INVESTIGATIONAL STUDY FOR DIRECT COOK POT FROM … · HEAT STORAGE. 1S.Babu Sasi Kumar, 1 ......

Transcript of INVESTIGATIONAL STUDY FOR DIRECT COOK POT FROM … · HEAT STORAGE. 1S.Babu Sasi Kumar, 1 ......

-

INVESTIGATIONAL STUDY FOR DIRECT COOK POT FROM PARABOLIC TROUGH

COLLECTOR (PTC) ASSISTED PCMs (PHASE CHANGE MATERIALS)

HEAT STORAGE.

1S.Babu Sasi Kumar, 1PhD scholar, St Peter‟s University, Avadi, Chennai, Tamilnadu, India,

2M.Chinna pandian, 2Professor and Head, Dept of Aeronautical Engineering, St.Peter‟s College

of Engineering & Technology, Avadi, Chennai-600054, Tamilnadu, India .

E-mail corresponding to sbs.kumar1212 @gmail.com

ABSTRACT

An experimental work on heat utilized for solar cuisine purpose. Solar warm was obtained from PTC

with manual operated Tracking System (TS). In order to get unsteadiness reheat was passing through the

intermittent sunshine, called PCMs filled Thermal Storage System (TES) and this heat employed for

cooking purpose. From the investigation comprehensive clarify Thermal efficiency (TE) of a PTC, TES

and effectual heat utilization analysis of the cooking vessel (CV) was carry out by functioning fluid water

at Mass Flow Rate (MFT) of 0.035 kg/sec, 0.045 kg/sec and 0.065 kg/sec respectively. The consequence

shows that Rim angle of PTC at 82° was achieved maximum TE at 1 PM MFT 0.035, 0.045 and 0.065

kg/sec 67.8 %, 62.4 % and 59.4 %, respectively. The storage tank filled with PCM was achieving the

Maximum Output (MO) 10,327, 9987, 9370 W at 1PM of MFT 0.035, 0.045 and 0.065 kg/sec

respectively. Production of 6977, 5720 and 4807 W for water MFT 0.035 kg/sec of SC at 6.00 to 8.00

PM, this power will be 10.9, 8.9 and 7.5 times higher than the dry average food energy. According to the

aforementioned results, MFT 0.035 kg / s was better than 0.045 and 0.065 kg / s, thus achieving greater

energy. Streaic Acid (SA) is used for PCMs materials.

1. Introduction:

For the present world, the energy

requirement is very high. To fulfill the demands

for energy in future, renewable resource

liveliness is used. As the usage of fossil fuel

(FF) augmented, it causes more pollutants in the

environment. In believe the above aspects, price

effective alternating energy is being developed.

Solar energy (SE) is one of its best vigor

sources. The current methods of industrial

process heating employ huge amount of FF

which in turn increase the import of fuels.

Shifting the means for emerald technologies will

be condensed by foreign currency savings and

reduction in fuels from other countries. The

projected technologies clearly illustrates that a

first-rate amount of cost saving immediately

International Journal of Pure and Applied MathematicsVolume 118 No. 20 2018, 425-437ISSN: 1314-3395 (on-line version)url: http://www.ijpam.euSpecial Issue ijpam.eu

425

-

(lower payback period) and also emission

control contributing to lower carbon foot prints.

SC is most suitable method for luminosity

energy is converted into reheat energy. The sun

has become most suitable a potential energy for

food preparation. The SC is most suitable,

simplest, low rate and most expedient manner to

cook foodstuff without stimulates or heat up the

kitchen. Also the foods are protected and

improve the quality. The use of SC is best for

rural household comparing time saving estimate

quality and security for fuel. In this paper

discuss to psychoanalysis TE of PTC, TES and

effective heat up consumption for energize and

exegetic of SC and monetary performance also

discussed.

Every year revolutionize the locality of sun to

focus light in ES. Therefore to truck the solar

light into TS, we needed to known the geometric

relationship between the collectors with respect

to the time. An elliptical path of earth budge

roughly the sun at every year called elliptical

plane and its axis of rotary motion is fully

completed at every one day. The tilted angle of

turning round of earth with respect to its orbital

plane is 23.45˚as shown in figure [1].But

Michael DiGrazia et al made alternative solar

reflector pane have light weight, inferior outlay

and durability of polymer layer with different

size of the lamination aluminum sheets

[2].Senthil Manikandan et al experimental labor

is footed on thermal concert of the PTC by

efficiency, useful energy and heat deletion

factor. The outcome illustrated that the increase

in heap gush rate, the attention ratio will cause to

increase the TE of PTC [3].TS are useful for

continuous prognostic reflected sun radiation on

focal point lane, to produce the maximum output

by adjusting power tracker device [4]. In modern

technologies the conversation of SE is hoarded

in LHS system. Justin et al investigated salt

hydrate PCMs as a LHS substance. Salt Hydrate

PCMs from the study have big storage

efficiency, elevated thermal conductivity, low

outlay and high manipulate deletion pace [5]

From the investigation vocation is footed on the

use of Nano-particles for TES, this latest system

is comparable to other storage settings, the lowly

cost to store more power [6].Numerical

psychiatry on heat sample in the crowded divan

in liable and dormant heat storage systems.

Models contrast balanced to the influence factors

of the particle shape, the vacuum, atom material,

flow rate variations, operational fluid

deterioration temperature, and the wall warmth

forfeit [7].Compared Sodium acetate try hydrate

(SATH) is extra proficient than paraffin Wax

(PW), which contains the numeral of PCMs balls

attached to the storage tank, in which the SE is

enthralled and accumulated as dormant heat

[8].An ephemeral stage alteration is constructing

of TES. Simple scheme was exercised to resolve

International Journal of Pure and Applied Mathematics Special Issue

426

-

the pressure and pace of the HTF. The persuade

factors analogous as radial hotness circulation,

stage alter interface level and heat concentration

are conversed [9].The review of TE trial of a

crammed divan LH TES, integrated with the

FPSC, the TES unit is enclosed paraffin as

PCMs is packed in spherical tablets [10].TE

storage wraps a numeral techniques that accrue

TE in reservoirs for later use. They achieved by

balance the energy stipulate between daylight

and darkness .SE is a principal renewable power

basis, of an intermittent nature, and its effectual

utilization is a part of efficient TES. If TES is

not used in SE systems, most of the energy

requirements will be supplementary energy, and

the annual solar load fraction is much less

[11].Multi- layer PCMs cumulus entities have

tried to attempted performance. The rooted

electric heat sources inside PCMs are used pro

heat storage and HTF for heat recovery.

Parametric surveys were demeanor to

guesstimate the things of assorted design and

work conditions, which usher to correlation for

the TES and the average output of heat load.

Two-dimensional model for PCM presented.

The equation is written in the appearance of

enthalpy, and thermal flow problems are allied to

the energy element on the liquid element.

Results of deviation upshot depending on the

radius of inside to outside tube of the Biot,

Stefan and NTU number are discussed

[12].Thermal transfer expansion test analysis of

LHS method during impeach and expulsion

processes. Hybrid TE saving system is

exploiting PCMs for stockpiled heat at the

identical time verified with test data. Simulation

initiated for an epoch of 4 continual frost

months, with a manner reduces the implement of

electricity at intervals of 32%. Additional 90%

of the dynamism consumed in hourly hours. The

time-to-use programs invest in such power

saving systems are very attractive [13].The

experimented event arrived that PTSC attained

highest temperature, efficiency of 86.5˚C,

31.53% compared to BTPC and PTSC are

52.36˚C, 43.5˚C and 77.4% and 67.4%

respectively also its stated that 74%

economically possible to utilized to protect the

environment [14].The solar power focused sun

rays on focal length is 47.02 cm. The PTC was

premeditated and fictitious and it‟s obtained a

maximum temperature of 90˚C at an ambient

temperature of 30˚C [15]. Box SC was

investigated by various water levels (1.5, 1 and

0.5 kg). As a result, the maximum cooking

temperature of 81.6 ˚C, 81.7 ˚C for 1kg and 0.5

kg respectively. The variation is depending upon

increases the sunlight [16].From the

investigation detail to explain the SE fabrication,

maximum absorption capture and temperature

profile [17]. Balakrishnan et al investigation

takes out for parabolic concentrator for cooking

International Journal of Pure and Applied Mathematics Special Issue

427

-

with different temperature profile and finally it

recommended to obtain maximum temperature

[18].Panwar et al investigated the initial energy

and exergy of the SC at different applications.

SE is lone of its best energy sources for cooking

[19]. Mawire et al investigated simulations

replica for oil /pebble-bed TES and the force

utilization format of an indirect SC. The

outcome proved that in a changeable stream rate

is suitable for cooking purpose because of its

stumpy pace of power extraction with rapid fall

in the heat [20].

2. Experimental setup

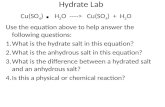

Fig 21 Experimental setup for cooking vessel from PTSC assisted PCM heat storage.

The experimental setup used to test the imagined

PTC as publicized in stature. It consists of (1)

PTC, (2) an 80 liter storage tank, (3) a circulating

impel with MFT of 0.035 kg/sec,0.045kg/sec and

0.065 kg/sec (4) Receiver tube (5) Manual TS (6)

CV. The TES circular tank is made of Mild steel

and inner side containing PCMs rectangular box,

are connected in parallel. Temperature in various

Suction outlet

Circulating pump

1 HP Motor

Parabolic Trough collector

Receiver inlet

Solar cooker outlet

Suction in

Manual tracking system

Check value

Storage tank

Main frame

Solar cooker inlet Semicircular cooking oven

International Journal of Pure and Applied Mathematics Special Issue

428

-

locations is realized using RTD sensors. Sensors

are connected to a computer through a data

logging system, which provides instant digital

outputs and records data for 30 seconds. Overall,

12 sensors are used on the computer to detect and

record the temperature. The TES system is

completely insulated using glass wool insulating

materials. Oil flow rate system is wholly

controlled by control value. Display the whole

layout of CV system, a thermo bath, motor, pump

and control values will be tied to the Thermic

Fluid (TF) line to indict and evict TES. Water,

PCMs is exercised as Sensible, Latent Heat

storage medium. PTC, ST and SC at inlet and

outlet and PCMs storage hotness are measured in

MFT 0.035 kg/sec, 0.045 kg/sec and 0.065 kg/sec

under the working medium of water. This

procedure continues for 1 month.

Formula to be used:

(i) Heat transfer for PTC receiver :

ΔT

Total Heat tranfer q = in W (1)R

rr1 1 1 1 132R= + ln + ln + (2)2πL har k r k r har

1 1 1 2 2 3

Where ∆T, R exist the diverse among the receiver

exit and bay temperature in °C, the resistance

of receiver °C/W.r1,r2 and r3 are radius of steel

tube inner and outer and vacuum tube. Similarly

,k1,k2 are thermal conductivity of steel and glass.

Table 1 PTC system specifications

ITEM Value/Type

Collector aperture area 5.04 m2

Aperture width 2.8 m

Length-to-Aperture ratio 0.64

Rim angle 67.8˚

Receiver diameter 48 mm

Tracking mechanism type Manually operated

Mode of tracking Single- axis

Concentration ratio 18

(ii) Heat transfer coefficient (ha and hb):

To find out ha and hb value is based on water and air

wfT +T

T C (3)2

inm d

Reynolds number Re = (4)A μ

The general equation for Nusselt number is

0.333

Re Pr (5)Nu = c m

h DaNu = (6)k

Where Tf , din is film temperature, diameter of

inside tube and µ is dynamic viscosity of water or

air.m for mass of fluid in kg/sec. Re, Pr are

Renolds,Prandtl number. The value c, m is based

on Re .

International Journal of Pure and Applied Mathematics Special Issue

429

-

Table 2 PTC receiver stipulations.

ITEM Value

Receiver length 3 m

Cover diameter 0.059 m

Absorber diameter 0.051 m

Cover Transmittance 0.91

Coated surface absorptance 0.93

Emissivity 0.08

Pressure of vacuum space 5x10-3 Pa

(iii) Thermal losses of PTC receiver (SS tube):

The mean temperature,

oim

T +T

2T =

° ine

m dR =

A μ h doutNu = K

ins

The resistance of receiver

o i

oinsth

ln(r -r ) 1R = +

2π K L 2 π r L h

Heat loss of receiver tube is expresses as

loss

th

ΔT= q

R

The useful heat gain of the receiver

useful loss

= (7)q q q

(iv) Useful energy the storage tank:

Heat transfer resistance of the cylindrical part

o

ic

ot t cins

rln

r 1R = + (8)

2π K L 2πr L h

due to convection & conduction

Heat transfer resistance of the flat part

o iflat 2

to ins

r - r1 1R = + (9)

K h2πr

Total rate of heat loss is expressed as

ΔT ΔTq = + (10)

loss R Rc f

Useful energy equation for the load of ST is

pstusefulq = ρV C ΔT (11)

Where ρ density of water kg/m3, Vst is the

volume of tank m3 and Cp is specific heat of water

in KJ/Kg K.

(v) Utilized energy output for SC at MFT

WF

T +T

2T =

V DeR =

Where V for velocity of working media an D is

diameter of copper tube and ν is kinematic

viscosity of medium .

0.333

Re Pr (14) Nu = c m

Nu kh =

D

The formula used for find out heat utilized SC

WQ = h A T -T Where h is a heat transfer coefficient W/m2C,

A (area) = πDL (L = length in m) and Tw, T are

temperature of water and air respectively.

International Journal of Pure and Applied Mathematics Special Issue

430

-

Result and discussion:

Retrieved from outdoor examination tests from the

days chosen for February and March -2018. TF as

water at MFT (0.035, 0.045 and 0.065 kg /sec) is

exploiting to evaluate and analyze the presentation of

PTC's with a block coated metal receiver and SA PCM

and CV.

Figure 1 shows variation of I, TE and HG versus Time at

MFT 0.035 kg/sec.

The environmental temperature of 37.6 °C and the

total intensity of radiation (I) 590 W / m2 was

observed at the test time at 1.00PM ,PTC receiver

(104.9°) and its MFT 0.035 kg / sec reaches the MO

of Heat Gain(HG) and TE was 1802 W, 67.2% as

revealed in numeral. After that, its value reduced,

but the PTC receiver was improved to OT 2 PM,

because of circulating ST hotness.

Figure 2 shows variation of I, TE and HG versus Time at

MFT 0.045 kg/sec.

Map showing that the PTC recipient OT (102.5 °)

reached uppermost worth HG, TE are 1658 W,

62.4%, at 1.00 PM at MFT 0.045 kg / sec. later than

its value diminished, but the PTC receiver was

upgraded to OT 2 PM because ST temperature.

International Journal of Pure and Applied Mathematics Special Issue

431

-

Figure 3 shows variation o f I, TE and HG, OT versus Time at

MFT 0.065 kg/sec.

MFT 0.065 kg / sec water, the peak value of HG

and TE of the PTC beneficiary OT (97.4 °) is 1578

W and 59.4% at 1.00pm. Behind that, its rate

diminishes, but the PTC recipient was improvement

to OT 2 PM because ST heat.

Figure 4 shows variation of OT, I, and HG of ST versus Time

at MFT 0.035 kg/sec.

Demeanor analyzes the performance ST with the

SA PCM filled rectangular box for stored and

release energy in MFT 0.035, 0.045 and 0.065 kg

/sec. It found that primarily inlet warmth of PTC

handset, TF and ST was almost equal, after a few

minutes ST, TF temperature augments due to

convection and raising proportional of I, stored

inside PCM materials. The storage energy has

continued to enhance by 1 PM, after which the

energy continues to decrease by 5 pm. After 6 PM,

there is no atmosphere and no seriousness of

radiation, so it is fast and rapidly reduced.

Since the chart identified that at 1.00 PM, ST MFT

0.035 kg/sec of water a MO of HG are OT

(107.5°C) and I (590 W/m2), 10237 W respectively

.This HG is 9.5 times higher than PTC phone. ST

output slowly lessens to 5 PM, after each an hour 0.9

times liveliness fatalities take place.

Figure 5 shows variation of OT, I, and HG of ST versus

Time at MFT 0.045 kg/sec.

As of the grid fixed that at 1.00 PM, ST MFT

0.045 kg/sec of water a MO of HG are OT

(90.7°C) and I (590 W/m2), 9987 W respectively

.This HG is 6 times upper than PTC recipient. ST

output leisurely dwindles to 5 PM, after each an

hour 0.93 times vigour losses obtain position.

International Journal of Pure and Applied Mathematics Special Issue

432

-

Figure 6 shows variation of OT, I, and HG of ST versus

Time at MFT 0.065 kg/sec.

The picture demonstrated that at 1.00 PM, ST

MFT 0.065 kg/sec of water a utmost significance

of HG are OT (72°C) and I (590 W/m2), 9370 W

correspondingly .This HG is 5 times superior than

PTC receiver.ST output unhurriedly drop off to 5

PM , after each an hour 1.08 era vigour losses

obtained.

Figure 7 shows changes ST PCM temperature versus Time

MFT (0.035, 0.045 and 0.065 kg/sec,)

ST filled with SA PCM accuses and liberation

process explains on top of drawing. At MFT 0.035

kg / sec, initial water ST temperature are same,

after few minutes the PCM storage heat augments

International Journal of Pure and Applied Mathematics Special Issue

433

-

due to convection hoist proportional of I awake to

1 PM and after its oomph reduce.

From the aforementioned map clearly, explain SC

exploited vigor is 0.02, 0.15 and 0.30 times less

than 0.035.0.045 and 0.065 kg / s ST, because

losses occur in the atmosphere. From 5.00 to 8.00

pm, each and every hour of SC 1.10 to 1.30 time‟s

vitality loss will take place.

Production of 6977, 5720 and 4807 W for water

MFT 0.035 kg/sec of SC at 6.00 PM, 7.00 PM and

8.00 PM, this energy will be 10.9, 8.9 and 7.5 times

elevated than the Dry Average Food Energy

(DAFE). At MFT 0.045 kg/sec in SC at 6.00, 7.00

and 8.00 PM is produced 5455, 4585 and 4021 W

respectively. This authority is more than 8.5, 7.2

and 6.3 times drying food average power. Similarly

MFT 0.065 kg/sec in SC at 6.00, 7.00 and 8.00 PM

is produced 3849, 3417, 2637 W. This strength be

6, 5.3 and 4.12 times higher than the DAFE.

Conclusion:

(i) PTC recipient (104.9°) and its MFT 0.035 kg

/ sec water, the MO of HG and TE in 1 PM is

1802 W, 67.2% respectively and its atmospheric

heat of 37.6 °C and I as 590 W / m2.

(ii) The PTC heir OT (102.5 °) reached

uppermost worth HG, TE are 1658 W, 62.4%, at

1.00 PM at MFT 0.045 kg / sec.

(iii) MFT 0.065 kg / sec water, the peak value of

HG and TE of the PTC receiver OT (97.4 °) is

1578 W and 59.4% at 1.00 PM.

(iv) At 1.00 PM, ST MFT 0.035 kg/sec of water

a MO of HG are OT (107.5°C) and I (590

W/m2), 10237 W respectively .This HG is 9.5

times higher than PTC receiver.

(v) ST MFT 0.045 kg/sec of water at 1.00 PM , a

main value of HG are OT (90.7°C) and I (590

W/m2), 9987 W respectively .This HG is 6 times

top than PTC receiver.

(vi) An utmost significance of HG are OT

(72°C) and I (590 W/m2), 9370 W

correspondingly at 1.00 PM, ST MFT 0.065

kg/sec of water .This HG is 5 times superior to

PTC handset.

International Journal of Pure and Applied Mathematics Special Issue

434

-

(vii) The ST filled with PCMs was attaining the

MO 10,327, 9987, 9370 W at 1PM MFT 0.035,

0.045 and 0.065 kg/sec respectively.

(viii)Production of 6977, 5720 and 4807 W for

water MFT 0.035 kg/sec of SC at 6.00 PM, 7.00

PM and 8.00 PM, this might will be 10.9, 8.9

and 7.5 times superior to the DAFE.

(ix) At MFT 0.045 kg/sec in SC at 6.00, 7.00

and 8.00 PM is produced 5455, 4585 and 4021

W respectively. This worth is more than 8.5, 7.2

and 6.3 times DAFE.

(x) MFT 0.065 kg/sec in SC at 6.00, 7.00 and

8.00 PM is produced 3849, 3417 ,2637 W ,this

power will be 6,5.3 and 4.12 times advanced

than the DAFE .

According to the aforementioned results, MFT

0.035 kg / s were better than 0.045 and 0.065 kg

/ s, thus accomplish better energy. Streaic acid is

used for PCM materials.

References:

Zekai Sen, "Solar Energy Fundamentals and

Modeling Techniques" © Springer –Verlag London

Limited 2008.

Michael DiGrazia, Gary Jorgensen „Reflectech

mirror film: Design flexibility and durability in

Reflecting solar applications,‟U.S Patent, CO

80007, 2011

K.Senthil Manikandan, G.Kumarasan, R.Velraj

and S.Iniyan „Parametric study of solar parabolic

trough collector system, „Asian journal of Applied

Sciences 5(6):384-393, 2012.

Helwa N., Bahgat ABG, AMR Eshafee ET. El

shanawy. 2000."Maximum Collectable solar energy

by different solar tracking systems", Energy

Resources; 22 (2000) No.1, 23-24.

Justin Ning-Wei Chiu, Dr. Viktoria Martin, and

Prof. Fredrik Setter wall‟ A Review of thermal

energy storage systems with salt hydrate phase

change materials for comfort cooling,‟ Department

of Energy Technology, Brinellvagen- 68.

Suhas Ramchandra Pawar, Mohite V.R.,

Vivekananda Navdagi,‟ Review of thermal energy

storage systems and their applications,‟

International journal of innovations in engineering

research and Technology‟, ISSN: 2394-3696,

Volume 2, Issue 6, June -2015

Ismail K.A.R. and Stuginsky R. (1999), “A

parametric study on possible fixed bed models for

PCM and sensible heat storage”, Journal of Applied

Thermal Engineering, Vol. 19, pp. 757-788.

Kanimozhi B. and Ramesh Bapu B.R. (2010),

“Enhancement of Solar Water Heating System

Using PCM”, National Journal of Advanced

Mechanics and Building Science, Vol. 1, No. 2, pp.

48-51.

Kamal A.R. Ismail and Mabruk M. Abugderahb

(2000), “Performance of a thermal storage system

of the vertical tube type”, International Journal of

Energy Conversion and Management, No. 41, pp.

1165-1190.

International Journal of Pure and Applied Mathematics Special Issue

435

-

Nallusamy N. and Velraj R. (2006), “Experimental

investigation on a combined sensible and latent heat

storage unit integrated with solar water heating

system”, Journal of Zhejiang university Science A,

Vol. 7, No. 8, pp. 1422-1430.

Brousseau P. and Lacroix M. (1996), “Study of the

thermal performance of a multi- layer PCM storage

unit”, Journal of Energy Conservation and

Management, Vol. 37, No. 5, pp. 599-609.

Ismail, K.A.R. and Goncalves M.M. (I999),

“Thermal performance of a PCM storage unit”,

International Journal of Energy Conversion and

Management, Vol. 40, pp. 115-138.

Kanimozhi B. and Ramesh Babu B.R. (2011),

“Experimental Study of Heat Transfer

Enhancement in Latent Heat Thermal Storage

System during Charging and Discharging

Processes”, International Journal of Design and

Manufacturing Technologies, Vol. 2, No. 5,

pp.42-49

Basil Okafor .E,‟ Performance Evaluation of a

Parabolic Solar Cooker‟, International Journal of

Engineering and Technology, Volume 3, ISSN:

2049-3444, 2013

Mohammed Hadi Ali,‟ Studying & Evaluating the

Performance of Solar Box Cookers (Untracked)‟,

International Journal of Computational Engineering

Research, ISSN: 2250 – 3005, Volume, 05, Issue,

08, August – 2015.

Yahuza I, Rufai Y.A and Tanimu L,‟Design

Construction and Testing of Parabolic Solar Oven‟,

Journal of Applied Mechanical Engineering, DOI:

10.4172/2168-9873.1000212, 2016.

Ibrahim Ladan Mohammed,‟ Design and

Development of a Parabolic Dish Solar Thermal

Cooker‟, International Journal of Engineering

Research and Applications, ISSN: 2248-9622, Vol.

3, Issue 4, pp.1179-1186, 2013.

M.Balakrishnan, A. Claude and D.R.Arun Kumar

„Engineering, design and fabrication of a solar

cooker with parabolic concentrator for heating,

drying and cooking purposes, „Archives of Applied

Science Research,2012,4(4):1636-1649.

N.L. Panwara, S.C. Kaushika, Surendra Kothari,‟

State of the art of solar cooking: An overview‟,

Renewable and Sustainable Energy Reviews 16, pp

3776– 3785, 2012.

A.Mawire, M.McPherson, R.J.van den Heet Kamp

„Simulated energy and exergy analyses of the

charging of an oil-pebble bed thermal storage

system for a solar cooker,‟ Solar energy materials

and solar cells 92 (2008) 1668-1676.

International Journal of Pure and Applied Mathematics Special Issue

436

-

437

-

438