Installation & Operating Manual · 2014. 5. 5. · Tested to:ASTM E 1509-04, ULC/ORD-C1482-M1990,...

Transcript of Installation & Operating Manual · 2014. 5. 5. · Tested to:ASTM E 1509-04, ULC/ORD-C1482-M1990,...

3-90-04301R23_JR11_04/14

INSTALLER: Leave this manual with party responsible for use and operation.OwNER: Retain this manual for future reference.Contact your local dealer with questions on installation, operation or service.

Please read this entire manual before installation and use of this pellet fuel-burning room heater. Failure to follow these instructions could result in property damage, bodily injury or even death.

• Donotstoreorusegasolineorotherflammablevaporsandliquidsinthevicinityofthisoranyotherappliance.

• Donotoverfire-Ifanyexternalpartstartstoglow,youareoverfiring.Reducefeedrate.Overfiringwillvoidyourwarranty.

• Complywithallminimumclearancestocombustiblesasspecified.Failuretocomplymaycausehousefire.

Checkbuildingcodespriortoinstallation.

• InstallationMUSTcomplywithlocal,regional,stateandnationalcodesandregulations.

• Contactlocalbuildingorfireofficialsaboutrestrictionsandinstallationinspectionrequirementsinyourarea.

Testedandapprovedforwoodpelletsandshelledfieldcorn fuelonly. Burningofanyother typeof fuelvoidsyourwarranty.

Hot glass will cause burns.• Donottouchglassuntilitiscooled• NEVERallowchildrentotouchglass• Keepchildrenaway• CAREFULLYSUPERVISEchildreninsameroomas

stove.• Alertchildrenandadultstohazardsofhightemperatures. High temperatures may ignite clothing or other

flammable materials.• Keepclothing,furniture,draperiesandotherflammable

materialsaway.

HOT SURFACES!

Glassandother surfacesarehotduringoperationANDcooldown.

To obtain a French translation of thismanual, pleasecontactyourdealerorvisitwww.harmanstoves.com

Pourobtenirunetraductionfrançaisedecemanuel,s’ilvous plaît contacter votre revendeur ou visitezwww.harmanstoves.com

NOTE

wARNING

wARNING

Installation & Operating ManualCare and Operation

Model(s):P43 Freestanding Pellet Stove

NOTICE: SAVE THESE INSTRUCTIONS

CAUTION!

CAUTION!

Service parts list has been removed from this manual.Refer to Owner’s Manual or Individual service parts list.

3P43PelletStove3-90-04301R23_JR11_04/14

"PRe

VeNT

HOU

Se F

IReS

"Ins

tall a

nd U

se O

nly in

Acc

orda

nce W

ith M

anufa

cture

r's In

stalla

tion a

nd O

pera

tion I

nstru

ction

s.Co

ntact

Loca

l Buil

ding o

r Fire

Offi c

ials A

bout

Restr

iction

s and

Insta

llatio

n Ins

pecti

on in

Your

Are

a.

WAR

NING

: THE

STR

UCTU

RAL I

NTEG

RITY

OF

THE

MANU

FACT

URED

HOM

E FL

OOR,

WAL

L,AN

D CE

ILING

/ROO

F MU

ST B

E MA

INTA

INED

. DO

NOT

INST

ALL I

N SL

EEPI

NG R

OOM.

An ou

tside

comb

ustio

n air i

nlet m

ust b

e pro

vided

. Refe

r to M

anufa

cture

r’s in

struc

tions

and l

ocal

code

s reg

ardin

g the

requ

ireme

nts fo

r pas

sing t

he ex

haus

t ven

ting s

ystem

thro

ugh a

comb

ustib

lewa

ll or c

eiling

.

Inspe

ct an

d Clea

n Exh

aust

Venti

ng S

ystem

Fre

quen

tly.

Use a

3" or

4" di

amete

r typ

e "L"

or "P

L" ve

nting

syste

m.

Do N

ot Co

nnec

t This

Unit

to a

Chim

ney F

lue S

ervin

g Ano

ther A

pplia

nce.

FOR

USE

WIT

H W

OOD

PELL

ET F

UEL O

R UP

TO

50%

COR

N / P

ELLE

T MI

XTUR

E ON

LY.

The U

se of

Othe

r Fue

ls Ma

y Cre

ate an

Uns

afe C

ondit

ion.

Input

Ratin

g Max

: 5.5

lb. fu

el/hr.

U.S.

Elec

trical

Ratin

g: 11

5 VAC

, 60 H

z, St

art 4

.2 AM

PS, R

un 2.

8 AMP

SRo

ute P

ower

Cor

d Awa

y Fro

m Un

it.

dANG

eR: R

isk of

Elec

trical

Shoc

k. Di

scon

nect

Powe

r Befo

re S

ervic

ing U

nit.

For F

urthe

r Ins

tructi

on, R

efer T

o Own

er's

Manu

al.

Repla

ce gl

ass o

nly w

ith 5m

m ce

rami

c ava

ilable

from

your

deale

r.

Keep

View

ing an

d Ash

Rem

oval

Door

s Tigh

tly C

losed

Dur

ing O

pera

tion.

dO N

OT R

eMOV

e TH

IS L

ABeL

/ Ne

PAS

eNLe

VeR

CeTT

e ÉT

IQUe

TTe

MINI

MUM

CLeA

RANC

eS T

O CO

MBUS

TIBL

eS/

dIST

ANCe

S de

SeC

URIT

e PA

R RA

PPOR

T AUX

MATe

RIAU

X CO

MBUS

TIBL

eS:

Back

Wall

/ Entr

e Mur

Arri

ère

2”/ 5

1mm

2”/ 5

1mm

Side

Wall

/ Entr

e Par

oi La

tér

16”/

406m

m 10

”/ 25

4mm

CORN

ER IN

STAL

LATI

ON / E

N AN

GLE

Wall

s to A

pplia

nce

9”/22

8mm

9”/22

8mm

Entre

Mur

s et a

ppar

eil

FLOO

R PR

OTEC

TION

/ Pro

tectio

n Du P

lanch

er

US

A Ca

nada

Side

s*/C

ôtés

(A)

6”

200m

mBa

ck**/

Arriè

re

(B)

6”

200m

mFr

ont*/

Avan

t (C

) 6”

45

0mm

**Mea

sure

d fro

m pe

desta

l bas

e in t

he U

S ON

LY**M

esur

é à pa

rtir de

la ba

se du

socle

aux É

tats-U

nis un

iquem

ent

*Mea

sure

d fro

m Gl

ass O

penin

g*M

esur

er à

partir

de la

surfa

ce de

la po

rte en

verre

Floor

Pro

tectio

n Mus

t Be a

Non

-Com

busti

ble M

ateria

l.Mu

st Al

so be

Plac

e Und

er An

y Hor

izonta

l Flue

Con

necto

r, Exte

nding

2”

or 51

mm B

eyon

d the

Pipe

Mea

sure

ment.

Pour

proté

ger le

plan

cher,

il fau

t sou

s le p

êole

un m

atéria

u. Qu

i doit

au

ssi ê

tre p

lacé

sous

les

partie

s ho

rizon

tales

du

tuyau

de

racc

ord

à la

chem

inée

et s’é

tendr

e à

51mm

o 2

po.

au-d

elà d

e la

mesu

re

du tu

yau.

Made

in U

.S.A

. of U

S an

d imp

orted

parts

. / Fa

briqu

éau

x État

s-Unis

-d’A

mériq

ue pa

r des

pièc

es d’

origi

neam

érica

ine et

pièc

es im

porté

es.

"PRe

VeNT

ION

deS

INCe

NdIe

S"Re

spec

ter sc

rupu

leuse

ment

les in

struc

tions

du co

nstru

cteur

pour

l'ins

tallat

ion et

les c

onsig

nes

de fo

nctio

nnem

ent. R

espe

cter le

s règ

les de

sécu

ritè en

vigu

eur d

ans v

otre r

égion

.AV

eRTI

SSeM

eNT

POUR

MOB

ILe

HOMe

S: N

e pas

insta

ller d

ans u

ne ch

ambr

e. ll e

st im

pera

tifde

prév

oir un

e pris

e d'al

r exté

rieur.

L'int

égrité

stru

ctura

le du

plan

cher,

du pl

afond

et de

s mur

s doit

étre

strict

emen

t pré

servé

e. Se

repo

rter a

ux in

struc

tions

du fa

brica

nt et

aux r

églem

entat

ions s

pécifi

ques

locale

s con

cern

ant le

s pré

cauti

ons r

equis

es lo

rs de

la tr

aver

sée d

'un m

ur ou

d'un

plafo

nd.

Contr

óler e

t nett

oyer

fréq

uemm

ent to

ut le

syste

me d'

evac

uatio

n des

fumé

es co

nform

émen

t aux

reco

mman

datio

ns du

cons

tructe

ur. U

tilise

r des

tuya

ux <

<Spé

cial g

ranu

lés>>

de Ø

76 m

m ou

102 m

m. N

e pas

racc

orde

r ce p

oéle

à un c

ondu

it de c

hemi

née d

éjà ut

ilisé p

our u

n autr

e app

areil

.FO

NCTI

ONNe

eXC

LUSI

VeMe

NT A

VeC

deS

GRAN

ULeS

de

BOIS

.Ap

pare

il de c

hauff

age à

gran

ulé ty

pe. C

onso

mmati

on m

axim

um: 2

.5 kg

/h.US

coup

ure:

115 V

AC, 6

0 Hz,

4.2 am

ps D

émar

rer, E

xécu

ter 2.

8 AMP

Sfon

ction

neme

nt no

rmal

1.1A.

Tenir

le co

rdon

d'ali

menta

tion à

l'éca

rt du

poèle

.dA

NGeR

: Risq

ue d'

électr

ocuti

on. D

ébra

nche

r l'ap

pare

il ava

nt tou

te int

erve

ntion

.Ne

remp

lacer

la vi

tre qu

'avec

une v

itre cé

rami

que 5

mm de

mém

e qua

lité di

spon

ible

aupr

ès de

votre

reve

ndeu

r.Po

ur un

e info

rmati

on pl

us co

mplét

e, se

repo

rter à

la no

tice d

'utilis

ation

. Ten

ir la p

orte

herm

étiqu

emen

t clos

e dur

ant fo

nctio

nnem

ent.

Ne fa

ites p

as ob

stacle

l’esp

ace s

ous l

e réc

hauff

eur. T

oujou

rs fou

rnir u

n app

rovis

ionne

ment

suffi s

ant e

n air f

rais

jusqu

’au lie

u d’in

stalla

tion A

pplia

nce

P.N. 3

-90-

0430

0

WIT

HOUT

SIDE

SHI

ELDS

WIT

HSI

DE S

HIEL

DSSa

ns É

cran

sLa

téra

uxAv

ec É

cran

sLa

téra

ux

US e

NVIR

ONMe

NTAL

PRO

TeCT

ION

AGeN

CYTh

is ap

plian

ce co

mplie

s with

Can

adian

Stan

dard

s Ass

ociat

ion (C

SA) B

415.1

and T

itle 40

of

the U

.S. C

ode o

f Fed

eral

Regu

lation

s, Pa

rt 60,

SubP

art A

AA. T

his m

odel

is ex

empt

from

EPA

certifi

catio

n und

er 40

CFR

60.53

1 by d

efi nit

ion [W

ood H

eater

(A) “

air-to

-fuel

ratio

”].

Cet a

ppar

eil e

st co

nform

e a

l’Ass

ociat

ion C

anad

ienne

des

Stan

dard

s (C

SA) B

415.1

-10,

claus

e 4 et

Titre

40 du

Cod

e des

Rég

ulatio

ns F

édér

ales d

es É

tats-U

nis, p

artie

60, s

ectio

n AA

A. C

e mo

dèle

est e

xemp

t de

la ce

rtifi ca

tion

EPA

sous

40

CFR

60.53

1 pa

r défi

nition

(A

ppar

eil de

chau

ffage

au bo

is (A

) “ ra

tio A

ir-Co

mbus

tible)

.

date

of M

anuf

actu

re / d

ate d

e fab

ricat

ion:

Fabr

iqué

par

: Hea

rth an

d Ho

me T

echn

olog

ies 35

2 Mou

ntain

Hou

se R

oad,

Hali

fax P

A 17

032

2013

20

14

2015

JA

N

FEb

M

AR

A

PR

MAY

JU

N

JUL

AU

G

SEP

OC

T N

OV

DEC

HarmanPP38+/P43PelletS

tove

BlackBackgroundwithbaremetalforprint-adhesivebacked,m

etalplate.

BARC

ODE

LABE

L00

8Se

rial N

o.No d

e sér

ie:

Repo

rt #/

Rapo

rt #1

35-S

-21-

6.2 (P

P38+

)Re

port

#/ Ra

port

#135

-S-2

3-4,

135-

S-23

b-6.2

(P43

)Te

sted t

o / Te

sté à:

ASTM

E15

09-0

4, UL

C/OR

D-C1

482-

M199

0, UL

C-S6

27-0

0

Room

Hea

ter P

ellet

Fuel

Burn

ing Ty

pe. A

lso fo

r use

in M

obile

Hom

es.

Appa

reil d

e cha

uffag

e à gr

anulé

s de b

ois U

tilisa

ble da

ns de

s mob

ile ho

mes.

This

pelle

t bur

ning a

pplia

nce h

as be

en te

sted a

nd lis

ted fo

r use

in

Manu

factur

ed H

omes

in ac

cord

ance

with

OAR

814-

23-9

00 th

roug

h 814

-23-

909

MODEL/M

ODÈLE

:"P

P38+/P

43"

2"(5

1mm

)

10" (

254m

m) w

ith s

ide

shie

lds

16" (

406m

m) w

/out

sid

e sh

ield

s

AA

C

b

USA

CA

NA

DA

Flo

or p

ro

tec

tor

PRO

TEC

TIO

N D

E SO

LFL

OO

R P

RO

TEC

TIO

N

9"(2

28m

m)

9"(228mm)

Rev

E

10-3/4"

4-3/8"

The

labe

l sho

wn

here

is fo

r ref

erre

nce

only

. For

spe

cific

info

rmat

ion

on c

lear

ance

s an

d te

stin

g, c

onsu

lt th

e ac

tual

labe

l on

the

rear

of t

he P

43 fu

el h

oppe

r.

Thislabelislocatedonthebackoftheunit.

PleasecopytheSerialN

umberforfuturereference.

Serial#:

4 P43 Pellet Stove 3-90-04301R23_JR11_04/14

SafetyInformation 5

Installation 6

Venting 8

ESPControl 15

AutomaticOperation 16

ManualOperation 19

LowDraftVoltageAdjustment 21

Maintenance 22

Troubleshooting 27

Specifications/WiringDiagram 28

FuelSpecificationDetails 29

PowerFailure/Back-up 30

Warranty 32

ServiceParts 34

Table of Contents

IntroductionTheP43PelletStovehashugefeaturesinasmallpackage,givingyou0to43,000BTUwhenyouneedit,automatically.Youbasicallyneedtosetyourdesiredroomtemperatureandfillthehopper.WiththeP43youwillnoticeevenheatthroughoutyourzoneandalevelofconvenienceyouneverthoughtpossible.TheP43epitomizesthecapabilityofHarmanPelletStoves,takingadvantageofHarman’s20+yearsofpelletstovedesign,technologyandmanufacturing.This43,000BTUstovehasthesmartestcontrolscoupledwithminimalmaintenance.TheP43'soutputismanagedbyamicroprocessorthatsensestheroomtemperatureandthefiretemperaturewithtinythermistorprobesandthendeterminesthebestfeedrateforyourheatingdemand.Thisimprovedandsmartercontrolalsohasadiagnosticportwhichallowsaservicerepresentativetoattachanexternaldisplayshowingliveworkingdataforeaseintroubleshooting.TheplatinumcombinationisHarman’sPatentedFeeder&BurnPot,andESPControlwhichhavebeendevelopedtotheirhigheststate.Thesefeaturesworktogethertoallowamazingheatoutputwithlittleregardforfuelquality.

Safety Listing: Omni-Test Laboratories, Inc.Tested to: ASTM E 1509-04, ULC/ORD-C1482-M1990,ULC-S627-00.Report#135-S-23-4,135-S-23b-6.2

Thisapplianceisalsoapprovedforinstallationintoashop.

DivisionofHearth&HomeTechnologies352MountainHouseRoad

Halifax,PA17032

= Contains updated information

5P43 Pellet Stove3-90-04301R23_JR11_04/14

DO NOT INSTALL A FLUE DAMPER IN THE EXHAUST VENTING SYSTEM OF THIS UNIT.

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE.

Important Notes

INSTALLATION AND REPAIR OF THIS HARMAN STOVE SHOULD bE DONE bY A qUALIFIED SERVICE PERSON. wE RECOMMEND THAT THE STOVE bE INSPECTED bEFORE USE AND AT LEAST ANNUALLY bY A qUALIFIED SERVICE PERSON. PERIODIC CLEANING IS REqUIRED THROUGHOUT THE HEATING SEASON AND AT THE END OF EACH wINTER FOR THE STOVE TO wORk EFFICIENTLY. SEE CLEANING INSTRUCTIONS ON PG 23.

SPECIAL NOTE: DUE TO FLY ASH bUILDUP, IT IS STRONGLY RECOMMENDED THAT YOU HAVE YOUR STOVE PROFESSIONALLY CLEANED AND SERVICED ANNUALLY. THIS INCLUDES ALL PARTS OF THE STOVE, AND THE ENTIRE VENTING SYSTEM.

MObILE HOME INSTALLATION SHOULD bE DONE IN ACCORDANCE wITH THE MANUFACTURED HOME AND SAFETY STANDARD (HUD), CFR 3280, PART 24.

kEEP COMbUSTIbLE MATERIALS (SUCH AS GRASS, LEAVES, ETC.) AT LEAST 3 FEET AwAY FROM THE FLUE OUTLET ON THE OUTSIDE OF THE bUILDING.

A CHIMNEY CONNECTOR SHALL NOT PASS THROUGH AN ATTIC OR ROOF SPACE, CLOSET OR OTHER CONCEALED SPACE, A FLOOR, OR A CEILING.

DO NOT CONNECT TO OR USE INCONJUNCTION wITH ANY AIR DISTRIbUTION DUCT wORk UNLESS SPECIFICALLY APPROVED FOR SUCH INSTALLATION.

DO NOT USE MAkESHIFT COMPONENTS OR OTHER COMPROMISES wHEN INSTALLING THIS APPLIANCE.

CAUTION!

ALwAYS bE SURE THERE IS NO UNbURNED FUEL IN THE ASH PAN PRIOR TO LIGHTING A FIRE. THIS wILL CAUSE SMOkE AND SOOT AND OTHER UNwANTED RESULTS.

CAUTION!

THE STRUCTURAL INTEGRITY OF THE MObILE HOME FLOOR, wALL, AND CEILING/ROOF MUST bE MAINTAINED.

CAUTION!

CAUTION!

CAUTION!

CAUTION!

MObILE/MANUFACTURED HOME STANDARDS DO NOT ALLOw INSTALLATION IN ROOMS DESIGNATED FOR SLEEPING.

WARNING!

6 P43 Pellet Stove

UnpackingTheP43 isbolted(1/4x1"hexheadbolts) to theskid topreventmovementduringshipping.Tofreethestovefromtheskidyoumustremovethehold-downboltsintherearofthepedestalbase.Removing rear cover panelsTherearcoverpanelsaresecuredtothestovewiththreebolts each.Twoof the bolts need only be loosened, notremoved,toremovethepanels.Itisrecommendedthattherearcoversareinstalledaftertheunitisinplaceandtheventpipeisinstalled,topreventcontactwithhotormovingparts.FirebrickInstallthesinglefirebrickhorizontallyontheanglebracketabovetheburnpot.Flame GuideInstallthecastironflameguideontopoftheburnpot.Makesurethattheflameguideisfullyseatedontheverticalsidesoftheburnpotandthatthebackoftheguiderestsagainstthebodyofthestove.INSTALLEXHAUSTVENTATCLEARANCESSPECIFIEDBYTHEMANUFACTURER.Mostpelletventpiperequiresaminimumof3"ofclearancetocombustiblematerialsalthoughsomecanbeinstalledat1"clearance.Followtheseinstructionsalongwithalllocalcodesregardinginstallationofthisappliance.Do NOT usemakeshift compromiseswhen installing thisappliance,seriousconsequencesmayresult.Withanyhearthappliance,installationofsmokedetectorsisrecommendedoneverylevelofthehome.Possible causes of smoke detector activation:Paintcuringprocess-Openawindowneartheapplianceforthefirstfewhoursofburning.Exhaustbeingdrawnbackinsidethedwelling-Outsideairconnectiontotheapplianceisnecessary.Ventleakage-Allinteriorseamsandjointsshouldbesealedwithsiliconewhereappliacable.Followventmanufacturersinstructionsforpropersealing.

Room Sensor InstallationTheroomsensorisasmalltemperaturesensorontheendofa60"wire.Thissensorisinstalledmuchlikeastandardwallthermostat.Thereisaremoteroomsensorportontherearoftheunitforeasyexternalconnection.Usestandard18-2thermostatwiretoextendthedistancetothedesiredlocation(50'maximum).Theroomsensorshouldbeinstalledinthelocationwhereyouwanttocontrolthetemperature.NOTE:Distancesofmorethan25feet fromtheunitor inanother roomarenot recommended.The roomsensor isessentialfortheP43'sexcellentefficiency.NOTE: It is recommended that the room sensor be installed,evenifonlyinstalledontherearoftheunitasareturnairsensor.

Rear Cover Panels

Shipping Bolts Note: These same holes are used for securing the stove in mobile home installation.

Figure 1

3-90-04301R23_JR11_04/14

Assembly and Installation

7P43 Pellet Stove3-90-04301R23_JR11_04/14

Installing Placethestoveonanoncombustible typefloororfloorprotectorthatextendsaminimumof6inches(152mm)tothefrontoftheloaddooropening,6inches(152mm)tothesidesofthedooropening,and6inchestotherear.Floorprotectionmustalsoextend2inches(51mm)beyondeachsideofanyhorizontalfluepipe.Theminimumfloorprotectormaterialis20gaugesheetmetal.Otherfloorprotectormaterialsareceramictile,stone,brick,etc.NOTE for Canadian installation only:PerULC-S627-00,Ifinstalledonacombustiblefloor,theneedtoprovideanoncombustiblefloor protector coveringtheareabeneaththespace heater andextendingatleast17.72"(450mm)onthefiringsideandatleast7.87"(200mm)ontheothersides.In Canada, you may follow smaller U.S. floor protection requirements ONLY if the user agrees to completely shut-down the appliance, and allow it to cool to where all fire is extinguished and the combustion blower and its indicator light shuts off, prior to opening the firebox door or ash door.PlacethestoveawayfromcombustiblewallsatleastasfarasshowninFigures3and4.Pleasenotethedifferenceinsidewallclearancewithandwithoutsideshields.Notethattheclearancesshownareminimumforsafetybutdonotleavemuchroomforaccesswhencleaningorservicing.Pleasetakethisintoaccountwhenplacingthestove.Connectthepowercordtoa100VAC,50Hzgroundedreceptacle.(A surgeprotector is recommended to protect the circuit board.)Alsobesurethatthepolarityoftheoutletthatthestoveispluggedintoiscorrect.Prior to installing thefluepipe, connectadraftmeter. (Thedraftmetermusthaveaminimumrangeof0-.5")Recordthefirstreading.Connectfluepipetostoveandbesurealldoorsandwindowsinthehomeareclosed.Recordtheseconddraftreading_______.Ifthesecondreadingismorethan.05"lowerthanthefirstreading,checkforpossiblerestrictionsortheneedforoutsideair(seepage10).Formoreinformationonthedrafttestprocedure,refertoPage21.Mobile Home InstallationWhen installing this unit in amobile home, several requirementsmustbefollowed:1. Theunitmustbeboltedtothefloor.Thiscanbedonewith1/4"

lagscrewsthroughthe2holesinthebaseplate.2. Theunitmustalsobeconnectedtooutsideair.Seepage10.3. Floorprotectionandclearancesmustbefollowedasshown.4. Unitmustbegroundedtothemetalframeofthemobilehome.CAUTION: This appliance must be vented to the outside.Duetohightemperatures,thestoveshouldbeplacedoutoftrafficandawayfromfurnitureanddraperies.Childrenandadultsshouldbealertedtothehazardsofhighsurfacetemperaturesandshouldstayawaytoavoidburnstoskinand/orclothing.Youngchildrenshouldbecarefullysupervisedwhentheyareinthesameroomasthestove.Clothingandotherflammablematerialsshouldnotbeplacedonornearthisunit.

Installation

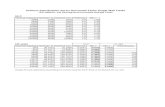

MinimumSizefloorprotection (USA) is321/2"wideBy33"deep(825mmX838mm).* Floor protection dimensions for the front and sidesare measured from the appliance door opening inThe United States. In Canada, the side dimension ismeasuredfromthewidestpartoftheappliance.

NOTE:Measurement"L"ismeasuredfromthepedestalbaseintheUSONLY

NOTE:Measurement"K"ismeasuredfromtheglassintheUSONLY

L

J

Floor Protection Requirements US Canada

Sides

Rear

6" 200mm

6" 200mm

k Front 6" 450mm

Figure 3

9"(228mm)With or W/Out Side Shields

9"(228mm)

9"(228mm

) Alternate floor protector dimension may be used as long as they satisfy the measurement requirements shown below.Minumum size floor protection for a corner installation hearth pad is 36" x 36". Clearance shown as 9" with optional side shields installed.

Figure 4

2"(51mm)

36"(914mm)

10" (254mm) with side shields

16" (406mm) without side shields

10" (254mm)16" (406mm)

JUSA

k

L

JCANADA

Floor protector

T H E S T R U C T U R A L I N T E G R I T Y O F T H E MANUFACTURED HOME FLOOR, wALL, AND CEILING/ROOF MUST bE MAINTAINED.

DO NOT INSTALL IN SLEEPING ROOM.

WARNING!

8 P43 Pellet Stove 3-90-04301R23_JR11_04/14

VentingRequirements for Terminating the VentingwARNING:Ventingterminalsmustnotberecessedintoawallorsiding.NOTE:Onlyapprovedpelletventpipe,wallpass-throughs,and fire stops should be used when venting throughcombustiblematerials.NOTE: Always take into consideration the effects of theprevailingwinddirectionor otherwind currents thatmaycauseflyashand/orsmokewhenplacingtheterminationofthevent.In addition, the following must be observed:A.Theclearanceabovegrademustbeaminimumof12".B.Theclearancetoawindowordoorthatmaybeopened

must be aminimumof 48" to the side, 48" below thewindow/door, and 12" above thewindow/door. (with outside air installed, 18” to the side or below)

C.A 12" clearance to a permanently closedwindow isrecommendedtopreventcondensationonthewindow.

D.Theverticalclearancetoaventilatedsoffitlocatedabovetheterminalwithinahorizontaldistanceof2feet(60cm)fromthecenter-lineoftheterminalmustbeaminimumof18".

E.Theclearancetoanunventilatedsoffitmustbeaminimumof12".

F.Theclearancetoanoutsidecorneris11"fromcenterofpipe.

G.Theclearancetoaninsidecorneris12".H.Aventmustnotbeinstalledwithin3feet(90cm)abovea

gasmeter/regulatorassemblywhenmeasuredfromthehorizontalcenter-lineoftheregulator.

I.Theclearancetoserviceregulatorventoutletmustbeaminimumof6feet.

J.Theclearancetoanon-mechanicalairsupplyinlettothebuildingorthecombustionairinlettoanyotherappliancemustbeaminimumof48”.

K.Theclearancetoamechanicalairsupplyinletmustbeaminimumof10feet.

(with outside air installed, 6 feet )L.Theclearanceaboveapavedsidewalkorapaveddriveway

locatedonpublicpropertymustbeaminimumof7feet.M.Theclearanceunderaveranda,porch,deckorbalcony

mustbeaminimumof12inches. (b. also applies)NOTE: The clearance to vegetation and other exteriorcombustiblessuchasmulch is36”asmeasuredfromthecenteroftheoutletorcap.This36”radiuscontinuestogradeoraminimumof7feetbelowtheoutlet.CertainCanadianand/or Localcodesorregulationsmayrequiredifferentclearances.A vent shall not terminate directly above a side-walk orpaveddrivewaywhichislocatedbetweentwosinglefamilydwellingsandservesbothdwellings.Onlypermitted ifveranda,porch,deck,orbalcony is fullyopenonaminimumof2sidesbeneaththefloor.See NFPA 211 for more installation clearance reductions when using outside air.NOTE: where passage through a wall, or partition of combustible construction is desired, the installation shall conform to CAN/CSA-b365. (if in Canada)

V =Vent Terminal A =Air Supply Inlet =Area where termination is not permitted

Door

Sidewalk

FixedClosed

Openable

Openable FixedClosed

Inside CornerDetail

Porch orOpenable

Deck or Fixed

9P43 Pellet Stove3-90-04301R23_JR11_04/14

Venting

VentingA combustion blower is used to extract the combustiongasesfromthefirebox.ThiscausesanegativepressureinthefireboxandapositivepressureintheventingsystemasshowninFigure7.Thelongertheventpipeandmoreelbowsusedinthesystem,thegreatertheflowresistance.Becauseofthesefactswerecommendusingasfewelbowsaspossibleand15feetor lessofventpipe.Themaximumhorizontalrunshouldnotexceed48".Ifmorethan15feetofpipeisneeded,theinteriordiametershouldbeincreasedfrom3"to4"becausealargerpipecauseslessflowresistance.be sure to use approved pellet vent pipe wall and ceiling pass-through fittings to go through combustible walls and ceilings. All joints for connector pipe must be fastened with a minimum of three screws and a termination cap must be installed. Follow pellet vent manufacturer instructions for properly securing each pellet vent joint. The pellet starting collar must be secured to the unit's flue collar.NOTE: Simpson DuraVent PelletVent Pro Harman Adapter Part #3PVP-ADHb and PelletVent Pro Harman Adapter Increaser Part #3PVP-X4ADHb are highly recommended to be installed on the starter collar to insure a proper pipe connection to the unit.

IMPORTANT NOTICEApproved3"or4"PelletVentPipeSuchAs,Type"PL",MustBeUsed.

Figure 7

Vent PipePelletventingpipe(knownasPLvent)isconstructedoftwolayerswithairspacebetweenthelayers.Thisairspaceactsasaninsulatorandreducestheoutsidesurfacetemperaturetoallowaclearancetocombustiblesof1to3inches.Thesectionsof pipe lock together to formanair tight seal inmostcases.However,insomecasesaperfectsealisnotachieved.Forthisreasonandthefactthattheunitoperateswith a positive vent pressurewe specify that the joints also be sealed with high temp (RTV) silicone. Aluminumtapecanalsobeusedforanyjointthatis1ft.ormorefromtheoutletofthestove.

Avoiding Smoke and OdorsNegative Pressure, Shut-down, and Power Failure:To reduce the probability of back-drafting or burn-back in the pellet burning appliance during power failure or shut-down conditions, the stove must be able to draft naturallywithoutexhaustbloweroperation.Negativepressureinthehousewillresistthisnaturaldraftifnotaccountedforinthepelletapplianceinstallation.

Heatrisesinthehouseandleaksoutatupperlevels.Thisairmustbereplacedwithcoldairfromoutdoors,whichflowsinto lower levels of the house.Vents and chimneys intobasementsandlowerlevelsofthehousecanbecometheconduitforairsupply,andreverseundertheseconditions.

Outside Air:Hearth & Home Technologies strongly recommends attaching outside air in all installations, especially lower level and main floor locations.

INSTALL VENT AT CLEARANCES SPECIFIED bY THE VENT MANUFACTURERDO NOT INSTALL A FLUE DAMPER IN THE EXHAUST VENTING SYSTEM OF THIS UNIT.DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE.A CHIMNEY CONNECTOR MAY NOT PASS THROUGH AN ATTIC OR ROOF SPACE, CLOSET OR SIMILAR CONCEALED SPACE, FLOOR , OR CEILING. REFERENCE LOCAL bUILDING CODES FOR DETAILS.

O+ = Positive static pressure= Negative static pressure

+

+

O-

DO NOT USE MAkESHIFT COMPROMISES wHEN INSTALLING THIS APPLIANCE. DAMAGE AND/OR INJURY MAY RESULT.

CAUTION!

10 P43 Pellet Stove 3-90-04301R23_JR11_04/14

Outsideairflexpipegoeshere.

InletCoverpart#1-10-09542

Pernationalbuildingcodes,considerationmustbegiventocombustionairsupplytoallcombustionappliances.Failuretosupplyadequatecombustionairforallappliancedemands,mayleadtoback-draftingofthoseandotherappliances.Whentheapplianceisside-wallvented:Theairintakeisbestlocatedonthesameexteriorwallastheexhaustventoutletandlocatedloweronthewallthantheexhaustventoutlet.When theappliance is roofvented:Theair intake isbestlocatedontheexteriorwallorientedtowardstheprevailingwinddirectionduringtheheatingseason.Theoutsideairconnectionwillsupplythedemandsofthepellet appliance, but considerationmust be given to thetotalhousedemand.Housedemandmayconsumesomeairneededforthestove,especiallyduringapowerfailure.Itmaybenecessarytoaddadditionalventilationtothespaceinwhichthepelletapplianceislocated.ConsultwithyourlocalHVACprofessionaltodeterminetheventilationdemandsforyourhouse.Toinstalloutsideairuse3"I.D.non-combustibleflexpipe.Thereisabreak-awayholeontherearpaneloftheP43stovewhichmustberemovedbeforeconnectingtheflexpipe.Thepipeshouldberunoutsideandterminatetothesideorbelowtheventpipeoutletsotheflueoutletismorethan12"fromtheinletcover.Inletcover,partnumber1-10-09542shouldbeusedtokeepbirds,rodents,etc.outofthepipe.Youmay choose to use the optional Direct VentWallPassthroughKit(part#1-00-677177)whichincorporatestheventingpassthroughandoutsideairinletintoonecomponent.

Venting

DirectVentWallPassthroughKit(part#1-00-677177)

Vent Configurations:Toreduceprobabilityofreversedraftingduringshut-downconditions,Hearth&HomeTechnologiesstronglyrecommends:• Installingthepelletventwithaminimumverticalrunoffivefeet,preferablyterminatingabovetheroofline.• Installingtheoutsideairintakeatleastfourfeetbelowtheventtermination.Topreventsootdamagetoexteriorwallsofthehouseandtopreventre-entryofsootorashintothehouse:• Maintainspecifiedclearancestowindows,doors,andairinlets,includingairconditioners.• Ventsshouldnotbeplacedbelowventilatedsoffits.Runtheventabovetheroof.• Avoidventingintoalcovelocations.• Ventsshouldnotterminateunderoverhangs,decksorontocoveredporches.• Maintainminimumclearanceof12inchesfromtheventterminationtotheexteriorwall.Ifyouseedepositsdeveloping

onthewall,youmayneedtoextendthisdistancetoaccommodateyourinstallationconditions.Hearth & Home Technologies assumes no responsibility for, nor does the warranty extend to, smoke damage caused by reverse drafting of pellet appliances under shut-down or power failure conditions.

11P43 Pellet Stove3-90-04301R23_JR11_04/14

#2 Preferred method Thismethod also provides excellent venting for normaloperationbutrequiresthestovetobeinstalledfartherfromthewall.Theverticalportionoftheventshouldbethreetofivefeethighandatleastthreeinchesfromacombustiblewall.Thisverticalsectionwillprovidenaturaldraftintheeventofapowerfailure.If the stove is installed below grade be sure the venttermination is at least 12" above grade. The outlet must also be 1 foot from the house/building.Note: Do not place joints within wall pass-throughs.

#1 Preferred method Thismethodprovidesexcellentventingfornormaloperationandallowsthestovetobeinstalledclosesttothewall.Twoinches from thewall is safe; however, four inchesallowsbetteraccesstoremovetherearpanel.Theverticalportionoftheventshouldbethreetofivefeethigh.Thisverticalsectionwillhelpprovidenaturaldraftintheeventofapowerfailure.Note: Do not place joints within wall pass-throughs.

Venting

Figure 9

Figure 8

3 Ft.to

Combustibles

3 Ft.to Combustibles

3 Ft.to

Combustibles

3 Ft.to Combustibles

CAUTION!keep combustible materials (such as grass, leaves, etc.) at least 3 feet away from the flue outlet on the outside of the building.

12 P43 Pellet Stove 3-90-04301R23_JR11_04/14

#4 Installing into an existing chimneyThismethodprovidesexcellentventingfornormaloperation.Thismethodalsoprovidesnatural draft in theevent of apowerfailure.Ifthechimneyconditionisquestionable*youmaywanttoinstallalinerasinmethod#7.InsomeplacesintheUSandCanadaitisrequiredthattheventpipeextendallthewaytothetopofthechimney.*The chimney should be inspected and cleaned beforeinstallingyourstove.Ifyoudiscoverthatthechimneydoesnothaveaclaytilelinerorhascracksorflakingofthetileliner youwill need to install a stainless steel linerwithinthechimney.Inmostcasestheinsidediameterofthislinershouldbe4".Eitherflexibleorrigidlinermaybeusedforthispurpose.RefertoMethod6&7.Besuretodesigntheventingsothatitcanbeeasilycleaned.

#5 Installing into an existing fireplace chimney Thismethodprovidesexcellentventingfornormaloperation.Thismethodalsoprovidesnatural draft in theevent of apowerfailure.Ifthechimneyconditionisquestionable*youmaywanttoinstallalinerasinmethod#6.InsomeplacesintheUSandCanadaitisrequiredthattheventpipeextendallthewaytothetopofthechimney.*The chimney should be inspected and cleaned beforeinstallingyourstove.Ifyoudiscoverthatthechimneydoesnothaveaclaytilelinerorhascracksorflakingofthetileliner youwill need to install a stainless steel linerwithinthechimney.Inmostcasestheinsidediameterofthislinershouldbe4".Eitherflexibleorrigidlinermaybeusedforthispurpose.RefertoMethod6&7.The chimney should be sealed at the damper using asteel plate.Kaowool,mineralwool or an equivalent non-combustibleinsulationisrecommendedtobeinstalledontopofthesealingplatetoreducethepossibilityofcondensation.The connector pipe should extend through the smokechambertothebaseorintothefirstfluetile.Besuretodesigntheventingsothatitcanbeeasilycleaned.

Figure 10

Figure 11

Venting

13P43 Pellet Stove3-90-04301R23_JR11_04/14

#6 Installing into an existing fireplace chimney Thismethodprovidesexcellentventingfornormaloperation.Thismethodalsoprovidesnatural draft in theevent of apowerfailure.InsomeplacesintheUSandCanadaitisrequiredthattheventpipeextendallthewaytothetopofthechimney.Thepipeorlinerinsidethechimneyshouldbe4"diameter.Inthismethodacapshouldalsobeinstalledonthechimneytokeepoutrain.Besuretouseapprovedpelletventpipefittings.Sealpipe jointswithsiliconeoraluminum tape inadditiontothesealingsystemusedbythemanufacturer.Pipesizeshouldbeincreasedto4"usingthismethod.

#7 Installing into an existing chimney Thismethodprovidesexcellentventingfornormaloperation.Thismethodalsoprovidesnatural draft in theevent of apowerfailure.InsomeplacesintheUSandCanadaitisrequiredthattheventpipeextendallthewaytothetopofthechimney.Thepipeorlinerinsidethechimneyshouldbe4"diameter.Inthismethodacapshouldalsobeinstalledonthechimneytokeepoutrain.

Figure 12

Figure 13

Venting

14 P43 Pellet Stove 3-90-04301R23_JR11_04/14

12"

min

. abo

ve g

roun

d le

vel

#7 Installing through the ceilingThrough the ceiling vent, followPL ventmanufacturersrecommendationswhenusingwallandceilingpassthrough.Sealpipejointswithsiliconeoraluminumtapeinadditiontothesealingsystemusedbythemanufacturer. Note: Do not place joints within wall pass-through.

Venting

Figure 15

Figure 14

Figure 16

12"min. wall to outlet

36"

min. clearance to any

combustible material

Areawithindottedcirclerepresentstheminimumclearancetocombustiblematerialssuchasshrubbery,mulchortallgrasses.

Minimum flue vent configurationIt is recommended that outsideair be installed with this ventingconfiguration.

PL vent manufacturer's �restop spacer and support

1" MIN.

No insulation or othercombustible materialsare allowed within 3"of the PL vent pipe.

�ashing

storm collar

1" MIN.

1" MIN.12

" MIN

1” MIN.

15P43 Pellet Stove3-90-04301R23_JR11_04/14

ESP Control

Status light error messages:3 blinks:IndicatesthattheESP(ExhaustSensingProbe)hasgoneoutofrangetoomanytimesinaspecifiedtime.Performamanual reset*, If thecodereturns immediately,theESPmaybedamagedordisconnected.Otherwise,theexhaustsystemmayneedcleaned.4 blinks: Can occur only in Room TempMode andindicatesRoomSensingProbe failedornot installed. IfaRoomSensingProbeistheninstalled,thestatuslightwillautomaticallyreset.5 blinks (In Igniter Auto. Mode Only):Indicatesthattheunithasfailedtolightwithinthe36minutestartcycle.Toreset-TurnModeSelectorto"OFF",thenturntoeithermodeagain.

6 blinks:Indicatesthatthecontrolhascalculatedpoororincompletecombustionoccurringformorethan25minutes.Asixblinkstatusmaybesetifthestoveisallowedtorunoutofpellets.Toreset,turnmodeselectorto"OFF"thenbackontothedesiredmode.Iftheunitwasnotoutofpellets,seeTroubleshootingsectionformoredetails.* Manual reset-disconnectpowercordforafewsecondsandreconnect.IferrorstilloccurscallyourDealer.

Feed Limit:Setsthemaximumfeedrate

Test:Runsallmotorsat fullspeed for oneminuteto check operation.A f t e r w a r d s t h econtrol will simulateaminimum burnwiththecombustionblowerremainingonlow.

Distribution blower speed adjustment range. L=lowH=highVa r i a b l e s p e e danywhere between LandH;althoughastheconstantburn.goesup,sodoestheLandHscale.

Temp Dial:Allowsyoutoadjusttheroomtemperaturesetting,inRoomTempMode,usingtheouterscalemarkedindegreesFahrenheit.Italsoallowsyoutoadjusttheconstantburnsetting,whileinConstantburnMode,usingtheinnerscalemarkedfrom1to7.

Mode Selector:Allows you to choose betweenRoomTempMode,ConstantburnMode,orOFF.Alsoallowsyou tovary thedistributionblower speedby turning theknob to thehighorlowsideofeachmode.

Power Light:Indicatespowertothecontrol.

IndicatespowertotheFeed Motor.

Indicates power toCombustion blower

Status Light:Willbelitineitherstoveor room temp modewhen pointer is notwithinoffpositionbandexcept after normalshut down. Blinks toindicate errors listedbelow.

Indicates power toDistribution blower.

Dealer Diagnostic Port:For dealer maintenanceonly.Requires specialDDMmonitorsuppliedtoHarman®Dealersexclusively.

IndicatesIgniterison.

Igniter Switch:Set to appropr iateStart-Upmode.

16 P43 Pellet Stove 3-90-04301R23_JR11_04/14

Automatic Ignition

Room Temperature Mode: Thissetting,seeabove,willproducearoomtemperatureof70degreeswiththedistributionbloweratmediumspeed.

Room Temperature ModeTheP43isafullyautomaticstovethatfeaturestwooperatingmodes;ConstantBurnModeandRoomTemperatureMode.InConstantBurnMode,youselectaburnrateandthestovewill remainat thesameburn rate regardlessof the roomtemperature.IntheRoomTemperatureModethestoveconstantlymonitorsthetemperatureintheroomandadjuststhesizeofthefireandtheheatoutputofthestovesothattheroomiskeptataconstanttemperature.Roommode,intheAUTOposition,hastheaddedadvantageofturningthestoveoffifnoheatisrequiredandturningthestoveonagainwhentheroomtemperaturedropsbelowyourdesiredroomtemperature.Room Temperature ModeMostconsumersuse thestove in theRoomTemperatureModebecause it is theeasiestandmostefficientmethodofkeepingtheroomatagiventemperature.IntheRoomTemperatureMode, theRoomSensingProbe constantlymonitorsroomtemperature.Astheweatherchangesoutsideandyourhomeneedsvaryingamountsofheat tobeatadesiredtemperature,thestovewillautomaticallyincreasefiresizeandheatoutputsothataconstanteventemperatureismaintained.Iftheweatherwarmsupandnoheatisrequired,thestovewillgraduallyshutdown.Whenthehousecoolsdown,thestovewillautomaticallybringtheroomtemperaturetotheprecisetemperatureyoudesire.IntheRoomTemperatureModeyoucanselecteitherAutoorManualmodesfortheigniter,usingtheignitertoggleswitch.Whenthetoggleswitchis intheAutoposition,theigniter,locatedinsidetheburnpot,isreadytoautomaticallylightthefirewhenrequired.WhenthetoggleswitchsettotheManualpositionthestovecanbelitmanuallywitheitheragelorawaxtypefirestarter.(seelightinginstructionsonpage19.)WiththeignitertoggleswitchsetintheManualpositionthestovewillautomaticallyadjustheatoutput,butthestovewillnotautomaticallyshutdownifnoheatisrequired.Insteaditwillgotoitslowestsettingandremainthere.TheManualpositionontheignitertoggleswitchletsyoulightthestovemanually,shouldtheigniterfailforanyreason.SecondlyifyouareusingtheHarmanbatterybackupsystem,theManualsettingwillpreventthestovefromturningoffandonduringapowerfailure,whichwoulddrainthebackupbattery.IntheRoomTemperatureMode,thedistributionblowerspeedcanbeincreasedordecreasedbyadjustingtheRoomTemp/Off/StoveTempdialbetweenLandH.Asoutputofthestoveincreases,thespeedoftheblowerwillincreaseautomaticallytoinsurethatmoreheatistransferredoutintotheroom.Thedistributionblowerwillshutoffastheroomreachesthesettemperature,thiswillpreventoverheatingoftheroom.

DONOTCONNECTTOANYAIRDISTRIBUTIONDUCTORSYSTEM.

DONOT BURNGARBAGEORFLAMMABLEFLUIDSSUCHASGASOLINE,NAPTHA,ORENGINEOIL.

HOT WHILE IN OPERATION. KEEP CHILDREN,CLOTHING,ANDFURNITUREAWAY.CONTACTMAYCAUSESKINBURNS.

KEEPFIREBOXANDASHREMOVALDOORSCLOSEDDURING OPERATION. MAINTAIN SEALS IN GOODCONDITION.

CAUTION!

17P43 Pellet Stove3-90-04301R23_JR11_04/14

Ifthestoveislefttorunoutoffuel,youmaygeta6blinkstatuslight.IfthishappenssimplyresetthecontrolboardbyturningthemodeselectortoOFFandbackON.

Automatic Ignition

The setting above will produce continuous maximum heat output with the distribution blower at full speed.

Constant burn Mode

The setting above will produce continuous medium heat output with the distribution blower at low speed.

HOT wHILE IN OPERATION. kEEP CHILDREN, CLOTHING, AND FURNITURE AwAY. CONTACT MAY CAUSE SkIN bURNS.

Constant burn ModeIntheConstantBurnModeandwiththeignitertoggleswitchintheAutoposition,thestovewilllightautomaticallyandcanbeadjustedtothedesiredsettingusingthesametemperaturecontrol dial as is used in theRoomTemperatureMode.Theheatoutputandfuelconsumptionwillremainconstantregardlessofroomtemperature.Thesettingsfrom1to7ontheinnerringofthetemperaturedialprovideforrelativeheatoutputsettingswith1beinglowand7beingthemaximum.InConstantBurnMode,thestovewillnotautomaticallyshutoffunlessthestoverunsoutoffueloristurnedoff.Neverpulltheplugtoshutdownthestove.Thiswillstopthecombustionblowerandsmokewillescapethroughwindowanddoorgaskets.Whentheignitertoggleswitchissettomanualinthismode,thedistributionblowerwillnotturnonwithatemperaturedialsettingfrom1to5.Theadvantageofthismodeistoallowtheoperatortohavealargeviewingfirewithoutblowingextraheatintotheroom.Duringmanual operation,with the temperature dial setat #4 or less, the distribution fanwill not operate.A #4on the temperaturedial anda#5on the feedadjuster isapproximately80%output.Itisnotnecessarytooperatethedistributionblowerbelowthispoint.Therefore,thecontrolallowsahigherburnrate(alargerviewingfire)withoutanexcessofhotairblowingintotheroom.AnexampleofwhentousetheManualConstantBurnModeisifyouwanttowatchalargefireandtheroomisalreadyup to temperature.TheConstantBurnModeallows youtohavea largerfireanda lowersound level,without thedistributionblower.NOTE: During the use of this mode, if you keep increasing the temperature dial setting to increase the fire size, the distribution blower will automatically come on when the ESP Temperature reaches 350o F, or 81% output.Feed Adjuster knobFormostpremiumgradepelletfuelstheFeedAdjusterKnobshouldbesetat4.Ifhigherashfuelsareusedthesettingshould be increased to 5 or 6. Also higher settings arerequiredifyouwouldliketogetthemaximumheatoutputfromthestove.Atthemaximumburnrate(withthetemperaturedialon7/90°andthefeedadjusterat6)thereshouldbe1"ormoreofashonthefrontoftheburnpot.Ifthereislessthan1"ofash,turnthefeedadjusterknobdowntoalowersetting.Shut Down ProcedureThe bestway to shut down the stove is to simply let itrunoutofpellets.Thestovewillshutdownautomatically.Alternatively,youcanturntheModeSelectorto“off”.Thiswillcausethefiretograduallydiedownandgoout.Thefirewillnotgooutimmediatelyandmaytakemorethananhourtofullyshutdown.

DO NOT USE CHEMICALS OR FLUIDS TO START THE FIRE. FOR EXAMPLE: NEVER USE GASOLINE, GASOLINE-TYPE LANTERN FUEL, kEROSENE, CHARCOAL LIGHTER FLUID, OR SIMILAR LIqUIDS TO START OR "FRESHEN UP" A FIRE IN THIS HEATER. kEEP ALL SUCH LIqUIDS wELL AwAY FROM THE HEATER wHILE IT IS IN USE.

CAUTION!

CAUTION!

18 P43 Pellet Stove 3-90-04301R23_JR11_04/14

Helpful Hints1. Fines are small pieces of broken pellets (sawdust). Fines do

not flow easily and often build up on the hopper funnel bottom angles. You can push these fines into the feeder opening and then fill the hopper with pellets. As the system works, they will be burned. Or you can clean them out before filling the hopper.

2. The "TEST" cycle will operate the feeder motor for exactly one minute. Turning to "TEST" again and again may purge too much fuel into the burn pot causing excessive smoke on start-up.

3. The firebox low pressure switch will not allow the auger motor or the igniter element to operate if the view door or the ash pan door are open.

4. Adjust Feed Rate. If this is your first fire or you are trying different pellets, set the feed adjuster to #4, Figure 17. This is a conservative number and will probably need to be increased. After you know a feed rate setting that works well, use that setting. Remember, if your feed rate is too high you may waste fuel.

5. This is usually a weekly maintenance procedure. Cleaning the burn pot with the scraper with a small amount of new fuel in the bottom is not a problem. First, scrape the ashes off the front of the burn pot into the ash pan. Then, scrape the top surface of the burn pot downward into the base of the burn pot. When the stove is ignited these scrapings will be pushed out by the feeder and burned.

6. The ash pan can hold the ashes from approximately 1 ton of premium fuel. This means the ashes will only need to be emptied a few times a year.

7. Setting the feed adjuster # for maximum burn: With the unit burning in "AUTO", turn to "Stove Mode" and put the fan on "H". Set the Temperature Dial to #7. Allow the unit to burn for about 30 minutes and check ash on front of burn pot. Figure 18. If the ash line is larger than 1", turn the feed adjuster from #4 to #5. Allow another 30 minutes of burn time and check again. If , at #6 setting, a 1" or less ash bed is not obtainable, it is not a problem. The 1" ash bed is only a maximum burn rate and at most normal settings the ash bed will be larger.

Starting First FireIgniter Switch to"AUTO"(up position)Makesuretheunitispluggedintoa100VAC,50Hzelectricalsource.Thepowerlightshouldbetheonlylightlit.

Automatic Start Up

"NEVER USE GASOLINE, GASOLINE-TYPE LANTERN FUEL, kEROSENE, CHARCOAL LIGHTER FLUID, OR SIMILAR LIqUIDS TO START OR "FRESHEN UP " A FIRE IN THIS HEATER. kEEP ALL SUCH LIqUIDS wELL AwAY FROM THE HEATER wHILE IN USE".

NOTICE: be sure there is no unburned fuel or other combustibles in the ash pan prior to lighting.

Figure 17

1. Turn Mode Selector to "OFF".2. Fill hopperwithpellets.3. Clean burn pot withscraper,ifnecessary.4. If starting after an empty hopper, turn Feed Adjuster

to "TEST" (forone60secondcycle).Figure17. Thiswillfeedpelletsintotheaugertubeandalsoallowyoutocheckthemotorsforoperation.

NOTE: The auger motor will not operate with the view door or ash pan door open.5. Turn Feed Adjuster to #4.6. Flip the Igniter Switch up intothe"AUTO"position.7. Turn the Temperature Dial tothedesiredtemperature.8. Turn Mode Selector toRoomTemperature or Stove

Temperature.9. Fill hopper withpelletsandremove ashesasrequired.kEEP THE APPLIANCE DOORS AND HOPPER LID CLOSED DURING OPERATION.

Figure 18

See Note 71"

ONLY USE wOOD PELLET FUEL. DO NOT bURN GARbAGE IN STOVE.

WARNING!

WARNING!

19P43 Pellet Stove3-90-04301R23_JR11_04/14

TheP43PelletStoveiscapableofmanualoperation.Thisalsoallowstheoperatortomanuallycontroloperationduringanemergency(i.e.igniterfailure,whenusinga502Hbatterybackup,asopposedtothe512H,orwhenusingcertaingenerators.)Theunitcanbeswitchedbetween"AUTO"and"MANUAL"atanytimeduringoperation.

Igniter Switch to "MANUAL"Room Temperature ModeThefirewillhavetobelitwithstartinggelandamatch,orstartedautomatically,see"AutomaticOperation"onPage16.Turnto"Manual"positionwhentheignitioncyclehasstarted.Thedifferencebetween"AUTO"RoomTemperatureModeand"Manual"RoomTemperatureModeisthatthefirewillnotgooutastheroomtemperaturegoesabovethecontrolboardsetting.Theunitcanonlygotolowburnandwillremainthereuntil it runsoutof fueloruntilmoreheat isneededandthefeedrateincreases.Feedrateadjustmentsanddialsettingsarethesameas"AUTO"settings.TheblowerwillshutoffcompletelyifthetemperatureontheESPistoolow.

Igniter Switch to "MANUAL"Constant burn ModeTheadvantageofthismodeistoallowtheoperatortohavealargeviewingfirewithoutblowingextraheatintotheroom.Duringoperation,withthetemperaturedialsetat#5orless,thedistributionfanwillnotoperate.A#5onthetemperaturedial anda#5on the feedadjuster is approximately 80%output.Itisnotnecessarytooperatethedistributionblowerbelowthispoint.Thiscontrolsettingallowsahigherburnrate(alargerviewingfire)withoutanexcessofhotairblowingintotheroom.AnexampleofwhentousetheManualConstantBurnModeisifyouwanttowatchalargefireandtheroomisalreadyup to temperature.TheConstantBurnModeallows youtohavea largerfireanda lowersound level,without thedistributionblower.NOTE: During the use of this mode, if you keep increasing the temperature dial setting to increase the fire size, the distribution blower will automatically come on when the ESP Temperature reaches 350o F, or 81% output.

Manual Ignition

Constant burn Mode

NOTE: when starting the unit in the "AUTO" mode and switching to "MANUAL", the ignition cycle must be allowed to begin prior to making the switch.

Room Temperature Mode: This setting, see below, will produce a room temperature of 70 degrees with the distribution blower at medium speed.

This setting will produce a large viewing fire without a distribution blower operating.

20 P43 Pellet Stove 3-90-04301R23_JR11_04/14

Manual Start Up

Starting First FireIgniter Switch to"MANUAL" (down position)Makesuretheunitispluggedintoa100VAC,50Hzelectricalsource.Thepowerlightshouldbetheonlylightlit.

1. Turn FEED ADJUSTER to desired feed rate.Number4isgoodformostpellets.Figure19.

2. Turn the MODE SELECTOR to “OFF” and then to the desired mode.Thiswill reset thecontrolandstart thecombustionmotor.

3. Turn the TEMPERATURE DIAL to the desired setting.4. Clean burn pot with scraper if necessary.5. Fill burn pot with pellets, only level with front edge.

(DoNotOverFill).6. Add starting gel on top of the pellets.Stirgelintopellets

forfastlighting.Figure20.7. Light starting gel with a match, and close the door.

Operationwill beginwhen the fire reaches thepropertemperature.

8. Fill hopper with pellets and remove ashes as required.

kEEP THE APPLIANCE DOORS AND HOPPER LID CLOSED DURING OPERATION.

1. Fines are small pieces of broken pellets (sawdust). Fines do not flow easily and often build up on the hopper funnel bottom angles. These fines can be pushed into the feeder opening and then fill the hopper with pellets. As the system works, they will be burned.

2. The "TEST" cycle will operate the feeder motor for exactly one minute. Turning to "TEST" again and again may load too much fuel into the burn pot causing excessive smoke on start-up.

3. The low pressure switch will not allow the feed motor to operate if the viewing door is open.

4. Adjust Feed Rate. If this is your first fire or you are trying different pellets, set the feed limit to #4, Figure 4.8. This is a conservative number and will probably need to be increased. After you know a feed rate setting that works well, use that setting. Remember, if your feed rate is too high you may waste fuel.

5. Setting the feed limit # for maximum burn: With the unit burning in "AUTO", turn to "Stove Mode" and put the fan on "H". Set the Temperature Dial to #7. Allow the unit to burn for about 30 minutes and check ash on front of burn pot. Figure 4.9. If the ash line is larger than 1", turn the feed limit from #4 to #5. Allow another 30 minutes of burn time and check again. If , at #6 setting, a 1" or less ash bed is not obtainable, it is not a problem. The 1" ash bed is only at maximum burn rate and during normal operation, the ash bed will be larger.

"NEVER USE GASOLINE, GASOLINE-TYPE LANTERN FUEL, kEROSENE, CHARCOAL LIGHTER FLUID, OR SIMILAR LIqUIDS TO START OR "FRESHEN UP " A FIRE IN THIS HEATER. kEEP ALL SUCH LIqUIDS wELL AwAY FROM THE HEATER wHILE IN USE".

ONLY USE wOOD PELLET FUEL. DO NOT bURN GARbAGE IN STOVE.

NOTICE: be sure there is no unburned fuel or other combustibles in the ash pan prior to lighting.

Figure 21

Figure 20

Figure 19See Note 7

1"

STARTER GEL

WARNING!

WARNING!

21P43 Pellet Stove3-90-04301R23_JR11_04/14

Low Draft Voltage AdjustmentTheseunitsarepre-testedatthefactorywithexactly100VAC,50Hz.Theyarecheckedandadjustedforfireboxtightness,gasketleakage,motoroperationandigniteroperation.TheP43isthenfactorysetatamid-pointadjustmentandinmostcaseswillnotneedanyadjustments.NOTE: The factory low draft setting may not be correct for the unit's permanent installation conditions.ThecontrolboardontheP43isequippedwithalowdraftadjustmentport.Locatedonthecontrolfacejusttotherightoftheigniterlight.Thisvoltageadjustmentisprovidedtoallowtheunittobeadjustedforthehouseholdvoltagewheretheunitisgoingtobeinpermanentoperation.NOTE: The line voltage varies from area to area and often home to home.Thelowdraftvoltageshouldbeadjustedtoachievethemostefficient burnon lowburnor "maintenance".This voltageadjustment allows the installer to change the lowvoltagesetpointapproximately10volts. Thisadjustmentshouldbedonebytheinstallerduringsetupbecauseadraftmeterreadingisrequired toinsurepropersetup.Iftheunitisnotadjustedproperly,itdoesnotcauseasafetyconcern.Iftheunitisadjustedtoohigh,onlyeffiencyislost.Iftheunitisadjustedtoolow,thelowdraftpressureswitchwillnotallowthefeedmotorortheignitertooperate.

Figure 22 Figure 23

Low Draft Voltage Adjustment

Asimpledrafttestshouldbeperformedaftercompletingthefluepipeinstallation.Torecordtheresultsforfuturereference:1. Plugunitintoa100VAC,50Hzoutlet.2. Closethehopperlid,frontviewdoor,andtheashpan.

Neitherpelletsorafirearerequiredforthistest.3. Withthemodeselectorinthe"OFF"position,turnthefeed

adjusterto"TEST".4. Record the high draft_____inW.C. (Normal is -.50 to

-.60)ThecontrolwillbeontheHighDraftforatotalof2minutes.

5. After1minute,thecombustionmotorwillgodowntolowdraft and thedistributionblowerwill goonhigh.Allowapproximately 15 seconds to pass for the combustionmotortoslowbeforecheckingthelowdraft.

6. Ifthelowdraftisbetween-.35and-.45,recordthereading_____ inW.C. If thereading ishigher,slowly turn thesetscrewcounter-clockwiseuntilthedraftlowers.Ifthereadingislower,veryslowlyturnthesetscrewclockwiseuntilthedraftincreases.

NOTE: In some cases, the draft may not go as low as -.35 to -.45 even with the set screw completely counter-clockwise. Ideally, you should just set it as low as possible.

Combust ion Motor

Speed ControlLow draft only set point.T h e s m a l l s t r a i g h t screwdriver slot is plastic; therefore, the unit can be adjusted while in operation.

Draft Meter bolt hole locationThe draft test hole is under the left rear corner of the firebox on the pedestal base.

22 P43 Pellet Stove 3-90-04301R23_JR11_04/14

MaintenanceMinimizing Creosote:Wheneverwoodisburnedslowly,thepotentialexistsforcreosotetoformintheventing.Thechimneyorventingsystemshouldbeinspectedperiodicallythroughouttheheatingseasontodetermineifacreosotebuilduphasoccurred.Ifasignificantlayerofcreosotehasaccumulated(3mmormore),itshouldberemovedtoreducetheriskofachimneyfire.Aprofessionalchimneysweepisrecommended,sincetheywouldnormallyhavethecorrectequipmenttoensurepropercreosoteremoval.

If you experience a fire in the venting system,turnthestoveto"OFF"toallowtheunittoshutdown.Callthefiredepartment,andbesureeveryoneisoutoftheresidence.Beforere-usingtheappliance,haveit,andtheventingsystemthoroughlyinspectedandreplaceanydamagedcomponents.

The glass in your Harman stove is a special 5mmceramicglass.• Donot abuse the glass by striking or slamming

thedoor.• Never burn the appliance if the door glass is

crackedorbroken.• Replace only with Harman supplied glass. Do

NOTUseSubstitutes.Soot and/or fly-ashmay accumulate on the viewingglass,andwillocassionallyneedtobecleaned.Cleantheglasswithasoftclothandmildglasscleaner.Donot clean the glasswhenhot, and avoid the use ofabrasivecleaners.GlassreplacementCarefully remove all remaining glass and gasketmaterialspriortoreplacingtheglass.

Laythedoorfacedownonaflatsurface.Removetheglassretainersandscrews.Applythegasketmaterialto the faceof thenewglass. Lay theglass into thedoor,makingsure that theglass is containedwithinthechannelsandraisedareasofthedooritself.Laytheglassretainersintopositionandinstallthescrews.Tighteneachscrewevenlytoavoidmakinganystresspoints.

RetainersandscrewsGlass

Adhesivegasket

DoorFrame

INSPECT APPLIANCE AND COMPONENTS FOR DAMAGE. DAMAGED PARTS MAY IMPAIR SAFE OPERATION.• DO NOT INSTALL DAMAGED

COMPONENTS.• DO NOT INSTALL INCOMPLETE

COMPONENTS.• DO NOT INSTALL SUbSTITUTE

COMPONENTS.REPORT DAMAGED PARTS TO DEALER.

FIRE RISk.HEARTH & HOME TECHNOLOGIES DISCLAIMS ANY RESPONSIbILITY FOR, AND THE wARRANTY wILL bE VOIDED bY, THE FOLLOwING ACTIONS:• INSTALLATION AND USE OF ANY

DAMAGED APPLIANCE.• MODIFICATION OF THE APPLIANCE.• INSTALLATION OTHER THAN AS INSTRUCTED

bY HEARTH & HOME TECHNOLOGIES.• INSTALLATION OF PARTS OR COMPONENTS

NOT SUPPLIED OR APPROVED bY HEARTH & HOME TECHNOLOGIES.

• OPERATING APPLIANCE wITHOUT FULLY ASSEMbLING ALL COMPONENTS.

OR ANY SUCH ACTION THAT MAY CAUSE A FIRE HAzARD.

WARNING! WARNING!

23P43 Pellet Stove3-90-04301R23_JR11_04/14

Scraping the burn pot:Whenever adding fuel to the hopper, take the time andscrapethegratesurfaceoftheburnpot,usingthescrapertoolprovided.Thiscanbedonewhileafireisburning.Wearingheatresistantgloves,openthefireboxdoor.Scrapeanyaccumulatedashesfrominfrontofthefire,intotheashpan.Now,scrapeunderthefire,inadownwarddirection,toloosenanycarbondeposits.Donotscrapethefireoutofthepot.Whateveryouloosenwillbepushedoutwiththeflowofnewfuelintothepot.Removing Ashes:Afterapproximately1tonofpelletshasbeenburned,itwillbenecessarytoemptytheashpan.Disposal of Ashes- Ashes should be placed in a steel container with a tight fitting lid. The closed container of ashes should be moved outdoors immediately and placed on a noncombustible floor or on the ground, well away from all combustible materials, pending final disposal. If the ashes are disposed of by burial in soil or otherwise locally dispersed, they should be retained in the closed container until all cinders have been thoroughly cooled. Other waste shall not be placed in this container.Cleaning:Itisrecommendedthatthestoveiscoldandshutdownwhenremovingtheashpan.1.Lift the latchhandle toopen theashdoorand remove

theashpan.Useashpanhandletocarryanddisposeofashes.

2.Slidetheashpanbackintothestoveandlatchthedoorbypushingdownonthelatchhandlewhenclosed.

Cleaning:Thestoveshouldbeshut-downandthoroughlycleanedaftereach tonofpelletsconsumed.Thecleaner thestove, themoreefficientitwillbe.Note: Fuelwith higher ash and/ormoisture contentwillrequiremorefrequentcleanings.1.Shut down the stove anddisconnect power cord to

insurethatallmotorsarestopped.2.CleanheatexchangerwithscraperasshowninFigure

27.3.Brushorscrapetheinsideofthestovetoremoveflyash.4.Scrape burnpotwith flat end of scraper providedwith

thestove.Inspecttheholesontheburnpotsurface.SeeFigure33.

5.Openburnpotclean-out.Cleanflyashfromburnpotandreplacecover.

Maintenance

Figure 27

Scraper

BlowerCoverLatch

BlowerWheel

FlueOutlet

HeatExchangerFins

Figure 26

CombustionBlowerCover

BlowerCoverLatch

24 P43 Pellet Stove 3-90-04301R23_JR11_04/14

Maintenance

Exposedblowerwheelandflueopening,NOTE:ESPisvisible.

Figure 30

Figure 31

BurnpotClean-outplate

Latch "open "with blowercoverpartlyremoved.Burnpotclean-outisopen.

Latch"closed"withblowercover in place. Burn potclean-outisclosed.

Blowercoverremoved.

Figure 29Figure 28

ESP

ESP

6.Removetheashpanandproperlydisposeoftheashes.7.Removecombustionblowercoverbyturningtheblower

coverlatchvertical,seeFigure26.Slidingthecoveroutof thesloton the left.Thiswillexpose thecombustionblowerwheelandflueoutlet,Figure27.

8.Cleanthecombustionblowerwheelwithabrushandavacuumcleaner.Note:Donotuseahouseholdvacuumtocleanthestove.Werecommendthatyouuseashopvacuumthat isequippedwithafinedustfiltercalledaHEPAfilteroravacuumspeciallymade forashesandsoot.Using a vacuum which is not equipped with a fine dust filter may clog and disperse fly ash and soot into the room.

NOTE: THE STOVE MUST bE COMPLETELY OUT bEFORE YOU VACUUM THE STOVE. LIVE PELLETS, IF SUCkED INTO THE VACUUM wILL LIGHT THE VACUUM ON FIRE AND MAY ULTIMATELY CAUSE A HOUSE FIRE.9.Useabrushtocleantheflue,beingcarefulnottodamage

theESP,seeFigure30.Thefluegoesstraightthroughintotheventpipe(Figure27)therefore,theventpipecanalsobecleaned,tosomeextent,throughtheflueoutlet.

10.Reinstalltheblowercoverandclosethelatch.11. Slidetheashpanintostoveandlatchthedoor.Soot and Fly AshFormation and Need for Removal - The products ofcombustionwillcontainsmallparticlesofflyash.Theflyashwill collect in theexhaust venting systemand restrict theflow of the flue gases. Incomplete combustion, such asoccursduringstartup,shutdown,or incorrectoperationoftheroomheaterwillleadtosomesootformationwhichwillcollectintheexhaustventingsystem.The exhaust venting system should be inspected at least once every year to determine if cleaning is necessary.Removingflyashandsootimprovesefficiencyandinsuresthattheflueventingpassagewayisclearandunobstructed.Thestoveshouldbecleanedaftereachtonofpellets(50bags)andtheventingsysteminspectedandcleanedaftereachheatingseason.

BecarefulnottodamageESPwhencleaningwithbrush.

25P43 Pellet Stove3-90-04301R23_JR11_04/14

burn Pot Cleaning and Maintenance1 Scrapethetopholedsurfaceandsidesoftheburnpot.

Figure33. It isnotnecessarytocompletelyremoveallmaterialfromtheburnpot.Theexcesswillbepushedoutduringthenextuse.

Note: The hot lead/cold lead connection must always be pulled to the rear of the feeder body before operation.

burn Pot Maintenance

Figure 34Loosenwingscrews

Figure 35

Use caution when cleaning burn pot clean-out chamber. Do not damage the high temperature igniter wires.

2. Loosen the (2)wing thumb screws on the lower frontangleoftheburnpotFigure34.Liftofftheclean-outcover(Figure35)toopenthebottomclean-outchamber.

3. Cleanashbuildupfrominsidethechamberwhilecoverisoff.Usethescrapertotaponthetopfrontedgeoftheburnpot.Thiswill helpknockpiecesofash, loosenedbythescrapingprocess,downthroughtheholes.Italsohelpsknockscaleoffoftheigniterelement.

Figure 35 Theigniterismadetoberemovableforservicebyinsulatedmale/femalewireconnectors.Theseconnectionsbetweenthehotleads(thewiresinsidetheburnpot)andthecoldleads(thewiresfromthecontrolboard)arealwayspulledtotherearofthefeederbody. (Not coiled inside the burn pot.)Itisveryimportantthattheseconnectionsaretotheinsiderearofthefeederbody.Also,theextrawireoftheigniterwireserviceloopmustbepulledoutthroughtherearofthefeederandtiedupsothatitwillnotbedamagedbyanymovingparts.

WARNING!

Disconnect the power to the unit before removing cover.

dANGeR!

Igniter hot lead wires(High temperature)

Burn pot igniter

Figure 33

26 P43 Pellet Stove 3-90-04301R23_JR11_04/14

Cleaning the Feeder body

BackdraftDamperAssemblyAlwayschecktoseeifthedamperplateswingsfreelyinwardandthattheseatingedgesarenotcoveredwithdirtorlint.

LowDraftPressureSwitch

FeedMotor

CombustionMotor

DistributionBlower

Feeder ChamberThischambermaygetabuildupoffinesfromthefeedermechanismmovement.Thisareashouldbecheckedandcleanedatleastonceayear.To remove the feeder cover:• Loosenthe5/16"wingnut.Figure36.• Liftupandslidethecoveroffofthethreadedstud.• InspectandcleantheinnerchamberifnecessaryFigure37.• Reinstallthecovermakingcertainitisseatedproperlyonthefeederbodyandtightenastightlyasyoucanbyhand.NOTE: Views are shown with the rear motor covers removed.

Pellet Metering Slide Plate

Possible pellet fines buildup area.

Figure 37

5/16" wing NutFeeder clean out cover

Figure 36

27P43 Pellet Stove3-90-04301R23_JR11_04/14

SMOkE IS VISIbLE COMING OUT OF VENT1. Air-fuelratioistoorich.

a. Feedratetoohigh.b. Drafttoolowcausedbyagasketleak.

LOw HEAT OUTPUT1. Feedratetoolow2. Drafttoolowbecauseofgasketleak.3. Poorqualityordamppellets4. Combinationof1and2.

Troubleshooting

Helpful HintsCleaning burn PotWheneveryourstoveisnotburning,taketheopportunitytoscrape theburnpot to removecarbonbuildup.Avacuumcleanerishandytoremovetheresidue.be sure the stove is cold if you use a vacuum.Carbonbuildupcanbescrapedloosewiththefireburningusingthespecialtoolprovidedwithyourstove.Scrapethefloorandsidesoftheburnpot.Thecarbonwillbepushedoutbytheincomingfuel.Alwayswearglovestodothis.Removing AshesTurntheTempDialtonumber1approximately30minutesbeforeremovingashes.Thiswillresultinacoolerstoveandashpan.MaximumFeedAdjuster settingsarenot needed inmostcases.Operatinginthenormalrange(#4)isrecommendedwhenmaximumheatoutputisnotrequired.TheESPcontrolpreventsthestovefrombeingover-fired.Keepthestovefreeofdustanddirt.

STOVE DOES NOT FEED1. Nofuelinhopper.2. Fireboxdraftmaybetoolowforsensingswitchinfeeder

circuit to operate.Check for closed doors, loose ormissinggasketondoorsorhopperlid.

3. Feedmotorwillnotrununtil theESPcontrolsensesacertaintemperature.Maybeyoudidnotputenoughfuelorstartinggelintheburnpotbeforemanuallylightingthefire.

4. Restrictioninthehopperorfeeder.Removeallfuelandexamine.Cleartheobstruction.

5. Feedmotorhasfailed.PARTIALLY bURNED PELLETS1. Feedratetoohigh.2. Poorairtofuelmixture.(Checkburnpotclean-outcover

andairintake).3. Burn pot or heat exchanger tubesmay need to be

cleaned.4. Combinationofalltheabove.5. #6 status blink:A6blinkcontrolboardstatusindication

iscausedbypoororincompletecombustion.ThecircuitboardhastheabilitytotrackthecombustionthroughfeedsettingsandESPtemperatures.Whenthecontrolboardhascalculatedpoororincompletecombustion,itwillshutdown theunitasasafety feature. (Pooror incompletecombustionisacontributorofcreosotewhichmaycauseachimneyfire)

A6blinkstatusmaybecausedbyseveralthings:1. Blockedorpartiallyblockedflue.2. Blockedorpartiallyblockedinletair.

a.Backdraftdamperontheinletpipemaybestuckclosed.b.Ifoutsideairisinstalled,theinletcovermaybeblocked.

3. Theairchamberundertheburnpotmaybefilledwithfinesandsmallbitsofash.

4. Theholesintheburnpotmaybegettingfilledwithashorcarbonbuildup.

5. Combustionblowerfanbladesmayneedcleaned.6. Fuelrestrictionsasnotedabove.SMOkE SMELLSealtheventpipejointsandconnectiontostovewithsilicone.Theexhaustventistheonlypartofthesystemthatisunderpositivepressure.FIRE HAS GONE OUT- Check for status light.1. Nofuelinhopper.2. Draftistoolow,blockedflue.3. Somethingisrestrictingfuelflow.4. Hopperlidnotclosedproperly.5. Feedmotororcombustionblowerhasfailed.

FuelPelletfuelsareputinto3categoriesintermsofashcontent.Premiumat1%orless,Standardat3%orlessandallothersat3%ormore.TheP43iscapableofburningall3categoriesofpelletsduetoapatentedfeederandburnpotsystem.Itshouldbenoted,however, thathigherashcontent,andwhenmixingwith corn, will requiremore frequent ashremoval, scraping of the burn pot, andmayprovide lessBTU'sperpound.Normally,standardandhighashpelletscost less thanpremiumpellets and canbe cost effectivewhenburnedintheP43.Themoisturecontentofpelletsmustnotexceed8%,andcorn15%.HighermoisturewillrobBTU'sandmaynotburnproperly.Fuel shouldnot be storedwithin the stove installationclearancesorwithinthespacerequiredforchargingandashremoval.SeePage7.

28 P43 Pellet Stove 3-90-04301R23_JR11_04/14

weight 212 lbs.blower 135 cfmFeed Rate approximate .75lb. to 5.5 lbs per hrHopper Capacity 50 lbsFuel wood Pellets / Corn-Pellet MixtureFlue Size 3 inchOutside Air Size 2 3/8" I.D. inchFuse Rating 6 amp

Specifications

wiring Diagram

FEEDER AUGER MOTOR

STANDARD USE WATTS - 384 @ 100/120VAC 50/60Hz = 3.2 AMAX WATTS - 516 @ 100/120VAC 50/60Hz = 4.3 A

LOW PRESSURE SWITCH

HARMAN P43/ P61A/ P68 PELLET STOVE WIRING DIAGRAM

18/3

RU

BBER

CO

RD

DISTRIBUTION BLOWERCOMBUSTION MOTOR

CONTACTSN.O.

MALE/FEMALE CONNECTIONS

BONDED TO STOVE BODYGREEN WIRE IS GROUND

POWER CORD

18/3 RUBBER CORD

WHITEGREEN

BLUE

GRE

EN

WH

ITE

RED

MALE/FEMALE CONNECTIONS

BROWN

WHITE

MALE/FEMALE CONNECTIONS

LT.BLUE

LT.B

LUE

INSIDE BURNPOTIGNITER ELEMENT

WH

ITE

11 P

IN P

LUG

PART NO. 3-89-06504J

BLACK

RED

11

10

4WHITE

EMPTY

BLUE

YELLOW

WHITE

WHITE

7

9

8

6

5

WHITE

PLUGGED

BROWN

2

3

1

TWISTED WIRE

REMOTE SENSOR PORTS

BLAC

K

WH

ITE

YELL

OW

ESP

ESP

BOARD CONTROL

ESP PROBE

6 AMP GLASS FUSE

4

910

11

56

8

3

1

20 3/4"

22"

10"

33 1

/2"

5 1/8"

13 3

/4"

28 5

/16"

29 P43 Pellet Stove

Fuel SpecificationsFuel and Fuel StoragePellet fuel quality can fluctuate from manufacturer tomanufacturer,andevenfrombagtobag.Hearth&HomeTechnologiesrecommendsusingonlyfuelthatiscertifiedbythePelletFuelsInstitute(PFI).FuelMaterial• Madefromsawdustand/orotherwoodby-products• Shelledfieldcorn(whenmixedwithwoodpellets)• Sourcematerialtypicallydeterminesashcontent

HigherAshContentMaterial• Hardwoodswithhighmineralcontent• Barkandleavesassourcematerial• "Standard"gradepellets,cornandotherbiomass

LowerAshContentMaterial• Softwood;pine,fir,etc.• Materialswithlowermineralcontent• "Premium"gradepellets

Shelledfieldcorn• Mustbe15%moisturecontentorless• Mustbecleanandfreeofdebris• Mustbemixedwithwoodpellets.(Upto50%)• Stalk parts, excessive fines and cob remnants may

causefeedsystemjamsorblockage

CAUTION! Do not burn fuel that contains an additive; (such as soybean oil) • Maycausehopperfire• DamagetoproductmayresultRead the list of ingredients on the packaging. If you arebuyingfieldcorn,theonlyingredient listedshouldbefieldcorn.

WARNING! Risk of Chemical Poisoning!DoNOTburntreatedseedcorn• Chemicalpesticidesareharmfulorfatalifswallowed• Burningtreatedseedcornwillvoidtheproductwarranty

ClinkersMinerals and other non-combustible materials, like sand,willturnintoahardglass-likesubstancewhenheated.Treesfromdifferentareaswillvaryinmineralcontent.Forthis reason, some fuels will produce more clinkers thanothers.

MoistureAlways burn dry fuel. Burning fuel with high moisturecontenttakesenergytodryandtendstocooltheappliancethus,robbingheatfromyourhome.Damppelletfuelcouldturnbackintosawdustwhichdoesnotflowproperlythroughthefeedsystem.

Tested and approved for usewith wood pellets and amixture of shelled field corn and wood pellets ONLY.Burningofanyotherfuelwillvoidyourwarranty.

NOTICEHearth&HomeTechnologiesisnotresponsibleforstoveperformanceorextramaintenancerequiredasaresultofusingfuelwithhigherashormineralcontent.

Size• Pellets are either 1/4 inch or 5/16 inch (6-8mm) in

diameter• Lengthshouldbenomorethan1-1/2inches(38mm)• Pellet length can vary from lot to lot from the same

manufacturer

Performance• Higherashcontentrequiresmorefrequentmaintenance.• "Premium" grade pelletswill produce the highest heat

output.• Burning pellets longer than 1-1/2 inches (38mm) can

causeinconsistentfeedingand/orignition.

Werecommendthatyoubuyfuelinmulti-tonlotswheneverpossible. However, we do recommend trying differentbrands prior to purchasing multi-ton lots, to ensure yoursatisfaction.

CAUTION! Attempting to burn fuels such as charcoal has the potential of generating Carbon Monoxide which is DEADLY. Never burn fuels other than those listed on the appliance safety label.

Whenchangingfromwoodpelletstoacorn/pelletmixture,theFEEDADJUSTERwill likelyneedadjusted toa lowersetting.Whenundermaximumdemand,ensurethereisnounburnedfuelbeingpushedintotheashpan.

Storage• Woodpelletsshouldbeleft intheiroriginalsealedbag

untilreadytouse,topreventmoisture.• Shelledcornshouldbestoredinatightlysealedcontainer

topreventmoistureandtodeterpests• Donotstorefuelwithinthespecifiedclearanceareas,or

inalocationthatwillinterferewithroutinecleaningandmaintenanceprocedures.

3-90-04301R23_JR11_04/14

CAUTION!

30P43PelletStove

AddendumMinimizing Smoke During Loss of Power Using Battery Back-up

Harman® strongly recommends installing battery back-up to minimize entry of smoke into theroom in the event of power loss.

Your pellet/biomass burning appliance relies on a combustion blower to remove exhaust. A power failure will cause the combustion blower to stop. This may lead to exhaust seeping into the room. Vertical rise in the venting may provide natural draft. It is, however, no guarantee against leakage.

There are two Harman® approved battery back-up options for your appliance:

Uninterruptible Power Supply (UPS) UPS battery back-ups are available online or at computer andoffice equipment stores. Your Harman® appliance with Rev E or later software available beginning inNovember 2010 may be plugged directly into a Harman® approved UPS:

• The APC (American Power Conversion) model #BE750G and the TrippLite model INTERNET750U are tested and approved. Other brands or models may not be compatible.

When power is lost, a fully charged UPS will power a safe, combustion blower only shut-down. Yourappliance will pulse the blower every few seconds to clear exhaust until the fire is out. NOTE: The UPSprovides safe shut-down only. It is not intended for continued operation.