IS 13573-2 (2011): Cable Accessories for Extruded Power ...Part 1 For working voltages from 1.1 kV...

Transcript of IS 13573-2 (2011): Cable Accessories for Extruded Power ...Part 1 For working voltages from 1.1 kV...

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to information for citizens to secure access to information under the control of public authorities, in order to promote transparency and accountability in the working of every public authority, and whereas the attached publication of the Bureau of Indian Standards is of particular interest to the public, particularly disadvantaged communities and those engaged in the pursuit of education and knowledge, the attached public safety standard is made available to promote the timely dissemination of this information in an accurate manner to the public.

इंटरनेट मानक

“!ान $ एक न' भारत का +नम-ण”Satyanarayan Gangaram Pitroda

“Invent a New India Using Knowledge”

“प0रा1 को छोड न' 5 तरफ”Jawaharlal Nehru

“Step Out From the Old to the New”

“जान1 का अ+धकार, जी1 का अ+धकार”Mazdoor Kisan Shakti Sangathan

“The Right to Information, The Right to Live”

“!ान एक ऐसा खजाना > जो कभी च0राया नहB जा सकता है”Bhartṛhari—Nītiśatakam

“Knowledge is such a treasure which cannot be stolen”

“Invent a New India Using Knowledge”

है”ह”ह

IS 13573-2 (2011): Cable Accessories for Extruded PowerCables, Part 2: for Working Voltages for 3.3kV(UE) upto andIncluding 33kV(E) - Test Requirements [ETD 9: Power Cables]

© BIS 2011

B U R E A U O F I N D I A N S T A N D A R D SMANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

December 2011 Price Group 7

IS 13573 (Part 2) : 2011

Hkkjrh; ekud

,DlVª wMsM ikoj ds cy ds fy, ds cylgk;dkax — fof'kf"V

Hkkx 2 3.3 fd ok ¼;w bZ½ vkSj 33 fd ok ¼bZ½ rd dh jsfVroksYVst — ijh{k.k i)fr;k¡

(igyk iqujh{k.k )

Indian Standard

CABLE ACCESSORIES FOR EXTRUDEDPOWER CABLES — SPECIFICATIONPART 2 FOR WORKING VOLTAGES FROM 3.3 kV(UE)

UP TO AND INCLUDING 33 kV(E) — TEST REQUIREMENTS

(First Revision)

ICS 29.060.20 ; 29.120.99

Power Cables Sectional Committee, ETD 09

FOREWORD

This Indian Standard (Part 2) (First Revision) was adopted by the Bureau of Indian Standards, after the draftfinalized by the Power Cables Sectional Committee had been approved by the Electrotechnical Division Council.

There are different methods followed for joints and terminations and the basic technique depends on the voltagerating of the power cable for which the accessories needs to be installed.

This standard was first published as IS 13573 : 1992 ‘Joints and terminations of polymeric cables for workingvoltages from 6.6 kV up to and including 33 kV — Performance requirements and type tests’. This revision hasbeen undertaken to bring it in line with international practices. It has been split up into three parts. Other parts inthe series are:

Part 1 For working voltages from 1.1 kV up to and including 3.3 kV(E) — Test methods and test requirementsPart 3 For working voltages from 3.3 kV(UE) up to and including 33 kV(E) — Test methods

The cable joints/terminations should normally have same electrical and thermal characteristics as the cable forwhich these are intended. As such this standard is to be used in conjunction with the following relevant IndianStandards:

IS No. Title

1554 (Part 2) : 1988 PVC insulated (heavy duty) electric cables: Part 2 For working voltages from 3.3 kVup to and including 11 kV (second revision)

7098 (Part 2) : 1985 Crosslinked polyethylene insulated PVC sheathed cables: Part 2 For working voltagesfrom 3.3 kV up to and including 33 kV (first revision)

9968 (Part 2) : 1985 Elastomer insulated cables: Part 2 For working voltages from 3.3 kV up to andincluding 11 kV

In the formulation of this standard assistance has been derived from IEC 60502-4 : 2005 ‘Power cables withextruded insulation and their accessories for rated voltages from 1kV(Um = 1.2 kV) up to 30 kV(Um = 36 kV) —Part 4: Test requirements on accessories for cables with rated voltages from 6 kV (Um = 7.2 kV) up to 30 kV(Um

= 36 kV)’.

This standard does not cover performance requirements of joints and terminations for paper insulated powercables and transition joints.

The joints and terminations of power cables are normally made at site. For practical reasons, this standard isconfined to type tests only. For tests at site, reference may be made to IS 1255 : 1983 ‘Code of practice forinstallation and maintenance of power cables up to and including 33 kV rating (third revision)’.

For the purpose of deciding whether a particular requirement of this standard is complied with, the final value,observed or calculated, expressing the result of a test or analysis, shall be rounded off in accordance with IS 2 : 1960‘Rules for rounding off numerical values (revised)’. The number of significant places retained in the rounded offvalue should be the same as that of the specified value in this standard.

1

IS 13573 (Part 2) : 2011

Indian Standard

CABLE ACCESSORIES FOR EXTRUDEDPOWER CABLES — SPECIFICATIONPART 2 FOR WORKING VOLTAGES FROM 3.3 kV(UE)

UP TO AND INCLUDING 33 kV(E) — TEST REQUIREMENTS

(First Revision)

1 SCOPE

This standard (Part 2) covers the performancerequirements and type tests for joints (straight jointsand branch joints), terminations, screened andunscreened separable terminations and stop ends forall designs of screened solid di-electric power cablesfor voltage grade from 3.3 kV (UE) up to and including33 kV (E).

This standard does not apply to transition joints fordissimilar cables.

It is not necessary to repeat these tests, oncesuccessfully completed, unless changes are made inthe materials, design or manufacturing process whichmight affect the performance characteristics.

2 REFERENCES

The following standards contain provisions, whichthrough reference in this text constitutes provision ofthis standard. At the time of publication, the editionindicated were valid. All standards are subject torevision and parties to agreements based on thisstandard are encouraged to investigate the possibilityof applying the most recent edition of the standardsindicated below:

IS No. Title

1885 (Part 32) : Electrotechnical vocabulary: Part 321993 Electric cables

13573 (Part 3) : Cable accessories for extruded power2011 cables — Specification: Part 3 For

working voltages from 3.3 kV (UE)up to and including 33 kV (E) — Testmethods

3 TERMINOLOGY

For the purpose of this standard, the definitions givenin IS 1885 (Part 32) and the following shall apply.

3.1 Type Test — Tests carried out to prove conformitywith the standard. These are intended to prove the

general qualities and design of a particular type of jointand/or termination.

4 TEST SPECIMENS

4.1 The test specimens shall be made out of cableswhich meet the relevant standards given in 2.

4.2 The test specimen shall be made in the testinglaboratory by using the materials prescribed and inaccordance with the instructions of joint/terminationkit (system) supplied by the manufacturer. Theaccessories kit shall be of the same nominal voltage asthe cable sample.

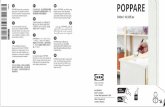

4.3 Number of joints and terminations shall be as perthe applicable test sequence (see Fig. 1 to 5).

4.4 The test specimen shall be made out of cables ofany of the following nominal cross-sections:

120 mm2 or 150 mm2 or 185 mm2 or 240 mm2

4.4.1 The cable of nominal cross-section of 240 mm2

and above shall be used for dynamic short circuit.

4.4.2 Approval of a range of conductor cross-sectionalareas from 95 mm2 to 400 mm2 of one type of accessoryfor both range taking and non range taking shall beobtained by successfully completing the full range oftype tests of this standard as listed in Tables 2 to 6 on aconductor cross-sectional area of 120 mm2 to 240 mm2.Extension of approval to a range wider than that givenabove shall be achieved by carrying out the additionaltests listed in Table 7 on the smallest and/or largestconductor cross-sectional areas of the required range.

Approval of a range of conductor cross-sectional areasfor a separable connector shall be obtained bysuccessfully completing the full range of type tests ofthis standard, as listed in the Tables 5 and 6, on aconductor cross-sectional area as indicated in Table 1.In addition, the type tests listed in Table 7 shall besuccessfully completed on the smallest and/or largestconductor cross-sectional areas in the range.

2

IS 13573 (Part 2) : 2011

Approval is independent of the cable conductormaterial. Tests may therefore be carried out usingcables with either aluminium or copper conductors.

4.4.3 Test performed on three core accessories shallbe deemed to cover single core accessories of the samedesign. The converse shall not apply.

4.4.4 The details of the cable used for testing as givenin Annex A are to be furnished in the test report.

4.5 The length of the test specimen between testingterminal shall not be less than 8 m. The length betweenthe joints and terminations shall not be less than 2 mand the distance between joints shall not be less than2 m.

4.5.1 For thermal/dynamic short circuit test a identicalcable of length not less than 2 m is to be connected inseries to the sample under test for ascertaining thetemperature of the conductor at the end of short circuit.Any damage on the dummy cable should not berecorded in the test report.

4.5.2 Tests under Sl No. (xiii) and (xiv) of Table 2 maybe performed on an additional test specimen whichhave not been previously subjected to other tests.

4.6 Marking and Labelling

All the kits are to be suitably labelled for identificationpurpose with the following details:

a) Manufacturers name or logo and the name ofthe component, wherever feasible;

b) Product reference to be indicated on the kit;

c) Manufacturing date and expiry date (ifapplicable) to be indicated on the kit; and

d) Safety marking and handling instructions,wherever relevant to be indicated.

Inside the packing following shall be given:

a) List of contents, and

b) Installation instructions including drawings orother information specific to the accessories.

5 TESTS AND EVALUATION

5.1 Type tests and their sequence with test conditionsand evaluation criteria shall be as per relevant tablesspecified in Tables 2 to 6.

5.2 If an accessory fails to meet the requirements due toeither installation or test procedure errors, the test shallbe declared void without discrediting the accessories.

The complete test sequence shall be repeated on a newset of samples.

If there is no evidence of such error, the type ofaccessory is not approved.

If a cable fails beyond any part of an accessory, thetest shall be declared void without discrediting theaccessories. Test may be repeated using newaccessories (start testing from the beginning of the testsequence) or alternatively by repair of the cable(continue testing from the point of break).

The summary of the tests is given in Table 9.

The summary of test voltages and requirements is givenin Table 10.

Sampling procedures shall be as per Figs. 1 to 5.

5.3 Optional Tests

Special tests to be carried out, when required, byagreement between the purchaser and the supplier.

6 TEST ON CRITICAL COMPONENTS USEDIN JOINTS AND TERMINATIONS

The following components form an additional kit (otherthan the kits used for installation on cable) are requiredto be tested for following tests and test results to berecorded. The manufacturer should submit theguaranteed technical particulars for the items to betested prior to taken up for testing along with theacceptable range for particular product to be typetested:

Sl No.

Name of the Component Tensile Strength

Ultimate Elongation

Di-electric Strength

Volume Resistivity

Permitiviy Resistivity/ Conductivity/

Resistance

Tracking and

Erosion

i) Insulating material X X X X — — — ii) Stress control material X X — X X — —

iii) Anti-tracking material X X X X — — X iv) Conductive material:

a) Metallic: lugs/ferrules and earthing connection

b) Non-metallic

—

X

—

X

—

—

—

X

—

—

X

—

—

—

3

IS 13573 (Part 2) : 2011

1)T

he c

able

len

gths

mea

sure

d be

twee

n th

e ca

ble

inle

t po

ints

of

the

acce

ssor

ies

shou

ld b

e >

2m

.2)

1.2

may

be

com

bine

d w

ith

1.3.

For

sin

gle-

core

acc

esso

ries

, 1.

2 m

ay b

e ca

rrie

d ou

t on

sep

arat

e lo

ops.

The

cab

le a

nd a

cces

sori

es c

lam

ping

met

hod

and

the

spac

ing

betw

een

acce

ssor

ies

shal

l be

as

reco

mm

ende

d by

the

man

ufac

ture

r.

NO

TE

S

1 S

ampl

e de

note

s th

e ac

cess

orie

s un

der

test

.

2 S

ee T

able

2.

FIG

. 1 T

ES

T A

RR

AN

GE

ME

NT

S A

ND

NU

MB

ER

OF S

AM

PL

ES F

OR

TE

RM

INA

TIO

NS

4

IS 13573 (Part 2) : 2011

1)T

he c

able

len

gths

mea

sure

d be

twee

n th

e ca

ble

inle

t po

ints

of

the

acce

ssor

ies

shou

ld b

e >

2m

.2)Te

stin

g of

join

ts in

sep

arat

e lo

ops

is p

erm

itte

d.3)2.

2 m

ay b

e co

mbi

ned

wit

h 2.

3. F

or s

ingl

e-co

re a

cces

sori

es,

2.2

may

be

carr

ied

out

on s

epar

ate

loop

s. T

he c

able

and

acc

esso

ries

cla

mpi

ng m

etho

d an

d th

e sp

acin

g be

twee

n ac

cess

orie

s sh

all

be a

sre

com

men

ded

by t

he m

anuf

actu

rer.

NO

TE

S

1 S

ampl

e de

note

s th

e ac

cess

orie

s un

der

test

.

2 S

ee T

able

3.

FIG

. 2 T

ES

T A

RR

AN

GE

ME

NT

S A

ND

NU

MB

ER

OF S

AM

PL

ES F

OR S

TR

AIG

HT O

R B

RA

NC

H J

OIN

TS

5

IS 13573 (Part 2) : 2011

1) T

he c

able

len

gths

mea

sure

d be

twee

n th

e ca

ble

inle

t po

ints

of

the

acce

ssor

ies

shou

ld b

e >

2m

.

NO

TE

S

1 Sam

ple

deno

tes

the

acce

ssor

ies

unde

r te

st.

2 S

ee T

able

4.

FIG

. 3 T

ES

T A

RR

AN

GE

ME

NT

S A

ND

NU

MB

ER O

F S

AM

PL

ES F

OR S

TO

P E

ND

S

6

IS 13573 (Part 2) : 2011

1) T

he c

able

len

gths

mea

sure

d be

twee

n th

e ca

ble

inle

t po

ints

of

the

acce

ssor

ies

shou

ld b

e >

2m

.2)

4.2

may

be

carr

ied

out

on s

epar

ate

loop

s or

com

bine

d w

ith

4.3.

The

cab

le a

nd a

cces

sori

es c

lam

ping

met

hod

and

the

spac

ing

betw

een

acce

ssor

ies

shal

l be

as

reco

mm

ende

d by

the

man

ufac

ture

r.

NO

TE

S

1 S

ampl

e de

note

s th

e ac

cess

orie

s un

der

test

.

2 S

ee T

able

5.

FIG

. 4 T

ES

T A

RR

AN

GE

ME

NT

S A

ND

NU

MB

ER

OF S

AM

PL

ES F

OR

SC

RE

EN

ED

DE

AD

BR

EA

K S

EPA

RA

BL

E C

ON

NE

CT

OR

S

7

IS 13573 (Part 2) : 2011

1) T

he c

able

len

gths

mea

sure

d be

twee

n th

e ca

ble

inle

t po

ints

of

the

acce

ssor

ies

shou

ld b

e >

2m

.2)

5.2

may

be

carr

ied

out

on s

epar

ate

loop

s or

com

bine

d w

ith

5.3.

The

cab

le a

nd a

cces

sori

es c

lam

ping

met

hod

and

the

spac

ing

betw

een

acce

ssor

ies

shal

l be

as

reco

mm

ende

d by

the

man

ufac

ture

r.

NO

TE

S

1 S

ampl

e de

note

s th

e ac

cess

orie

s un

der

test

.

2 S

ee T

able

6.

FIG

. 5 T

ES

T A

RR

AN

GE

ME

NT

S A

ND

NU

MB

ER O

F S

AM

PL

ES F

OR

UN

SC

RE

EN

ED

DE

AD

BR

EA

K S

EPA

RA

BL

E C

ON

NE

CT

OR

S

8

IS 13573 (Part 2) : 2011

Table 1 Cable Cross-Section for Testing of Separable Connectors(Clause 4.4.2)

Cable Cross-Section mm2

Sl No. Rating

A

Cu Al (1) (2) (3) (4)

i) 200/250 50 70 ii) 400 95 150 iii) 600/630 185 300 iv) 800 300 400 v) 1 250 500 630

NOTE — The current value should be sufficient to achieve the specified conductor temperature [see 9.1 of IS 13573 (Part 3)].

Table 2 Test Sequences and Requirements for Terminations(Clauses 4.4.2, 4.5.2, 5.1; and Fig. 1)

Sl No. Test1) Requirements Test Methods as per IS 13573

(Part 3)

Test Sequences (See Fig. 1)

1.1 1.2 1.3 1.4 1.5 (1) (2) (3) (4) (5) (6) (7) (8) (9)

i) Conductor resistance — 4.1 X X X X X

ii) a) a.c. or d.c. voltage

b) a.c. (wet)

a) a.c. for 5 min at 4.5 U0 or d.c. for 15 min at 4 U0

b) 1 min at 4 U0 2)

4.2 or 5

4.2

X

X

X

—

X

—

—

—

—

—

iii) Partial discharge 10 pC Max at 1.73 U0 7 X — — — —

iv) Impulse at θt3) 10 impulses of each polarity 6 X — — — —

v) Heating cycles in air 60 cycles4) at θt3) and 2.5 U0 9.1 and 9.2 X — — — —

vi) Partial discharge at θt3),5)

and ambient temperature 10 pC Max at 1.73 U0 7 X — — — —

vii) Thermal short circuit (screen)6)

Two short circuits at Isc of the cable screen. No visible deterioration

10 — X X7) — —

viii) Thermal short circuit (conductor)

Two short circuits to raise conductor to θsc of the cable. No visible deterioration

11 — X X7) — —

ix) Dynamic short circuit8) One short circuit at Id. No visible deterioration 12 — — X7) — —

x) Impulse 10 impulses of each polarity 6 X X X — —

xi) a.c. voltage 15 min at 2.5 U0 4.2 X X X — —

xii) Humidity 9),10) 300 h at 1.25 U0 13 — — — X

xiii) Salt fog 2),10) 1 000 h at 1.25 U0 13 — — — X

xiv) Examination For information only11) — X X X X X

1) Unless otherwise specified, tests shall be carried out at ambient temperature. 2) For outdoor terminations only. 3) θt is the maximum cable conductor temperature in normal operation +5°C to + 10°C. 4) 8 h total with ≥ 2 h steady and ≥ 3 h cooling. 5) Measurement is made at the end of the heating period. 6) This test is only required for terminations that are equipped with a connection to, or adaptor for, the metallic screen of the cable. 7) Thermal short circuit may be combined with the dynamic short circuit. 8) Only required for single core cable accessories designed for initial peak currents ip > 80 kA and three core accessories designed for

ip > 63 kA. Value of id shall be declared by the manufacturer. 9) For indoor terminations only. Not required for compound filled terminal boxes. Shrouded terminations shall be tested in a three phase

condition. 10) Not required for terminations having porcelain insulators. 11) It is advised that the accessory is examined for signs of any of the following:

a) Cracking in the filling media and/or tape or tube components; and/or b) A moisture path across a primary seal; and/or c) Corrosion and/or tracking and/or erosion which would, in time, lead to failure of the accessory; and/or d) Leakage of any insulating material.

9

IS 13573 (Part 2) : 2011

Table 3 Test Sequences and Requirements for Straight or Branch Joints(Clauses 4.4.2, 5.1; and Fig. 2)

Sl No.

Test1) Requirements Test Methods as per IS 13573

(Part 3)

Test Sequences (See Fig. 2)

2.1 2.2 2.3 (1) (2) (3) (4) (5) (6) (7)

i) Conductor resistance — 4.1 X X X

ii) a.c. withstand or d.c. withstand a.c. for 5 min at 4.5 U0 or d.c. for 15 min at 4 U0 4.2 or 5 X X X

iii) Partial discharge 10 pC Max at 1.73 U0 7 X — —

iv) Impulse at θt2) 10 impulses of each polarity 6 X — —

v) Heating cycles in air 30 cycles3) at θt2) and 2.5 U0 9 X — —

vi) Heating cycles under water 30 cycles3) at θt2) and 2.5 U0 9 X — —

vii) Partial discharge at θt2),4) and

ambient temperature 10 pC Max at 1.73 U0 7 X — —

viii) Thermal short circuit (screen) Two short circuits at Isc of the cable screen. No visible deterioration

10 — X X5)

ix) Thermal short circuit (conductor) Two short circuits to raise conductor to θsc of the cable. No visible deterioration

11 — X X5)

x) Dynamic short circuit6) One short circuit at Id. No visible deterioration 12 — — X

xi) Impulse 10 impulses of each polarity 6 X X X

xii) a.c. Voltage 15 min at 2.5 U0 4.2 X X X

xiii) Examination For information only7) — X X X

1) Unless otherwise specified, tests shall be carried out at ambient temperature. 2) θt is the maximum cable conductor temperature in normal operation from +5°C to + 10°C. 3) 8 h total with > 2 h steady and > 3 h cooling. 4) Measurement is made at the end of the heating period. 5) Thermal short circuit may be combined with the dynamic short circuit. 6) Only required for single core cable accessories designed for initial peak currents ip > 80 kA and three core accessories designed for

ip > 63 kA. Value of id shall be declared by the manufacturer. 7) It is advised that the accessory is examined for signs of any of the following:

a) Cracking in the filling media and/or tape or tube components; and/or b) A moisture path across a primary seal; and/or c) Corrosion and/or tracking and/or erosion which would, in time, lead to failure of the accessory; and/or d) Leakage of any insulating material.

Table 4 Test Sequence and Requirements for Stop Ends(Clauses 4.4.2, 5.1; and Fig. 3)

Sl No. Test1) Requirements Test Methods as per IS 13573 (Part 3)

Test Sequences (See Fig. 3)

(1) (2) (3) (4) (5)

i) a.c. or d.c. voltage a.c. for 5 min at 4.5 U0 or d.c. for 15 min at 4 U0 3.1, 4.2 or 5 X ii) Partial discharge 10 pC Max at 1.73 U0 7 X

iii) Impulse 10 impulses of each polarity 6 X iv) a.c. voltage 500 h at 2.5 U0 4.2 X v) Partial discharge 10 pC Max at 1.73 U0 7 X

vi) Impulse 10 pC Max at 1.73 U0 6 X vii) a.c. voltage 15 min at 2.5 U0 4.2 X

viii) Examination For information only2) — X

1) Unless otherwise specified, tests shall be carried out at ambient temperature. 2) It is advised that the accessory is examined for signs of any of the following:

a) Cracking in the filling media and/or tape or tube components; and/or b) A moisture path across a primary seal; and/or c) Corrosion and/or tracking and/or erosion which would, in time, lead to failure of the accessory; and/or d) Leakage of any insulating material.

10

IS 13573 (Part 2) : 2011

Table 5 Test Sequences and Requirements for Screened Deadbreak Separable Connectors(Clauses 4.4.2, 5.1; and Fig. 4)

Sl No.

Test1) Requirements Test Methods as per IS 13573

(Part 3)

Test Sequences (See Fig. 4)

4.1 4.2 4.3 4.4 (1) (2) (3) (4) (5) (6) (7) (8)

i) a.c. or d.c. voltage a.c. for 5 min at 4.5 U0 or d.c. for 15 min at 4 U0 4.2 or 5 X X X —

ii) Partial discharge 10 pC Max at 1.73 U0 7 X — — —

iii) Impulse at θt2) 10 impulses of each polarity 6 X — — —

iv) Thermal short-circuit (screen)5)

Two short circuits at Isc of the cable screen. No visible deterioration

10 — X X6) —

v) Thermal short-circuit (conductor)

Two short circuits to raise conductor to θsc of the cable. No visible deterioration

11 — X X6) —

vi) Dynamic short circuit7) One short circuit at Id. No visible deterioration 12 — — X — vii) Heating cycles in air 30 cycles3) at θt

2) and 2.5 U011) 9 X — — —

viii) Heating cycles under water 30 cycles3) at θt2) and 2.5 U0

11) 9 X — — —

ix) Disconnect/Connect8) Five times. No visible damage to contact — X X X —

x) Partial discharge at θt2),4) and

ambient temperature 10 pC Max at 1.73 U0 7 X — — —

xi) Impulse 10 impulses of each polarity 6 X X X —

xii) a.c. voltage 15 min at 2.5 U0 4.2 X X X —

xiii) Operating eye Axial force 1 300 N for 1 min, torque 14 Nm 19 — — — X

xiv) Partial discharge 10 pC Max at 1.73 U0 7 — — — X xv) Examination For information only12) — X X X X

xvi) Screen resistance9) 5 000 Ω Max 15

xvii) Screen leakage current9) 0.5 mA at Um Max 16

xviii) Fault current initiation 10) 17

xix) Operating force Force <900 N 18

xx) Capacitive test point

a) Capacitance of test point to cable conductor:

Ctc > 1.0 pF

b) Ratio of capacitance of test point to earth Cte and capacitance of test point to cable conductor Ctc

Cte / Ctc < 12.0

20

Tests xvi) to xx) are carried out on separate samples

For tests xvi) to xix), no cable is required

For tests xvii), xviii) and xx), appropriate cable lengths are to be used

—

1) Unless otherwise specified, tests shall be carried out at ambient temperature. 2) θt is the maximum cable conductor temperature in normal operation from +5°C to + 10°C. 3) 8 h total with > 2 h steady and > 3 h cooling. 4) Measurement is made at the end of the heating period. 5) This test applies only to separable connectors that are equipped with a connection to, or adaptor for, the metallic screen of the cable. 6) Thermal short circuit may be combined with dynamic short circuit. 7) Only required for single core cable accessories designed for initial peak currents ip > 80 kA and three core accessories designed for

ip > 63 kA. Value of id shall be declared by the manufacturer. 8) This test shall be carried out only when the cable is de-energized. 9) This test is required for separable connectors without a metallic housing or with a removable metallic housing. The metallic housing

shall be removed prior to the test. This test is not required for separable connectors which can only be used in service with the metallic housing in position.

10) For solidly earthed system, the fault initiation shall occur within 3 s. For unearthed or impedance earthed systems, the fault current shall flow continuously.

11) Current, see Table 1. 12) It is advised that the accessory is examined for signs of any of the following:

a) Cracking in the filling media and/or tape or tube components; and/or b) A moisture path across a primary seal; and/or c) Corrosion and/or tracking and/or erosion which would, in time, lead to failure of the accessory; and/or d) Leakage of any insulating material.

11

IS 13573 (Part 2) : 2011

Table 6 Test Sequences and Requirements for Unscreened Separable Connectors(Excluding Shrouded Terminations)

(Clauses 4.4.2, 5.1; and Fig. 5)

Sl No.

Test1) Requirements Test Methods as per IS 13573

(Part 3 )

Test Sequences (See Fig. 5)

5.1 5.2 5.3 5.4 (1) (2) (3) (4) (5) (6) (7) (8)

i) a.c. or d.c. voltage a.c. for 5 min at 4.5 U0 or d.c. for 15 min at 4 U0 4.2 or 5 X X X —

ii) Partial discharge 10 pC Max at 1.73 U0 7 X — — —

iii) Impulse at θt2) 10 impulses of each polarity 6 X — — —

iv) Thermal short-circuit (screen)5) Two short circuits at Isc of the cable screen. No visible deterioration

10 — X X6) —

v) Thermal short-circuit (conductor) Two short circuits to raise conductor to θsc of the cable. No visible deterioration

11 — X X6) —

vi) Dynamic short circuit7) One short circuit at Id. No visible deterioration 12 — — X —

vii) Heating cycles in air 30 cycles3) at θt2) and 2.5 U0 9 X — — —

viii) Heating cycles under water 30 cycles3) at θt2) and 2.5 U0 9 X — — —

ix) Disconnect/Connect8) Five times. No visible damage to contact — X X X —

x) Partial discharge at θt2), 4) and

ambient temperature 10 pC Max at 1.73 U0 7 X — — —

xi) Impulse 10 impulses of each polarity 6 X X X —

xii) a.c. voltage 15 min at 2.5 U0 4.2 X X X —

xiii) Humidity9) 300 h at 1.25 U0 13 — — — X

xiv) Examination For information only10) — X X X X

1) Unless otherwise specified, tests shall be carried out at ambient temperature. 2) θt is the maximum cable conductor temperature in normal operation from +5°C to + 10°C. 3) h total with ≥ 2 h steady and ≥ 3 h cooling. 4) Measurement is made at the end of the heating period. 5) This test applies only to separable connectors that are equipped with a connection to, or adaptor for, the metallic screen of the cable. 6) Thermal short circuit may be combined with dynamic short circuit. 7) Only required for single core cable accessories designed for initial peak currents ip > 80 kA and three core accessories designed for

ip > 63 kA. Value of id shall be declared by the manufacturer. 8) This test shall be carried out only when the cable is de-energized. 9) Test to be carried out with three samples in a test terminal box.

10) It is advised that the accessory is examined for signs of any of the following: a) Cracking in the filling media and/or tape or tube components; and/or b) A moisture path across a primary seal; and/or c) Corrosion and/or tracking and/or erosion which would, in time, lead to failure of the accessory; and/or d) Leakage of any insulating material.

Table 7 Additional Tests for Smallest and Largest Conductor Cross-Sectional Areas(Clause 4.4.2; and Fig. 1, 2 and 3)

Sl No.

Test1) Requirements Test Methods as per IS 13573 (Part 3)

Test Sequences (See Fig. 1, 2 and 3)

1.12) 2.13) 3.14) (1) (2) (3) (4) (5) (6) (7)

i) a.c. or d.c. voltage a.c. for 5 min at 4.5 U0 or d.c. for 15 min at 4 U0 4.2 or 5 X X X ii) Partial discharge 10 pC Max at 1.73 U0 7 X X X

iii) Impulse 10 impulses of each polarity 6 X X X iv) Examination For information only5) — X X X

1) Unless otherwise specified, tests shall be carried out at ambient temperature. 2) Terminations—Testing half the number of samples in Fig. 1. 3) Joints—Testing half the number of samples in Fig. 2. 4) Stop ends—Testing half the number of samples in Fig. 3. 5) It is advised that the accessory is examined for signs of any of the following:

a) Cracking in the filling media and/or tape or tube components; and/or b) A moisture path across a primary seal; and/or c) Corrosion and/or tracking and/or erosion which would, in time, lead to failure of the accessory; and/or d) Leakage of any insulating material.

12

IS 13573 (Part 2) : 2011

Table 8 Additional Tests for Different Types of Cable Insulation Screen and Approval from Round toShaped Conductors (Not Applicable to Stop Ends)

(Fig. 1 to Fig. 5)

S1 No.

Test1) Requirements Test Methods as per IS 3573

(Part 3)

Test Sequences (See Fig. 1 to 5)

1.12) 2.13) 4.1-5.14) (1) (2) (3) (4) (5) (6) (7)

i) a.c. or d.c. voltage a.c. for 5 min at 4.5 U0 or d.c. for 15 min at 4 U0

4.2 or 5 X X X

ii) Partial discharge at ambient temperature and θt

5),6) 10 pC Max at 1.73 U0 7 X X X

iii) Heating cycles in air 60 cycles7) at θt5) and 2.5 U0 9 X X X

iv) Partial discharge at θt5),6) and

ambient temperature 10 pC Max at 1.73 U0 7 X X X

v) Impulse 10 impulses of each polarity 6 X X X vi) a.c. voltage 15 min at 2.5 U0 4.2 X X X

vii) Examination For information only8) — X X X

1) Unless otherwise specified, tests shall be carried out at ambient temperature. 2) Terminations—Testing half the number of samples in Fig. 1. 3) Joints—Testing half the number of samples in Fig. 2. 4) Separable connectors—Testing half the number of samples in Figs. 4 and 5. 5) θt is the maximum cable conductor temperature in normal operation from +5°C to + 10°C. 6) Measurement is made at the end of the heating period. 7) 8 h total with ≥ 2 h steady and ≥ 3 h cooling. 8) It is advised that the accessory is examined for signs of any of the following:

a) Cracking in the filling media and/or tape or tube components; and/or b) A moisture path across a primary seal; and/or c) Corrosion and/or tracking and/or erosion which would, in time, lead to failure of the accessory; and/or d) Leakage of any insulating material.

Table 9 Summary of Test(Clause 5.2)

Tests Terminations

Separable Connectors Deadbreak Sl No.

Indoor Outdoor

Straight and Branch Joints

Stop Ends

Screened Unscreened (1) (2) (3) (4) (5) (6) (7) (8)

i) Conductor resistance: X X X — — a) a.c. voltage — — — — — — b) 4.5 U0/5 min dry X X X X X X c) 2.5 U0/15 min dry X X X X X X d) 2.5 U0/500 h dry — — — X — — e) 4 U0/1 min wet — X — — — —

ii) d.c. voltage: a) 4 U0/15 min dry X X X X X X

iii) Partial discharge: a) At θt X X X — X X b) At ambient temperature X X X X X X

iv) Impulse: a) At θt X X X — X X b) At ambient temperature X X X X X X

v) Thermal cycles: a) In air X X X — X X b) Under water — — X — X X

vi) Thermal short circuit: a) Screen X X X — X X b) Conductor X X X — X X

vii) Dynamic short circuit X X X — X X viii) Humidity X — — — — X

ix) Salt fog — X — — — — x) Disconnect/connect — — — — — X

xi) Operating eye — — — — X — xii) Screen resistance — — — — X —

xiii) Screen leakage current X — xiv) Fault current initiation — — — — X — xv) Operating force — — — — X —

xvi) Capacitive test point — — — — X — xvii) Examination X X X X X X

NOTE — The purpose of this table is to list test, and not sequences.

13

IS 13573 (Part 2) : 2011

Table 10 Summary of Test Voltages and Requirements(Clause 5.2 )

Rated Voltage U0/U (Um) kV Sl No. Test Test Voltage

3.8/6.6 (7.2)

6.35/11 (12)

12.7/22 (24)

19/33 (36)

Requirements

(1) (2) (3) (4) (5) (6) (7) (8)

i) Humidity and salt fog 1.25 U0 4.7 7.93 15.8 23.7 No breakdown or flashover No more than three trippings No substantial damage1)

ii) Partial discharge2) 1.73 U0 6.6 11.0 22.0 33.0 Max partial discharge 10 pC iii) Heating cycles and ac voltage/15 min and 500 h 2.5 U0 9.5 15.8 31.7 47.5 No breakdown or flashover iv) a.c. voltage/1 min 4 U0 15.2 25.4 50.8 76 No breakdown or flashover v) d.c. voltage/15 min 4 U0 15.2 25.4 50.8 76 No breakdown or flashover

vi) a.c. voltage/5 min 4.5 U0 17.1 28.5 57.1 85.5 No breakdown or flashover vii) Impulse (peak) — 60 75 125 170 No breakdown or flashover

1) It is considered that substantial damage has occurred when it is evident that the performance of the accessory has been severely reduced by,

a) loss of dielectric quality due to tracking; and/or b) erosion to a depth of 2 mm of 50 percent, whichever is the smaller, of the wall thickness of the insulating material as applied;

and/or c) splitting of the material; and/or d) puncture of the material. 2) Not required for accessories installed on 3.6/6 (7.2) kV cables having unscreened insulation.

ANNEX A(Clause 4.4.4)

IDENTIFICATION OF TEST CABLE

Rated Voltage U0/U (Um): kV Not individually screened

Construction: Single-core Three-core

Individually screened

Conductor(s): Al Cu

Stranded Solid

Round Shaped

120mm2 150 mm2 185mm2 240mm2

Other cross-section area: mm2

Insulation: PVC XLPE

EPR HEPR

Insulation screen: Bonded Strippable

Metallic screen: Wires Tapes Extruded

Cross section area: mm2

Oversheath: PVC PE(ST3) PE(ST7)

Water blocking, if any: In conductor Under oversheath

Diameters:

a) Conductor: mm

b) Insulation: mmc) Insulation screen: mm

c) Oversheath: mm

Cable marking/Embossing

Bureau of Indian Standards

BIS is a statutory institution established under the Bureau of Indian Standards Act, 1986 to promoteharmonious development of the activities of standardization, marking and quality certification of goodsand attending to connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any formwithout the prior permission in writing of BIS. This does not preclude the free use, in the course ofimplementing the standard, of necessary details, such as symbols and sizes, type or grade designations.Enquiries relating to copyright be addressed to the Director (Publications), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewedperiodically; a standard along with amendments is reaffirmed when such review indicates that no changes areneeded; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standardsshould ascertain that they are in possession of the latest amendments or edition by referring to the latest issue of‘BIS Catalogue’ and ‘Standards : Monthly Additions’.

This Indian Standard has been developed from Doc No.: ETD 09 (5977).

Amendments Issued Since Publication

Amend No. Date of Issue Text Affected

BUREAU OF INDIAN STANDARDS

Headquarters:

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002Telephones : 2323 0131, 2323 3375, 2323 9402 Website: www.bis.org.in

Regional Offices: Telephones

Central : Manak Bhavan, 9 Bahadur Shah Zafar Marg 2323 7617NEW DELHI 110002 2323 3841

Eastern : 1/14 C.I.T. Scheme VII M, V. I. P. Road, Kankurgachi 2337 8499, 2337 8561KOLKATA 700054 2337 8626, 2337 9120

Northern : SCO 335-336, Sector 34-A, CHANDIGARH 160022 60 384360 9285

Southern : C.I.T. Campus, IV Cross Road, CHENNAI 600113 2254 1216, 2254 14422254 2519, 2254 2315

Western : Manakalaya, E9 MIDC, Marol, Andheri (East) 2832 9295, 2832 7858MUMBAI 400093 2832 7891, 2832 7892

Branches: AHMEDABAD. BANGALORE. BHOPAL. BHUBANESHWAR. COIMBATORE. DEHRADUN.FARIDABAD. GHAZIABAD. GUWAHATI. HYDERABAD. JAIPUR. KANPUR. LUCKNOW.NAGPUR. PARWANOO. PATNA. PUNE. RAJKOT. THIRUVANANTHAPURAM.VISAKHAPATNAM.

�

��

�

�

Published by BIS, New Delhi