inventory management system in balasore alloy

-

Upload

pabitrakiranparhi -

Category

Documents

-

view

1.640 -

download

1

description

Transcript of inventory management system in balasore alloy

1.1 Objectives of the Study The main objective of this study is to evaluate the efficiency of Inventory

management in Balasore Alloys Limited (BAL) over a period of 5 years (2004-

2005 to 2007-2008). The specific objectives of the study are as under:

1) To find out the trend of inventory investment in Balasore Alloys Limited.

2) To examine the management pattern of inventory.

3) To analyze closing stock position

4) To establish a relationship between total asset and inventory

5) To establish a relationship between current asset and inventory

6) To establish a relationship between total asset and current asset

7) To know standard consumption of raw material

8) To suggest some measures for improvement of inventory management

practices.

ORGANISATION STUDY

1

2.1INTRODUCTION

Balasore Alloys Limited(BAL), Balgopalpur, Balasore formerly Ispat Alloys Limited, is a member of ISPAT group of companies owned by the Mr. P.K Mittal. It was incorporated in 1984 and started its commercial production in 1987.

2.2GENERAL PROFILE OF BALASORE ALLOY LTD

2.2.1MISSIONThe mission of Balasore Alloys Limited in short BAL is as follows;

Managing our business with integrity and highest ethical standard

Acting in a socially responsible manner with particular emphasis on the wellbeing of all stack holder and communities we serve.

Adopting new technology, initiative, continuous learning and innovation for productive use of all resources.

Maintaining and developing a team of highly motivated trained professionals.

Providing total customer support through continuing pursuit of technical excellence, understanding of product quality, reliability and services.

Striving constantly self reliance and self-sufficiency in all operation.

2.2.2VISION

To be globally trusted supplier of Ferro-alloy as well as to create sustained value addition for all stakeholders.

2.2.3STRATEGIC BUSINESS OBJECTIVE

2

To be among top fifteen manufacturer of Ferro-chrome in world by 2011.

To achieve 10000 MT per month production level by may 2009.

To be most competitive Ferro-alloys producer by 2011 with reasonable profitability.

To achieve TPM special award by2010.

To achieve zero customer complaint.

2.2.4 SWOT ANALYSIS

3

Strength Positive work culture, skilled and motivated workforce and employee

participation.

Healthy IR, Union Recognition, Public Utility Service Status

Balance Score Card and Online PMS system

Focus on Training and Development.

Well Laid down policies and procedures ( Policy Manual/ SOPs)

Monthly Open House Meeting ( Trust/ Transparency)

Review of HR Policies by HRC on Monthly basis and corrective action plan.

Finds a place in top ten quality supplier of Ferro Chrome in the world

Won the most prestigious CII award continuously during last two years.

Strong customer relation ship both in Domestic and abroad.

Strongly competes in the market because of low cost of production.

Financial Management of the company touches the benchmark level.

Provides a very good platform for career growth of employees

Long term contracts

WEAKNESS

Quality variation in RM(Dolomite) Discussion is going on with TISCO for increasing quality.

Non available of lumpy ore. (planned for procuring from Pakistan and Turkey)

Space constraints for storage of material.

Deterioration and wastage of material.

OPPORTUNITY

4

Global souring of raw material

Acquiring mines

SAP implementation

Using Dhamara port for raw material transportation

Development of premises railway siding for bulk cheap and easy transportation

Using RFCD system(planed with it dept)

THREAT Change in import and export policy

Volatility of coke and coal price hike

Unfavourable changes in taxation and duties

Highly unstable global petroleum prices and monopolistic behaviour of OPEC.

5

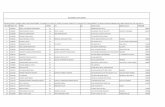

2.2.5 BORD OF DIRECTOR Balasore alloy is managed by board which comprises of directors with significant experience. A team of qualified and experienced personals assist the board in carrying out day to day operations effectively. The list of present board of directors of the company is as per the table given bellow.

a) Mr. Promod Mittal, chairmanb) Er. R.K Jena, managing directorc) Mr.V.K mittal, directord) Mr. R.N Pandey, independent directore) Mr. S Mohapatra, independent directorf) Mr. S.K Pal, independent directorg) Dr. A.k Bhatachaya, independent director

2.2.6 AWARD AND RECOGNITIONThe company receives the recognition in different field as follows:

India manufacturing excellence award -2007 (platinum award – 1st

runner up). The company has owned the first position in productivity award for

sustained level of high overall productivity by CII(ER) The company has been conferred with a special inertia award 2007

for energy efficiency. ISO 14000 certification from bureau of Indian standards. Company’s chrome mines division accredited with ISO 9001:2000

certification by DNV

2.2.7 HISTORY OF BALASORE ALLOYYEAR EVENTS

6

1984 - The company was incorporated on 1st May in Orissa. It was promoted by Ispat Group headed by M.L. Mittal. The main objective of the company is to manufacture calcium silicide ferro silicon calcium carbide and all other ferrous and non-ferrous metal based alloys.

1987 - Due to erratic power situation production of calcium silicide could not be taken up. Unstable power situation once again stalled the commencement of calcium slicide production.

- The company installed a second furnace and a captive power plant with a total outlay of Rs 22.60 crores.

- The company along with an Indonesian firm set up a joint venture project for manufacture of Silicon Ferro Silicon and Ferro Chrome.

- 100 shares subscribed for by the signatories to the Memorandum of Association. 31 49 900 shares then issued at par of which the following shares reserved and allotted:

- (i) 6 09 900 shares to Indian promoters directors etc.

- (ii) 4 50 000 shares to NRI promoters on repatriation basis and

- (iii) 3 00 000 shares to IPICOL Out of the remaining 17 90 000 shares the following shares were reserved for preferential allotment:

- (i) 89 500 shares to employees including Indian working directors and

- (ii) 35 800 shares to business associates of the Company. Out of (i) and (ii) only 36 600 shares taken up.

- The balance 16 64 700 shares along with the unsubscribed portion of 88 700 shares out of the preferential quota were offered to the public during Sept. 1986.

- Additional 4 47 500 shares allotted to the public to retain oversubscription.

7

1989 - The company received a letter of intent for the setting up a third furnace at the existing site at Balgopalpur for the implementation of charge chrome/ferro chrome with a licensed capacity of 15 000 TPA.

- The company issued 45 45 454-14% secured fully convertible debentures of Rs. 220 each of which (i) 18 00 000 debentures were reserved for preferential allotment to the existing equity shareholders of the company in the ratio of 50 debentures for every 100 equity shares (only 17 58 345 debentures were taken up);

- (ii) 1 36 000 debentures allotted to NRI (all were taken up);

- (iii) 13 63 636 debentures reserved for preferential allotment to the equity shareholders of Nippon Denro Ispat Ltd. and Ispat Profiles India Ltd. (all were taken up);

- (iv) 2 27 000 debentures reserved for UTI ICICI Insurance companies and Mutual Funds (all were taken up); and

- (v) 2 27 273 debentures offered to the employees (including Indian working directors) of the Company (only 185 debentures were taken up).

- The balance of 7 91 545 debentures along with the 2 68 743 debentures not taken up by employees and equity shareholders were offered to the Indian public (all were taken up). Additional 2 04 544 debentures and 4 47 274 debentures were allotted to the shareholders of Nippon Denro Ispat Ltd. Ispat Profiles India Ltd. and Indian public respectively to retain oversubscription.

- Part-A of Rs. 60 has been converted into two equity shares of the face value of Rs. 10 at a premium of Rs. 20 per share at the end of 6 months from the date of allotment. Part-B of Rs. 160 will be converted into appropriate number of equity shares of the face value of Rs. 10 at such premium as may be decided by the CCI between a period of 18 months to 24 months from the date of allotment.

8

1990 - With the Government of India extending the scheme of broad-banding to bulk ferro-alloys industry since January the company hoped to have a diversified product mix within the existing licensed capacities.

- 1 00 00 544 No. of equity shares allotted due to the conversion of Part-A convertible debentures.

1991 - The project was at an advanced stage of implementation and it was expected to be commissioned in March/April.

- Another letter of intent was received for the setting up of an 100% Export Oriented Unit (EOU) at Dhenkanal in Orissa for the manufacture of charge chrome/high carbon ferro-chrome with a licensed capacity of 75 000 TPA.

1992 - Profitability also improved due to optimum utilisation of company's resources and adoption of various cost control measures.

- 352 82 219 shares allotted on conversion of pref. `B' of debentures.

- The said furnaces are set up as Domestic unit in place of 100% EOU origin with in build facility to produce other ferro alloys in addition to charge/ferro chrome to enable the company to market internationally 2 Nos. of imported DG sets of 5 MW each were commissioned.

1993 - The company successfully implemented the commissioning of two new furnaces of 7.5 MVA capacity each at Balgopulpur.

1994 - The company undertook steps to increase captive power generation capacity from 19 MW to 40 MW by installing two new imported D.G. Sets of 10.5 MW each at Balgopalpur Orissa.

1996 - The Company has been conferred with various awards during the period under review such as Regional Top Exporter Shield for 1994-95 from Engineering Export Promotion council (Eastern Region) HRD First Prize for 1994 from CII. (Eastern

9

Region) and Best Exporter Award for 1994 from Directorate of Export Promotion Council Orissa.

- The Company has also received prestigious IS 14002/ISO 9002 accreditation from the Bureau of Indian Standards.

- The Company has successfully used PLCs for economic use of Resources like Power and Raw Materials.

1997 - IAL is a leading manufacturer of silicon metal and ferro-silicon. Its products are manufactured under technical collaboration with global leaders like Nippon Denro Japan Danieli Italy Elkem Norway and Outokumpo Finland IAL has aggressively added capacities and diversified within the realms of the ferrous industry.

- IAL have suffered a similar fate of delayed project implementation for as long as a decade.

1998 - Power generation capacity was increased by installing two new imported D G sets of 10.5 MW each from MAN B & W Germany at its works at Balgopalpur Orissa.

- The management of Ispat Alloys Ltd has declared an indefinite lockout following violent incidents at the Balgopalpur factory premises in Balasore district of Orissa.

- Ispat Alloys Ltd a subsidiary of the Mittals-promoted Ispat Industries Ltd.

1999 - Two leading manganese alloy producers -- Ispat Alloys and Maharashtra Elektrosmelt -- have made losses during first quarter April/June.

2007 -Balasore Alloys Ltd has informed that Mr. Rabindra Kumar Jena Executive Director of the Company has been elevated to and appointed as Joint Managing Director of the Company w.e.f. January 31 2007.

-Balasore Alloys Ltd has appointed Mr. Debadatta Sengupta as Director of the Company w.e.f. January 31 2007.

10

2.2.8 MODERN MANAGEMENT

The company continuous to actively pursue its modern management initiatives in the area of

Six sigma

Total productive maintenance (TPM)

Activity based cost management

Total quality management

Performance management system

Just in time (JIT) in order to maximize performance efficiency and nature of burning desire to excel in each of this faculty.

These initiatives have efficiently assisted the company in rationalizing its work force and in giving it enough experience to manage the operation efficiently thus enhancing the company’s global competitiveness and recognition eventually catapulting the company into the higher echelons of modern management, in the process giving it a strong leadership position in the market.

11

2.2.9 PURCHASE SYSTEM OF BALASORE ALLOY

Balasore alloy purchase department do two type of purchase work. These are store item and raw material item.RAW METERIAL Raw materials are the materials out of which finished product are made by any manufacturing process. MEASURE RAW METERIAL ITEM

SL NONAME OF THE RAW METERIALS PLACE

A. FLUXES 1 QUARTZ BARIPADA, ORISSA

2 DOLOMITERAULKELA, RAJGANGPUR,ORISSA

3 MAGNESITE NAINITAL, US4 BAUXITE JHARKHAND5 MILLSCALE DHANKANAL, ORISSA

6EC PASTE(INDEL, HIRAKUD)

HIRAKUD ORISSA, BELGOWN

7EC PASTE(INDEL,BELGAON)

8 EC PASTE(INDIA CARBON) B REDUCTENTS 1 LAMC (10-20)MM-RAW MET DURGAPUR, WB2 LAMC (20-70)NAYAN 3 LAMC –KTC 4 LAMC (10-40)STC 5 LAMC (10-40)MMTC ORISSA

6ANTHRACITE COAL-NABA BHARAT

7 ANTHRACITE COAL-ROHIT 8 LAMC(10-70)KALIKA 9 LAMC(10-100)PRAVA 10 CIL COCK WBC CHROME ORES

1 CR LUMP(38-40)S.MINERALSUKINDA, (OWN PLANT)

2 TURKEY(40/80) IMPORTED3 TURKEY (50%) 4 S.MINERAL(42-44) ORISSA

12

5 S.MINERAL(40-42) 6 FACOR LUMP +54 BHADRAK,ORISSA7 BAL-CHIPS-MG ORISSA8 BAL-CHIPS-HG/SHG 9 BAL-CHIP-SMS

10WASHING POINT CHIPS (LG/MG/HG)

11 IKP FRIABLE LUMP 12 BAL PRESS BRQT-MG

13 BAL PRESS BRQT-SHGSUKINDA, (OWN PLANT)

14 BAL PRESS BRQT-HGSUKINDA, (OWN PLANT)

15 BAL PRESS BRQT-LGSUKINDA, (OWN PLANT)

16 CEMENT BRIQUETTE JHAR GRAM,WB17 BAL PRESS BRQT-SMG

DBRIQUETTING REQUIREMENT

1 BAL CR FINES-MG 2 BAL CR FINES-HG 3 BAL CR FINES-SHG 4 BAL CR FINES-LG

5 LIME POWERJAMSEDPUR, JHARKHAND

6 MOLASSES

JATANI ORISSA,ANDHRA PRADESH,BIHAR,KARNATAKA

7 CEMENT JHAR GRAM,WB

8 FURNACE OILSOMNATHPUR ORISSA, HALDIAA WB

PURCHARE SYSTEMAccording to production, production department decide, how much quantity of raw material required fulfilling the production target.

Purchase department analyse in respect of stock at yard, minimum stock level and requirement, how much quantity of raw material should be procure.

13

After deciding the procurement quantity purchase department or procurement committee decide from which supplier how much of raw material and which item should be procure.

Issue of purchase order, transportation order accordingly.

Purchase order should is audited by internal auditor.

When material reaches in the yard, it is tested in the lab to decide the supplied material is accepted or rejected.

STORE ITEMThose item which is not directly use in production work, these are store item. MEASURE STORE ITEM STORE PURCHASE ITEM NAME PLACE

1 DA FULL CYLINDERJAMSEDPUR, JAGPUR

2 LANCING PIPS KOLKATA

3 OXIGEN GASJAMSEDPUR, JAGPUR

4 M.S ROUND ROURKELA5 SODIUM SILICATE KOLKATA6 HR SHEET JAMSEDPUR7 LIQUID OXIGEN GAS KOLKATA8 HIGH SPEED DISEL HALDIA9 WELLDING ROD ANUGUL10 GUNY BAG BHADRAK11 JOMBO BAGS KOLKATA, BALASORE12 HDPE BAGS KOLKATA, BALASORE13 COTTON THREAD KOLKATA, BALASORE

PURCHASE SYSTEM

14

For purchasing of store item Balasore Alloy Company follow ICIS (integrated computerised information system) system. Through this system company search, where are needed item found, through internet. They follow some roll in purchase of store item. These are describing bellow.

User department send an indent to purchase department, that what item they required.

Then purchase committee make verification and give approval if it is purchase or not.

It is initialise by commercial department.

Purchase department make an enquiry through internet where this item is found.

Vender sent there quotation to purchase department.

Purchase department make a comparison and decide where to purchase.

Purchase department then negotiate with the vender.

Then company place order.

2.3BUSINESS PROFILE

15

Balasore Alloy Ltd. a measure player in the international Ferro-chrome market, has notched up an impressive growth of 435.59% in its net profit at RS. 3329.11 lakes for the 15 months period ended 31st march, 2008, as compared with Rs.621.58 lacks recorded during the corresponding 15 months period ended 31st December, 2006.

Turnover for the 15 month period ended 31st march 2008 increased by 55.53% to Rs.53085.62 lakes as against Rs.34132.59 lakes during the corresponding 15 months period ended 31st December 2006. Export turnover for the 15 month period ended 31st March 2008 increased by100%to Rs.40514.75 lakes as against Rs.20296.66 lakes during the corresponding previous financial period. PBT for the 15 month period ended 31st march 2008 registered a heavy growth of 352.97% at Rs.5116.83 lakes as against Rs.1129.61 lakes registered in the corresponding previous financial years. EPS jumped by 366.09% at Rs.5.36 per share for the 15 months period ended 31st march 2008 as compared to Rs.1.15 per share for the previous financial period. (Face value per share =Rs.5/-)

The company has been able to sustain the momentum of its accelerated growth chiefly on account of judicious product mix, improved capacity utilisation better realization and improved cost efficiencies, despite rising input cost and appreciating rupee.

MEASURE CUSTOMER

16

17

JAPAN & KOREA

Mitsui

Toyota tsusho corporation

Kinso corporation

Stemcor

Glencore

EUROPIAN UNION

Indo-german

Stemcore

Traxys

Arcelor mittal

CMM(consider metal marketing)

INDIA

Mukand

Jewels seamless limited

Chandan

Rathi ispat

Bhusan

Vardhman special

CHINA

Sino-trust corporation

Sindchem international corporation

Magotteaux

Tsingshan

Kovintrade

LATIN AMERICA

Pimasa

London metal company

INFRASTRUCTURE

RAW MATERIAL SUPPLYBalasore alloy utilise chrome ore from captive mines. All raw materials transported up to the plant through road and rail.

MAN POWERBalasore alloy enjoys an excellent blend of Techno-Commercial man power of 450 personnel coupled with cordial labour relationship.

FINISHED PRODUCT MOVEMENTPacked in bags and transported by trucks up to port and debagged at port at the time of shipment to avoid contamination, fines generation, spillage and shortage of material.

QUALITY CONTROL

18

QUALITY ASSURANCE

Stringent Quality Assurance procedures are in place to ensure proper Raw Material feeding, Process Control as well as quality of Finished Products.

Sophisticated Analytical equipment is used by experienced Chemists to ensure that the desired quality standards of the customers are fulfilled.

Chemical: Balasore alloy has a well equipped laboratory with the modern facilities for analysing the raw materials and the finished goods. It carries out the analysis of chromium and silicon by wet method as per is 1559-1961. Balasore alloys test method are standardised by analyzing the standard sample like Japanese, euro & bsc. It uses leco-cs-300 for determination of carbon and sulphur by calibrating with standard sample .it determines phosphorous by wet method partially and by uv/vis spectrometer with colour developing (phosphomolybdate complex) by comparing standard sample. Balasore alloy uses aas-3110 for determining rare elements. it has hollow cathode lamps for specific element. The instrument is is celebrated by using standard sample.Physical: At the time of handling the material to required size – both undersize and oversize are tested using suitable screen and weighing scale. Further at the time of packing size fractions are tested at random.Mining: Balasore alloy acquired about 100 hectares of chrome ore mines in Sukinda valley in the state of Orissa. Mining operations have resulted in company’s self sufficiency in meeting entire chrome ore requirement to produce Ferro chrome on sustained basis.

FINANCE AND ACCOUNTING SECTION

19

Finance and accounting both play an important role in any business organisational setup. The main function of any finance and accounting of an organisation are funds management, cost monitoring, cost reduction and financial appraisal.

Money is a very scarce resource & is the most sought after commodity because all of the transaction of the human society is settled in term of money. Money & finance are of not one & the same things. Money store in vaults, or kept in shape of gold bars, or an ornament is not finance. Money is a static value expressed in currency of the country, where as, finance is an expression of dynamic function of money. Depending upon the requirements and close monitoring of expenditure Balasore alloy has formed the following section for smooth running of the finance and accounts department and to maintain the liability position of the company.

a) Bills payable sectionb) Payroll sectionc) Provident fund sectiond) Cash office sectione) Finance sectionf) Material sectiong) Costing sectionh) Bills receivable sectioni) Book-keeping section

20

3.RESEARCH METHODOLOGY

3.1 REVIEW OF LITERATUREThis study is based on both secondary and primary data. While secondary data

was collected from the company annual reports, websites and various journals

available through library work.

These are as follows websites are as follows

1. www.balasorealloy.com

2. www.outokumpu.com

3. D:\alloy\inventory\Inventory Accuracy article - white paper.mht

4. D:\alloy\inventory\The Aisle Width Decision Wide Aisles, Narrow

Aisles (NA), and Very Narrow Aisles (VNA).mht

5. D:\alloy\inventory\How effective is your Lift Truck Safety program.mht

LIST OF BOOKS

1. Inventory management (s. Chandra)

2. Production and operation management (S.N CHARY) TATA

McGRAW HILL

3. FINANCIAL MANAGEMENT (I M PANDEY)VIKAS PUBLIGHING

HOUSE PVT.LTD

4. MANAGEMENT ACCOUNTING (Shashi K. Gupta & R.K. Sharma)

KALYANI PUBLISHERS

21

The primary data was collected by taking personal interviews as well as

discussions with senior and middle level executives. The researcher had also

visited the factory to collect information through personal observations.

3.2 Methodology and Data Base

After making a review the available literature and setting objectives in the

preceding paragraphs, an attempt is made to crystallize the whole work by way

of making a blue-print of the study. As such the research structure is designed

as follows:

The present piece of research work is analytical and explorative in nature. The

purpose of this research is to contribute towards a very important aspect of

financial management known as inventory management with reference to

Balasore Alloys Limited operating in the Ferro alloys sector.

3. 3 Period of the study

The study covers a four-year period starting from 2004-05 to 2007-08. The

period of study was restricted due to paucity of time

3.4Data Set This study is based on both secondary and primary data. While secondary data

was collected from the company annual reports, websites and various journals

available through library work; the primary data was collected by taking

22

personal interviews as well as discussions with senior and middle level

executives. The researcher had also visited the factory to collect information

through personal observations.

3.5Tools of Analysis

The collected data being tabulated was analyzed and interpreted with the help

of different financial ratios, percentage, average, trend analysis, and

correlation.

4. VIEW TO INVENTORY MANAGEMENT

4.1 INTRODUCTION

Inventories constitute the most significant part of current assets of a large majority of companies in India. On an average, inventories are

23

approximately 60% of current asset in public limited companies in India. Because of the large size of the inventories maintained by firm, a considerable amount of funds is required to be committed for them. It is, therefore, absolutely imperative to manage inventory efficiently and effectively in order to avoid unnecessary investment. A firm neglecting the management of inventories will be jeopardising its long run profitability and may fail ultimately. It is possible for the company to reduce its level of inventories to a considerable degree, e.g., 10 to 20 percent, without any adverse effect on production and sales, by using any simple inventory planning and control techniques. The reduction of excessive inventories carries a favourable impact on a company’s profitability. 4.2 What is inventory? Inventories are resources of any kind having an economic value. An inventory consists of raw material, finished goods, work-in-progress, consumable and stores. Thus inventory control is all about planning and devising procedures to maintain an optimal level of these resources. 4.3What is inventory management? Inventory management is primarily about specifying the size and placement of the stocked goods. Inventory management is required at different locations within a facility or within multiple locations of a supply network to protect the regular and planned course of production against the random disturbance of running out of materials or goods. The scope of inventory management also concerns the fine lines between replenishment lead time, carrying costs of inventory, asset management, inventory forecasting, inventory valuation, inventory visibility, future inventory price forecasting, physical inventory, available physical space for inventory, quality management, replenishment, returns and defective goods and demand forecasting.

4.4Definition of inventory management

Involves a retailer seeking to acquire and maintain a proper merchandise assortment while ordering, shipping, handling, and related costs are kept in check.

24

Systems and processes that identify inventory requirements, set targets, provide replenishment techniques and report actual and projected inventory status.

Handles all functions related to the tracking and management of material. This would include the monitoring of material moved into and out of stockroom locations and the reconciling of the inventory balances. Also may include ABC analysis, lot tracking, cycle counting support etc.

Management of the inventories, with the primary objective of determining. Controlling stock levels within the physical distribution function to balance the need for product availability against the need for minimizing stock holding and handling costs.

In business management, inventory consists of a list of goods and materials held available in stock.

4.5 Need for inventory Primarily inventory is held for transaction purpose. In the field of production, an enterprise cannot ensure uninterrupted

production unless it maintains an adequate inventory for materials. Inventory is also held as a precaution against a contingency for any

increase in lead time or consumption rate. It largely guards against apprehensions of changes in price

4.6 Benefits:4.6.1• Help reduce purchasing and inventory costs . Connect inventory control, purchasing, and sales order processing with demand planning and help reduce costs, improve cash flow, and help ensure that you have the right stock available when you need it.

4.6.2• Gain visibility into inventory processes. Effectively balance availability with demand and track items and their possible expiration dates throughout the supply chain to help minimize on-hand inventory, optimize replenishment, and increase warehouse efficiency.

4.6.3• Improve customer satisfaction.

25

Make more accurate order promises and intelligent last-minute exceptions with access to up-to-date inventory information. Respond quickly and knowledgably to customer queries for improved customer service. 4.6.4 • Reduce time to market . With integrated order, inventory, and distribution processes, as well as item tracking capabilities, your business can reduce manual data entry and get your goods to market fast.

4.7 FEATURES:

4.7.1 Inventory costing- Understand item costs throughout your warehouse and production processes, including inventory, work-in-process (WIP), and cost of goods sold (COGS), to help efficiently manage sales and purchase prices and line discounts with customers and vendors. Break down costs according to categories such as materials, capacity, subcontracting, and overhead.

4.7.2 Automated Data Collection System (ADCS) Help increase the accuracy and efficiency of your warehouse management—picking and putting away of items, physical inventory counts, and moving items from bin to bin—with ADCS.

4.7.3 Radio frequency identification (RFID) enablement Comply more easily with customer or supply chain mandates for RFID.

4.7.4 Order processing Provide customers with accurate item availability and deliver on time with support for available-to-promise (ATP) and capable-to-promise (CTP) insight.

4.7.5 Returns management Process returned inventory and account for additional costs. Automatically organize credit memos, replacement goods, returns to vendors, and partial or combined return of shipments or receipts. Exact cost reversal helps increase inventory accuracy.

4.7.6 Item tracking Trace lot or serial numbers to quickly determine where items were purchased, processed, or sold. Help eliminate waste due to expiration of goods with support for first expired/first out (FEFO) handling.

26

4.7.7 Item substitution Offer customers alternative items when those they want are out of stock, or if the alternatives can be provided less expensively with a higher profit margin.

4.7.8 Item cross-references Identify what your customers want by cross-referencing any customer code, internal code, or vendor code.

4.7.9 Internal pick/put-away Pick or put away items and debit or credit inventory records independently of purchase receipts, sales, or other source documents to help maintain accurate inventory records even when you access items for testing, display purposes, or other internal or operational needs.4.7.10 Multiple locations and responsibility centres Provide customers who request non-stock items with immediate quotes. Automatically create non-stock items and process them in the same way you process stock items.

4.7.11 Location transfers Manage items individually per location. By grouping items into stock keeping units, items can be described and managed individually per location—including replenishment methods, safety stock, and costs.

4.7.12 Stock keeping units Handle inventory across multiple locations from one database to gain a complete, real-time business overview and create manageable cost and profit centres.

4.7.13 Warehouse management system Help reduce costs through effective warehouse processes such as directed pick and put-away and automatic bin replenishment.

4.7.14 Cycle counting Determine the counting frequency per item or stock keeping unit to help increase inventory accuracy and meet shipping deadlines.

4.7.15 Business notifications Generate e-mail messages to alert your people, suppliers, or partners to changes in critical inventory levels, order status, or replenishment needs.Purpose of Inventory Management4.8 Inventory control

27

Inventory control is concerned with minimizing the total cost of inventory. In the U.K. the term often used is stock control. The three main factors in inventory control decision making process are:

The cost of holding the stock (e.g., based on the interest rate). The cost of placing an order (e.g., for raw material stocks) or the set-up cost of production. The cost of shortage, i.e., what is lost if the stock is insufficient to meet all demand.

The third element is the most difficult to measure and is often handled by establishing a "service level" policy, e. g, certain percentage of demand will be met from stock without delay.

4.8.1The ABC Classification The ABC classification system is to grouping items according to annual sales volume, in an attempt to identify the small number of items that will account for most of the sales volume and that are the most important ones to control for effective inventory management.

4.8.2 Reorder Point: The inventory level R in which an order is placed where R = D.L, D = demand rate (demand rate period (day, week, etc), and L = lead time.

4.8.3 Safety Stock: Remaining inventory between the times that an order is placed and when new stock is received. If there are not enough inventories then a shortage may occur.

Safety stock is a hedge against running out of inventory. It is an extra inventory to take care on unexpected events. It is often called buffer stock. The absence of inventory is called a shortage.

Select quantity with the lowest Total Cost, including the cost of the items purchased.

4.9 Some concepts About Inventories

28

Inventories considerably influence the profitability and liquidity of

the industrial units. It is therefore essential to have a clear-cut idea about

the various aspects of inventories, which are as follows:

1. Inventory – a major cost component

2. Material – a fertile area for more research

3. Material – a limiting factor

4. Lead time influences on inventories

5. Productivity of inventories

4.9.1 INVENTORY – A MAJOR COST COMPONENT

An analysis of sales of some industrial undertakings during 2000-2001

gave the following information:

Direct materials 60%

Labour 15%

Overheads and profit 25%

Total 100%

The above data shows that direct materials and indirect materials

forming part of the overhead cost, constituting inventories, account for a

large percentage of the total cost. Inventories, therefore, offer the most

important and fruitful area of cost reduction and increased profits.

The inventory problem is therefore one of balancing various costs

so that the total cost is minimized. These costs are:

(a) Cost of ordering

(b) Cost of holding or carrying inventory

(c) Under stocking cost

29

(d) Overstocking cost

The cost of ordering opposes the cost of carrying while the under

stocking cost opposes the overstocking cost. If these costs operate in the

same direction, instead of behaving in opposition, there will be no

inventory problem. The cost of ordering and the cost of carrying enable

us to optimize on the number of orders and the quantity of inventory to be

ordered. The under stocking and overstocking costs help an industrial unit

to determine the service level that has to be maintained by the inventory.

4.9.1.a. Cost of Ordering

An organization can meet its need for materials only after fulfilling

certain activities. These activities consume executive and non-executive

time, stationery and communication charges, thus giving rise to the

ordering cost. The cost of an imported order is much higher than that of a

cash purchase from the market. This is on account of the variation in the

level of activities for different ranges of items.

The ordering cost consists of several costs attributable to the

following factors.

1. Stationery, typing and dispatching of orders and issuance

of reminders

2. Advertisements, tender forms, tender opening formalities,

etc.

3. Follow-up costs. These constitute the travel costs,

telephone and postal bills.

4. Costs incurred by the goods received bay, inspection and

handling

30

5. Rent and depreciation on the space and the equipment

utilized by the concerned purchasing personnel

6. Salaries and all statutory payments to the purchasing

personnel

7. Cost of source developments

8. Cost of entertaining suppliers

Thus the average ordering cost is:

Total costs incurred on all these heads during a year

Number of orders in that year

4.9.1.b. Cost of Holding or Carrying Inventory

One of the motivating factors to control inventory arises on account of its

carrying cost. It comes to around 30 per cent of the total inventory cost in

most of the industrial undertakings, i.e. if the annual average inventory is

valued at Rs 100 lakh, then it will cost the company Rs 30 lakh to carry it.

Inventory carrying cost is usually expressed as a percentage of the

average investment in inventory. Capital cost, cost of storage and

handling and deterioration and obsolescence costs are its main

components.

4.9.1.c.Under stocking Cost

It is penalty that an undertaking has to pay on account of its inability to

meet the demand in time. The quantum of penalty depends on the nature

of the demand. In the cases where the demand is from a customer of the

retail establishment, the shortage condition may result in a cost relatively

31

small compared with the item cost. If, on the contrary, the demand arises

in a manufacturing activity, the penalty cost for shortage may be

extremely high relative to the cost of the item. This is because the entire

manufacturing activity would necessarily have to wait for the item which

is out of stock.

4.9.1.d. Overstocking cost

The overstocking cost arises on account of the opportunity lost when

disinvestment in inventories is postponed for a longer period than is

necessary. In the case of items which will ultimately be used, this cost be

equated with the carrying cost. For items which cannot be used after a

certain period, this cost will be the difference between the cost of the item

and its salvage value.

As far as an organization is concerned, the situation of both

overstocking and under stocking is not at all desirable. Both shortages

and surpluses prove costly and need to be balanced – one against the

other. Arriving at the happy medium between too much and too little is

the essence of inventory management.

4.10 Tools and Techniques of Inventory Management

4.10.1 INTRODUCTION

32

The basic problem of inventory management is to strike a balance

between the operating efficiency and the cost of investment and other

costs associated with large inventories, with the object of keeping the

basic conflicts at the minimum while optimizing the inventory holding.

The decisions as to which item to manufacture and when to keep

inventories in balance, require the application of a wide range of

techniques ranging from simple graphical methods to more sophisticated

and complex quantitative techniques. Many of these techniques employ

concepts and tools of mathematics and statistics and make use of various

control theories from engineering and other fields. They are primarily

aimed at helping to make better decisions and following a sound policy.

4.10.2INVENTORY MANAGEMENT TECHNIQUES

The various techniques applied for inventory management are as follows:1. Selective inventory control

2. Setting of various stock levels

3. Systems of inventory control

4. Economic ordering quantity (EOQ)

5. Re-order point and safety stock

6. Application of computers to inventory management

7. Just-in-time inventory management

8. Materials requirement planning (MRP)

9. Inventory audit.

33

Selective Inventory Control

Effective inventory management requires the understanding and

knowledge of the nature of inventories and to gain this under standing the

following analysis and classification techniques are available.

1. ABC analysis2. HML analysis3. XYZ analysis4. VED analysis5. FSN analysis6. SDE analysis7. GOLF analysis8. SOS analysis

The motive behind these analyses and their classifications is to tackle the important aspects more rigorously. Moreover, and equally critical analysis of all items will be very expensive and will have a diffused effect regardless of priorities. Table 5.1 shows the available classifications, their bases and their uses.

TABLE 5.1 Classifications of inventoriesTechnique Basis Main use

ABC(Always Better Control)

HML(High, Medium, Low)XYZ

VED(Vital, Essential, Desirable)

Value of Conception

Unit price of the material

Value of the items in storageCriticality of the component

To control raw material, components and work-in –progress inventories in the normal course of businessMainly to control purchases

To review the inventories and their uses at scheduled intervals To determine the stocking levels of spare parts

34

FSN(Fast moving, Slow moving Non-moving)SDE(Scarce, Difficult, Easy to obtain)

Consumption pattern of the components

Problems faced in procurement

To control obsolescence

Lead time analysis and purchasing strategies

TABLE Classification of inventories (Contd.)

Technique Basis Main use

GOLF (Government Ordinary, Local, Foreign source)

SOS (Seasonal, Off-Seasonal)

Source of the material

Nature of supplies

Procurement strategies

Procurement/holding strategies for seasonal items like agricultural products.

ABC analysis

The method of ABC classification for managing inventories has been currently adopted in most of the industrial units. Inventories of undertakings are classified into various categories on the basis of their importance, namely their value and frequency of replenishment during a period. One category called group ‘A’ items, consists of only a small percentage of the total items handled but has a combined value that constitutes a major or large portion of a total stock holding of the concern. The second category consisting of group ‘B’ items is relatively less important. The third category consisting of ‘C’ items is of least importance, i.e. the group consists of very large number of items, the value of which is not very high.

35

The ABC analysis is a rational approach for determining the degree of control that should be exercised on each item in inventories. Obviously, the ‘A’ class items should be subjected to a strict management control under either continuous review or periodic review with short review cycles. The ‘C’ class items require little attention and can be relegated down the line for periodic review say, just once a year. The control over ’B’ class items should be somewhere in between.

The ABC analysis follows the general principles of pare to (Wilfredo Pareto, Italy, 1896) that “in any series of elements to be controlled, a selected small fraction in terms of the number of elements would always account for a large fraction in terms of effect”.

HML analysis While the ABC classification is based on the annual consumption value of an item, the basic criterion for HML classification is the unit value of an item. In this respect the HML classification is district from the ABC classification. On the basis of the unit value of an item, the materials arte further classified as high-value materials, medium-value materials and low – value materials. In HML analysis, the items should be listed out in descending order of unit value and the management may fix limits for determining the three categories. .

XYZ analysisThe XYZ analysis is based on the value of the inventory stored. The X items are those whose values are high while the Z is those whose inventory values are low. And the Y items are those which have moderate inventory stocks. This analysis, therefore, helps to identify those few items which account for the large amount of money locked up in stock and take steps for their liquidation/reduction.

Usually the XYZ analysis is made in conjunction with ABC analysis or HML analysis. The XYZ analysis can be combined with the ABC analysis as given below.

Class of items

A B C

36

X

Y

Z

Efforts to be made for reducing stocks to the Z category.

Efforts to be made for converting stocks to the Z category

--

Efforts to be made for converting stocks to the Y category.

--

Stock levels may be reviewed twice a year

Steps to be taken for disposing of the surplus stocks.

Control may be further tightened.

--

VED analysis

The VED analysis popularly known as Vital, Essential and Desirable analysis is used primarily for the control of spare parts. On the basis of the critical nature or relative importance, spare parts may be classified into three categories, namely vital (V), ESSENTIAL (e) and desirable (D). The vital items have extreme criticality, the desirable items are not critical and the essential items fall somewhere in between the vital and desirable categories.

FSN analysis

When analysis is carried out on the basis of the rate of movement of materials in the stores or on the basis of consumption pattern of components, it is known as the FSN analysis. The three letters stand for fast-moving, slow –moving and non-moving. This classification comes in very handy when it is necessary to control obsolescence. The demand for fast-moving items is generally high. Thus special care should be taken in respect of these items, otherwise the production may be interrupted due to the shortage of such materials. Inventories which have only a low turnover are brought under the category of slow moving items. These items are not issued at frequent intervals.

37

SDE analysis The SED analysis is generally done on the basis of the problems faced in procurement of an item. These letters stand for Scarce items, those which are Difficult to obtain and those which are fairly Easy to obtain.

GOLF analysis

The GOLF analysis is carried out mainly on the basis of the source of material. GOLF stands for Government, Ordinary, Local, and Foreign. There are many imported items which are channelized through the State Trading Corporation, Metals Trading Corporation, etc.

SOS analysis

The SOS analysis is making on the basis of the nature of supplies. As such it classifies the items into two groups S (Seasonal) and OS (Off Seasonal). The analysis identifies items into (i) seasonal, but available only for a limited period, (ii) seasonal, but available throughout the year; and (iii) off-seasonal items whose quantity is determined on different considerations.

4.10.3 Systems of Inventory Control are:(a) Perpetual inventory (Automatic inventory) system(b)Double bin system

.1Perpetual inventory systemThe control of inventories while in storage is affected through what is known as the perpetual inventory. Thus the two main functions of the perpetual inventory are recording store receipts and issues so as to determine at any time the stock in hand, in terms of quantity or value, or both, without the need for a physical count of the stock.Continuous verification of the physical stock with reference to the balance recorded in the stores records, at any frequency, as convenient to the management.

38

The perpetual inventory system consists of:(i) Bin cards(ii) Stores ledger(iii) Continuous stock taking

1.1Bin cards Bin cards are printed cards used for accounting the stock of material, in stores. For every item of materials, separate bin cards are kept.The details regarding the material such as the name of the material, the part number, the date of receipt ad issue, the reference number, the name of the supplier, the quantity received and issued, the value of the material,, the rate the balance quantity, etc. are recorder in the bin cards. The bin cards are kept in the bin serially according to part number of the component. At the end of the financial year the balance quantity in the bin cards is taken as the closing stock, and it is valued at the rates noted in the bin cards.

Stores ledger- Like bin cards, a store ledger is maintained to record all the receipts and issues in respect of materials with the difference that along with the quantities, the values are entered in the receipt, issue and balance columns. Additional information as noted in the bin cards regarding the quantity on order and the quantity reserved, together with their values may also be recorded in the stores ledger.Continuous stock taking- The perpetual inventory system is not complete without a systematic procedure for physical verification of the stores. The bin cards and the stores ledger record the balances, by but their correctness can be verified by means of physical verification only.There is a proper procedure for the physical verification of the stocks in most of the industrial units. The excesses/shortages found in the verification are reported for action so as to reconcile the differences in stock.Double bin systemThe double bin system is a recently developed technique in certain industries in respect of low consumption value items, i.e. items belonging to class ‘C’ in ABC analysis. This system separates the stock of each item into two bins, one to store the quantity equal to the minimum quantity and the other to store the remaining quantity. There are instructions not to use the quantity in the smaller portion as long as there is stock in the other portion. As soon as it becomes necessary to use the quantity marked as

39

minimum, it is a signal to place new orders. When the fresh order is received, the minimum quantity is segregated again. The double bin system is ideal for items for which demand and lead time are fairly regular and established. It also avoids the necessity of taking physical inventories as in the case of the perpetual inventory system. Since the storekeeper k knows automatically when to initiate the replenishment action, this being the time when he is forced to dip his hand into the minimum stock bin.In the fixed order quantity or the double bin system, there is a built-in safety provision in that the replenishment interval between two successive orders varies and hence adequate arrangements are required to take care of variations in the rate of demand. If the usage rate rises, the re-order level is reached earlier than expected and hence the replenishment interval is shortened. On the other hand, if the rate of usage goes down, the replenishment interval is lengthened. In either case the safety stock has to provide protection against variations in demand and lead time.

4.10.5 Economic Ordering Quantity (EOQ)In the fixed order quantity system, the reorder quantity is the economic order quantity which is fixed in such a manner as would minimize the total variable cost of managing the inventory. The various components of this cost are as follows:

(a) Procurement cost (this includes administrative and provisioning costs)

(b)Storage cost (this includes carrying and handling costs, etc.)(c) Stock out cost (this may be laid down by the management

according to its policy)

40

The appropriate term for economic order quantity appears to be 'economic lot size', meaning thereby the quantity that should be accepted per occasion so as to make the inventory procurement cost equal to the inventory carrying cost.

A company is said to be on a point of minimum cost wl1en its ordering cost is just equal to the carrying cost. In other words, a company should neither store excess quantity of material nor should it frequently place too many orders for the same material. When the unit price is same regardless of the quantity purchased, the following formula is used. Then it is found that the order quantity varies in proportion to the square root of the demand. There are indices given on scientific basis to help calculate the order quantity, keeping in view the position cost of inventories, namely the set-up costs, the ordering costs and the carrying costs. This is known as Economic Order Quantity (EOQ) or Square Root Formula, developed by.R.B. Wilson around the 1930s, which may be modified according to the individual requirement.

41

Where Q=annual requirement in unitsA=unit cost of pacing an orderC = annual carrying costD=optimum lot quantity or batch size.The formula for EOQ can be verified with reference to the following assumptions:Suppose the cost of each article is one rupee. The annual demand is 40,000 units. The cost of carrying inventory is 20 percent. The cost per order is Rs 10. Using the given formula, we have

=2000 units

Here the economic order quantity is 2000 units. Both the ordering cost and the average inventory carrying cost are the same, i.e. Rs 200 each as shown in Table 5.4 when the economic order quantity is 2000 units. Moreover when both the ordering cost and the inventory carrying cost are the same, the number of orders to be placed in a year is 20. thus the total cost becomes Rs 400 (i.e. ordering cost Rs 200 + carrying cost Rs 200), which is the minimum (see Table 5.4).

The graphical presentation of the behavior f carrying and ordering costs is shown in Figure 5.4 in the figure, EOQ units and costs have been plotted along x-axis and y-axis respectively. The inventory carrying cost line intersects the ordering cost line at a point P where both the carrying cost and the ordering cost are equal to Rs 200. thus the economic order quantity (EOQ) is 2000 units as shown at the point Q in Figure 5.4. Re-order Point and safety Stock

The computation of the re-order point is expressed in terms of the number of units used per day., multiplied by the lead time in days with adjustments to provide safety stock as will. Thus the formula to be followed is:

Re-order point = Average daily usage x Lead time in days + Safety stock

42

The various problems identified to be tackled in most of the industrial units in India for the implementation of JIT are:

(a) Reduction of set-up times (b)Kanban system (c) Delivery (from vendor) of exact quantity as per exact schedule (d)Preventive maintenance (e) Group technology.

All these problems can be tackled only with a very serious planned effort. Workers' motivation and literacy need to be enhanced. These are important for reducing the set-up time and introducing the Kanban systems. Moreover, the involvement and commitment of top management are needed to bring a drastic change in the working environment and change of attitude in people. These changes are difficult but possible. As there are wide differences in the operating environments of Japanese and Indian industries, the work environments in the industrial units in India need to be improved before the implementation of JIT.

43

Materials Requirement Planning (MRP)

Most of the blue chip companies in India faced an acute cash crunch situation during some periods of 1990s. Indian companies were, therefore, compelled to bring efficiency in working capital management, which in turn resulted in better receivables and inventory management. Table 5.6 shows the capital sensitivity vis-a-vis profitability of some leading Indian companies, related to a period in 1990s.

The American industries have been successful, simply because of the implementation of new management systems like MRP and JIT. The efficiency attained by the various American industries after the successful introduction of MRP is clear from Table 5.7.

The post-MRP achievements by the American firms are really worth emulating. In fact, the US and other industrially developed countries have set a way for the rest of the world to follow. The changes taking place on the Indian business scene are also forcing the Indian industries to make full use of the MRP and other cost effective systems.

The MRP system

Materials requirement planning is a special technique used to plan the requirements of materials for production. In other words, it is a

TABLE 5.6 Working capital sensitivityCompany 10% of working

capital(Rs in crore)

Increase in profits due to reduction of 10% in working capital(Rs in crore)

RelianceACCGrasim MLMTelcoTiscoBajaj AutoBBLILHLLITCL&T

394216376.8160.4209.3105.230.240.3115.1

788.432.615.432.141.921.16.18.123.1

44

Ashok LeylandCentury TextileGSFCNalcoVidecon IntBSES

143.1117.374.263.060.384.152.0

28.623.514.812.612.116.810.4

Source: The Economic Times, Tuesday, 15 March, 1997, P.14.

TABLE 5.7A VERAGE OPERATING PERFORMANCE OF MRP (300 companies) in the USA

Operation Pre-MRP Post-MRP Future estimateInventory turnover ratioMeeting delivery promises(%)Inventory costs (%)Number of expeditors Delivery lead times (days)

4.573.952.310.855.6

15.288.644.05.141.7

22.099.639.22.131.8

Source: “Japanese Manufacturing Lessons for India” ASCI Journal of Management, Vol. 19, No. 2 (March 19900), p. 117.

System of planning and scheduling the time-phased material requirements for production operations. It is geared towards meeting the end-item inputs and it updates the material requirements on a regular basis. The MRP system combines inventory control with production planning and works backwards from planned quantities (Master Production Schedule) for determining the material requirements. Thus the unique feature of the system is its continuous adjustment of material requirements with the changes in production schedule.

45

The MRP system is not based on the averaging process as the EOQ model is, it actually determines how much is needed and when needed on the basis of a master production schedule.

MRP and EOQ Models

Material requirement planning is a simple system of calculating (arithmetically) the requirement of the inputs at different points of time based on the plan or schedule for the production of the finished goods, Firms usually deal with bunched requirement of materials when they formulate plans to make assemblies out of various components. Thus the requirement of raw materials depends on the requirement of production of the finished product. However, it would be better if the firms know the production plan/schedule for the assembly of the finished product so as to arrange all the raw materials that go into the finished products. This is precisely what the materials requirement planning (MRP) attempts to do.- Under the MRP system, the material requirements of inputs are derived on the basis of requirements or plan for production of the final products, It means that there are no probabilities involved anywhere. Such a system will work well for materials that have no direct demand of their own, but have only a derived demand. These materials are called dependent demand items. On the contrary, as the finished assembly has a direct demand of its own, it is known as an independent demand item. Let us review the economic order quantity (EOQ) models. All of them assume a uniform (or more or less uniform) pattern of consumption of materials, The EOQ model answers the questions such as 'how much' and 'when' for optimal cost consideration on the basis of average consumption. HovJever, some basic difficulty arises in some peculiar production situations on account of the averaging of the consumption of materials. When a company deals with five different varieties of soaps, five varieties of shampoos, another five of cleaning powders, the requirement for many raw materials over time for these formulations does not fall in the smooth average consumption pattern. Figure 5.6 shows that in case the material is stocked in accordance with EOQ a firm may have excess material in inventory during the months of March, May- and September when

46

The firm does not need the material at all. Moreover, thefirm falls terribly short of the required material during the months of FEBRUARY, April and August. In all respects, the EOQ model tries to answer the questions of ‘how much?’ and ‘when to stock’. But this model fails miserably when encountered with an erratic requirement pattern for the material. Thus in many industries such erratic requirement patterns are common, especially for dependent items.

CONCLUSIONMost of the industrial units in India have adopted certain efficient techniques like ABC analysis, and perpetual inventory for controlling their inventories. But with the advent of electronic data processing, better selective inventory control measures are available, the adoption of which will lead to better control of inventory at a reduced amount of investment. The just –in-time inventory control technique can be implemented only after improving the work environment. The industrial units do not strictly adhere to the control measures such as EOQ and fixing of material stock levels. So it results in high inventory costs.

47

4.11 INVENTORY RATIO

The impact of various inventory management techniques such as ABC analysis, perpetual inventory, etc adopted in most of the industrial undertakings is not very clear. An analysis of inventory ratio will clarify this point. These ratios provide guidelines for planning and controlling of inventories of industrial units. They also provide relative or comparative information about the performance of the inventory function. The manufacturing firms generally have four kinds of inventories.

a) Stores and sparsb) Raw materialsc) Work-in-progressd) Finished goods

Thus ratios useful to inventory management are:1. inventory turnover ratio2. store and spares inventory holding period3. conversion period of work in progress4. inventory as per percentage of current asset5. inventory as percentage of total asset6. inventory in term of months of production7. number in days stock in hand ratio8. return per rupee invested ratio

4.11.1 INVENTORY TURNOVER RATIO (ITR)It is an important parameter used to evaluate the performance of the inventory function, and expressed as:

Here the average stock indicates the yearly average (average of opening and closing inventory), where the numerator of the ratio, i.e. the cost of sales means sale minus gross profit. Since inventories are valued in term of their cost, the cost of sales rather then sales has been used in computing the turnover ratio.

The inventory turn over shows how quickly the inventory is turning into receivable/cash through sale. This ratio indicates the number of times the stock is turned over on the average and must inventories is reflected in the number of time the firm’s average inventory is turned over during the year.

48

Inventory turnover has a direct relationship with the profit-earning capacity of the firm. Generally, the higher the rate of inventory turnover, the larger the amount of profit, the smaller the amount of work-in-capital tied up with inventory, and the more current the stock of merchandise. Each turn over adds to the volume of profit. A low inventory turnover implies excessive inventory levels compared to those warranted by production and sales activities, or a slow moving, or obsolete inventory. A high level of sluggish inventory amount to unnecessary tie-up of funds is impairment of profits and increased cost. If the obsolete inventories have to be written off, this will adversely affect the working capital. And liquidity position of the firm. Thus a higher turnover is better then a lower turnover.

Ideally, the inventory should be 12 and 20 percent of the sales value. As such, inventory turnover ratio should be within the range of 5.0-8.3, while it is also opined that the same could be 9 as well. It is, therefore, recommended that the inventory turnover ratio should be between 5 and 9.

Against the above background the inventory turnover ratio of the firm in India is an average of 1.0only. This situation suggests that inventory is most slow moving component of current asset. Thus, most of the firm in India keep excessive stock of inventory. Excessive stocks are usually unproductive and represent an investment with a low or zero rate of return.

Table 6.1 gives an insight into an average inventory turnover ratio of Japanese, American and Indian industries in order to highlight the potential available for cost reduction in Indian industries on account of inventories.

A low inventory turnover ratio implies excessive inventory levels compared to those warranted by production and sales activities or indicates slow-moving inventories. A high level of sluggish inventories amounts to unnecessary tie-up of funds which in turn result in more cost and finally, less profitability. An inventory turnover ratio of 45.5 by Japanese companies is commendable by any standard. It means that the Japanese industries carry an average Inventory for 8 days at any point of time while the Indian industries carry an average inventory for 48 days. The American industries have also been able to reduce investment in inventories to a large extent.

TABLE inventory turn over ratio of Japanese, U.S and India automobile industries

49

year Japan

U.S

India

1950 3 3 11960 8 10.5 21975 21 10.5 3.71985 38 12 4.21990 44 20.3 7.51992 45.5 21 7.5

Source: consolidated from the data given in Chartered Finance Analyst (Hydrabad) ASCI Journal of management and management accountant (1993), kolkata.

Of course, the inventory turnover ratio alone should not serve as the sole determinant of the liquidity of a firm’s inventories. More in-dept analysis, involving a thorough item-by-item check on existing inventories, is necessary to fully assess the liquidity of the inventory. 4.11.2 STORES AND SPARES INVENTORY HOLDING PERIODStores and spares is a term which commonly covers all kinds of supplies necessary to keep the production equipments operating in order to turn out production to the desired quantity and quality at the desire time. The lack of spares is often the one of the most serious bottlenecks in on interrupted production.

Stores and spares inventory constitute a large number of items, some of them are most important and require longer period of time to procure while most of them are not that important and require shorter periods of time to procure. In discriminate stocking of each and every item of stores and spares is not wise because a huge amount of funds may unnecessarily get locked up in the component of stores and spares. Thus the stock of components of stores and spares should be kept to a reasonable level.

Stores and spares inventory is the slowest moving among the four components of inventory. A close watch on the movement of this component of inventory and its affective control can pay rich dividends to a firm. In most of the firms, the stores and spares inventory occupies, on an average, about two-third of the total inventory. Such huge amount of investment in the stores and spares .inventory affects both liquidity and profitability of firms.

50

Stores and spares inventory turnover

The suggested norm for the stores and spares inventory holding period should be between three and six months. But in most of the firms, the stores and spares holding period is above the suggested norms. Thus the inference that can be drawn is that there is an over investment in stores and spares on account of poor inventory management. Long lead time’s procedural delays in procurement and uncertainty about availability, particularly of imported items are the main reasons which compel the firm to have more stocks of stores and spares. Moreover, heavy initial purchases at the time of procurement of new machineries and subsequent purchases without proper assignment of the requirement are also responsible for such huge investment in stores and spares.4.11.3 CONVERSION PERIOD OF WORK-IN-PROGRESS (WIP)Work-in-progress inventories represent product that need more work before they become finished product for sale. They are semi manufactured products. The longer the production cycles, the grater the volume of work-in-progress and vice-versa. It is calculated by dividing the WPI inventory by the cost of production and then multiplying the result by 365.

The suggested norm is that the work-in-progress conversion period should be less then 15 days. But this period is abnormally high in most of the firms. This situation is the result of week inventory management and hence is liable to affect the profitability of the firms.4.11.4 Inventory as a percentage of current asset

The share of inventory in the current assets indicates how much liability of a firm is locked up in inventory. Inventory is generally ness liquid then other current asset. As such the inventory is the most non-liquid current asset.

Inventory as a percentage of current asset

The quality and liquidity of current asset are largely dependent on the composition of current asset. The lower the percentage of inventory to the current assets is the greater the liquidity of current assets and vice-versa. Thus a low ratio is greater then high ratio asset

51

In the most of the firm in India, inventory on an average, occupies about 50% of the total current assets. Such a high ratio reveals that the quality and liquidity of current asset are very low in various firms.4.11.5Inventory as a percentage of total assets

Inventory is an important element in the asset structure of an industrial under taking. As such, its share in the asset structure and the proportion if the funds invested in inventory for operational activities of the undertaking should be examined.

Inventory to total asset

Studies have suggested that the ratio of inventory to total asset should be concentrated in the 16 to 30 percentage range. As against this norm, the average ratio in India is 54.4 percentages. Thus, inventory alone occupies more then half of the total assets in most of the firms. 4.11.6 INVENTORY IN TERM OF MONTHS’ COST OF PRODUCTION

The main yardstick used to measure the accuracy of the inventory is the month’s value of the usage. For the purpose, the aggregate inventory is converted in to month’s value of production, the stores and spares inventory to their month’s consumption and the worked-in-progress is assessed in term month’s cost of production.

Investment in inventory in term of months’ value of production is ascertain as follows

Depreciation is excluded from the cost of production as

depreciation does not involve case outflows.The Tariff commission of India has suggested that the inventory in

public sector enterprises should not exceed 4 to 6 months’ value of production. Against this background, it is found that most of the firms maintain a large quantity of inventory and thus a considerable overstocking exist therein. Overstocking is due to huge investment in store and spares. The management of most of the firms fear that it may not get spares in time for repair and upkeep of machineries, which situation is likely to disturb the production schedule. All these are the main reason for heavy accumulation of inventories. NUMBER OF DAYS STOCK-IN-HAND RATIO

52

Number of days in stock-in-hand ratio =

The ratio measures the efficiency in selling the goods. The smaller the number of day’s stock-in-hand, the higher the efficiency in inventory management.4.11.7RETURN PER RUPEE INVESTED RATIO

Return per rupee invested ratio is given by

The ratio shows efficiency in management of inventory in term of profitability. The higher this ratio is the better the management.CONCLUSION

The inventory turnover ratio is an important parameter used to evaluate the performance of inventory management techniques. It has a direct relationship with the profit-earning capacity of a firm.

Inventory as a percentage of current asset, inventory as a percent of total asset and inventory in term of months’ value of production, are all important parameter that reflect the adequacy or otherwise of the inventory holdings.

53

5. DATA ANALYSIS

5.1 COMPARISON BETWEEN TOTAL ASSETS TO CURRENT ASSETS

YEARTOTAL ASSET CURRENTASSET PERCENTAGE

2005-06 5068566335 1122682462 22.15%2006-07 5190874943 1445536182 27.85%2007-08 5971879681 2148380616 35.97%

According to this table from 2005 to 2006 total asset is 5068566335 and current asset is 1122682462 which are 22.15% of total asset. From 2006 to 2007 total asset position is 5190874943 and current asset is 1445536182 which are 27.85% of total asset. From 2005 to 2006 and from 2006 to 2007 current asset increases 5.7%. From 2007 to 2008 total asset is 5971879681 and current asset is 2148380616 which are 35.97% of total asset. If we compare 2006 to 2007 b/s and 2007 to 2008 b/s current asset increase 8.12%. From this above table we can know that current asset is very lower from total asset. Every year when total asset is increases current asset also increases.

0100000000020000000003000000000400000000050000000006000000000700000000080000000009000000000

05 TO06

06TO07

07 TO08

YEAR

AM

OU

NT

CURRENTASSET

TOTAL ASSET

54

5.2 COMPARISION BETWEEN TOTAL ASSETS TO INVENTORY

YEARTOTAL ASSET INVENTORY PERCENTAGE

2005-06 5068566335 625717065 12.35%2006-07 5190874943 759536657 14.63%2007-08 5971879681 1168153161 19.56%

Total asset is divided into two parts, Such as fixed asset and current asset. Inventory is a part of current asset and total asset. In Balasore alloy from 05 to 06 total assets is 5068566335 out of that inventory is 625717065 which is 12.35% of total asset. From 06 to 07 total assets is 5190874943 out of that inventory is 759536657 which is 14.63% of total asset. From 07to 08 total assets is 5971879681 out of that inventory is 1168153161 which is 19.56% of total asset. In Balasore alloy total asset is always in increasing mode. As well as inventory is always in an increasing mode.

0

1000000000

2000000000

3000000000

4000000000

5000000000

6000000000

7000000000

8000000000

05 TO 06 06TO 07 07 TO 08

YEAR

AM

OU

NT

INVENTORY

TOTAL ASSET

55

5.3COMPARISON BETWEEN CURRENT ASSETS TO INVENTORY

YEAR CURRENTASSET INVENTORY PERCENTAGE 2005-06 1122682462 625717065 55.73%2006-07 1445536182 759536657 52.54%2007-08 2148380616 1168153161 54.37%

Inventory is a part of current asset. In Balasore alloy from 05 to 06 current assets is 1122682462 out of that inventory is 625717065 which is 55.73% of current asset. From 06 to 07 current assets is 1445536182 out of that inventory is 759536656 which is 52.54% of current asset. From 07to 08 current assets is 2148380616 out of that inventory is 1168153161 which is 54.37% of current asset.

The current asset portion of Balasore alloy is always in increasing way. Similarly inventory is also in increase in an increasing mode. Inventory is above 50% of current asset.

0

500000000

1000000000

1500000000

2000000000

2500000000

05 TO 06 06TO 07 07 TO 08

YEAR

AM

OU

NT

CURRENTASSET

INVENTORY

56

5.4 Current Ratio

Table 5.6Current Ratio

Particulars 2004 2005 2006 2007 2008

Total Current Assets

3415.69 6024.35 8818.80 12955.91 16983.90

Total Current Liabilities

5419.69 8029.35 10824.8 14962.91 18991.90

Current Ratio 0.63 0.75 0.81 0.87 0.89

The current ratio is used to evaluate the liquidity, or ability to meet short

term debts. High current ratios are needed for companies that have

difficulty borrowing on short term notice. The generally acceptable

current ratio is 2:1 and the minimum acceptable ratio is 1:1

57

0.000.100.200.300.400.500.600.700.800.90

1 2 3 4 5

Year

Current Ratio

Analysis

The table above gives an overall picture of ability of Balasore Alloys

Limited to meet its short tem obligations. It is found that out of five years

of our study, the company is unable to meet the standard current ratio.

However, the overall liquidity position is improving from 0.63 in the year

2004 to 0.89 in the year 2008 gradually.

Interpretation

As the company is unable to maintain the minimum acceptable norm

(1:1) of current ratio over the period of study, it can be said that the

liquidity position is unsatisfactory in Balasore Alloys Ltd.

58

5.5 Quick Ratio

Sometimes a company could be carrying heavy inventory as part of its

current assets, which might be obsolete or slow moving. Thus eliminating

inventory from current assets and then doing the liquidity test is measured

by this ratio. The ratio is regarded as an acid test of liquidity for a

company. It expresses the true 'working capital' relationship of its cash,

accounts receivables, prepaids and notes receivables available to meet the

company's current obligations.

Table 5.7Quick Ratio

Particulars 2004 2005 2006 2007 2008

Quick Assets1794.41

2449.67

4003.41 6127.23 7837.49

Total Current Liabilities

5419.69

8029.35

10824.80

14962.91

18991.90

Quick Ratio 0.33 0.31 0.37 0.41 0.41

59

0.00

0.10

0.20

0.30

0.40

0.50

1 2 3 4 5

Quick Ratio

From the table it is clear that though the quick ratio position is developing from 0.33

to 0.41 over the period of our study, but it is far from satisfactory. None of the year

reaches normal standard of 1:1.

60

5.6 Inventory turnover ratio

The inventory turnover ratio measures the number of times a company sells its

inventory during the year. A high inventory turnover ratio indicated that the

product is selling well and vice-versa. It is calculated as follows:

The table shows that in the year 2004 the company’s Inventory turnover Ratio

was 6.75, but gradually it deteriorated and reached at 2.46 in the year 2008.

This adverse trend of ITR may be attributed to the accumulation of inventory