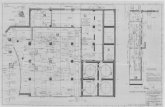

'Reactor Auxiliary Building El 43 Ft,62 Ft Conduit,Trays ...

Installation of additional trays in urea reactor

-

Upload

prem-baboo -

Category

Technology

-

view

37 -

download

2

Transcript of Installation of additional trays in urea reactor

Prem BabooSr. Manager(Prod)National Fertilizers Ltd.,Vijaipur, India

The installation of five additional high efficiency trays are giving an increased production of urea and reduced steam consumption, the financial benefits are determined by the urea sales and energy prices.It has been demonstrated that the installation of high efficiency reactor trays in existing urea plant is very profitable. The pay out time for the investment is in the order of few months.

Reactor Height Top Temperature must not be

more than 1900C

Top So, Temp. Bottom Temp Shifted to Left Density as solid line. To maintain Top Temperarature

ΔT=180C

10 old HET ΔT=110C

After H.E.T.

Installation Before H.E.T installation

5 New HET. Bottom

Temp.

ReactionStarted

170 180 190 200 210 220 0C CO2. Temp.

NH3.

"Purpose" 1.-The main purpose HET.to improve the redistribution

of unreacted carbon dioxide inside the liquid phase rich in free ammonia.2.-To reduce the back mixing phenomenon due to densityincrease of carbamate and urea solution from bottom to reactortop3.-To reduce also channeling which has a negative effect on the solution residence time.4.-All the five No. trays are made up of 2-Re -69

"Advantages" 1.-Urea production increase upto 5% referred to the

production before trays installation.

2.- Co2 conversion rate increase about 2 %.

3.-Energy saving about 0.002G.Cal/ton of Urea4.- Recycle decrease 25-30 kg/t of urea.

5.-Reactor top temperature increase 5-70C

"Conclusion" The density of solution increase bottom to top. The

Temp.of top increase about 6-70C after installation of

HET it shows increase of conversion. To maintain

NH3/CO2 ratio. top temp kept constant 1900C and

bottom decrease by increasing ammonia .

"Operation with High Efficiency Trays"