International standard supply chain certified

-

Upload

managementteam -

Category

Business

-

view

166 -

download

2

Transcript of International standard supply chain certified

1

INTERNATIONAL STANDARD CERTIFIED SUPPLY CHAIN MANAGEMENT

Introduction Supply Chain Management as a science that is unique and yet has the international standard, then the implementation has always had a diversity strategy, so the Supply Chain have diverged between theory and practice and generate performance varied, making it difficult to determine the net value of a product of goods and services. After doing research on a variety of manufacturing industries from 2012 to 2014, especially in the field of supply chain, the creation of a standard that will be applied and implemented worldwide. Socialization for implementing International Standards in the field of Supply Chain, will be done by the end of 2015, so that the general public relating to the activities of Supply Chain can understand, comprehend and use these standards to the creation of a business commitment and sustainable business growth in the future. Background The absence of a provision of international standards governing the Supply Chain Management, resulted in many occur at the crux of professional competence fields of Supply Chain Management, as well as the diversity of the business processes implemented by organizations (profit and non-profit) in various types of industrial manufacturing, in the activities of the warehouse (warehouse/storage), so that the understanding of Supply Chain Management referred by Keith Oliver, a resident of the United Kingdom working as a Consultant Supply Chain, in an interview with Arnold Kransdorff who worked as a journalist at the Financial Times on June 4, 1982, be biased or undirected and tend to follow the interpretation of brackish individual for purposes different interests, so that the understanding of Supply Chain Management becomes unfocused. Through the International Certified in the field of Supply Chain Management, the professional who wants to express competence areas of Supply Chain Management, and activities of the organization (profit and non-profit) in the field of Supply Chain, either directly or indirectly, be aligned based on international standards for Supply Chain Management. Goal Give uniformity to standardizing on business processes, infrastructure, and operations management are needed for the entire company in Indonesia in particular and the world in general, which is engaged in the industry of manufacturing including the competence of human resources as well as the company as a business partner (vendor/supplier) involved the activities of manufacturing industry, which aims to achieve consistency and sustainable business growth in the future.

2

Understanding Supply chain management (SCM) is the management of the flow of goods and services, including the movement of goods and storage of raw materials, raw material inventory in process into finished goods, and delivery of finished goods from the starting point to the point of final consumption, as well as interconnection or interconnected by channels and business node involved in the provision of products and services required by the final consumer in the supply chain. SCM is defined as "the design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, increasing the worldwide logistics, synchronizing supply with demand and measuring performance globally." SCM activities are focused to make an integrated approach to the field of operations management, logistics, procurement, and information technology, to create activities that can support sustainable business growth in the future. Objective 1. Guide to plan, create and develop a strategy as a set of tools and guidelines, standards to establish the

structure and framework and organizational processes. 2. Guide to plan, organize and make the programs needed for the mastery of key skills and competencies

required. 3. Guide in providing proper guidance in the same way as the Quality Standard for Occupational Health,

Safety and Environmental Management System. 4. Guidelines to improve the involvement of professional standards in the discipline, which is a mixture

of specialist technical skills, understanding of the whole business, and supply chain management skills 5. Guide in providing professional consistency at international level as a framework for world quality

standards 6. Guide to deepen the commitment to carry out the assessment and continuous performance

improvement 7. Guidelines in providing global consistency to help align the specification and quality of company

management. 8. Guidelines to provide economic benefits and social standards is greater in terms of improving the

standard of supply chain management in global services in the field of manufacturing and guarantee the achievement of higher levels of efficiency

9. Guidelines in providing an international framework to facilitate top-level strategic management, on the conditions, resources and development contracts that will be built with suppliers (vendors) as a service provider to the customer.

Benefits I. Organization (Company)

1. Provide standard processes on the activities organized by the company, in the field of Supply

Chain Management, which also includes, health, hygiene, security and safety

3

2. Provide a standard measurement of performance generated by the department or division that

manage supply chain activities, including the activities of logistic and warehouse administration 3. Provide standard net value creation in the organization (company) in the supply chain activities.

II. Individual

1. Provide individual competency standards (leader, supervisor, manager and director) who will be

responsible for supply chain activities in accordance with the assignment (assignment) has. 2. Provide performance assessment standards that were created as a result of the assignment

(assignment) has 3. Provide standard career development through training for skills required as responsible in the

supply chain of activities in accordance with its assignment. 4. Provide a standard to have the ability to analyze and solve a variety of risks, so that the risks

faced do not inhibit the growth of sustainable business III. Environment

1. Distribution channel

1.1. Provide standards to deal with supply chain activities on goods handled from

manufacture through to consumers, including the activities of the supply chain from the raw material to manufacture up to manufacture

1.2. Provide performance assessment standards that will be applied to the distribution channel in the supply chain activities, including hygiene, health, safety and security

1.3. Provide a standard must-have skills for individuals working in the distribution channel, to create consistency continuity work performance, to support sustainable business growth for manufacture

2. Vendor (Supplier)

2.1. Provide standard facilities should be owned, in providing services to manufacturing (buyer), the goods needed to ensure the survival of a business partner (buyer).

2.2. Provide standard skills for individuals to provide an explanation for product knowledge, the volume of goods produced, the organizational structure of the trade system, pricing strategy, product quality, and distribution system as well as the techniques of sales (sales and marketing strategy) including business development (business development), including training for human resource development.

2.3. Standards provide an assessment of the performance generated based on the skills required to create future business continuity including sustainable growth.

Content International Standard Supply Chain Certified 1. Standardization of operational activities goods flow management, movement, storage, inventory and

delivery processes as well as 2. Standardization of training needs to achieve the required competence

4

3. Standardization of infrastructure facilities and/or organizations 4. Standardization individual competencies (leader, supervisor, manager and director) 5. Standardization of risk management, aligned with ISO 31000: 2009 6. Standardization assessment of individual performance (KPI) is engaged in supply chain activities 7. Standardization performance appraisal vendor (supplier) 8. Standardization operations management, logistics, procurement (procurement), and information

technology 9. Standardization of information management system 10. Standardization of health, hygiene, safety and workplace safety Who Will Be Affected 1. Mining and Manufacturing Company 2. Hospitality and Logistics Company 3. Agriculture 4. The service company belonging to the vendor/supplier for the field of mining, manufacturing,

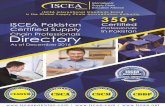

hospitality and logistics 5. Company out sourcing of human resources in the field of mining and manufacturing Author Setiono Winardi, SH.,MBA E. [email protected], M. +62-813-1542-1509 Partner – UPDI LLC Vice Chairman – Institute Supply Chain Indonesia (ISCI) Managing Partner – RBS International Training