Instrukcja montażu i obsługi - Breal -...

Transcript of Instrukcja montażu i obsługi - Breal -...

Installation and operation instruction

automatic pellet boiler with lambda probe

Inter FireThis instruction should be stored by the user.

In order to maintain warranty as well as long and safe boiler operation it is absolutely required to follow this instruction.

All rights reserved.

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 1

Revision date: 17/06/2010

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 2

Dear users of Inter Fire boiler!

Thank You for your trust. We will do our best to make our device operation failure-free,

comfortable and satisfying.

The Inter Fire boiler, purchased by You, is one of the most technologically advanced devices,

suitable for the ecological fuel – pellet. The Inter Fire boiler, as one of few available devices on the

marked, is equipped with modern control system, which assures optimal fuel combustion conditions

with use of lambda probe. Such solution allows to obtain very high boiler efficiency – over 91% - in

full range of its power.

In order to assure the highest comfort of operation the Inter Fire boiler is equipped with the

innovative solutions:

• pneumatic fuel transport system;

• automatic exchanger cleaning system;

• automatic burner cleaning system;

• automatic ignitor.

Those features allowed to obtain the certificate of device, fulfilling the energetical and ecological

standard criteria.

Become familiar with this instruction and the attached controller instruction in order to assure safe

operation of the boiler. Contact us in case of any doubts.

Yours faithfully

Marcin Lazar

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 3

Table of contents 1 General information. ........................................................................................................................5

2 Recommendations. ..........................................................................................................................5

3 Safety recommendations. ................................................................................................................6

4 Boiler technical data.........................................................................................................................8

5 Boiler design.....................................................................................................................................9

6 Fuel types........................................................................................................................................13

7 User instruction manual..................................................................................................................15

7.1 Boiler operation start-up....................................................................................................15

7.2 Boiler operation..................................................................................................................15

7.3 Boiler maintenance and cleaning.......................................................................................17

7.4 Boiler putting out...............................................................................................................18

8 Installer instruction manual............................................................................................................19

8.1 Bringing the boiler inside...................................................................................................19

8.2 Boiler room – device positioning.......................................................................................20

8.3 Boiler installation...............................................................................................................21

8.4 Fuel pneumatic transport system – Vacum.........................................................................23

9 Service personnel instruction manual.............................................................................................25

9.1 Inspection before start-up...................................................................................................25

9.2 Start-up...............................................................................................................................25

9.3 Troubleshooting.................................................................................................................26

9.4 Annual inspection...............................................................................................................26

10 Device disposal after the operation period...................................................................................27

11 Warranty and responsibility conditions........................................................................................27

12 Certificates and declarations.........................................................................................................30

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 4

1 General information.

The Inter Fire boiler is a highly advanced technical device for pellet combustion, equipped with the

weather control system with lambda sensor, automatic fuel transport system, automatic exchanger

and burner cleaning system and automatic ignitor. It is designed for heating of buildings with use of

central heating system and for heating of potable water in hot water tanks.

The Inter Fire boiler is in standard supplied with:

• Installation and operation instruction;

• Controller instruction;

• Ash pan.

The Smart Fire boiler is a low-temperature device and is not subjected to registration in the regional

Office of Technical Inspection.

The boilers for solid fuels, designed for operation in closed loop are subjected to the limited

technical inspection. The boiler user should report it in the Office of Technical Inspection after

installation and before operation.

2 Recommendations.

It is absolutely required to follow this instruction.

The first boiler start-up and connected operations, as well as any other service works with the

boiler, should be performed only by the producer’s or authorized service personnel.

Only the fuel described in this instruction should be used.

The boiler must be periodically maintained according to the instruction.

For the protection against Legionella it is required to follow the general principles of heating

technique.

In case of not following the above recommendations the warranty will be voided and the producer

will not take responsibility for the device operation results.

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 5

3 Safety recommendations.

Before the boiler operation it is absolutely require to read the recommendations below. Not

following the instruction, especially the recommendations below may lead to: injuries, health

loss, life threat, damages of the device, installation and building!

The boiler installation must be performed only by the personnel with proper qualifications,

knowledge, skills and tools.

The installation must be performed according to the valid regulations, standards and building

craftsmanship.

The boiler must be operated only when the boiler and the installation are in perfect technical

condition. Failures, damages and operation irregularities must be immediately reported to the

proper services.

Before the first start-up, and then periodically (at least every 6 months) check the proper water

volume in the central heating system.

It is absolutely forbidden to open the revision holes during the boiler operation, as the dust and

gases may escape and ignite or explode.

It is forbidden to make any repairs and modifications by yourself.

Before any works with the boiler it should be put out and cooled.

Periodically (at least once a month) check the boiler door and installation connections for their

tightness.

At least once a year check the STB fuse operation.

The boiler must be installed only in the suitable rooms, properly equipped and fulfilling certain

requirements.

In the boiler installation room the warning sign of the smoking and fire use prohibition should be

placed. In the boiler room there should be operational fire extinguisher.

Ventilation and air intake to the boiler room should be operational and should fulfil proper

requirements.

The boiler room must be protected against the unauthorized access, especially children.

It is absolutely forbidden to remove or block the measurement and protective devices.

Use the protective clothes and measures during the boiler operation and ash removing: gloves, dust

mask and work clothes.

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 6

When the potable water temperature exceeds 60ºC, it is required to add the cold water in order to

prevent burns hazard.

Take care of proper boiler and installation venting.

During the fuel supply with use of vehicle with pump the boiler must be put out.

Only the original spare parts must be used.

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 7

4 Boiler technical data

Boiler model

Parameter Unit IF 20

Boiler class Class 3 (the highest)

Efficiency % 91.7%Nominal heating power kW 20Heating power range kW 6 ÷ 20Fuel consumption at the nominal power kg/h ok. 5Approximate combustion time at the nominal power (for buffer dispenser) h ok. 24

Width mm 1180Height mm 1650Depth mm 870Water capacity dm3 55Flue outlet diameter (ext./int.) mm 120 / 110Supply and return pipes inch 1¼Maximum allowable water operational pressure bar 2.0Maximum allowable water test pressure bar 3.0Safety valve bar 2.0Water flow resistance ΔT=10K mbar 6.60Water flow resistance ΔT=20K mbar 1.70Required chimney draft Pa 10Flue temperature at the maximum power 0C 130Flue temperature at the minimum power 0C 70Maximum boiler temperature 0C 85Recommended boiler temperature 0C 65 ÷ 80Minimum return water temperature 0C 50Flue mass flow at the nominal power g/s 12Flue mass flow at the minimum power g/s 5

CO emission at the nominal power (for 10% O2) % 480

CO emission at the minimum power (for 10% O2) % 300

CO emission at the nominal power (for 13% O2) % 344.4

CO emission at the minimum power (for 13% O2) % 224.5Table no. 1: Inter Fire boiler dimensions and technical parameters

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 8

Noise levelwithout pneumatic pellets transport system dB below 65

Supply voltage 1 PEN ~50Hz 230V TN-S

Electric insulation IP 20

Electric energy consumption (fans + motoreducer) W 95Buffer dispenser volume dm3 170Ash pan volume dm3 7Primary fan model R2A1500-AASecondary fan model 622HHMotoreducer model ISG-3240RTF 3.8

Table no. 1: Inter Fire boiler dimensions and technical parameters

5 Boiler design

The Inter Fire boiler has compact design. Most of the boiler’s subassemblies are located under the

housing, which protects them from the harmful external factors and mechanical damages.

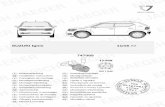

The Inter Fire boiler, its dimensions and connections locations are shown in fig. 1. The boiler design

with the most important subassemblies is shown in fig. 2 and fig. 3.

Inside the boiler housing there are two main elements: boiler body and fuel supply system. The

boiler body consists of: manifold, steel exchanger, combustion chamber and ash pan chamber.

Inside the steel exchanger there are vertical flue tubes and deflector. The exchanger is equipped

with the automatic cleaning system. The exchanger is closed from above by the manifold, which

collects fumes and directs them to the smoke conduit. The exchanger is located on the lower part of

the boiler body, which consists of combustion chamber and ash pan chamber. Inside the combustion

chamber there is the ceramic burner, on which the catalyst is installed in form of stainless steel tube.

The burner is also equipped with the automatic cleaning system. The fuel is supplied to the burner

from above with use of gravitational method, using the screw feeder. Directly under the combustion

chamber there is the ash pan chamber, where the ash pan is located, collecting ash from the burner.

Another element of Inter Fire boiler is the fuel supply system. It is an integral part of the boiler

external housing. It consists of: fuel buffer dispenser, pneumatic fuel transport system – Vacum, and

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 9

fuel screw feeder with motoreducer. The fuel drops from the buffer dispenser to the fuel screw

feeder. It, in turn, transports fuel to the burner in the combustion chamber. The fuel pneumatic

transport system is located on top of the fuel buffer dispenser, and is used for the automatic fuel

refilling. The boiler body is connected with the fuel supply system with the screw feeder flange.

On the Inter Fire boiler front wall there are two opened masking frames. Under the left one the is

the revision door, allowing for access to the combustion chamber and the ash pan chamber. Under

the right one the is the plugged revision hole for the fuel supply system lower section. There is also

the pocket for the boiler and controller operating instructions. Above the right masking frame, on

the front wall, there is the controller panel, which displays: current boiler condition, operation

parameters and boiler configuration.

The heating water inlet and outlet, used for connecting the boiler to the heating system, are located

on the boiler back wall. They are the connection pipes with thread 1¼”. On the boiler back wall

there is also the fume connection pipe, used for fume transport to the chimney. The detailed

locations are shown in fig. 1.

On the boiler back wall, above the smoke conduit, there is the primary (exhaust) air fan. On its both

sides there are: fume temperature sensor and lambda probe. The secondary air fan is connected to

the pipe located under the fuel buffer dispenser, which pumps air directly to the combustion

chamber. The volume of air pumped by fans is controlled and adjusted by the controller.

The external housing and the boiler body are insulated with the mineral wool, which protects from

the heat losses during operation. The boiler housing is made from the steel sheets, coated with the

high quality powder coating.

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 10

Fig. no. 1: Inter Fire boiler dimensions

Front view

Fig. no. 2: Inter Fire boiler description:

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 11

12

5

6 3

47

8

1-control panel; 2-safety thermostat STB reset (under the plastic cap);

3-instructions pocket; 4-masking frame; 5-revision hole; 6-combustion chamber door;

7-masking frame; 8-ash pan chamber revision door

Side view

Back view

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 12

13

1415

16

1712

10

11

9

Fig. no. 3: Inter Fire boiler description:

9-fuel pneumatic transport system connection pipe; 10-revision hole; 11-revision hole; 12-primary

air fan housing; 13-heating water connection pipe; 14-smoke conduit; 13-smoke conduit; 14-return

water connection pipe;15-smoke conduit washout hole; 16-return water connection pipe; 17- fuel

pneumatic transport system motor housing

6 Fuel types

The Inter Fire boiler is designed and constructed for the efficient and ecological combustion of fuel

pellets. The pellets are the combustible material, made from the high-pressure pressed wood waste

material, available in form of balls or cylinders.

It is recommended that the fuel fulfils the pellets standards. That recommendation refers especially

to the fuel calorific value and its humidity.

PELLETS

Ö-Norm DIN-Norm DINplus

Calorific value 18 MJ/kg 18 MJ/kg 18 MJ/kg

Density 1.12 kg/dm2 1.0- 1.4 kg/dm2 1.12 kg/dm2

Humidity max. 10.0 % max. 12.0 % max. 10.0 %

Ash content max. 0.5 % max. 1.5 % max. 0.5 %

Length max. 5 x diameter max. 50 mm max. 5 x diameter

Diameter 8 mm 8 mm 8 mm

Fines content max. 2.3 % max. 2.3 %

Composition wood wood wood

Table no. 2: Standard and standardized fuel parameters

CAUTION!! THE FUEL HUMIDITY MUST NOT EXCEED THE RECOMMENDED

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 13

VALUES. HUMID FUEL CAUSES SIGNIFICANT BOILER POWER DROP (EVEN UP TO 50%), AND DECREASES THE MECHANICAL PARTS LIFE, WHICH HAVE DIRECT CONTACT WITH WET FUEL. USING THE LOW QUALITY OR HUMID FUEL CAUSES THE WARRANTY VOID FOR THE ELEMENTS SUBJECTED TO THE FUEL INFLUENCE.

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 14

7 User instruction manual.

Dear User, in order to fully use the Inter Fire boiler features, before using the device it is required

to become familiar with this instruction and the controller instruction – it assures comfortable and

long operation. The detailed information about the boiler electronic adjustment are given in

mentioned controller instruction.

7.1 Boiler operation start-up.Before the device start-up it is required to check if there is sufficient fuel amount in the buffer

dispenser. We recommend to start the pellets suction in the manual mode – the dispenser will be

fully loaded.

After the controller start-up and switching to the automatic operation the boiler will start firing up.

That process consists of a few activities and is finished by the fuel ignition in the burner. Then the

boiler switches to the automatic operation. If the firing up process is unsuccessful (there is no flame

or the fume temperature is too low), it will begin again. If the second firing up trial is unsuccessful,

the display will show proper message. It may be caused by improper fuel or incorrect settings. In

such case it is required to contact the authorized service.

7.2 Boiler operation.After firing up and switching to the automatic operation the boiler controller, according to the

measurements from the lambda probe and the temperature sensors automatically adjusts the amount

of supplied fuel and fans power. It allows to obtain high efficiency in the whole operation range.

Any irregularities in the boiler operation should be immediately reported to the authorized service,

together with the messages from the display.

Any corrections of the parameters may be made only when You are sure, how the given parameter

influences the boiler and installation operation. All changes should be recorded, as it allows return

to the previous values, facilitates the service personnel work and allows us to give You the

telephone advice.

• During the operation the boiler periodically feeds fuel, with breaks between the successive

doses. The feeding complete cycle and time are factory-adjusted for the device nominal Inter Fire instruction rev. 17/06/2010/PL

HKS LAZAR page 15

power. However, the fuel lower quality may require the parameters correction. The

symptoms may be the following: the boiler does not reach proper power or feeds too much

pellets to the burner. Use the controller instruction while changing those parameters. Before

the feeding parameters change check the pellets quality. Pay special attention to their

humidity, hardness and the powder content after soaking the sample in the water.

• The factory-adjusted boiler temperature assures correct operation. However, in extreme

conditions that parameter may require adjustment. While changing it follow the

recommended boiler temperature range and the controller instruction.

• Depending on the installation type adjust: central heating temperatures, potable water

temperature, heating curves and night drop in the week mode. Those parameters are initially

set by the authorized service. Before any adjustments become familiar with the controller

instruction and record all changes. While changing the above parameters keep in mind, that

the reaction time for the whole installation may be a few hours.

• In case of using the mixing valves the parameters for their operation are also available.

Those parameters are set by the authorized service. In case of any changes it is required to

record them in order to return to the previous settings when required.

• The boiler automatically sucks fuel from the stock to the buffer dispenser. Loading takes

place according to the settings made by the service and lasts until the dispenser is full.

• The heat exchanger is automatically cleaned at the time set by user.

• The burner is automatically cleaned according to the set number of operation hours.

All flaps and revision doors must be absolutely closed during the boiler operation!

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 16

7.3 Boiler maintenance and cleaning.The routine activities, connected with the boiler cleaning during its operation include:

• Removing ash from the ash pan – the ash amount should be checked every week;

• Removing ash from the combustion chamber.

The ash amount, produced during the fuel combustion depends on the fuel quality and its amount,

consumed by the boiler. Besides the ash, also the trace amounts of soot are produced. In order to

remove ash it is required to open the ash pan chamber revision door by unscrewing four wing-nuts,

located in the corners. The ash should be removed from the chamber by emptying the ash pan in for

of a drawer.

The combustion chamber contains impurities, dropped by the exchanger cleaning system. In order

to obtain access to the combustion chamber unscrew two screw clamps, fixing its revision door. The

ash should be removed with use of brush by scraping it to the ash pan drawer.

After each heating season, during longer standstills and when required the boiler should be

thoroughly cleaned and maintained. For that purpose the Inter Fire boiler is equipped with:

• smoke conduit washout hole;

• fume manifold cover.

In order to remove ash from the fume manifold it is required to remove the upper part of the boiler

housing and the fume manifold cover. The manifold cleaning may be performed by the authorized

service.

During ash removing and boiler cleaning it is required to use gloves and other required

personal safety measures!

Before the cleaning and maintenance activities put out the boiler and wait at least 1 hour for

the temperature drop. Also disconnect the boiler from the electric power supply. Only then it

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 17

is allowed to open the doors and washout holes and start cleaning!

7.4 Boiler putting out.In order to put out the boiler it is required to enter the putting out mode. Putting out is performed

automatically, assuring safety, using all fuel and venting the device. Due to those reasons it is

absolutely forbidden to disconnect the electric power before the automatic putting out process ends.

If the boiler operation break is longer than one day, it is required to remove fuel from the

boiler, as it may become humid and blocked!

If the boiler operation break is longer than one day, it is required to remove ash and any soot,

and assure proper device ventilation. Not fulfilling of those conditions may cause corrosion!

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 18

8 Installer instruction manual.

Dear Installer, the Inter Fire boiler is the precise, technically advanced and highly efficient device.

Therefore we ask for cautious and sensible work during the installation.

The boiler installation must be performed only by the personnel with proper qualifications,

knowledge, skills and tools. However, start-up, inspections and repairs must be performed only by

the authorized service personnel after proper training.

During the Inter Fire boiler installation it is required to follow the valid Polish and European

Standards and regulations, referring to the boilers installation! In particular those are:

• Decree of Minister of Infrastructure from 12.04.2002 regarding the technical

conditions for buildings and their locations;

• Decree of Minister of Infrastructure from 12.03.2009 regarding the technical

conditions for buildings and their locations;

• Standard PN -B -02411:1987“Heating – Built-in boiler rooms for solid fuels –

Requirements”;

• Standard PN -B -02413:1991“Heating and heat engineering – Protection of open system

heating installations – Requirements”;

• Standard PN -B -02414:1999“Heating and heat engineering – Protection of closed loop

system heating installations with membrane expansion vessels – Requirements”;

• Standard PN -B -02415:1991“Heating and heat engineering – Protection of closed loop

system heating networks – Requirements”;

• Standard PN -B -02416:1991 “Heating and heat engineering – Protection of closed

loop system water heating installations, connected to heating networks – Requirements”;

• Standard PN -B -02440:1976“Protection of hot potable water devices – Requirements”;

• Standard PN-EN 12828:2006 “Heating systems in buildings – Designing of central

heating water systems”;

their amendments or replacing regulations.

8.1 Bringing the boiler insideBringing the boiler inside should be performed carefully, paying special attention to the electronic

elements and wiring. When it is required to uninstall any element, remember its installation method,

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 19

make notes or photographs. It allows for quick installation of those elements and facilitates the

service personnel work.

8.2 Boiler room – device positioningThe room for the boiler installation must fulfil proper regulations and standards, referring to the

solid fuel boilers. Pay special attention to the safety of water and electric installation, proper

ventilation, fume exhaust system and fire safety.

Boiler positioning in the room requires proper space around it for operation, maintenance and

repairs:

• in the front – min. 1200 mm;

• in the side of the fuel dispenser – min. 1000 mm;

• in the side – min. 150 mm;

• in the back – min. 500 mm;

• from above – min. 800 mm.

The exemplary Inter Fire boiler positioning in the boiler room with the required space is shown in

fig. 11.

Due to low temperature of fume and the possibility of condensation pay special attention to

proper selection of smoke conduit!

The chimney for the device must fulfil all standards, requirements and principles of building

craftsmanship!

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 20

Fig. no. 4: Example of boiler positioning in the boiler room

8.3 Boiler installation.In order to protect the boiler from corrosion, caused by the water return from the installation

in temperature below the condensation point, the heating system should be equipped with

proper thermal protection. Not fulfilling of that requirement will cause the warranty void!

The return water temperature must be at least 50ºC. That condition must be absolutely fulfilled in

order to maintain warranty and assure correct boiler operation. Therefore it is recommended to use

proper valve: four-way mixing valve with actuator or thermostatic valve TV 45ºC.

The installation must be performed according to the valid regulations, standards and building

craftsmanship. During the installation it is recommended to use the system diagram, shown in fig.

12. It is also possible to use other systems, if they are hydraulically correct.

The heating system must be equipped with the drain pipe, located in its lower point and as close to

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 21

the boiler as possible - next to the return water connection pipe.

Fig. no. 5: Hydraulic system diagram:

1-boiler; 2-controller; 3-control panel; 4-fans; 5-feeder temperature sensor; 6-motoreducer; 7-

boiler temperature sensor; 8-potable water temperature sensor; 9-circuit supply temperature

sensor; 10-weather sensor; 11-central heating pump; 12-potable water pump; 13-heating circuit

pump; 14-mixing valve with actuator; 15-potable water tank; 16-room thermostat;

17-circuit return temperature sensor; 18-mixing valve with actuator; 19-boiler return temperature

sensor; 20-heating circuit pump; 21-themostatic valve TV; 22-room thermostat; 23-throttle valve;

24-circuit supply temperature sensor; 25-hydraulic clutch;

Above data are for reference only! Nevertheless, the hydraulic installation must be made

according to the valid regulations, standards and building craftsmanship. It must assure

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 22

correct and safe operation of the heating devices. The installation must be inspected by proper

units, when required!

Presented hydraulic diagrams do not replace the central heating installation design and are

for reference only!

8.4 Fuel pneumatic transport system – VacumThe air pneumatic transport system is designed for operation with the plastic hoses with smooth

internal surface in copper braid. They must assure proper system strength and durability in range of

transported fuel.

Vacuum hose should be connected to the system with use of clamping ring. Another hose end

should be connected to the designed connection in silo or suction probe. The secondary air hose

should be connected in the same way.

The vacuum hose should be installed on the wall or ceiling, fixing it approx. every 50 cm with use

of clamping rings. It must not be folded or bent. The hose should be installed with the highest

possible bending radius – minimum 300 mm. The vacuum hose maximum length is 30 m.

Before the system start-up check the air-lock closing correctness and the air-lock limit switch

operation.

During the first start-up check if the air flow in the system takes place in the correct direction.

Check the possible leaks in the system, especially in the vacuum hoses. The air flow in the hoses

should be high enough to assure the uniform flow of the pellets.

With activated suction the amount of pellets in the hose should not exceed 50% of the hose section

– it refers to all pile-ups (levels). When there will be more pellets in the hose, make the bypass

holes (max. Ø6 mm) in the hose next to its connection with the suction probe.

In order to adjust the optimum amount of suctioned fuel it is required to test the system in several

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 23

suction cycles. Otherwise there is a risk of hose clogging.

It is forbidden to use the system for transport of materials not allowed by the producer! The

system must not be used in the rooms with the explosion risk!

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 24

9 Service personnel instruction manual.

Dear Servician, by servicing the Inter Fire boiler You work for the boiler, producer and Your brand.

Therefore we ask You for the professional and solid service.

9.1 Inspection before start-up.In order to assure safe start-up of the device it is required to perform thorough inspection of the

boiler, installation and boiler room. Pay special attention to correct installation of all boiler

elements. Especially those, which might have been disassembled during bringing of boiler into the

boiler room. Moreover, before the start-up:

• Check if the central heating system is filled with proper volume of water. Water in the

heating system must be clean and must not contain many additives. Keep in mind that water

may be supplied only to the cooled boiler. Otherwise the device may be damaged.

• Check the position of combustion chamber cover (deflector) – unscrew upper boiler cover,

check if the combustion chamber cover is placed centrally and if the chamber is tight.

• Check the heating system tightness.

• Check the correctness of connection with the chimney.

• Check the connection to the electric installation.

• Check the boiler sensors and mechanical elements.

• Check the correctness of the fuel pneumatic transport system.

9.2 Start-up.The boiler start-up consists in its firing up, control and initial adjustment of boiler and boiler room

parameters, and user training in range of operation. During the start-up pay special attention to the

boiler operation in order to make any adjustments. Follow the controller instruction while changing

the parameters. Pay special attention to the following points:

• Tightness of boiler plugs and washout holes – during the firing up check if the smoke does

not escape from beneath the covers, seal the possible leaks.

• Tightness of upper manifold cover – during the firing up remove the upper housing and

check if the smoke does not escape from beneath the covers, seal the possible leaks.

• Tightness of doors – during the firing up check if the smoke does not escape around the

doors, adjust the hinges when required.

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 25

• Tightness of dispenser – during the firing up check if the smoke does not escape from the

dispenser, seal the possible leaks.

After the firing up heat the boiler to the recommended operational temperature (minimum 65ºC).

When the boiler reaches the expected temperature, check its tightness again.

During the start-up train the user in range of Inter Fire boiler and controller operation. The start-up,

user training and required data should be recorded in the warranty card.

9.3 Troubleshooting.Before troubleshooting perform the failure analysis in order to find its reasons. Remember that most

of reported failures are caused by incorrect parameters, incorrectly installed sensors, incorrect

installation and poor quality of fuel. When the failure refers to the subassembly, it should be

removed and replaced. All services and spare parts covered with the warranty should be

documented with the warranty tickets. They are the basis for the claim acceptance.

9.4 Annual inspection.The annual inspection is performed by the authorized servician, called by the user. It is the

condition of maintaining the warranty. The inspection must be performed maximum every 8 months

and at least every 14 months. During the inspection the servician checks the boiler installation and

operation correctness and its condition, especially:

• sealing of doors and dispenser flap;

• condition of ceramic lining;

• condition of insulation;

• condition of catalyst;

• condition of screw feeder;

• condition of auxiliary equipment (e.g. swirlers, exchanger cleaning system, etc.);

• correctness of controller, fans and fuel feeding system operation;

• protection against the low-temperature corrosion;

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 26

• presence of any unauthorized modifications and repairs.

During the inspection replace the worn elements and repair all failures. After the inspection the

servician makes record in the warranty card, documenting all notes and performed repairs and

replacements. The inspection must be also recorded in the service ticket, which should be sent to

HKS LAZAR company in order to register it in the system.

10 Device disposal after the operation period.

As the boiler elements are made from various materials, they should be transported to the recycling

centre for the proper utilization of steel, plastics, etc.

11 Warranty and responsibility conditions.

The producer gives 2 years of warranty for the Inter Fire boiler and 5 years for the exchanger

tightness. When the boiler is used for the commercial purposes, it is covered by 1-year warranty.

The warranty condition is the boiler operation according to this instruction, proper standards and

regulations:

1) The boiler installation in the system must be performed by the installation personnel with

the general installation authorization, under the condition of following this instruction. After

the installation the installing personnel makes record in the warranty card.

2) Start-up, inspections, repairs and any other activities, not included in the user’s

responsibility range must be performed only by the authorized service personnel of HKS

LAZAR.

3) The repair does not include the activities obligatory for the user, especially: boiler firing up, maintenance and cleaning, setting of parameters from the users instruction.

4) The service company, responsible for the start-up, is obligated to assure the warranty and

post-warranty service.

5) The boiler is not covered by the warranty, when the properly filled Warranty Card is not sent

back to the producer.

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 27

6) The boiler is not covered by the warranty, when it is not protected from the return of cold

water (below 50ºC) from the installation with use of thermostatic valve TV45ºC or 4-way

valve with actuator.

7) The warranty is lost, when:

• no annual inspection (9.4) with the record in the Warranty Card and sending the filled

service ticket to the producer have been realized;

• the boiler was repaired or modified by unauthorized persons;

• the user refuses or precludes the access to the boiler for HKS LAZAR personnel, as well as

does not allow for the inspection of boiler room and installation condition.

8) The producer takes no responsibility for the damages, when the boiler is used, installed and

operated contrary to this instruction and valid standards and regulations.

9) The user is obliged to cover the servicing costs in case of:

• unjustified Service call;

• repair of damages, resulting from the User’s fault;

• no possibility of repair due to reasons independent from the Service (e.g. no fuel, no

chimney draft, no electric energy, leaks in central heating system);

• the user refuses or precludes the access to the boiler for HKS LAZAR personnel, as well as

does not allow for the inspection of boiler room and installation condition.

10) The user should immediately inform the servician about all irregularities in the boiler

operation.

11) During the warranty period the user has right to:

• free repairs (except the user’s activities described in the instruction);

• replacement the device with the new one, when HKS LAZAR service finds that the repair is

impossible.

12) The warranty does not include the elements subjected to normal wear during the boiler

operation, especially: seals, thermal insulations, catalyst, ceramic elements, paint coating,

bearings, cotter pins, air supply elements.

13) The boiler must be periodically inspected and maintained according to the instruction.

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 28

14) The mechanical damages will not be covered by the warranty.

15) The produces takes no responsibility for incorrectly selected boiler power.

16) It is forbidden to check the boiler leaks with use of compressed air.

17) Damages resulting from not following this instruction, especially not fulfilling the warranty

conditions, are not subjected to the warranty claims.

18) The producer is authorized to implement any modifications in the boiler design, which are

not included in this instruction.

19) The warranty card has the warranty tickets attached. They are used in two cases:

• filled service ticket should be sent after the annual inspection, otherwise the warranty will be

void;

• filled service ticket should be sent after the warranty repair, otherwise the claim will not be

acknowledged.

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 29

12 Certificates and declarations.

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 30

DECLARATION OF CONFORMITYWe declare conformity of our device –

automatic central heating boiler “Inter Fire”

power 20 kW – with standard PN-EN 303-5 “Section 5: Heating boilers

for solid fuel, with manual and automatic fuel feed, with nominal power up to 300 kW –

Definitions, requirements, tests and marking”.

It is confirmed by this mark

placed on the device.

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 31

For the userHKS LAZARul. Wodzisławska 15 B44-335 Jastrzębie Zdrójtel. 32 / 472 95 78www.hkslazar.pl

Warranty Card and boiler quality and completeness confirmationInter Fire

(20* - * delete as applicable)

Boiler serial number ……………………………… Boiler power …………….

User (Name) …………………………………………………

Address (street, city, postcode) …………………………………………………

Telephone / Fax no. …………………………………………………

Boiler thermal protection*: four-way valve with actuator

*- delete as applicable valve TV45

The adjustment of parameters according to the table in the operation and installation instruction will be realized by the authorized service company of HKS LAZAR.The completeness and equipment are assured by HKS LAZAR.Not filled Warranty Card is not valid.

Measurement type Value Chimney draft (Pa)

Fume temperature (ºC)

The user confirms that:1. the boiler has revealed no defects during the start-up by the service company,2. the operation and installation instruction with filled Warranty card and boiler quality and completeness confirmation has been supplied,3. the training in range of boiler operation and maintenance has been realized.

............................................Production date

...........................................Company stamp

............................................Technical control (signature)

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 32

...........................................Installation date

...........................................Service company(stamp, signature)

............................................User’s name, address, date and

signature

The User and the installation and service company with their own signatures express their acceptance for processing of their personal data for the service evidence and marketing needs, according to Act from 29th of August, 1997, regarding the Personal Data Protection (Journal of Laws No. 133, pos. 883).Addition to the user’s Warranty Card

Record of realized warranty and post-warranty repairs and regular annual inspections of Inter Fire boiler.

During the inspection the servician called by the user checks the boiler condition and its operation according to the instruction. All remarks are recorded in the table below

Record date Performed activity Signature and stamp of authorized service Customer’s signature

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 33

Record date Performed activity Signature and stamp of authorized service Customer’s signature

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 34

For the service.HKS LAZARul. Wodzisławska 15 B44-335 Jastrzębie Zdrójtel. 32 / 472 95 78www.hkslazar.pl

Warranty Card and boiler quality and completeness confirmation Inter Fire

(20* - * delete as applicable)

Boiler serial number ……………………………… Boiler power …………….

User (Name) …………………………………………………

Address (street, city, postcode) …………………………………………………

Telephone / Fax no. …………………………………………………

Boiler thermal protection*: four-way valve with actuator

valve TV45*- delete as applicable

The adjustment of parameters according to the table in the operation and installation instruction will be realized by the authorized service company of HKS LAZAR.The completeness and equipment are assured by HKS LAZAR.Not filled Warranty Card is not valid.

Measurement type Value Chimney draft (Pa)

Fume temperature (ºC)

The user confirms that:1. the boiler has revealed no defects during the start-up by the service company,2. the operation and installation instruction with filled Warranty card and boiler quality and completeness confirmation has been supplied,

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 35

3. the training in range of boiler operation and maintenance has been realized.

............................................Production date

...........................................Company stamp

............................................Technical control (signature)

...........................................Installation date

...........................................Service company(stamp, signature)

............................................User’s name, address, date and

signature

The User and the installation and service company with their own signatures express their acceptance for processing of their personal data for the service

evidence and marketing needs, according to Act from 29th of August, 1997, regarding the Personal Data Protection (Journal of Laws No. 133, pos. 883).

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 36

For HKS LAZAR (fill and send to HKS LAZAR).HKS LAZARul. Wodzisławska 15 B44-335 Jastrzębie Zdrójtel. 32 / 472 95 78www.hkslazar.pl

Warranty Card and boiler quality and completeness confirmationInter Fire

(20* - * delete as applicable)

Boiler serial number ……………………………… Boiler power …………….

User (Name) …………………………………………………

Address (street, city, postcode) …………………………………………………

Telephone / Fax no. …………………………………………………

Boiler thermal protection*: four-way valve with actuator

valve TV45*- delete as applicable

The adjustment of parameters according to the table in the operation and installation instruction will be realized by the authorized service company of HKS LAZAR.The completeness and equipment are assured by HKS LAZAR.Not filled Warranty Card is not valid.

Measurement type Value Chimney draft (Pa)

Fume temperature (ºC)

The user confirms that:1. the boiler has revealed no defects during the start-up by the service company,2. the operation and installation instruction with filled Warranty card and boiler quality and completeness confirmation has been supplied,3. the training in range of boiler operation and maintenance has been realized.

............................................Production date

...........................................Company stamp

............................................Technical control (signature)

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 37

...........................................Installation date

...........................................Service company(stamp, signature)

............................................User’s name, address, date and

signature

The User and the installation and service company with their own signatures express their acceptance for processing of their personal data for the service

evidence and marketing needs, according to Act from 29th of August, 1997, regarding the Personal Data Protection (Journal of Laws No. 133, pos. 883).

Inter Fire instruction rev. 17/06/2010/PLHKS LAZAR page 38