IRSTC 24 Nov 2015

-

Upload

amiral-aziz -

Category

Documents

-

view

315 -

download

4

Transcript of IRSTC 24 Nov 2015

Agency for the Assessment and Application of Technology - IndonesiaAgency for the Assessment and Application of Technology - Indonesia

LOCAL CONTENT (TKDN) REQUIREMENT AND ITS IMPLEMENTATION FOR DEVELOPMENTS OF THE POWER

PLANT PROJECT IN INDONESIABy :

Prof. Ir. Amiral Aziz, MS.c. APU

PRESENTED in 3rd INTERNASIONAL SEMINAR ; Innovation Research for Science , Technology and Culture ( IRSTC )

Polyteknik - Banda Aceh 24 -25 November 2015

Agency for the Assessment and Application of Technology - Indonesia

Projection of Electric Power Utilization by Sector

• BPPT predicted the Electric Power Utilization in Indonesia significantly increasing around 5 times in period of 2012-2035 , It is 903 TWh in 2035 or growth 7,4% per year.

• In period of 2013 – 2035, industry sector will growth 8,7% per year (base scenario ) and 10,3% per year (high scenario).

• In 2035, Electric Power Utilization in industry sector will be 45 % for base scenario and 47 % for high scenario

2

Agency for the Assessment and Application of Technology - Indonesia3

Projection of Electric Power Utilization by Sector

Agency for the Assessment and Application of Technology - Indonesia

Projection of National Power Plant Capacity

• Installed Capacity of power plant in period of 2012-2035 will increase from 44,8 GW to 215 GW or growth 7,1% per year.

• For high scenario in 2035 , installed capacity will be increasing abaut 26 % larger than base scenario , it will reach 270 GW (2035), or growth 8,1% per year.

• In 2035 Coal Fired Steam Power Plant will be 65% (139 GW) for base scenario and 72% (194 GW) for high scenario

4

Agency for the Assessment and Application of Technology - Indonesia5

Projection of National Power Plant Capacity

Agency for the Assessment and Application of Technology - Indonesia6

Agency for the Assessment and Application of Technology - Indonesia

DEVELOPMENT OF INDONESIAN ELECTRICITY INFRASTRUCTURE 2015 - 2019

8

Sumatera Kalimantan

Sulawesi

Maluku

Papua

Nusa TenggaraJava-Bali

Sumatera:PLN : 1.108 MWIPP : 7.632 MWTotal : 8.740 MW

Jawa-Bali:PLN : 5.019 MWIPP : 15.872 MWTotal : 20.891 MW

Kalimantan:PLN : 916 MWIPP : 955 MWTotal : 1.871 MW

Sulawesi:PLN : 2.022 MWIPP : 682 MWTotal : 2.704 MW

Nusa Tenggara:PLN : 675 MWIPP : 26 MWTotal : 701 MW

Papua:PLN : 224 MWIPP : 118 MWTotal : 342 MW

Maluku:PLN : 259 MWIPP : 20 MWTotal : 279 MW

Indonesia:PLN : 10.223 MWIPP : 25.305 MWTotal : 35.529 MW

Agency for the Assessment and Application of Technology - Indonesia

• Presidential Instruction No. 2 of 2009 regarding the Utilization of Domestic Products for Government Procurement of Goods/Services

• Law No. 30 of 2009 regarding Electric Power

• Presidential Decree No. 54 of 2010 regarding Government Procurement of Goods/Services.

• Regulation of the Minister of Industry No. 54/M-IND/PER/3/2012 regarding Guidelines for the Use of Domestic Products in the Construction of Electric Power Infrastructure

9

LOCAL CONTENT REQUIREMENT FOR

ELECTRICITY INFRASTRUCTURE PROJECT

Agency for the Assessment and Application of Technology - Indonesia

LOCAL CONTENT REQUIREMENT FOR

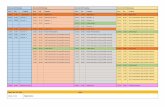

ELECTRICITY INFRASTRUCTURE PROJECT Based on Regulation of the Minister of Industry No. 54/M-IND/PER/3/2012regarding Guidelines for the Use of Domestic Products in the Constructionof Electric Power Infrastructure ,the minimum TKDN Minimum is given onthe following tables.

Agency for the Assessment and Application of Technology - Indonesia

LOCAL CONTENT REQUIREMENT FOR

ELECTRICITY INFRASTRUCTURE PROJECT Based on Regulation of the Minister of Industry No. 54/M-IND/PER/3/2012regarding Guidelines for the Use of Domestic Products in the Constructionof Electric Power Infrastructure ,the minimum TKDN Minimum is given onthe following tables.

Agency for the Assessment and Application of Technology - Indonesia

LOCAL CONTENT REQUIREMENT FOR

ELECTRICITY INFRASTRUCTURE PROJECT Based on Regulation of the Minister of Industry No. 54/M-IND/PER/3/2012regarding Guidelines for the Use of Domestic Products in the Constructionof Electric Power Infrastructure ,the minimum TKDN Minimum is given onthe following tables.

Agency for the Assessment and Application of Technology - Indonesia

Verification of Local Content (TKDN)

Mean Equipment1. Coal Fired Steam Power Plant

- GOOD : Steam Turbine, Boiler, Generator, Electrical, Instrument and Control, Balance

Of Plant dan atau Civil and Steel Structure;

- SERVICE : Consultan Service (Feasibility Study),(Engineering, Procurement &

Construction, Sevice QA/QC, Testing and Comissioning , Sertification and Supporting

Services

2. Transmission Line

- GOOD : Cables, Insulators & Fittings & Tower

- SERVICE : Transportation, Erection, Stringing, Testing & Commissioning

3. Sub Station

- GOOD : Outdoor Equipment (Switching Yard), Indoor Equipment (Control Building) and

Civil & Steel Structure

- SERVICE : Test and Commissioning

Sumber : Kemenperin - SI

Agency for the Assessment and Application of Technology - Indonesia

Calculation Method of TKDN

Based on Regulation of the Minister of Industry No. 16/M-IND/PER/2/2011 Regarding

Calculation of Local Content (TKDN)

1.Material

TKDN

Regulation

2.

Man Power

3.Equipment

KDNKLN

KDNKLN

KDNKLN

Abroad Production, TKDN 0% Local Poduction, TKDN 0% - 100%

DIBUAT DI

DALAM NEGERI

DIBUAT DI

LUAR NEGERI

DIMILIKI

DN

DIMILIKI

LN

DIMILIKI

DN + LN

%TKDN =

100%

%TKDN =

75%

%TKDN =

75% + 25%

(Proporsional

Saham)

DIMILIKI

DN

DIMILIKI

LN

DIMILIKI

DN + LN

%TKDN =

75%

%TKDN =

0%

%TKDN =

Proporsional

Saham

Sumber : Kemenperin - SI

Agency for the Assessment and Application of Technology - Indonesia15

Calculation Method of TKDN

Agency for the Assessment and Application of Technology - Indonesia16

Calculation Method of TKDN

Agency for the Assessment and Application of Technology - Indonesia17

Calculation Method of TKDN

Agency for the Assessment and Application of Technology - Indonesia18

Calculation Method of TKDN

Agency for the Assessment and Application of Technology - Indonesia19

Calculation Method of TKDN

Agency for the Assessment and Application of Technology - Indonesia

TKDN scenario for 35.000 MW Project

20

Parameter

Kelas Kapasitas Pembangkit (PLTMG/PLTG/PLTU di atas 100 MW)

(Rata-rata nilai TKDN 32 %)

PLTMG PLTU*

Percentage 15MW 15 – 25 MW Percentage100 – 600

MW*

> 600

MW*

Civil 10% 10% 10% 14% 14% 14%

Boiler - - - 26% 12% 10%

Gas Engine or Turbin /

Generator62% 9% 0% 21% 0% 0%

Elektrical 9% 7 % 7 % 12% 4% 4%

BOP & Auxiliary 17% 0% 0% 16% 5% 5%

Instrumentation &

Control2% 1.5% 1.5% 5% 1% 1%

Engineering Service Very small 6% 4% 4%

Total TKDN 100% 26.5% 18.5% 100% 40% 38%

* Sumber data Kemenperin

Agency for the Assessment and Application of Technology - Indonesia21

N

oPROYEK KONTRAKTOR

TKDN PERMEN

PERINDUSTRIANKETERANGAN

KONTRAK PENCAPAIAN

1 PLTU 2 JAWA BARAT (3X 350 MW) PELABUHAN RATUFTP 1 (TTD : 7-Aug-2007)

SHANGHAI ELECTRIC CORPORATION dan PT MAXIMA INFRASTRUKTUR 20% 14% No. 11/2006

TKDN untuk PLTU belumdiatur . Baru HimbauanMemakai Produk DalamNegeri.

2 PLTU 2 JAWA TENGAH (1 X 600-700 MW) ADIPALAFTP 1 (TTD: 22-Des-2008)

CNTIC CONSORTIUM

30% 33.20% No. 11/2006.

TKDN untuk PLTU belumdiatur . Baru HimbauanMemakai Produk DalamNegeri.

3 PLTU 3 JAWA TIMUR2 X (300-400 MW)

TANJUNG AWAR-AWARFTP 1 (TTD: 25-April-2008)

JO :1. CHINA NATIONAL ELECTRIC

EQUIPMENT CORP (CNEEC)2. CHINA NATIONAL MACHENERY

INDUSTRY CORP (SINOMACH)3. PT PENTA AL SAMUDRA

15% 23.55% No. 11/2006.

TKDN untuk PLTU belumdiatur . Baru HimbauanMemakai Produk DalamNegeri.

4 PLTGU TANJUNG PRIOK GAS FIRED POWER PLANT EXTENTUON PROJECT (1 X 740 MW) LOAN JICA (TTD: 6-Des-2008)

MITSUBISHI CORPORATION

NA 29.27% No. 11/2006.TKDN tidakDipersyaratkan dalamBIDDOC

5 PLTU 1 JAWA TIMUR 2 X (300-400 MW)PACITANFTP 1 (TTD: 7-Aug-2008)

DONGFANG ELECTRIC CORPORATION & PT DALLE ENERGY

20% 32.90% No. 11/2006.

TKDN untuk PLTU belumdiatur . Baru HimbauanMemakai Produk DalamNegeri.

6 PLTU KALIMANTAN TIMUR(2 X 100 MW)FTP 1 (TTD: 21-Des-2010)

CONSORTIUM ADHIKARYA –SINOHYDRO 40.31% 38.74%

No.48/2006Min.40%

TKDN tidak Memenuhi

Implementation ofTKDN Based on Peraturan Menteri Perindustrian RI No. 54/M-IND/PER/3/2012

(Sumber : Paparan PLN pada rapat tanggal 27 Maret 2015)

Agency for the Assessment and Application of Technology - Indonesia

TKDN Achievement of Installed Power plant

22

NO POWER PLANT Number

Physical Progress(%)

TKDN (%)PERMENPERI

N 54

1 STEAM POWER PLANT 0 - 15 MW 8 77,81 27,59 70,79

2 STEAM POWER PLANT 15 - 25 MW 6 77,56 23,12 49,09

3 STEAM POWER PLANT 25 - 100 MW 8 65,22 14,64 44,14

4STEAM POWER PLANT 100 - 600

MW9 89,32 20,50 40,00

5 STEAM POWER PLANT > 600 MW 3 84,26 7,52 38,21

6GEOTHERMAL POWER PLANT 10 -

60 MW1 99,60 29,42 33,24

7GEOTHERMAL POWER PLANT 0 - 5

MW1 71,14 9,52 42,00

36

Agency for the Assessment and Application of Technology - Indonesia

. TKDN Achievement of Installed Transmissions (Sumber : Pemaparan Kemenperin pada Rapat 10 April 2015)

23

NO Transmission Number

Physical Progress(%)

TKDN (%) PERMENPERIN 54

1 Voltage 20 KV 1 100,00 39,78 71,00 (Permenperin 48)

2 Voltage 70 KV 8 61,45 36,28 76,17

3 Voltage 150 KV 61 84,96 42,43 76,17

4 Voltage 275 KV 10 78,06 38,99 74,59

5 Voltage 500 KV 2 96,02 51,96 74,59

82

Agency for the Assessment and Application of Technology - Indonesia

TKDN Achievement of Installed Sub Station (Source PT. Surveyor Indonesia)

24

NO SUB STATION NUMBERPROGRES

FISIK (%)

NILAI TKDN

(%)PERMENPERIN 54

1 Voltage 70 KV 2 100,00 23,94 65,14

2 Voltage 150 KV 30 96,25 25,47 64,39

3 Voltage 275 KV 2 100,00 11,80 43,27

4 Voltage 500 KV 3 100,00 20,73 42,77

37

Agency for the Assessment and Application of Technology - Indonesia

Turbine & Generator

Bobot 25 %

Condensor

Boiler

Bobot 30%

Component of Steam Power Plant and NATIONAL Company

Deaerator

Fan, Pump,

Compressor,

Civil

Bobot 15% Electrical, Instrumentation

and Control

Bobot 8 %

Unindo, Trafindo, etc

Balance of Plant

Bobot 17 %

15 Perusahaan

Boma Bisma

Indra, Barata,

Alsthom, etc

EPC COMPANY

Bobot 5% 10 Companies:

BBI, Barata,

Alsthom, Hitachi,

Basuki Weltes, etc

48 Companies :

Rekayasa Industri, WIKA,

Dale, Truba Enjiniring

etc

Wijaya Karya,

Hutama Karya, Adi

Karya, PP etc

4 Companies:

Siemens Indonesia,

Pindad, Sulzer, Nusantara

Turbin & Propulsi, Texmaco

Data terakhir rata-rata capaian TKDN proyek10.000 MW tahap I adalah 22 %.

Jauh dibawah batas minimal Permerin No. 54/2012 minimal rata-rata 48%

Agency for the Assessment and Application of Technology - Indonesia

Capability of Indonesian Manufanturer for boiler & accessories

EAG, 05/12/2014 26

No Pabrikan Kemampuan Partner1 Basuki Pratama 70 t/jam (~ 15 MW), Eng. inhouse Lisensi dari Ecrohr-boiler Jerman2 Indomarine Boiler 50 t/jam Kasuga (Jepang) > 50 t/jam3 Atmindo Boiler 80 t/jam Babcock boiler4 Boma Bisma Indra Casing boiler Paiton kapasitas 600 MW

(sub-kontrak)Alstom Swiss untuk BOP (FWH, deaerator)

5 ZUG Indonesia Masih impor ZUG China. Kemampuansaat ini sampai 75 MW

ZUG China

6 Dinamika Energitama Nusantara

Boiler skala 25 MW

7 Weltes 75 ton /jam (15 MW)8 JV Pindad Barata Boiler skala 25 MW9 JV Alstom ESI, PAL,

BarataBoiler skala 100 MW JV sejak 1996

10 Bukaka Boiler sd. 30 MW Lisensi dari Hailu, China

Pabrikamiliki pengalaman memproduksi boiler sampai dengan kapasitas setara 30 MW.Sebagian sudah memiliki kemampuan inhouse engineering.

Alstom Indonesia (PMA) sanggup memproduksi 1.000 MW boiler pressure part untukMalaysia

Kemampuan pabrikan boiler dalam negeri

Agency for the Assessment and Application of Technology - Indonesia

Cooling

System

Generator

Air Management

Fuel

System

COMPONENT OF PLTD and PLTMG

Engine

Management

System

Lube Oil System

Engine

Core

• PLTD pembangkit listrik yang paling sederhana, investasi pembangunannya murah, waktu pembangunan relatif singkat, tetapi biaya operasional PLTD tinggi, bisa mencapai 35 sen US$ per kWh, lima kali lebih mahal dari PLTU Batubara ≈ 7 sen US$.

• Industri Manufaktur Komponen Utamanya yaitu Mesin Diesel belum ada yang lokal 100%, masih tergantung prinsipal dan komponen impor, khususnya yang berkapasitas besar. Beberapa Industri tsb.: KUBOTA – Semarang, Yanmar – Cibubur, Tri Ratna – Surabaya (mitraMitsubishi, Boma Stork : JV BBI dan Stork BV.

Bobot :

•Sipil 10 %

•Engine & Generator

62 %

•BOP 17 %

•Electrical, Instrumentation &

Control 11%

Agency for the Assessment and Application of Technology - Indonesia28

CAPABILITY OF GENERATOR MANUFACTURER

TKDN Generator : 7-10 MW (TKDN sebesar 65%)

PT Pindad

sampai dengan 7 – 10 MW

Generator 7 MW (lisensi Siemens) dan generator PLTD dibawah 5 MW bekerja

sama dengan MAN Turbo

Skala sd. 50 MW, berencana Joint Venture Crompton Greaves UK (tahap MOU)

Material kira-kira masih 90% impor

Konstruksi generator AC

Agency for the Assessment and Application of Technology - Indonesia29

No Perusahaan Alamat

1 PT. Siemens Indonesia Jl. Pulomas

Jakarta

2 PT. PINDAD (Persero) Jl. Jend. Gatot Subroto Bandung

KEMAMPUAN MANUFAKTUR GENERATOR

Agency for the Assessment and Application of Technology - Indonesia30

CAPABILITY OF GENERATOR MANUFACTURER

TKDN Tranformator : MV (TKDN sebesar < 50%)

Oli trafo masih harus impor

Semi silicon steel masih impor

Konstruksi Transformator

Agency for the Assessment and Application of Technology - Indonesia31

CAPABILITY OF GENERATOR MANUFACTURER

No Perusahaan Alamat

1 PT. CG Power System Indonesia Kawasan Industri Menara Permai Kav. 10

Jl. Raya Narogong, Cileungsi, Bogor

2 PT. Trafoindo Prima Perkasa Jl. Hayam Wuruk No. 4 FX, Jakarta Pusat

3 PT. Bambang Djaja Jl. Rungkut Industri III/56, Surabaya

4 PT. Unindo Jl. Swadaya PLN-Klender, Jakarta

5 PT. Asata Utama Elektrical

Industries

Jl. Raya Tegal Alur No. 14, Cengkareng, Jakarta

6 PT. Mega Karya Persada Jl. A. Yani Dusun Galur Lap. PI RT 02/03

Cikampek, Karawang 7 PT. Morawa Electric

Transbuana

Jl. Raya Medan - TG. Morawa KM. 20,5 Medan

Agency for the Assessment and Application of Technology - Indonesia32

CAPABILITY OF SWITCHGEAR MANUFACTURER

TKDN Sub Station: (TKDN sebesar 0-41,01%)

TKDN minimal ada pada GITT 150 kV Sanur dengan TKDN 0%

TKDN maksimal ada pada GITT 150 kV Lolak (ext) dengan TKDN 41,01%

Switchgear Sub Station

Sumber : Data Verifikasi TKDN 2012 SI

Agency for the Assessment and Application of Technology - Indonesia33

CAPABILITY OF SWITCHGEAR MANUFACTURER

No Perusahaan Alamat

1 PT. ABB Transmission and

Distribution

Jl. Gajah Tunggal Km. 1, Tangerang 15135

2 PT. Siemens Indonesia Jl. Pulomas

Jakarta

3 PT. Hitachi Power System

Indonesia (Ex PT. JAEPSI)

EJIP Industrial Park, Plot 8E,

Cikarang, Bekasi

Agency for the Assessment and Application of Technology - Indonesia35

CAPABILITY OF TRANSMISSION /DISTRIBUTION MANUFACTURER

TKDN Jaringan : (TKDN 0,11-95,64%)

TKDN terendah ada pada jaringan 150 kV dari Meulaboh ke Blang Pidie (0,11%)

TKDN tertinggi ada pada jaringan 150 kV dari Ampenan ke Praya (tahap II) (95,64%)

Sumber : Data Verifikasi TKDN 2012 SI

Agency for the Assessment and Application of Technology - Indonesia

Komponen Kelistrikan yang sudah memilikisertifikasi Nilai TKDN

• Generator bekapasitas 15-25 kVA dengan TKDN 18,73%-20,52%• Trafo Distribusi kapasitas 25-8450kVA TKDN 23,60-68,62%• Kabel dengan TKDN 11,96-99,61%• Arrester dengan TKDN 10,84-25,24% • CB dengan TKDN 22,46-36%• kWH meter dengan TKDN 27,02%-47,43%• Tiang Listrik• Switchgear• CT da PT• DS dan LBS• Panel• Isolator

Sumber : Website P3DN Kemenperind (tkdn.kemenperin.go.id)

Agency for the Assessment and Application of Technology - Indonesia37

Produk (Barang/Jasa) berikut ini sudah dihasilkan oleh produsen dalam

negeri dan diharapkan diutamakan penggunaannya :

1.Electrical (Power cable, Switchgear, Trafo, Power distribution panel,

electric motor)

2.Instrument & Control (Instrument cable, Control panel)

3.Balance Of Plant (WWT, WWTP, Coal & Ash Handling, Cooling

Tower)

4.Civil and Steel Structure (Anchor bolt, Steel structure)

5.Boiler (Kapasitas s.d. 100 MW mempergunakan Barang/jasa Dalam

Negeri : Teknologi Stocker, CFB dll)

6.Turbine Accessories (diluar package : handrail, bolt & nut, grating,

turbine casing, turbine skid, dll)

7.Generator Accessories (diluar package : Cover plate, handrail, bolt &

nut, grating, generator skid, dll)

8.Piping System

9.GIS (Gas Insulated Swithgear)

Produk / Jasa Dihasilkan oleh Produsen Dalam Negeri(sumber : Laporan Akhir Survey dan Verifikasi TKDN Ketenagalistrikan 2010)

Agency for the Assessment and Application of Technology - Indonesia

PROBLEMS of SMALL TKDN

• Funding Sources from International

They tend to uses product and technology from theircountry.

• Main Contractor from Foreign Company

National manufakturers are difficult to optimizetheir capabilities in joint activities.

• Low Engineering Capabilities of Local Industry(Guarantie Performance)

Local Industry need licency of proven technology.

Agency for the Assessment and Application of Technology - Indonesia

CONCLUTION

• Many regulations on the local content requirements for theprocurement of goods and services in all government projectsincluding electric power plants have issued by theGovernment of the Republic of Indonesia to improvedomestic production in Indonesia

• Based on the audit and verification that were carried out byPT Surveyor Indonesia and PT Scofindo, it could be concludedthat for Steam Power Plant (PLTU) capacity of up to 15 MWand capacity of larger than 600 MW the TKDN is 27.59 % and7.52 % respectively. These values are lower than the localrequirement based on the Regulation of Ministry of Industry.For the geothermal power plant with capacity of 10-60 MW,the percentage of TKDN is 20.50 %. This achievement isslightly lower than requirement value of 33.24 %.

39

Agency for the Assessment and Application of Technology - Indonesia

... in harmony we progress ...

Thank You

40

![arXiv:1509.05971v2 [cond-mat.mtrl-sci] 24 Nov 2015](https://static.fdocuments.in/doc/165x107/61bd203a61276e740b0f9e56/arxiv150905971v2-cond-matmtrl-sci-24-nov-2015.jpg)

![arXiv:1304.4400v4 [math.NT] 24 Nov 2015](https://static.fdocuments.in/doc/165x107/62a638658bca4f7348299d4c/arxiv13044400v4-mathnt-24-nov-2015.jpg)

![arXiv:1511.07608v1 [cs.RO] 24 Nov 2015](https://static.fdocuments.in/doc/165x107/61c733512b16240dc67ae9f9/arxiv151107608v1-csro-24-nov-2015.jpg)

![arXiv:1511.07916v1 [cs.CL] 24 Nov 2015 November 26, 2015 · 2 In fact, they are still taking the course as of 24 Nov 2015. They have two guest lectures and a final exam They have](https://static.fdocuments.in/doc/165x107/5f2c02209ca0912c01342249/arxiv151107916v1-cscl-24-nov-2015-november-26-2015-2-in-fact-they-are-still.jpg)

![DENNIS GAITSGORY arXiv:1303.2763v3 [math.AG] 24 Nov 2015 · arXiv:1303.2763v3 [math.AG] 24 Nov 2015 FUNCTORS GIVEN BY KERNELS, ADJUNCTIONS AND DUALITY DENNIS GAITSGORY Contents Introduction](https://static.fdocuments.in/doc/165x107/5fd1d0a54484502427782216/dennis-gaitsgory-arxiv13032763v3-mathag-24-nov-2015-arxiv13032763v3-mathag.jpg)