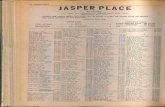

ISMR BLASTER RETRAINING Workshop Jasper, Indiana December 07, 2009 Jasper Inn & Convention Center.

-

Upload

jacob-mason -

Category

Documents

-

view

219 -

download

1

Transcript of ISMR BLASTER RETRAINING Workshop Jasper, Indiana December 07, 2009 Jasper Inn & Convention Center.

ISMRISMRBLASTER RETRAININGBLASTER RETRAINING

WorkshopWorkshop

• Jasper, Indiana

• December 07, 2009

• Jasper Inn & Convention Center

FLYROCKFLYROCK

&&

“ “ PREVENTION”PREVENTION”

Dennis Clark, PEDennis Clark, PE

Mining EngineerMining Engineer

OSMRE – KFOOSMRE – KFO

Number One Rule of BlastingNumber One Rule of BlastingALL BLASTING SHALL be ALL BLASTING SHALL be

CONDUCTED to PREVENT:CONDUCTED to PREVENT:

• Injury to Persons

• Damage to Public or Private Property

• Throw off the Permit/Blasting Site

Adverse Effects of Fly-rockAdverse Effects of Fly-rock

• Increases the Area of Disturbance On & Off the Permit

• Endangers Employees and Equipment

• Physical Damage to Private Property

• Endangers Humans and Livestock

• Can Result in Death – Flyrock Kills!

Tools to Assist in Fly-rock Tools to Assist in Fly-rock Investigations Investigations

• Blast Hole Drill Logs for each Hole • Blast Report or Log:

1) with Diagrams of how Holes are Loaded 2) the Site Specific Drill & Blast Pattern

• On Site Investigation• Eye-Witness Accounts• Instrumentation & Monitoring Data

Before “Blasting” You Drill the HolesBefore “Blasting” You Drill the HolesWhat is Going on Here?What is Going on Here?

Drill Log – ExampleDrill Log – ExampleA Requirement Prior to LoadingA Requirement Prior to Loading

AAlso log any rock type changeslso log any rock type changes

HOLE

Number

HOLE

Depth

LOOSE

Material

in feet

Depth to SOLID

Contact

SEAMS

&

CRACKS

CAVITIES

Location

in feet

Location of Soft Formation

In feet

Depth to

WATER

1 42' 0-2 3' -- -- -- 38'

2 44' 0 0 -- 22-24 -- -- 3 43' 0-4 5' -- -- 20-25 36'

4 41' 0-2 3' 33' -- -- -- 5 42' 0-1 2' -- -- -- 40'

BLAST REPORT or LOGBLAST REPORT or LOG• Location of Blast• Date & Time• Drill & Blast Pattern • Explosives & Delays used• Max. Pounds/8ms Delay• Location of Closest “House”• Distance & Direction to “”• Compliance Method Data• Assure Accuracy Of Blast

Log Information• Any Blast Log Discrepancies

will require additional in-depth investigations

• Every Blank Space of the REPORT should be Filled

Flyrock per 816.67(c)Flyrock per 816.67(c)Rock cast from blasting site via the air or Rock cast from blasting site via the air or

along the groundalong the ground

• Rock traveled > ½ distance to nearest dwelling

• Beyond the area of control

• Beyond the permit boundary

PROJECTED ROCK-CAST RANGESPROJECTED ROCK-CAST RANGES

• Blaster projects expected rock-cast range & determines security zone (area of control)

• Flyrock is any throw outside the security zone, within the permit and always outside the permitted site.

Throw Distances for Varying Size Throw Distances for Varying Size Rock (Spherical in Meters)Rock (Spherical in Meters)

for a Given Hole Diameterfor a Given Hole Diameter

Swedish Rule-of ThumbSwedish Rule-of ThumbBlasting of Dense RockBlasting of Dense Rock

• Maximum Fly-rock Range 100 meter distance for every

centimeter of Bore-Hole-Diameter

• Example in English System5 inch Blast-Hole-DiameterMaximum Throw = 4,128 feet

• Note: Less Dense Rocks will not Travel as Far!!!

Common Optimum Fly-rock DistancesCommon Optimum Fly-rock DistancesFor a 8 Inch Diameter Blast Hole For a 8 Inch Diameter Blast Hole

Sandstone: 6,000 ft.

Sandstone/Shale 5,000 ft.

Limestone: 6,200 ft.

Shale: 4,100 ft.

Decomposed Rock: 6,700 ft.

Bedded Clay: 2,100 ft.

Examples of Flyrock Travel DistancesExamples of Flyrock Travel DistancesState of Virginia/State of Virginia/Pit & Quarry 1991Pit & Quarry 1991

• Rock Distance PFLS 3,063 ft. 0.45LS 1,159 ft. 0.90LS 4.057 ft. ~1.70LS 5,050 ft. 0.70LS 4,057 ft. -------LS 6,292 ft. -------Trap Rock 828 ft. 0.68Taconite 11,360 ft. 1.20Porphyry 2,119 ft. -------Sandstone 1,987 ft. 0.53

Material Displacement via Material Displacement via AirAir GroundGround

• Primary Cause due to “Blast Confinement”

• Conventional throw from within the permit

• Material propelled by “Explosive Energy”

• Primary Cause due to “Blast Site Location”

• Common along permit boundaries

• Material propelled by “Gravity”

Points to Consider when Blasting Points to Consider when Blasting Adjacent to Permit BoundariesAdjacent to Permit Boundaries

• Displaced material has tendency to “roll” downhill &/or bounce off the permit

• Any & all “throw” has the opportunity to land or roll off the permit

• Occurrence can result even if all “Rules-of-Thumb” are observed

• Prevention requires pre-planning & thoughtfulness prior to drilling & Loading

Primary Reasons for Material Off the Primary Reasons for Material Off the PermitPermit

• Material displaced by design – the movement toward the ‘vertical free face’ by the intended use of explosive energy

• Material displaced by the adverse reaction of explosive energy - back break & swell, vibration plus unintended movement toward a natural slope or vertical outcrop

Corrective Actions When Blasting Corrective Actions When Blasting Adjacent to Permit BoundariesAdjacent to Permit Boundaries

By Blast Design @ Drilling & Loading By Blast Design @ Drilling & Loading

• Orient ‘Blast Pattern’ to ensure multi-free-face movement

• Reduce ‘Loading Densities’ in front rows of holes

• Decrease # of rows so throw from rear is lessened

• Modify ‘Drill Hole Pattern’ to facilitate a proper ‘Blast Pattern’

• Ensure proper Timing• Decrease # of rows of

holes to be loaded• Reduce ‘Loading

Densities’ in rear rows

Conventional FlyrockConventional Flyrock

• Results from available ‘Explosive Energy’ far exceeding the competency and inherit strength of overburden material being blasted

• Flyrock is not from the Hole-Collar or Stemming ejection

• Flyrock is from material adjacent to the explosive• Therefore You Require Confinement in terms of

Burden & Confinement via the Stemming

Examples of the Effects of ConfinementExamples of the Effects of ConfinementBased on Military Cratering UsageBased on Military Cratering Usage

CONFINEMENT = PERFORMANCECONFINEMENT = PERFORMANCE

All Results in Blasting Performance are All Results in Blasting Performance are Due to the Degree of Confinement, Due to the Degree of Confinement,

Based on the Columns of the Blasting Based on the Columns of the Blasting Product being Utilized for a Given Product being Utilized for a Given

Overburden MaterialOverburden Material

Bell Curve Showing Bell Curve Showing EfficiencyEfficiency of of Explosive YieldExplosive Yield & &

Blast ConfinementBlast Confinement

BURDENBURDEN is the DETERMINING FACTOR for is the DETERMINING FACTOR for

all OTHER BLAST DIMENSIONSall OTHER BLAST DIMENSIONS

BURDEN & STEMMINGBURDEN & STEMMINGDEFINEDEFINE

CONFINEMENTCONFINEMENT

Seismographs Provide Data onSeismographs Provide Data onGround Motion Over Pressure Ground Motion Over Pressure

• Real Blast Detonation Time a

check on Total Delay Time• PPV depends on Max. Lbs

per Delay & Distance, a check on # Holes/Delay Interval

• Over-Confinement yields Higher than Normal PPV

• Under-Confinement results in Lower than Normal PPV

• Assist in Determining Distance to Seismograph

• Higher than expected dBs? Confinement Concerns

• Over-Confinement results in Rifling, Cratering & Throw from Back Rows

• Under-Confinement results in Flyrock well beyond the Area of Control

TWO PRINCIPLES MUST BE KEPT IN TWO PRINCIPLES MUST BE KEPT IN MIND DURING THE DESIGN PROCESSMIND DURING THE DESIGN PROCESS

• Explosives Function Best When There is a Free Face Approximately Parallel to the Explosives Column at the Times of Detonations

• There Must be Adequate Space into Which the Broken Rock can Move and Expand

THE USBM (IC-8550 & 8925) Presented Principles by THE USBM (IC-8550 & 8925) Presented Principles by Dr. Richard Ash of “Mo. School of Mines” Dr. Richard Ash of “Mo. School of Mines”

““Rules of ThumbRules of Thumb Based on Based on TwoTwo Major Points” Major Points”

1: 1: Rock Density Rock Density is the Basis for the is the Basis for the Amount of Amount of ExplosivesExplosives Required to Break a Given Required to Break a Given Volume of Volume of

RockRock

2: Blast Designs for 2: Blast Designs for Harder Rock Require Closer Harder Rock Require Closer Control & Tighter Tolerance Control & Tighter Tolerance Than Those for Than Those for

Softer RockSofter Rock

General Causes of Flyrock General Causes of Flyrock

• Blasthole Overloading• Inadequate Burden @ Face• Excessive Burden @ Face• Loose Material in Front of Free Face • Excessive Burden Between Rows • ‘Multiple’ Row Blasts (> 5 Rows)• Inadequate Timing Between Rows• Excessive Powder Factor• Adverse Geology

For a Solution to the Flyrock For a Solution to the Flyrock Problem!Problem!

The Following is a MUST The Following is a MUST • Anticipated Blast Designs & Blasting Plans

Certified Blaster in Charge Prior to Loading - Review Drill Logs Explosives & Stemming Placed in Competent Rock

Prior to Loading check & Double check Best Management Practices for all Blasting Scenarios must be Used

What is What is COMPETENT ROCKCOMPETENT ROCK

• Competent Rock is rock that is of sufficient hardness and integrity that it Requires Explosive Energy to break into fragments to muck

• Therefore: One places not only the Explosive in Competent Rock, but also the Stemming that retains the energy

• If not, Cratering & Throw is Guaranteed !

Use When Non-Competent Rock is at the Collar of Use When Non-Competent Rock is at the Collar of the Blast Holethe Blast Hole

Adjust for Rock Type & ExplosivesAdjust for Rock Type & Explosives

Summary: Rule-of-Thumb for BurdenSummary: Rule-of-Thumb for BurdenFor First ApproximationsFor First Approximations

Typical OverburdenTypical Overburden

• Low Density Blasting Agents & Typical Rock: – Burden in ft. = 2.5 x Hole Diameter– 20 ft. of Burden for a 8 inch Hole

• Emulsions & Typical Rock:– Burden in ft. = 3 x Hole Diameter– 24 ft. of Burden for a 8 inch Hole

Rule-of-Thumb for BurdenRule-of-Thumb for BurdenContinuedContinued

• Low Density Blasting Agents in

– Weak Shale: Burden = ≥ 2.5 Hole Diameters– 22 ft. to 24 ft. of Burden for a 8 inch Hole

– Cap Rock: Burden = ≤ 2.5 Hole Diameters– 16 ft. to 18 ft. of Burden for a 8 inch Hole

Rule-of Thumb for BurdenRule-of Thumb for BurdenContinuedContinued

• Emulsions in

– Weak Shale: Burden = ≥ 3 Hole Diameters– 26 ft. to 28 ft. of Burden for a 8 inch Hole

– Cap Rock: Burden = ≤ 3 Hole Diameters– 20 ft. to 22 ft. of Burden for a 8 inch Hole

Summary: Rules-of-Thumb for StemmingSummary: Rules-of-Thumb for StemmingIn Competent Rock Where Flyrock Must be PreventedIn Competent Rock Where Flyrock Must be Prevented

• To prevent Violence stemming should vary from 14 to 28 times the B.H.D.

Example: for a 10″ dia. hole the range by the ‘blast design rules-of-thumb’ is between 0.5 to 1.0 the B. Typically 0.7 x 25 ft. = 18 feet

Using the ratios above: stemming = 14' to 28′

Additional stemming is required in competent rock when the rock sonic velocity exceeds detonation velocities or where rock is fractured or a less dense material like a shale overburden

SHORT CASE HISTORYSHORT CASE HISTORYWhen Things Go Wrong – Every Thing Goes WrongWhen Things Go Wrong – Every Thing Goes Wrong

• One Innocent Victim– Wrong Place @ the Wrong Time

• One Blaster Not Following Good Practice– Not Present– Not Communicative– Not Observant

– Not Performing per Regulations

Post-Blast High-wall Geology Post-Blast High-wall Geology

Site Conditions Prior to BlastSite Conditions Prior to Blast

Varying Geology Row by RowVarying Geology Row by RowHole by HoleHole by Hole

RESULTS: Craters & Fly-rockRESULTS: Craters & Fly-rock

SUMMARY of ERRORSSUMMARY of ERRORS

• Did not Observe Changes in Geology Visible in High-wall Faces

• Did not have Drill-Logs Available• Did not Know that Each & Every Hole Encountered a

Varying Thickness of or Type of Overburden• Did not Vary Loading Parameters Based on Varying

Material• Did not Change Stemming Lengths to Compensate for

Overburden Strengths• Did not Change Timing Between Rows to Ensure

Movement to a Free-Face (‘Rock’ Reaction Time)