Iron Sportster design...Open-Sport.org Design landing page - Open-Sport.org 8 of 11 7/26/2015 6:12...

Transcript of Iron Sportster design...Open-Sport.org Design landing page - Open-Sport.org 8 of 11 7/26/2015 6:12...

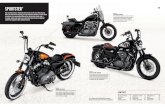

Iron Sportster design

One design principle that is important to a pieceof industrial machinery such as an IronSportster. Do not change it too often.

It would be wrong tosay I have learned a lotabout Sportster design.Instead, a lot of greatpeople taught me a lotabout Sportster design.Duncan Keller taughtme about engines.

Vance Breese taughtme about racing and alot of other things.

Bill Johnson taught meto hate covers sincethey only hideproblems. He rode aShovelhead with only ared shop towel on thebattery. He consideredthe seat anotheruseless cover.

Roger Shaw taught meto not use silicone toglue my bike together.Sportster Jim explainedthat ignition timing,even a degree or two,can make a bigdifference.

A cross-section of the Iron Sportster transmission. Genius.

Roger Reed pointed out there is way too much oil going intothe crankcase. Crazy Larry pointed out that most guys runway too rich. He said heat makes power. You want it lean forthe heat but not so much heat it melts the pistons.

Seeing old chrome parts pealing taught me to never chromealuminum, not even billet. You are putting very hard metalcoating over a very soft metal. It will not end well in 10 or 20years. Having to put my bike in a 40-foot trailer halfway toReno taught me cone motor Sportsters eat ignitionflyweights. That and a thousand other things has been agreat education. I will try to pass it along here.

file:///C:/Archive/Stage/Open-Sport_stage/Desi... Open-Sport.org Design landing page - Open-Sport.org

1 of 11 7/26/2015 6:12 PM 1 of 11

Ironhead design starts with anyinformation you can get from the factorymanual. Harley gives detailed framedimensions so we can fix the bikes after acrash.

Based on those dimensions you can drawup the frame pretty well, and in this case,use it to figure out how to mount the7-Amp-hour battery in the front down lowby the motor mounts.

I used this same drawing to figure out thatthe VW 15-degree 4-cyinder engine wouldfit in a Sportster frame. I'll get it postedand link to it this later this year.

CAD (computer-aided-design) drawingsare great, but you can figure out a lot witha 25-cent Bic pen and a piece of graphpaper as well. Here I studied an oil-cooledSportster.

But where CAD really pays off is when youtake that 2-D drawing and use it as atemplate to make a 3-D drawing. Now youcan fit things and see how they will work.The tubes have all those lines because itwas made way back in the AutoCAD days,probably AutoCAD 11. I have sinceswitched to Solidworks.

file:///C:/Archive/Stage/Open-Sport_stage/Desi... Open-Sport.org Design landing page - Open-Sport.org

2 of 11 7/26/2015 6:12 PM 2 of 11

With the frame reproduced in thecomputer, I then could see if a 60-degreehigh-cam engine would fit. It looks prettyclose.

And the same 3-D computer stuff helpsfiguring out that very same high-camengine. You can see I made the enginemore like a car engine, with two valvesside-by-side. It was the 3-D drawing thatgot me to realize I could make the rockerboxes into one piece.

This might be a fun project but it is such ahuge effort to make a 60-degree engine,much less one that drives a high cam, Iput this one on the shelf for now.

Sometimes Sportster design is usinghot-wax adhesive to save a loose mirror.

Design is also building things and makingsure parts don't clank together.

And design is not just paper, you have toride the heck out of your bike(s) to seewhat breaks.

file:///C:/Archive/Stage/Open-Sport_stage/Desi... Open-Sport.org Design landing page - Open-Sport.org

3 of 11 7/26/2015 6:12 PM 3 of 11

When I got tired of the Sprocket cover onmy 1977 Sporty breaking, I sketched up asteel bracket that would mount to the rearengine mount studs.

Years later, a 3-D sketch made thingsmuch more presentable.

Years after that I switched to Solidworksand things really started to look good.

This was a study where I modeled a 9/16deep-well socket taking out the stud nuts. Icould see the thick wire was going to getin the way. It anchors the return spring.

This is the great thing about 3-D CAD. Ittakes forever to draw things up, but onceyou do, you can find mistakes before youmake the part, not after. You know thesaying, "Experience is a mean teacher, itgives you the lesson after it gives you thetest."

This is why it is critical to have the frame,tools, rider, and the all the other stuffmodeled in the computer.

file:///C:/Archive/Stage/Open-Sport_stage/Desi... Open-Sport.org Design landing page - Open-Sport.org

4 of 11 7/26/2015 6:12 PM 4 of 11

So without having to scrap a weldment, Icould sit and look at the screen and try tofigure out the cleanest way to provideclear access to the stud nuts and stillanchor the return spring.

The inspiration came with the realizationthat the kickstarter return spring can go on4 different ways. I know, I learned the hardway putting it on 90-degrees off, only tohave to remove the kicker lever toreposition it.

So with the spring rotated on the shaft,one of the flanges can be extended and itis a much cleaner design with one lessweld to worry about breaking.

Solidworks helped me design a headlampbracket for my 1996 Evo.

It fit the first time.

And looks pretty clean, should you want tomount a Bates headlamp to a 1996.

file:///C:/Archive/Stage/Open-Sport_stage/Desi... Open-Sport.org Design landing page - Open-Sport.org

5 of 11 7/26/2015 6:12 PM 5 of 11

Not everything has to be draw on paper. Igot tired of filling my 2-gallon gas tank onthat 1977 Sporty, my daily driver. So I gotthe aftermarket weld-on mount kit meantto restore chopped big-bike frames.

I was reluctant to weld on my frame. Isplatter more than I weld. Just sitting nextto the bike and playing with the mount, Irealized I could weld side-plates to theaftermarket mount, and then bolt thewhole thing to the frame.

Another principle of design is havingsomething to start with. I disliked theShovelhead tanks since I had to bash theinsides to get them to fit. Later I boughtthe aftermarket kit to adapt flat-side tanks.

Since you don't need CAD or a computerto draw on paper, its easy to draw thingsup. I have scanned all these documentsso they are in the computer.

Here I wonder if extending the cambearings will keep the shaft from wearing.Once documents are scanned its easy toshare them, like I am doing now.

file:///C:/Archive/Stage/Open-Sport_stage/Desi... Open-Sport.org Design landing page - Open-Sport.org

6 of 11 7/26/2015 6:12 PM 6 of 11

Where CAD really helps is the layout ofthings, and to see if they will fit. This is anold sketch where I tried to put a shockwhere the battery and oil bag usually is. Itis fun to sketch things like this, but it still isimprecise.

But after a few years on Solidworks, I wasable to "build" an Iron Sportster engine tosee how I could hack on it. Without a caseyou can learn a lot. The cam gears andtransmission gears are out in the openand you can see exactly how things lineup and where things will fit if you hack onthem.

I will start putting these CAD models up onthis site this year, so everyone can playwith them. An educational version ofSolidworks is 120 bucks.

Even with all the CAD, it still can be niceto doodle on a piece of paper. This carbstudy is to see if you could make it sonarrow it will fit inside the air cleaner.

Even if I used CAD, this clutch releaseramp to operate the front brake wouldhave not worked very well. I think I stillhave the hacked-up caliper, or at least apicture. I will look for it.

file:///C:/Archive/Stage/Open-Sport_stage/Desi... Open-Sport.org Design landing page - Open-Sport.org

7 of 11 7/26/2015 6:12 PM 7 of 11

For wiring, its essential to draw things upso you see what goes where. This was myfiguring out the wiring on my 1977 Sporty.Anyone that has seen a factory wiringdiagram knows it may be correct, but it isnot very helpful.

Once you have the schematic, the schemeof things, you can make a wire harness,and a helpful diagram to show where itgoes.

That is the headache with the factorywiring diagram and all automotive wiringdiagrams. They are not a schematic, andthey are not a layout. They are trying to doboth so they do both poorly. I neverthought I would understand the mess ofwires on my 1996 Sport. It took a day ortwo, but I finally untangled it.

This diagram is not done, all theconnectors are supposed to have thelocation on them. This is a schematic. Itshows the scheme of the wiring, not whereit goes or what goes into what connector.That is for other documentation.

Thing is, you often need the scheme ofthings to figure out what is wrong, or howyou might want to improve things. I neverunderstood how my 1996 Sport canceledits turn signals until I drew this diagram.Then I saw there is a wire from thespeedometer to the turn signal box. Ohhh,I see, the box looks for the speed to goback up after the turn, and cancels thesignals. Now I get it.

file:///C:/Archive/Stage/Open-Sport_stage/Desi... Open-Sport.org Design landing page - Open-Sport.org

8 of 11 7/26/2015 6:12 PM 8 of 11

And once again, paper is just part of it.Keep riding and you realize why it is badto make the rocker boxes into the topmotor mount like Harley did in 1977. Whenother mounts get loose, you end up withthis. And this is only when things go reallywrong. The rocker box gaskets startleaking long before this stage ofdestruction. Maybe those old-time Harleyengineers tied the top mount to the headsfor a reason.

And here is a 7AH battery CAD model Ifound in my archives that reminded mehow much I like working on IronSportsters.

file:///C:/Archive/Stage/Open-Sport_stage/Desi... Open-Sport.org Design landing page - Open-Sport.org

9 of 11 7/26/2015 6:12 PM 9 of 11

The Chassis assembly

The Chassis assembly with these sub-assemblies.

Fender_rear

Strut License plate bracket

Wraparound fender strutsLicense plate bracket

The chassis mounts the rear forks andsuspension, the oil and gas tanks, thebattery, and the rear fender. The frontend has its own category.

Chassis is a top-level assembly.

file:///C:/Archive/Stage/Open-Sport_stage/Desi... Open-Sport.org Design landing page - Open-Sport.org

10 of 11 7/26/2015 6:12 PM 10 of 11

The Engine assembly

The Engine assembly with these sub-assemblies.

Case Sprocket cover Top-end Gearcase Primary

Starter

Kick Electric

Starter, latemodel

Clutch release

Clutchrelease, sidearm

Heads

Heads,steel

Heads,3 valve

Headswith evo valves

Billetheads, AME

Oil pump

Planetary oilpump

Clutch

The engine category has all enginecomponents, including the coil, eventhough yours may mount to the frame.Same deal for voltage regulators. Theintake and exhaust tracts are also in theengine category. The oil tank is a chassiscomponent.

Engine is a top-level assembly.

file:///C:/Archive/Stage/Open-Sport_stage/Desi... Open-Sport.org Design landing page - Open-Sport.org

11 of 11 7/26/2015 6:12 PM 11 of 11