (RESPECTIVE BOM'S INCLUDED).

4. DESIGN INFORMATION: - MAXIMUM CAPACITY (STEAM FLOW): 1,567,859 LBS/HR.

5. DRUM IS TO BE WEIGHED PRIOR TO SHIPMENT & WEIGHT PAINTED ON DRUM IN 3" (76mm) TALL NUMBERS.

6. ALL NON-PRESSURE ATTACHMENT WELDS TO BE PER ASME SECTION 1.

7. ALL WELDS TO BE P1-P1 UNLESS NOTED OTHERWISE.

8. ALL CARBON STEEL PLATE TO BE A36 OR EQUAL.

9. ALL BOLTING TO BE SNUG TIGHT PLUS 14 TURN.

10. QUANTITIES SHOWN ARE FOR ONE (1) UNIT, ONE (1) UNIT REQUIRED TOTAL.

GENERAL NOTES:

NORMAL LEVEL +7.0"

PRE-ALARM LOW LEVEL +4.0"LOW ALARM LEVEL +1.0"

STARTUP LEVEL -9.0"

LOWEST LEVEL -27.5"

PRE-ALARM HIGH LEVEL +10.0"

HIGH ALARM LEVEL +12.0"HIGHEST LEVEL +14.0"

DETAILSCALE: 6" = 1'-0" ----

E

BAFFLE PLATE

TIE BAR TOSUPPORT PLATE

ASSEMBLY 3/163/16

TIE BAR

SUPPORT PLATEASSEMBLY

316

G

BAFFLE PLATETO TIE BAR

TIE BAR TOSUPPORT PLATE

ASSEMBLY

SECTION0002

A

DETAILTYPICAL BAFFLE BORESCOPE

INSPECTION PORTSCALE: 3" = 1'-0"

----101

TYP.1/8 SEAL

B0002

C0002

3/8

75°

5010004

DRUM CENTER LINE 0"

D0002

3/16 SEAL3/16 1-6

TYP.

3/16 SEAL3/16 1-6

TYP.

600005

3/16 SEALTYP.

3010003

FRONT REAR

15

31 32

33

2728

20

22

21

250006

6020006

6010006

230006

30240006

0004502 501

00040004502

0003302

000561

6000050005

61

630005 0005

64

16

650005 0005

66

6300050005

64

6500050005

66

670005 0005

68

6900050005

70000571

000572

000573

000574

1516

1516

16 15

5110004

15 16

51516"

[151]

263020003

0004512

3 16"

[5]

58"

OVE

R L

AP[1

7]11 2"[3

8]

101----

12

3/163/16 TYP. MID PLATE

TO DRUM

3010003

TYP.1/8

11

13

14

3/16 SEAL3/16 1-6 TYP. END PLATE

TO DRUM

45°

45°

DISTRIBUTIONHOLES

DISTRIBUTIONHOLES

DRAINHOLES

3/163/16

TYP. 1/8 1TYP.

1'-7

9 16"

[497

]

MID SUPPORTPLATE

LC DRUM

LCD

RU

M

DETAIL----F PIPING DETAIL

CONTINUOUS BLOWDOWN PIPE,ASPIRATED PIPES & LOWER LEVEL

TRANS. CONN. PIPES

CONTINUOUS BLOWDOWN,LOWER LEVEL TRANS. CONN. PIPE(SEE PIPING DETAIL)

35

34

(8) PLACES

(8) PLACES

FITTING TOBAFFLE3/16 SEAL

17 16"

[37]

09A

0507A

08A

07B09B

08B

PERFORATED PLATEBOLTING DETAIL

(SIDE VIEW SHOWN)

0006601

000625

0006602

0006603

19

21

26

2027 21

CONTINUOUSBLOWDOWN

LOWER LEVEL GAUGECONNECTIONLOWER LEVEL TRANS.

CONNECTION75

0003

760003

800003

810003

3030003

29

712"

[190]

1'-5

38"

[442

]

1'-538"

[442]

9" REF.[228]

06

DISTRIBUTIONHOLES

TYP.3/16

3/16

E----

TRIM ALL U-BOLTS TO APPROX.1

4" EXPOSED THREADS ANDREMOVE ALL BURRS ANDSHARP EDGES

F----

316

TYP. SUPORT TOSUPPORT

30°

6 58"[168]

2'-0

"[6

11]

63 8" REF.

[162]

0007123

0008223

0007124

0008224

0007125

0008225

0007702

0008802

6030006 0007

7030008803

LEFT SIDE

0008802

RIGHT SIDE

0007702

(3X)

0007703

(3X)LEFT SIDE

0008803RIGHT SIDE

1'-6"

[457]

FIRST ISSUE JP MAS05-MAR-21

FOR RECORD V17531-HIND-0002

DLN DP

71" I.D. HP DRUM INTERNAL

SECTIONS "B", "C" & "D"

V17531-HIND-0001 - 71" I.D. HP DRUM INTERNAL SECTION "A"

V17531-HIND-0003 & 0004 - 71" I.D. HP DRUM INTERNAL

SUB-ASSEMBLIES & DETAILS

V17531-HIND-0005 -71" I.D. HP DRUM INTERNAL DETAILS

V17531-ICND-0006 THRU 0008 - 71" I.D. HP DRUM INTERNAL

SUB-ASSEMBLIES & DETAILS

01

NOTES:

1. FOR GENERAL NOTES, SEE DRAWING V17531-HIND-0001.

2. PART NUMBERS 26, 27, 28, 29, 30, 31, 32 & 33 ARE SUPPLIED BY

VOGT POWER AND INSTALLED BY DRUM VENDOR.

3. QUANTITIES SHOWN ARE FOR ONE (1) UNIT.

ONE (1) UNIT REQUIRED TOTAL.

3

8

" = 1'-0"

0001

A

13

SECTION

VIEW ROTATED 90° CCW

0001

B

L

C

DR

UM

A

B

C

D

8

Revisions

Vogt Power International, Inc. all rights reserved as an unpublished work.

Title

Internal Drawing Status Size Drawing No. Rev.

3rd ANGLE

PROJECTION

Scale:

Appr.DrawnDateDescriptionRev.

D

Chkd.

1

Chkd.

2

13551 Triton Park Blvd

Suite 2000

Louisville, Ky. 40223 USA

WWW.VogtPower.com

EXCEPT AS EXPRESSLY STATED IN ANY WRITTEN CONTRACT - ALL WARRANTIES RELATING TO THIS DRAWING,

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS, ARE DISCLAIMED.

This drawing contains Vogt Power International's confidential and proprietary information and cannot be used,

duplicated or disclosed in whole or in part, except with the express written permission of Vogt Power International.

©

7 6 5 4 3 2 1

8 7 6 5 4 3 2 1

A

B

C

D

00

01

02

03

04

05

Project

REFERENCE DRAWINGS:

ALABAMA POWER COMPANY

BARRY 8 COMBINED CYCLE PROJECT

BUCKS, AL

Heat Recovery Steam Generator for

MHPSA

14111214

5'-9"

[1753]

8'-4"

[2540]

5'-9"

[1753]

050507A07A 07A 07A 08A 09A08A

08B

09B

0005

82

0005

82

0005

82

04

10

0005

83

0003

301

0003

81

0003

81

0003

81

0003

81

0003

80

0003

80

0003

80

0003

302

07B 07B

07B

07B

08B

09B

LEFTRIGHT

0003

75

0003

76

L

C

PLA

TE

L

C

PLA

TE

L

C

PLA

TE

0003

75

0003

76

0003

75

0003

76

0003

75

0003

76

0003

303

0003

303

EN

D O

F P

IP

E

L

C

PLA

TE

L

C

PL

AT

E

0003

301

0003

302

0003

302

0003

301

0003

302

0003

302

0003

301

0005

83

0003

80

0003

302

0003

301

0003

301

0003

302

0003

302

0003

301

8'-4"

[2540]

5'-3"

[1600]

5'-3"

[1600]

6'-5"

[1956]

7'-6"

[2286]

7'-6"

[2286]

7'-6"

[2286]

10'-4"

[3149]

10'-4"

[3149]

10'-2"

[3098]

5'-3"

[1600]

5'-3"

[1600]

L

C

PL

AT

E

L

C

PLA

TE

C PLATE

L

L

C

PLA

TE

C PLATE

L

LEFTRIGHT

RIGHTLEFT

26

1'-2

1

2

"

[368]

1'-2

1

2

"

[368]

6'-0"

[1829]

6'-0"

[1829]

4'-0"

[1219]

4'-0"

[1219]

6'-0"

[1829]

6'-0"

[1829]

0008

803

0005

60

(2X)

(4X)

(2X)

0005

60

(2X)

0006

601

0005

60

(2X)

0004

502

0005

63

(2X)

0005

64

0005

63

(2X)

0005

64

0005

65

(2X)

0005

66

0005

68

0005

67

(2X)

0005

65

(2X)

0005

68

0004

502

0004

501

(2X)

0004

501

(2X)

0005

63

(2X)

0005

65

(2X)

0005

64

L

C

PL

AT

E

L

C

PL

AT

E

0005

67

(2X)

0005

66

L

C

PL

AT

E

L

C

PL

AT

E

L

C

PL

AT

E

1'-2

1

2

"

[368]

1'-2

1

2

"

[368]

6'-0"

[1829]

6'-0"

[1829]

4'-0"

[1219]

4'-0"

[1219]

6'-0"

[1829]

6'-0"

[1829]

L

C

PL

AT

E

L

C

PL

AT

E

L

C

PL

AT

E

L

C

PL

AT

E

0005

66

0005

63

(2X)

0005

65

(2X)

0005

66

0005

64

0005

69

0005

70

0005

71

0005

73

0005

74

0005

72

0004

511

SINGLE POT ASSEMBLY

SHOWN IN PHANTOM

31 32 33

SHOWN IN PHANTOM

FOR EACH POT, TYP.

0004

502

0004

511

SINGLE POT ASSEMBLY

SHOWN IN PHANTOM

31 32 33

SHOWN IN PHANTOM

FOR EACH POT, TYP.

0004

512

DOUBLE POT ASSEMBLY

SHOWN IN PHANTOM

(10X)

BILL OF MATERIAL

PART # QTY. DESCRIPTION MAT'L SPEC.

04 2FITTING, 10" SCH. 40 CAP

A-234 WPB

05 2FITTING, 2

1

2

" 3000#, THD TEEA-105

06 3FITTING, 1" 3000#, 45° THD ELBOW

A-105

07A 4

1

2

" x 2

1

2

" U-BOLT W/ 4 NUTS C.S.

07B 4

1

4

" x 1" U-BOLT W/ 4 NUTS C.S.

08A 32

LIN. FT., PIPE, 2

1

2

" SCH. 40 (0.203"

WALL), CUT & THREAD AS REQUIRED

A-106 Gr.B

08B 4

LIN. FT., PIPE, 1" SCH. 40 (0.133"

WALL), CUT & THREAD AS REQUIRED

A-106 Gr.B

09A 1FITTING, 2

1

2

" 3000#, 90° THD ELBOWA-105

09B 2FITTING, 1" 3000#, 90° THD ELBOW

A-105

10 1FITTING, 1" 3000#, THD TEE

A-105

11 1

PIPE, 14" SCH. 40 (0.437" WALL), 5

5

8

"

LG

A-106 Gr.B

12 1FITTING, 14" SCH. 40 L.R., 45° ELBOW

A-234 WPB

13 1FITTING, 14" SCH. 40, TEE

A-234 WPB

14 2

FITTING, 14" SCH. 40 x 10" SCH. 40

ECCENTRIC REDUCER

A-234 WPB

15 14BAR,

3

8

" x 1

1

2

" x 3'-11" LGA-36

16 28BAR,

3

8

" x 1

1

2

" x 5'-11" LGA-36

19 316BOLT,

1

2

" DIA. x 1" LGA-193 B7

20 156STUD BOLT,

1

2

" DIA. x 4" LGA-193 B7

21 1182NUT,

1

2

" DIA. HEXA-194 2H

22 78STUD BOLT,

1

2

" DIA. x 9" LGA-193 B7

26 2

FINAL SCRUBBER LOWER END PLATE

(12-4204)

A-36

27 78

FINAL SCRUBBER "L" SHAPE (12-4201)

A-36

28 78

FINAL SCRUBBER "S" SHAPE (12-4200)

A-36

29 5

FINAL SCRUBBER DRAIN (12-4248-04)

C.S.

30 78

10" FINAL SCRUBBER (12-4244-04)

A-36

31 84

SEPARATOR SCRUBBER BOX ASSY.

(12-4247-09)

A-36

32 84

VORTEX DRYER SCRUBBER ASSY.

(12-4246-04)

A-36

33 84

VORTEX DRYER PYRAMID

(12-4182-01)

A-36

34 8

FITTING, 3", 3000# THRD HALF

COUPLING

A-105

35 8

FITTING, 3", 3000# THRD SQUARE

HEAD PLUG

A-105

PART NUMBERS TO HAVE PREFIX "HI". FOR EXAMPLE, "04" WOULD

BE "HI04"

0606

30

(78X)

151616

1616 15 151616

1516 16

08A

08A 08A 08A

0005

82

0004

82

0004

82

SECTION

0001

C

SECTION

0001

D

0003

303

0003

303

0004

501

(2X)

0004

501

(2X)

0004

512

DOUBLE POT ASSEMBLY

SHOWN IN PHANTOM

(10X)

0004

502

0004

512

DOUBLE POT ASSEMBLY

SHOWN IN PHANTOM

(10X)

0004

511

SINGLE POT ASSEMBLY

SHOWN IN PHANTOM

0004

512

DOUBLE POT ASSEMBLY

SHOWN IN PHANTOM

(10X)

0004

511

SINGLE POT ASSEMBLY

SHOWN IN PHANTOM

0005

60

(2X)

0007

703

29

29

39'-0

1

4

" INSIDE

[11894] PLATES

G

TOP BAFFLE

TO TOP BAFFLE,

TYP.

16'-10

1

4

"

[5137]

08B

04

0007

703

0006

603

29

0007

703

29

29

C

ON

TIN

UO

US

B

LO

WD

OW

N

F

EE

DW

AT

ER

IN

LE

T

LE

VE

L T

RA

NS

MIT

TE

R

LE

VE

L T

RA

NS

MIT

TE

R

10" REF.

[254]

LE

VE

L T

RA

NS

MIT

TE

R

CORRECTED SECTION C & D SD MAS29-MAY-21 DLN

L

C

PL

AT

E

L

C

PL

AT

E

L

C

PL

AT

E

L

C

PL

AT

E

L

C

PL

AT

E

L

C

PL

AT

E

A

B

C

D

8

Revisions

Vogt Power International, Inc. all rights reserved as an unpublished work.

Title

Internal Drawing Status Size Drawing No. Rev.

3rd ANGLEPROJECTION

Scale:

Appr.DrawnDateDescriptionRev.

D

Chkd.1

Chkd.2

13551 Triton Park BlvdSuite 2000Louisville, Ky. 40223 USAWWW.VogtPower.com

EXCEPT AS EXPRESSLY STATED IN ANY WRITTEN CONTRACT - ALL WARRANTIES RELATING TO THIS DRAWING,INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS, ARE DISCLAIMED.

This drawing contains Vogt Power International's confidential and proprietary information and cannot be used,duplicated or disclosed in whole or in part, except with the express written permission of Vogt Power International.

©

7 6 5 4 3 2 1

8 7 6 5 4 3 2 1

A

B

C

D

00

01

02

03

04

05

Project

REFERENCE DRAWINGS:

ALABAMA POWER COMPANYBARRY 8 COMBINED CYCLE PROJECT

BUCKS, ALHeat Recovery Steam Generator for

MHPSA

71" I.D. HP DRUM INTERNALSUB-ASSEMBLIES & DETAILS

1" = 1'-0"

FOR RECORD V17531-HIND-0003 00

FIRST ISSUE 05-MAR-21 JP DLN DP MAS

V17531-HIND-0001 - 71" I.D. HP DRUM INTERNAL SECTION "A"V17531-HIND-0002 - 71" I.D. HP DRUM INTERNAL SECTIONS "B", "C" & "D"

END SUPPORTPLATE ASSEMBLY

(8) REQUIRED 0001,0002

301

3/16 SEAL3/16 1-3

10" PIPE SUPPORTSCALE: 3" = 1'-0" 0001,

0002

76

----36

85

TACK 1/2 - 2

TYP. EXPANDED METAL TOEXPANDED METAL AND TOVORTEX BREAKER PLATES

LC DRUM

BEND UP 15°

134"

[44]

23 16"

[56]

3 14 "

[83]

7 916"[192]

C TIE BAR

LCD

RU

M1"

[25]12"

[13]

LC DRUMLCD

RU

M

LC DRUMLCD

RU

M

LC DRUMLCD

RU

M1'-3

1 2"[3

93]

1'-9

"[5

33]

2'-7

"[7

87]

2'-5"[737]

2'-218"

[664]

1'-4

1 8"[4

10]

812"

[215]

R2'-1112"

[902]

1" x 45° CHAMFER

SUPPORT PLATE----36

3/16 1-33/16 1-3

----37

134"

[44]

23 16"

[56]

3 14 "

[83]

7 916"[192]

C TIE BARL L

1"[25]1

2"[13]

----38

R2'-1112"

[902]

3" [76]

1'-3

1 2"[3

93]

1'-5

1 2"[4

45]

3"[76]

1 12 "[38]

1'-4

1 8"[4

10]

2'-7

"[7

87]

812"

[215]

3"[76]

112"

[38]

212" TYP.[64]

R1" TYP.[25]

MID SUPPORTPLATE ASSEMBLY

(8) REQUIRED 0001,0002

302 SUPPORT PLATE----37

FORMED VIEW

1'-7

3 16"

[488

]2'

-61 16

"[7

63]

4'-4

78"

[134

3]

BEND UP 35°

BEND UP 40°

5'-1

3 16"

[155

4]

SUPPORT BAR DETAIL----38

3" [76]

3" [76]

2'-218"

[664]

2'-5"[737]

1'-9

"[5

33]

45 16"

[110

] TRIM TOFIT DRUM

LCD

RU

M

VORTEX BREAKERASSEMBLY

(2) REQUIRED 0001,0002

303

SEE DETAIL "G"

NOZZLE ODREF.

3/163/16VORTEX BREAKER

TO NOZZLE.THIS LOCATION ONLY

45°

LCD

RU

M

DETAILSCALE: 1 1/2" = 1'-0" ----

G

----86

----87

3/16 23/16 2

TOP ONLY

BOTTOM ONLY3/16 23/16 2

958"

[244]

1'-714"

[489]

1'-3

"[3

81]

516"[8]

112"

[38]1'-41

4"[413]

3" [76]

71 2"[1

91]

958"

[244]

1'-714"

[489]

1'-3

"[3

81]

516"[8]

112"

[38]1'-41

4"[413]

3" [76]

71 2"[1

91]

VORTEX BREAKER PLATESCALE: 1 1/2" = 1'-0" ----

86 VORTEX BREAKER PLATESCALE: 1 1/2" = 1'-0" ----

87

2 1/2" PIPE SUPPORTSCALE: 3" = 1'-0" 0001,

0002

80

Ø516" (2X)

[8]

1" [25]

8" [203

]

3"[76]

158"

[41]

118"

[29]

214"

[57]

9" [229

]

2"[51]

1316

"[2

1]37 16

"[8

7]

118"

[29]

214"

[57]

R34" TYP.[19]

Ø916" (2X)

[14]

1" PIPE SUPPORTSCALE: 3" = 1'-0" 0001,

0002

81 10" PIPE SUPPORTSCALE: 3" = 1'-0" 0001,

0002

75

R5716"

[138]

R12" TYP.[13]

R5716"

[138]

5" [127

]

1"[25]

1078"

[276]

30° TYP.

3" TYP.[76]

6"[152]

1'-0"[305]

11 2" TY

P.[3

8]

81 8" T

YP.

[206

]10

34"

TYP

.[2

73]

BILL OF MATERIALPART # QTY. DESCRIPTION MAT'L SPEC.

36 8 PLATE, 316" (5mm) THK., (SEE DETAIL) A-36

37 8 PLATE, 316" (5mm) THK., (SEE DETAIL) A-36

38 8 BAR, 3 8" (10mm) x 1" (25mm) x 5'-1 316"(1554mm) LG. A-36

75 4SHEET, 10 GA. (3mm) THK. x 1" (25mm)x 2'-3 14" (692mm) LG. 1011 CS

76 4 PLATE, 14" (6mm) THK., (SEE DETAIL) A36

80 4 PLATE, 14" (6mm) THK., (SEE DETAIL) A36

81 4 PLATE, 14" (6mm) THK., (SEE DETAIL) A36

84 2EXPANDED METAL, 16 GA (1.5mm)THK., 12" (13mm) FLATTEND x 1'-7 14"(489mm) DIA.

C.S.

85 2EXPANDED METAL, 16 GA (1.5mm)THK., 12" (13mm) FLATTENED x 4 12"(114mm) x 5'-0 12" (1537mm)

C.S.

86 2 PLATE, 14" (6mm) THK., (SEE DETAIL) A36

87 2 PLATE, 14" (6mm) THK., (SEE DETAIL) A36

PART NUMBERS TO HAVE PREFIX "HI". FOR EXAMPLE, "36" WOULDBE "HI36"

84

NOTES:

1. FOR GENERAL NOTES, SEE DRAWING V17531-HIND-0001.2. QUANTITIES SHOWN ARE FOR ONE (1) UNIT. ONE (1) UNIT REQUIRED TOTAL.

50°

32°

C TIE BARL C TIE BARL----38

R34" TYP.[19]

FIRST ISSUE JP MAS05-MAR-21

FOR RECORD V17531-HIND-0004

DLN DP

71" I.D. HP DRUM INTERNAL

SUB-ASSEMBLIES & DETAILS

01

NOTES:

1. FOR GENERAL NOTES, SEE DRAWING V17531-HIND-0001.

2. PART NUMBERS 40, 41, 42 & 43 ARE SUPPLIED BY VOGT

POWER AND INSTALLED BY DRUM VENDOR.

3. QUANTITIES SHOWN ARE FOR ONE (1) UNIT.

ONE (1) UNIT REQUIRED TOTAL.

1 1/2" = 1'-0"

A

B

C

D

8

Revisions