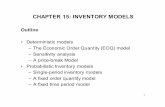

Inventory Control Models Chapter 6. 2 Types of Inventory.

-

Upload

angel-adams -

Category

Documents

-

view

229 -

download

7

Transcript of Inventory Control Models Chapter 6. 2 Types of Inventory.

Inventory Control Models

Chapter 6

2

Types of Inventory

3

Uses of Inventory

As a buffer to decouple – suppliers and users,– manufacturers and customers,– two workstations in a workshop.

4

Costs Related to Inventory

Carrying (holding) cost Ordering cost Stockout cost Purchase (material) cost

5

Carrying Cost

Includes:– Capital cost– Opportunity costs, – Storage space rental, and labor and

facilities for storage,– Cost of obsolescence and damage,– Insurance.

Varies with the amount of inventory.

6

Ordering Cost

Includes:– Shipping and handling cost,– Cost of processing orders, such as forms,

papers, labor. Typically, this cost varies with number of

orders, not with number of units in an order.

7

Stockout Cost

Includes:– Lost profit, – Expediting and back ordering expenses,– Cost of reputation and goodwill

8

Inventory Profile

9

Average Inventory

Inventory level changes everyday. Average inventory is often used to

measure inventory level Average daily inventory level

22

orderan in units ofnumber

Q

10

Some Basic Calculations (1 of 2)

D=annual demand in units

Co=ordering cost per order

Ch=carrying cost per unit per year

Q=order quantity = number of units in an order. Number of orders required in a year

Q

D

orderan in units ofnumber

unitsin demand annual

11

Some Basic Calculations (2 of 2)

Total annual holding cost =

Total annual ordering cost Total annual inventory cost

hCQ

2

oCQ

D

oh CQ

D C

2

Q

12

Economic Order Quantity (EOQ)

EOQ is the order quantity at which the total annual cost (annual holding cost + annual ordering cost) is minimized.

13

EOQ Total CostsTotal annual costs

= annual ordering costs + annual holding costs

14

Formula for EOQ

Let Q* be Economical Order Quantity (EOQ):

h

o

C

DCQ

2*

15

Simco Pump Example (p.197)

Annual demand = 1,000 units Ordering cost = $10 / order Annual holding cost = $0.5 / unit

What is the best order quantity?

16

Simco Pump Example (p.197)

With order quantity Q*=200 units,

(a) How many orders would be made annually?

(b) What is the total annual ordering cost?

(c) What is the average daily inventory?

(d) What is total annual holding cost?

(e) What is the total annual inventory cost?

17

Simco Pump Example (p.197)

We have found the EOQ is 200 units per order, and the associated total annual inventory cost is $100.

If the company orders 250 units each time, what is total inventory cost then?

If the company orders 100 units each time, what is total inventory cost then?

18

Purchase Cost, C

Purchase cost, C, of inventory items is not in the EOQ formula, since the order quantity Q does not affect the annual purchase cost, DC. That is, C is not relevant in determining the order quantity.

Sometime, unit carrying cost is a percent, I, of the purchase cost of the item, i.e., Ch=IC.

19

Reorder Point

Reorder point is in terms of number of units on hand, at which an order should be placed.

Reorder point must be at least the demand during the lead time (delivery time).

20

Safety Stock

Safety stock is the extra stock to help in avoiding stockout, when there exist uncertainties in demand and lead time.

21

Safety Stock and Uncertainties

22

Formula for Reorder Point

Reorder Point

= dL + SSwhere

d = average daily demand in units

L = lead time in days

SS = safety stock in units

23

Example (p.201 extended)

Procomp’s annual demand is 8,000 units. There are 200 work days per year. So, daily demand is 40 units.

Lead time = 3 days Safety stock = 20 units What is the reorder point (ROP)?

24

How Does EOQ Work in Inventory Control?

For each item k, calculate its economic order quantity Qk

* and its reorder point ROPk.

Keep watching the inventory on hand. If the stock of item k drops to ROPk, order Qk

* units of item k.

25

EOQ Assumptions (p.193)

Demand rate is constant. The ordered units are delivered in a

single shipment (instantaneous). No quantity discount is available All demand is satisfied (no shortages)

26

EOQ without Instantaneous Receipt Assumption (p.201) The ordered units arrive piece by piece. Application example:

– A company's finished good inventory that is supplied by its production department.

It is called Production Run Model The best order quantity is called Optimal

Production Quantity (OPQ).

27

OPQ Formula

d = daily demand in units,

p = daily production capacity in units,

Cs = setup cost (similar to Co)

D and Ch are defined same as before,

then

)1(

2*

pd

C

DCQ

h

s

28

Meaning of Q* in OPQ:

Q* here is still the “order quantity” (number of units in an order), but the order is issued to the production department of the same company.

Therefore, Q* can also be understood as the production batch size.

29

Formulas in Production Run Model

Maximum Inventory Level

Average Inventory Level

)1(p

dQ

)1(2 p

dQ

30

Formulas in Production Run Model

Total annual ordering cost =

(same as for EOQ) Total annual holding cost Total annual inventory cost

sCQ

D

hC )(12

Q

p

d

hs C )(12

Q C

Q

D

p

d

31

Example of Brown Manuf. (p.203)

Annual demand = 10,000 units;

Setup (ordering) cost = $100/order

Carrying cost = $0.50/unit/year

Daily production rate = 80 units

Daily demand rate = 60 units.

Once a unit is finished, it is counted into the inventory.

32

To Find EOQ under Quantity Discount (p.206 – 209)

Trial-and-error method in general May develop a spreadsheet that

calculate the total cost for each possible order quantity. Then, pick up the order quantity with the lowest total cost. (See class demonstration)

33